Leaderboard

Popular Content

Showing content with the highest reputation on 12/31/16 in all areas

-

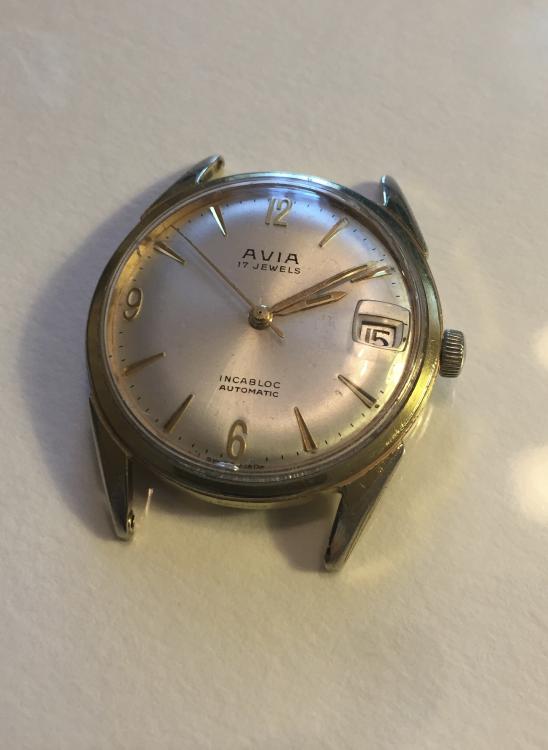

Santa came through this year with my first real tools. I replaced the movement in my dad's watch, the one I broke when I was about 5 by winding it all of the time. I found a used movement, the exact same one that was in it to begin with. It cost me $15 including shipping all the way from England. It started ticking again on Christmas Day for the first time in 38 years. I wish dad was still around. He would be tickled pink. He loved this watch. Nothing fancy to most, but it was to him. I've been wearing it for 5 days now. It keeps perfect time, and it turns out I still like to wind watches. I'll be more careful now though.4 points

-

Just my opinion but old watches should look old the dial on yours would be perfectly exceptable to me its original and shows its age but is still usable. I have seen many truly horrendous redials that look just too sterile and obvious thus ruining the look of the watch, I would live with it. Just keep it in mind and you may find one pop up on Ebay at some point but at this stage I would not be looking to do anything with the dial if it was mine. Once its restored it's no longer original and it cant be undone later, for now live with it and save your money. Defintley in my opinion3 points

-

2 points

-

1 point

-

Here is a video I made on the disassembly of a Eagle Star Geneve SQUALE Diver watch. My wife bought this in the mid 70ies ($500 bucks) for diving and she had been waiting a long time for me to service it. It was used by female competitive deep divers in the 60ies to 80ies. It is a Swiss movement with the case made by an Italian company. Squale Company is now back in business. Sent from my iPhone using Tapatalk Pro1 point

-

If you look at the discussion groups with wristwatch collectors you'll notice that they don't believe in changing anything in the watch. Is not even clear whether they would be happy with replacing parts if they were broken I think the purists would be unhappy. So from a collecting point of view they would rather have a tarnished dial than a nice new shiny dial.1 point

-

Sorry if this is going a little off topic... The zinc is required because the surface of the aluminium oxidizes as soon as it's exposed to the air. Copper adheres nicely to the zinc and the chrome. As aluminium is relatively soft and chrome hard, this combination is still susceptible to cracking and flaking of the chrome, so treat with care.1 point

-

Thanks for the advice. What about chrome? It was invented and used in pocket watches starting in the 20ies and 30ies. I have an aluminum guitar that was chromed and they had to add Zinc, Copper and then chrome. Sent from my GT-N5110 using Tapatalk1 point

-

Some of the letters in "Longines" are missing, and for me, that's it shot. I'd search for a replacement one. They do turn up eventually. I don't really like re-painted dials.1 point

-

Personally if as my dial I would find somebody that's specializes in this and send it to them. But isn't my dial and you're asking a question. So first step of solving a problem is what is the problem? So typically a wristwatch dial is not dirty as it is sealed behind a crystal. So you're not looking at something that's dirty that can be washed you're looking at something that has aged with time. A lot of the white dials are frosted silver it's a silver finish it will tarnish with time especially as the lacquer disintegrates. The various lacquers they put on the paint everything can disintegrate with time. Washing is not going to help that at all. The printed letters that are falling off or whatever happen to them touching of those is going to make that much much worse. Then fortunately there are still companies specializing in restoration of dials if you don't like the price of one shop around. Some of the pricing may have to do whether they have to make a special plate for printing the letters in other words they don't already have a plate for that dial.have to make a new one.1 point

-

Bestfit also confirms this 392 interchange ability is with 391 & 394 interchange ability is with 392.1 point

-

Copper plate is often used as an intermediate layer before other more difficult plating materials. For the faker, making all your blanks in brass means you can use the same part for a steel effect or a gold effect. Yours is probably nickel plated. If you want to try some fun chemistry then you can buy nickle plating solution on the internet. If it works then great, if it doesn't, then one more fake can be consigned to the scrap bin1 point

-

Don't be so stupid. Each of those markers are individually fixed to the dial. No matter what you look up on the net it doesn't provide you with experience which you don't have. The more damage you do the more it will cost. Longines watches are not a run of the mill they one of the top brands and can be highly sort after.1 point

-

I have one and it's exactly what I think. This goes for quite a few other ridiculously priced Bergeon things in my opinion.1 point

-

1 point

-

This is the first time I have read this post. I would like to congratulate Scott and all who have offered assistance, especially Ry. I look forward to the end result You have gone one better than me Scott, a chronograph was my second watch refurbishment, well done sir!1 point

-

I've posted this one before, but I wear so seldom I figured it wouldn't be too déclassé to show it again. This one is a constellation 504 in stainless steel case with gold arrowhead markers on a pie-pan face. I am also including a picture of the movement. A Happy New Year to all. J 20161230_155207 (1).jp21 point

-

OK, I've got the non-chrono portion of the watch back together and lubed, with all parts accounted for. The mainspring worked great and caught the arbor right away. Getting the pallet, escape wheel, their bridge, and the balance in place was incredibly challenging. I don't know how many times I had to place, nudge, fuss, fiddle, adjust, and start over again when it wasn't right. But it was hours. Anyway, I was rewarded with a beating movement. It's great fun to pull the stem out and watch the keyless works turn while now understanding how the whole thing functions. Hopefully I didn't screw up anything too bad with all that fiddling! On to the chronograph parts...1 point

-

my ikea one i did a while back, has changed since then but will give you an idea http://watchinprogress.com/new-ikea-hacker-style-watchmakers-bench/1 point

-

1 point

-

Szbalogh, Do you live in a part of the world where you are surrounded by watchmakers? You have a clear picture in your mind of what you want done to the watch and then work out the procedure to achieve that goal. Your degree of focus and innovation has to come from somewhere. The work itself is amazing but watching the machinery you are using moves it up to extraordinary. david1 point

-

So far it has been faultless & I have been using it for just over a year. I don,t know if this a fault that is going to cause issues or loctite & drilling recess holes for the screws will resolve this problem.1 point

-

I seldom use the 'dangling balance' method. It's always been holding the balance and cock together in the tweezers for me. The only times I've dangled the balance is when I remove the balance without removing the movement from the case..(pure laziness). Anilv1 point

-

Hi everyone. I have a shop where we do mostly batteries and straps, and basic repairs, glasses, crowns, etc. I do not do mechanical repairs mostly, as I just lack the knowledge, and have found it hard to get proper training, though I must say the youtube channel gives great advice. When we do quartz, we usually just do a movement, or circuit swap rather than a clean and oil job. On this occasion however, I have a watch with an eta movement, and I want to see if I can service it, and get it running again (it keeps stopping). I dont mind if I fail, I can simply buy a new movement for it as the customer is happy to pay 100 quid or so, so I thought I would use the xmas break to see if I can learn something new and get this watch cleaned and working. I do not wish to put thousands into a watch cleaning machine, I am unsure if I would get my money back for it. I am thinking about using an ultrasonic to clean it, and then try to oil it. I am sure that I have read on here that people do use these machines, with some chemicals to do this successfully, but I cannot seem to locate the thread/s now. Would anyone who has done this please advice on what I should buy, what chemicals, and what oil? I would appreciate it. If there are any people in the Herts/north london area who can service mechanical watches (strip clean oil), and would like to teach me in person, for money, then please let me know.1 point

-

Stuart, A lot of people buy these machines thinking that if they stay with an old school designer label brand lathe they can't go wrong. Often this does not work out as the purchaser does not have the necessary machinery and skill set to put the lathes back into original factory specifications. This could include designing components, turning, milling, lapping, surface grinding, spindle grinding, hand scraping and inspection procedures. Just removing the old paint and refinishing a machine opens up an expensive can of worms. This is usually beyond the budget and skill set of most watchmakers. The second problem then arises which is finding the necessary accessories in good condition in order to make the machinery actually perform usable work. To the best of my knowledge the only companies left making small machines are Horotec, Levin, Derbyshire, Star, Bergeon and Sincere. The Derbyshire and Levin lathes are, in my view, the best of the lot (50 millionths spindle runout). The Star, Bergeon and Sincere are cone bearing lathes and, once adjusted, all work in a satisfactory manner. Of the remaining three, the Sincere is the most affordable. Buying a used machine requires a considerable investment of skill, effort and equipment .Here is a picture of a Levin drill press that I helped my friend Tom Mc Allister restore. david1 point

-

sad day in Watchville. a very good intention and a lesson learned. a good lesson on any forum. its safer to only work on your own stuff. good presentation and very good pix.. vinn1 point

-

It was an interesting time at that. I filled the jars up to the raised lettering as per manual, and when the basket dipped in the cleaner over flowed all over the place. I think the basket went in too fast I will try to adjust that speed. I'm guessing your not supposed to put in all the small screws, I put them all in but not all came back out. A few disappeared. And I'm guessing I'll need to arrange the parts more carefully, the pallet fork came out in the middle of the hair spring. Two quick questions, Do the small screws normally go in the machine or just leave them in a safe place and reuse as is ? This is an L&Road variomatic with a whole big separate ultrasonic unit underneath. Is it worth trying to use the ultrasonic part or just stick with the basic cleaning machine ? Not sure if the ultrasonic part works or if it's worth bothering with. Thanks for any advice, Tom1 point