Leaderboard

Popular Content

Showing content with the highest reputation on 03/19/17 in all areas

-

Ok, quick update. Returned to TAG UK repair centre. Good news is that the bezel will be replaced 'on this occasion' free of charge. They have not given any indication yet as to what caused the damage or why it was returned in this condition after they serviced it in the first place. Only downside is that at the moment they are estimating another month until the watch is returned. I'll update again when the watch is returned.....3 points

-

Lol. It was. Just picked them from a tree - I asked what they were and they said Fuhk - i said wash your mouth out!!! .... Sent from my iPhone using Tapatalk3 points

-

Pip I will let you know, I just think not checking the mainspring is like doing a service on a car and not changing the oil, maybe mark could put us right......2 points

-

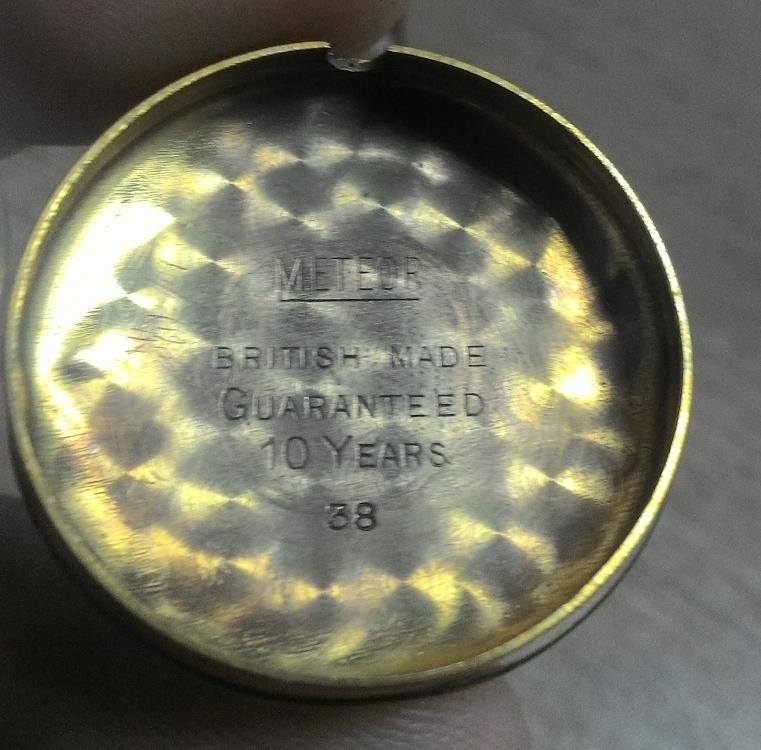

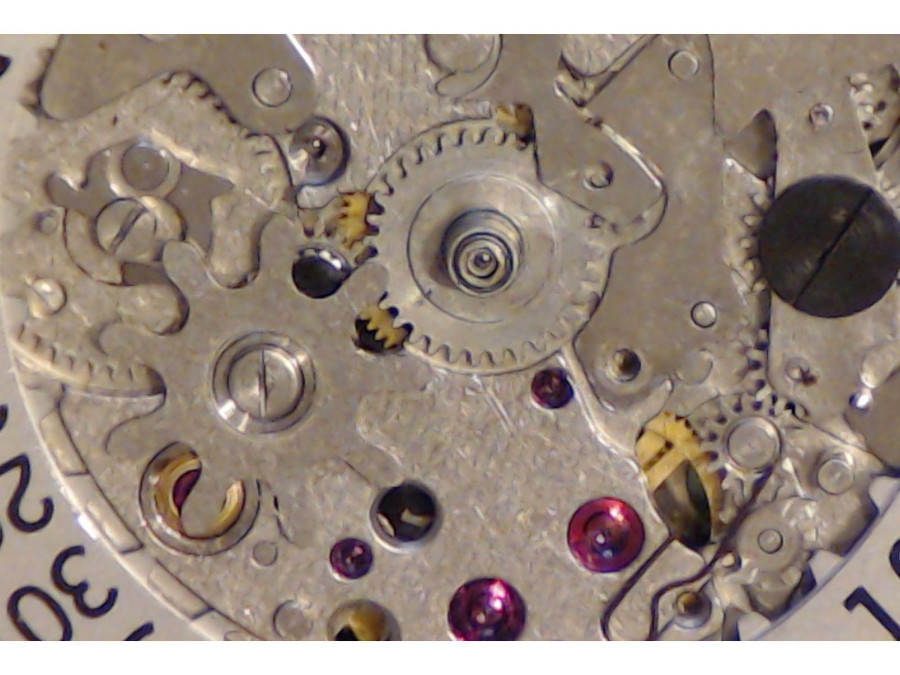

Hi guys, Wearing an old Rotary today. This is an older watch, probably from the 40s. The case is Gold-plated and has seen some wear. Under the "Rotary' it says 'Super sports' . Above the sub-seconds dial it says 'shock-absorber' and 'anti-magnetic'. It has fixed lugs which makes swapping strap difficult, the one it has on is meant for fixed lugs and has a sturdy fold-over (probably metal inside) which clips on the lug. It has nice simple hands which have been blued well, the center of the minute hand has been left silver given a niece contrast. The case back is a faithful rendition of the dark side of the moon. Nice hands The dark side of the moon... not much can be done here without spending too much money. The inside of the dark side of the moon.. I believe the '38' means 1938? At any rate, its more than 10 years old ;so good job Meteor! When you pop off the bac, the movement stays in the caseback. You have to use a bit of force, working around the edges, before it comes away and you are left with this.. an inner caseback. This is comes off easily. Revealing the movement. I think it's an FHF of some sort. Note the early form of shock protection on the balance cock .. the cap jewel is retained by a spring plate and will 'give' is subjected to a hard knock. The problem with these early shock absorbers is that they were only mildly effective and that only if it hit the ground level. It had not much lateral movement built-in so if it landed edge-on the pivot would still break. Still better than no shock-absorber I suppose, If I am not mistaken Breguet pioneer this and later on it is common to find a similar system on Cyma watches. The ratchet-wheel has the normal Rotary 'Flying-wheel' which reminds me of a vintage car..Austin I think? You can see the early type dial holding screws at 6 o'clock and slightly after 12. The movement is marked 7/440 and just belove that there's a 'V" or maybe the 'pheon'? The watch runs well and keeps time. I haven't done anything to it but the regulator is cranked over to slow so there may be other issues, need to get some case screws too. Not so evident from the pictures is that the plates have been plated with a 'whiter' finish which looks like silver. You see similar on Movado movements. Finally in the era before center seconds, 15 jewels was as good as it got so this would have been made for the higher end of the market. v Well its almost the weekend so have a good one! Anilv1 point

-

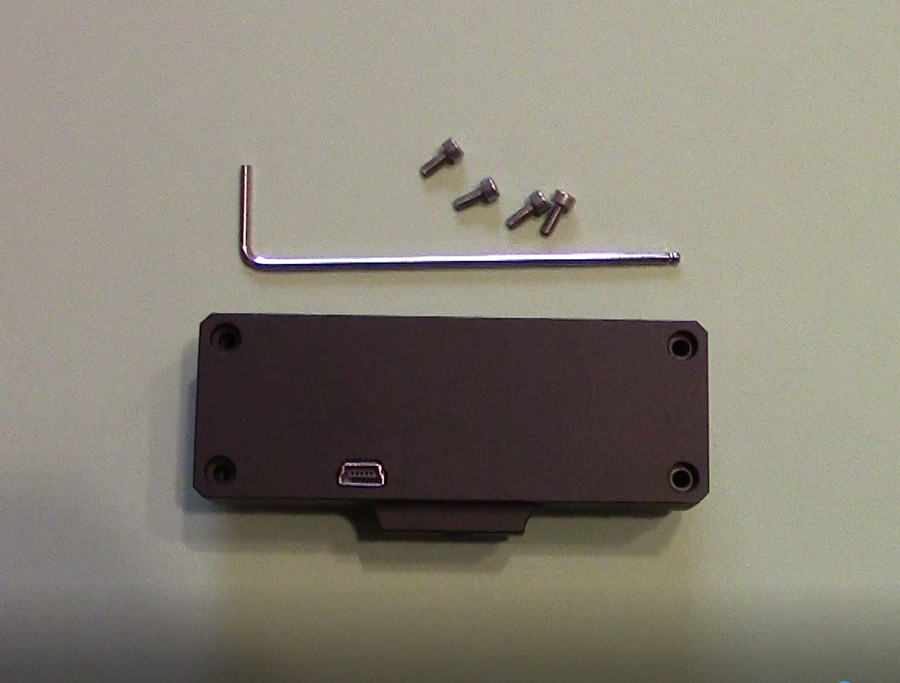

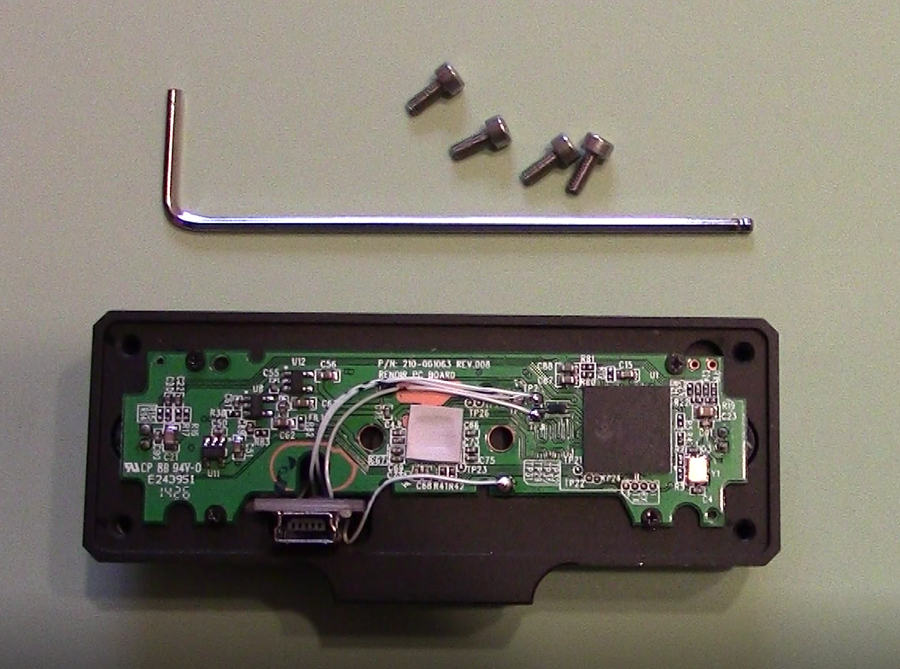

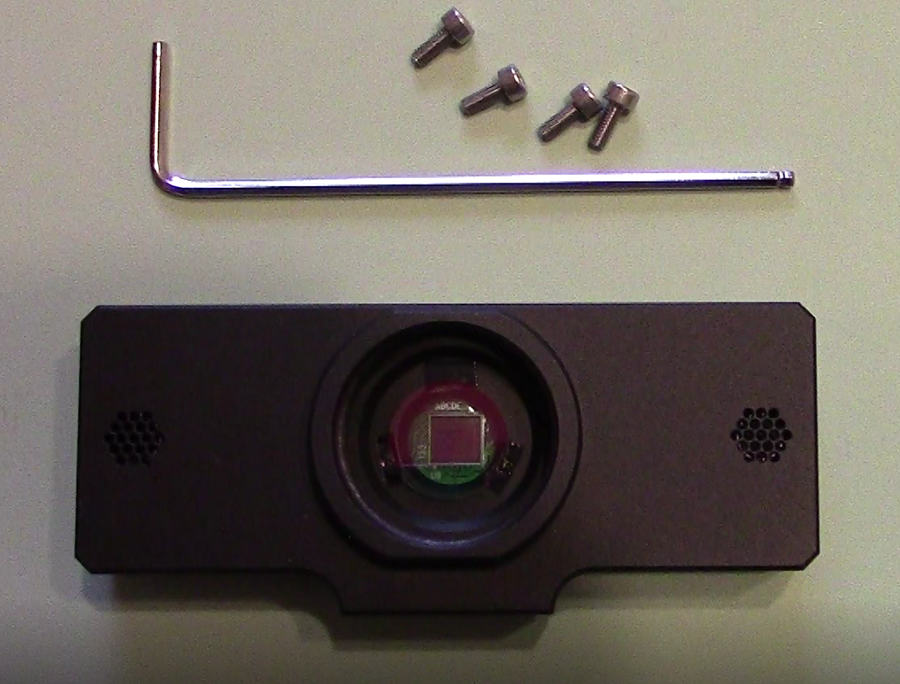

Welcome to my custom made watchmaker and repair video camera. Paul Stuart’s Professional Watchmaker Video Camera Project Historical methods of magnification There are many well established historical methods still used today by watchmakers to magnify watch movements while working on them. Without suitable magnification, it is almost an impossible task. To this day, these historical methods still serve the industry well. Stereo and USB microscopes Modern technology has come to the aid of the watch manufacturing and repair industry. Many watchmakers/repairers use stereo and USB microscopes to assist in their work. These have proven to be of benefit for work on extremely small parts such as pivots, hairsprings and so on. Some of these types of microscopes can be connected to monitors so that one can see, magnified and in real time, exactly what is being worked on. However, sometimes the working distance between the watch and the end of the microscope can make life difficult. Microscopes with a reasonable working distance of say, 30cm to 50cm, or even more can be very expensive. Not that one would require more of course. My watchmaker/repairer video camera project As an amateur watch repairer, I have often wished for a better method to magnify and view watch movements in real time on my computer so that I can, without straining my eyes so much, take movements apart and reassemble them. I’ve already mentioned working distance, I think 30cm to 50cm would be a good with its obvious benefits. Also, being able to capture reference photos and HD video is important. To have that capability to stream live video, and upload to YouTube etc. would be an additional benefit. Well, I had an idea for a lightweight camera that should be able to achieve the above. I think my idea may appeal to others. The project cost was reasonable. More on that later. Could I adapt a webcam to suit my requirements? No doubt the idea of using a webcam has been tried before. However, the zoom capability of most webcams is rather limited and they have wide angle lenses. Nearly all have a fixed lens. But a plus point is the webcam management software some manufacturers provide. To be fair, I have never tried using a decent DSLR or camcorder to achieve the above, but I believe I’m correct in thinking firewire connectivity is a problem between modern cameras and computers to monitor in real time. I think it is something to do with the fact they have SD cards. For me though, they seem a bit bulky and expensive for this purpose. I like tinkering with things, my idea was, what if I removed the fixed lens from a webcam and replaced it with one that could be manually adjusted for zoom and focus, together with an acceptable working distance capability and narrower the field of vision. The following is how I went about testing this idea out. How I modified a webcam After researching several different webcams specifications, I decided t adapt a Logitech c920. The c920 has proven to be one of the best webcams and was recently succeeded by the c922. But it is the c920 I used for this modification. The c920 can do real full HD streaming of 1920×1080p @ 30fps with image size up to 2304x1563p. This is how I went about it: I took a Logitech c920 apart to expose the circuit board, its fixed lens and USB wiring assembly. I removed 2 screws securing the lens assembly, then unsoldered the lens and USB screening wire. The lens, complete with its IR low pass filter, came away from the PCB quite easily to expose the CMOS sensor and its infrared (IR) part of the spectrum. For my purpose the IR part of the spectrum is not needed, so I had to add an IR low pass filter. More about that later. I solder connected 30 gauge (0.5mm) single strand wire between the main circuit board and USB board as follows: TP3 to USB board D+ TP2 to USB board D- TP1 to USB board Vcc Removed green solder mask adjacent to TP25 on the main PCB for the GND connection and GND on the USB board. Used the existing shielding solder tab on the main PCB for a shielding connection to the USB socket housing. Unsoldered the four LED’s from the main PCB at D3, D5, D6 and D8. I could have left the diodes in place and simply put some black tape over them. Both the modified circuit board and new USB socket were then mounted into a custom-made aluminum housing having a CS lens thread. Because the original filter was removed with the lens assembly, it had to be replaced with an IR Low Pass filter and mounted with double sided tape in the new custom housing. I then attached a 5-50mm CS varifocal lens with manual iris and focus. This was a f1.4, 3 mega pixels, 1/2.7” lens and suitable for the original Logitech 1/3” format CMOS sensor. Custom watchmaker camera case, rear view. With Logitech c920 lens removed, custom wiring done and circuit board assembled. Front view without the new lens attached, new IR low pass filter is assembled. Parts required 1 x Logitech c920, these can be obtained at a very reasonable price from auction websites. 1 x Custom made box for the reworked c920 circuit board, and with CS type lens mount. 1 x IR low pass filter (to replace the one removed with the c920 fixed lens). 1 x CS lens – f1.4, 5-50mm, 3 megapixel, manual focus and manual zoom. 1 x 5mm CS lens extension ring. Result I now have a camera to zoom in close and a respectable working distance between 30cm to 50cm or more. It can stream live, record videos and take snapshots. I can see all this on my computer, live as I’m working on watch movements. Example full screen captures at a working distance of 30cm At 50cm Paul Stuart’s Professional Watchmaker Video Camera Project – Parts and Specifications Parts price list Logitech C920 webcam £27.00. I got mine off an auction website cheap because the USB wire was broken. This was not needed anyway because of the new connection I was going to make to a new USB output port in the new case. Custom c920 anodised aluminium (aluminium) case. £56.00 0.5mm copper core silver plated bodge wire. £2.00. From auction website Lens 1/2.7" 5-50mm Manual Iris 3 Megapixel Lens. Features: 1. 3 Mega Pixel, manual focus iris and zoom lens 2. 2.1/2.7" High quality 5-50mm varifocal CCTV IR CS lens 3. Low distortion 4. High resolution £89.00 5mm C to CS lens extension ring. £3.00. From auction website. Total spend: £177.001 point

-

During the early part of the 20th century with the miniaturisation of watch movements many novelty items where produced all by very well respected watch manufactures and jewellers, penknives, keys, ladys compacts, cigarette lighters all at one time where produced with watch faces utalising movements normally used in ladies cocktail watches. In my collection I own one such novelty a propelling pencil made by Carl.F.Bucherer and produced in the mid 1920's, these pencils can be found with various names Cartier, Dunhill and Rolex. The Rolex ones where made by Bucherer for them and are extremely rare. The one I own is signed Bucherer and is made from solid silver they where also produced in 18ct and 14ct gold and some of the silver ones where enameld with various designs. I have seen two versions of the basic design of these watches one version has the watch permantley on display at the top of the pen the other has a hidden watch which is revealed by releasing a catch on the side of the pencil releasing a spring so the watch pops out of the top. The pencil is around 5 and a half inches and the watch face being oblong in shape and measuring 9mm by 15mm The watch part of the pencil can be pulled upwards and then unscrewed from the main body of pencil this reveals a hole into which the pencil leads are placed The watch part is held together with a screw on the top or in some cases a loop attached to a chain so it can be worn around the neck, undoing this allows the back to be taken off inside is a high quality 15 jewel movement it has proved to be very accurate the only problem with a oblong faced watch of this size is it can be extremley difficult to read at a glance The whole thing is beautifully finished with engine turned detail throughout the length of the watch, the pencil lead is deployed via a twist mechanism at the tip It is a fine example of the craftmanship of the era in which it was made it would have been very expensive in its day to buy even though being meerly a novelty. The only difficultey I had with this watch when purchased the crystal was broken in two, I could not find one of the correct size so ordered the next nearest from cousins it came about a month after ordering I then had to file it to size. Wayne1 point

-

Thanks, it looks ok visually I'm going to put it together tomorrow and give it a whirl....1 point

-

That's the point exactly, what you would do with other movements is not needed with sealed Seiko barrels, you don't gain anything messing with them. If you are looking to address a real problem and a way to increase amplitude on low ends Seiko look at the non-jeweled barrel bushings (just holes in the plates) which gets ovali with time.1 point

-

I believe Seiko has been using "sealed for life" barrels since many decades. Beside that is debatable if mainsprings needs to be greased (certainly not oiled), that applies to mov.ts with barrels and mainsprings designed to be opened and replaced. Seiko doesn't fall into this category. You will also have trouble finding a winder that fits well with Seiko mainsprings.1 point

-

i don't have a "machinst;s hand book" or a tap chart in front of me ! BUT, if you have a digital vernier caliper (with switching from metric or S. A. E. readings) AND a machinist's thread pitch gauge, you are half way there. sorry, often the existing thread dimension - does not help. vinn1 point

-

1 point

-

A quick google and these came up and don't forget ebay. Did you know many of the really old P/W stems only pushed onto want can only be described as a crude typed filed square. http://www.esslinger.com/pocket-watch-crowns/ https://www.cousinsuk.com/category/pocket-watch-crowns https://www.hswalsh.com/categories/pocket-watch-crowns1 point

-

The word is SUSPENSE....Perhaps it is because you have to wait so long to see inside because the back is so difficult to remove. The bezel came of when struggling to remove said case back....Now I cant get it back on1 point

-

I would firstly try to tighten the hand, DO NOT USE LOCTITE, if the loctite runs down the pivot it will stop the watch and cause no end of problems if it gets stuck in the pipe. If you can measure the diameter of the pivot I am sure a replacement will be available but may look different. I use a tool for collets to tighten hands but have used a worn pair of cheap cutters that have had bits chipped out of the blades cutting stems. I found if you can use one of the little notches in the damaged blade it works well and stops you nipping it too much and squashing the hands pipe too much.1 point

-

I think I've located the crown & stem that you need. Since yours is a UK model, I don't have an exact reference, but I believe that I have found its American cousin, 26760. As far as I can tell the cases are the same. The Timex part number is 025-060054 The crown and stem can be found in the material system 401/1 TX1K, listed as compartment 10. I've attached some pictures, and if you want it just send me a PM and I'll mail one off to you.1 point

-

For the last weeks I have I tried soaking the bridge in degreaser and isopropanol for some time and then using compressed air to blow it clean. No luck. However, recently I bought an Elmasolvex SE and yesterday I received my Elma cleaning fluids. After one clean/rinse/dry- cycle both holes are spotless. God bless German quality machines :).1 point

-

This is a eta 955 112, slightly bigger than the 955 412 as suggested. also be aware these movements come in different heights, when exchanging the movement always check the hour wheels are the same height otherwise the hands will catch the glass or rub on the batons on the dial.1 point

-

Are you serious? Is it worth the extra work? I would buy an IPA spray and an air spray and just blow all the dirt out. B1 point