Leaderboard

Popular Content

Showing content with the highest reputation on 02/25/17 in all areas

-

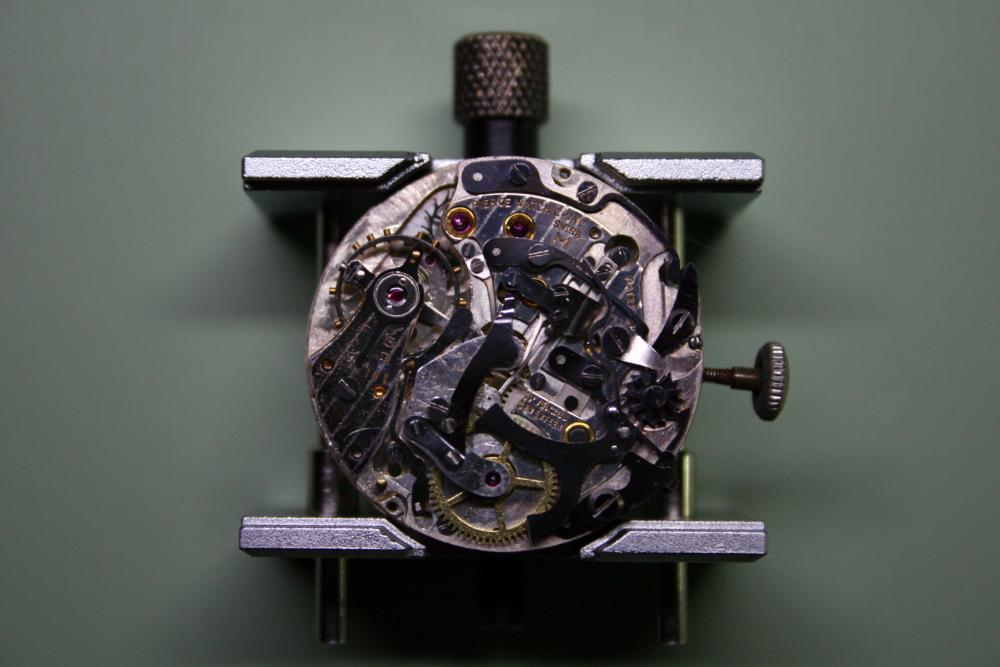

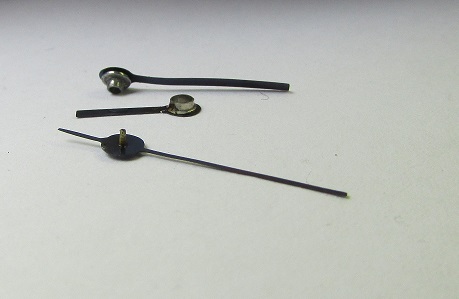

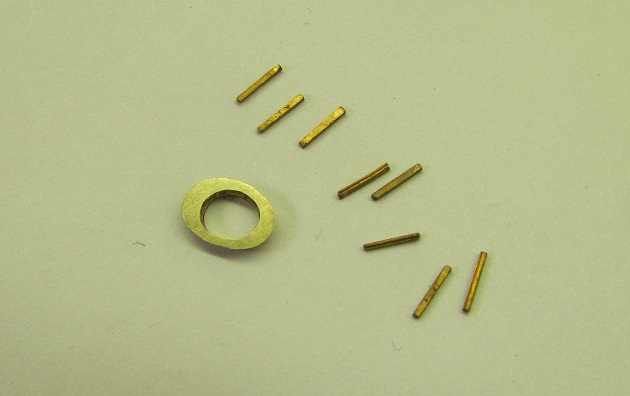

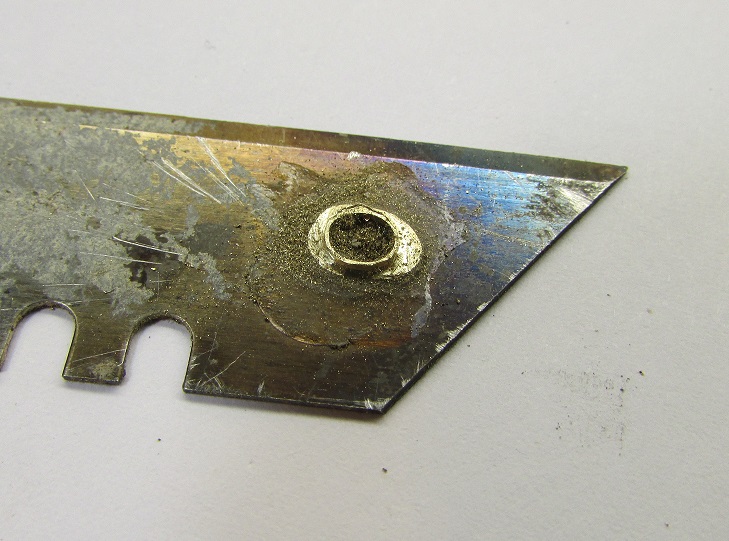

I've done a lot of Pierce Navigator repairs in the last year but this one was a bit special as it was the first I completed for someone other than myself. The watch is an heirloom and as such was received in much better condition than the those I've purchased off the bay. The bracelet was broken and would eventually be replaced and right off the bat I noticed that the sweep second hand was missing. The crown was also stuck in the setting position and therefore it was impossible to wind the watch. With the caseback off I could see that the chronograph staff and pinion had actually been removed sometime back. Also missing was the intermediate wheel which activates the minute recording wheel when the chronograph is engaged. My guess is that the rubber clutch for the chronograph had failed sometime in the past and the watchmaker simply removed the other bits as opposed to attempting a fix. I also noted a chip in the upper balance cap jewel. I've never seen a defect such as this before. With the dial removed, the normal accumulation of dirt and debris came to light. The setting lever snapped back into place smartly and with that I was able to check the timing. With the movement out I turned my attention to the case and pushers. The spacers for the pushers often become jammed inside the pusher button as the result of an accumulation of grime beneath the button cap. The springs, which sit between the spacer and the button, are made of stainless steel and generally hold up well over the years. I've discovered that a good soak in vinegar will usually free the spacers and springs from the buttons. With the pushers soaking I turned my attention back to the movement. As I said before, this Pierce 134 is in much better condition than those I've restored in the past. It's clear the owner has taken good care of the watch over the years. Generally I'll follow the Esembl-O-Graf (volume 15) in reverse order when disassembling a Pierce movement. I've done a few now and am getting used to the process. Looking the parts over I didn't find any that required immediate replacement so the only order placed was for a mainspring and crystal (in addition to the missing chronograph staff, pinion, and intermediate wheel). The old crystal was in fair shape but a little loose in the bezel so I opted for a new one. The damaged cap jew was chipped only on the topside and therefore I opted not to replace it. The parts were whisked off to the L&R cleaner and I turned my attention back to the pushers. The vinegar bath succeeded in freeing the spacers and springs from the buttons. I set the parts out for cataloging after cleaning and drying. At this point I'll also do any rust remediation. This movement was in fine shape but the levers for the chronograph did suffer from a bit of oxidation. The rusted bits were placed in a bath of vinegar for a good soak, then any pitting was smoothed using the Dremel tool or a rub on the Arkansas stone. The replacement chronograph staff, pinion, and intermediate wheel arrived in time for assembly. The staff needed a new clutch plate. In the past I've cut these out of nylon and although this is an adequate solution, it makes the final adjustment a lot more difficult since the nylon has so much less give than rubber. A while ago I began experimenting with rubber o-rings as a substitute. I use a rubber o-ring which had a thickness of 2mm. By sharpening an Exacto knife and lubricating it with a bit of watch oil I can cut through the o-ring with very little compression. This results in a disk that is thin enough and flat enough to use as a clutch plate for the chronograph. A punch I made on the lathe is used to place the center hole. Unfortunately since I made the o-rings before I began this service, I didn't have any images of the procedure. Assembly is straightforward provided all the gremlins have been discovered beforehand. The pallet, escape wheel, and cap jewels receive epilame treatment. The balance wheel is cleaned separately with One Dip. Put back together I noted a funky reading not the timegrapher. The culprit was a slightly bent pivot on the pallet. I replaced the pallet with one from my own stock and this resolved the problem straight away. I let the watch run overnight before beginning on the chronograph layer. It comes together a little slower as there are many more parts to lubricate and adjust. A missing sweep second hand can be a real problem with Pierce watches as the center post is 0.35mm (which is large). Fortunately I had a hand in my stock from a parts movement that would do- once I attached a post to it! I have some brass tubing that has an inside diameter of 0.35mm so I just needed to turn the outside diameter down on the lathe and rivet the post to the hand. Here I test the fit of the hand prior to painting. Once that was settled I discovered the post on the minute hand was loose also. A new post was turned on the lathe for it as well. Problems with the chronograph became apparent after fitting the hands. The culprit in this case turned out to be a damaged center jewel. This must have occurred during assembly as the jewel checked out after cleaning. Bad luck. The jewel is pressed in from the topside and so it must be removed by pressing from the bottom side (dial side). Unfortunately the jewel sits at the bottom of a long tube which required me to turn a special adaptor piece on the lathe for my Seitz tool. A replacement jewel was sourced from a donor movement and I was back in business. The owner decided on a replacement crown and a new strap and the watch finally came together. I have a bit of a thing for Pierce watches but at the same time I don't think it's much of a coincidence that the watches housing a Pierce 134 movement only seem to exist from the late 40's and early 50's as they can be a bear to get running right. In the end I was really pleased with this service though.2 points

-

2 points

-

I could not find an adequate lower balance jewel already in casing so I removed the jewel from its casing and found a replacement that fit the pivot and fit the hole, and tada it fits. Sent from my iPhone using Tapatalk Pro1 point

-

This project has got to the stage where I am getting glad it is over. Anyway, crown made, parts sprayed with clear laquer, acrylic fitted and strap fitted. A few other problems I had to deal with to get the watch keeping regular time. The watch now keeps good time and I will regularly wear it and see what snags come up (which I am sure they will !!)1 point

-

1 point

-

hi guys, hoping for a little guidance. i'm looking to polish up a few hardlux crystals and cases/bracelets in my collection. and wondering what tools i should get to have a fairly complete set of them to do the typical work in this area. so far, i've found this video the other videos i've found are pretty bad on this topic. and i've found these kits http://www.ebay.com/itm/NEW-684-01Dremel-Cleaning-And-Polishing-Moto-Tool-Kit-20-Pc-NEW-/271227643126?hash=item3f266d64f6:g:tnIAAOxykVNRwusc https://www.amazon.com/Dremel-684-01-20-Piece-Polish-Accessory/dp/B00005LEXV/ref=sr_1_10?ie=UTF8&qid=1485665200&sr=8-10&keywords=watch+polishing is one of these kits suitable or should i be looking for something watch specific? is this compound from the video what's commonly used? it says on the product page that it's for gold and silver rather than SS https://www.amazon.com/DIALUX-JEWELERS-POLISHING-COMPOUND-forGOLD/dp/B00TZVMXZA/ref=sr_1_2?ie=UTF8&qid=1485665653&sr=8-2&keywords=dialux is there maybe a sticky on this topic that i've missed? any help is much appreciated.1 point

-

I'm liking it a lot too . Very Nice . I think I'll search for an Avia and hope I can find something as nice . Aloha , Louis1 point

-

1 point

-

Well it took a bit of trial and error actually. Initially I thought it was a balance issue but having checked it out I just started to work my way back. When I removed the pallet I noticed a slight bed in the pivot and figured it would need attention. Replacing it with a good pallet solved the timing issue.1 point

-

This video has Around 12 min of disassembly: then I fast motioned the cleaning and the reassembly and back to Slow for a chat about the movement and back to fast for the casing Sent from my iPhone using Tapatalk Pro1 point

-

1 point

-

1 point

-

Well, after much, way too much, thought and cogitation, I took the plunge and purchased a Peerless watchmaker's lathe from my best friend Uncle Larry. It was in great shape and came with a good selection of collets, some gravers, and a bag of raw materials to practice on. I've since rounded out my set of collets, made a few additional gravers, and bought a used Jacob's chuck. I know Peerless lathes aren't as highly regarded as, say, Boley but I'm really impressed with the quality and design of it, and it had obviously been treated well during its life with a old lady who only ever drove it once a week, to church on a Sunday. Oops, I'm confusing my purchases; that was the car I bought with only 350,000 miles on the clock! Anyway, I have been practicing on it for some weeks and am now considering upping the ante and purchasing a cross slide so I can use it as a conventional, albeit tiny, lathe. My question is, is this viable, or would I be wasting money by doing so, given the expense of purchasing a good, but used, cross-slide for a 8mm lathe, which will be around $600, which is actually more than the lathe itself cost? Why would I consider this, well I'd like to get into model building, small steam engines and the like? I certainly can't do this without some sort of lathe unless really ugly will do, which it wont. I will be guided by opinions on this so please let me know your thoughts if you would be so kind. Cheerio for now. Roger Adams1 point

-

@RyMoeller Thank you I still have that small wear groove in the top, or technically speaking in the bottom of the balance staff pivot ....that is if the pivot(s) survives the whole ordeal. A staking set is on my wish list, but I'm currently facing lack of money and not enough bonus point by my wife .......... Perhaps this little groove is of no influence, we have to see that on the timegrapher......... lets hope we get to that stage1 point

-

1 point

-

1 point

-

The 0.5mm will work in place of the .60mm and you'll see the difference when you use those sizes. I suggest you use the screwdriver that is closest to the slot size to prevent slipping. This happens anyway, but will be reduced if you use the proper size screwdriver. I remember I was tempted to use smaller screwdrivers on the larger barrel or winding wheel screws and simply messed up my small blades when they came up short on torque and slipped. Lesson learned! JC1 point

-

1 point

-

Hi all And thanks for the replies. I am waiting for a new battery before I go any further with the Seiko. In the meantime I received my watch repair course a day early. A donor watch also was delivered, a side wind lever set Elgin. The watch is running and seems to be keeping good time. To be honest with you I really like it and hate to take it apart, it even has my first initial carved into it, but I guess some have to be sacrificed for the better good. Wish me luck. Here are a few shots of the victim.1 point