Leaderboard

Popular Content

Showing content with the highest reputation on 06/23/16 in Posts

-

A box arrived today from Tudor405 parts needed plus many more. Very many thanks very kind of you. This is a great forum.2 points

-

2 points

-

My name is Alexander and I’ve been an amateur watchmaker for over 5 years now. My journey started when I found my grandfathers old Lagonda watch in the bottom of a drawer. Still ticking and keeping time it had a plexi glass full o scratches (probably caused by the garbage it had been living with for the past decades). I decided to polish the glass and to try to get it open to see what it looked like inside. Since that I’m stuck in this fascinating craft. I’ve serviced a handful of watches over the years with some good (and some bad) results and I’m trying to improve my skills every day in any way I can. Being a parent, raising small chaos generating kids, it’s incredibly valuable to have a space in time and room where you can relax, let everything take as much time as it has to, aim for perfection, keep maximum tidiness etc. I love good quality tools and that is maybe one reason to why I got hooked in the first place. There are so much high quality watchmaking tools out there j just waiting to be used (and bought). Often decades old but still in good condition and fully functional. After buying my first K&D staking set I pretty much wanted to own every tool that K&D have ever created. Today I have a lot of them but they’re also sharing shelves with other fine German and Swiss brands such as Bergeon, Horotec and more. One day, when I grow up, I will quit my everyday job as Software developer and become a full time watchmaker. Nearly all watchmakers I’ve ever met have been old, gray haired glass wearers so I bet it’s an occupation that you can keep on doing until the day your own hairspring decides to stop pumping. By joining this community I hope to learn more and try to share when I have something that I think is worth sharing .. Sincerely yours, A1 point

-

Eek! Missed that!!! Appreciate the assist @Geo... @jdrichard, let me know if you want me to post another photo - I can take one of my press at home if it will help Stu...1 point

-

Oh and I work with the spring I'm copying and the one I'm manipulating inside a clear thick plastic bag with a zip top and I work on the outside of the bag. There's nothing worse than nearly bending one into shape and it pinging away never to be seen again.1 point

-

With some held from a genealogy site where they decipher old writing this is what they have come up with. It's definitely John, and I think it's quite likely to be Masgreave. Ancestry have a number of old directories, which mention a John Masgreave in Birmingham: Wrightson's Directory for 1815 and 1818 has him as a Brass Founder The England Commercial Directory 1816-17 has him as a Brass Founder with the note "(clock)" after his name, and the address Summer-row1 point

-

1 point

-

Welcome Alex to this friendly forum. I 'm sure you will find lots on here to interest you. Nearly all watchmakers I’ve ever met have been old, gray haired glass wearers so I bet it’s an occupation that you can keep on doing until the day your own hairspring decides to stop pumping. That's me off to a t. The other trouble is the failing of or poor eyesight which is me.1 point

-

Not what he meant. He meant he doesn't take on service jobs as he's just a hobbyist but someone asked him to do one.1 point

-

1 point

-

This is one practice I never did. I kept recorders in a book. I think its wrong to deface a case. I know many watch repairs/ makers did this years ago. Just my opinion I don't like it.1 point

-

Today, it's a Bulova Accutron. I got this a few weeks ago, and it runs like new......well, it's about -2 seconds a day. Sent from my XT1585 using Tapatalk1 point

-

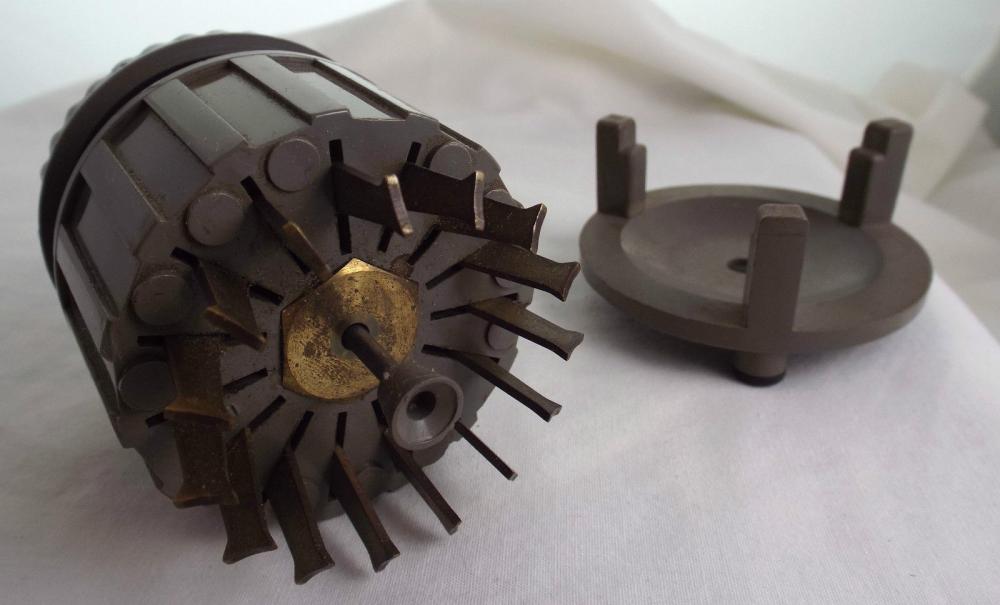

I have a set of those dies from the first image. I actually thought they were only used to measure round crystals - not to be used with a lift. I don't believe the tools shown are correct for a hunting case as pointed out. There is likely not enough of a lip to catch. I have a tool similar to this: Mine is hand operated - the one pictured probably has a foot pedal. The pusher presses the crystal into a round die, essentially compressing it like the crystal lift tool would do, but without requiring the tall lip. The case can then be lowered onto the crystal.1 point

-

Like others on here I don't restrict myself to just one set of screw drivers. I have one set ground to a thinner profile, and another set ground to a slightly fatter profile. I also have numerous screw drivers ground to extra thin and extra fat. As a rule I find that Swiss screw slots are thinner than Japanese, Quartz movements tend to have a few have extra fat slots, very old pocket watches seem to have extra thin slots. This sounds like an expensive investment in screw drivers but I have probably spent less on my multiple sets than many others have on just one as I have picked them up second hand and in job lots from all over the place. They are good quality, vintage, French or Swiss. They don't necessarily have the silkiest smooth ball bearing tops to them but they are perfectly functional. If you generally work on the same type of movements (pocket watch, or Japanese, or Russian for instance) then one set of screw drivers tailored to that specific family of watch movements is all you need. As for throwing away old blades it does seem a bit of a shame. Generally speaking all that is needed to bring a chipped blade back into trim is 5 minutes on a stone (or decent quality wet & dry paper on a sheet of glass, or your diamond stones). If you find that you are regularly suffering from chipped blades then it might well be worth exploring the possibility of adjusting the temper of the blades. If you get it right you not only get more resiliant blades which are less likely to scratch movement plates, but you also gain an understanding of heat treatments for steel on a macro or even micro scale. Useful stuff.1 point

-

For sharpening the blades I always used an arkansas stone with a little 3 in 1 oil with the same tool that sstakoff has posted. It takes a lot of practise to get it right. If you're like me when I first tried I messed up many. Make sure you have the correct size blade for the screw again its practise, first make sure you hold the screwdriver dead upright and not leaning to a side, master that and your screwdriver won't slip out of the screw slot.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

If you refinish your presto tool like I do, you can get the cut out to be the right size to actually grab the tube whilst pulling upwards1 point

-

I didn't think you could reach the bottom of the hand tube, if it's exposed then it's by far the best option!1 point

-

Absolutely, good advise, otherwise the tube may come apart and you will have to source another hand! This is very important since they are usually tight. Cheers, Bob1 point

-

I usually remove the main chronograph hand with a presto tool, but not using it as normal, but to simply fit under the hand, and firmly pull upwards.1 point

-

It can't be that tight, because its a very small small area of friction. However, someone wrote that it's easier to push small hands out with the dial itself (clear plastic applied for protection and loss prevention).1 point

-

I'll bet it was fun getting all the wheel train pivots lined up on that thing! Dave1 point

-

I would have gone slightly longer, five to seven years, five if an everyday wearer, and seven if worn only occasionally. Don't loose too much sleep about it, but I would schedule one in the not too distant future.1 point

-

Normally the recommended service period is 3 to 5years & I would say that is about correct. If your watch starts to act like it needs servicing, then it does.1 point

-

1 point

-

Well I would definitely start with Moebius 9010 (for train wheels and balance endstones) and 9020 (for train wheels) if you are working on Pocket Watches. Moebius 9415 is a must for Pallet/Escape wheel teeth. A quality silicon grease. Moebius D5 is essential (barrel arbor, motion work). Molycote DX or Moebius 9501 grease for keyless work. Moebius 9501 or 9504 for high friction (e.g. Cannon pinion, Setting lever spring and anything at high friction). Moebius 8200 grease for mainspring. Moebius 8217 for barrel wall (automatic watches) It's a lot but at a minimum get 9010, 9415, D5 and 8200 I hope this helps. Recommended Lubricants for Getting Started.pdf Moebius_Oil_Chart.pdf1 point