Leaderboard

Popular Content

Showing content with the highest reputation on 03/24/24 in all areas

-

My first attempt at silvering of watch hands. First I rubbed the hands back to the brass with 7000 grit paper. Then I polished a bit with pegwood and 1 micron diamond paste. Cleaned in solvent (Essence of Renata is what I have handy). Then used silvering powder as directed from Priory polishes (eBay). Finished of with a brush stroke of lacquer to avoid tarnishing. I think they look quite good, a nice satin effect.4 points

-

I do the fine-tuning with the movement in the watch-housing (with or without bracelet), but one has to be aware of the fact that a housing can cause extra vibrations and those extra vibrations could cause interference / "corrupt" the timegrapher signal. When the movement runs fine without the housing, and the build-in went flawless, but the timegrapher results are slightly "off", I take in consideration that it may be the housing which causes the interference. Most of the times, at least in my experiences, housings don't cause a problem, but if the signal on the timegrapher suddenly changes after the build in, the housing may be the culprit. There could be other reasons too, like one of the hands touching the inside of the crystal. Changing the position of the housing in the timegrapher microphone, or having the crown against the pick-up may help too.3 points

-

The watch may not be identifiable, even if so watches of this age still vary made by the same maker. Balance parts need to be assessed , if one of the cyljnder plugs are damaged then this part should be easy for a watchmaker to source or make. It is also something he would need to fit and adjust to the watch, not something a something a hobbyist with limited experience should tackle. I tried this myself a few months ago only to fail miserably breaking the cylinder in half, believe it or not i consider i was being very careful2 points

-

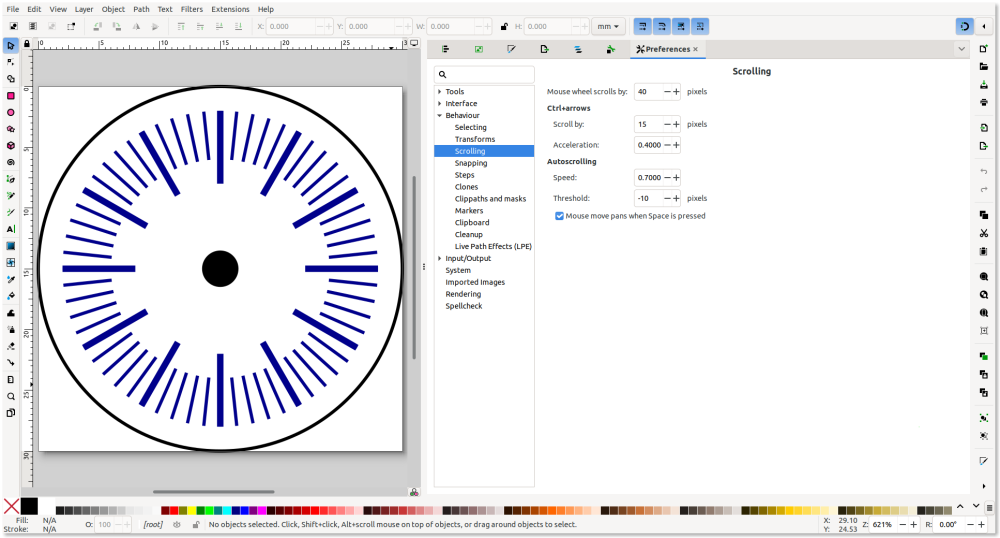

I feel I should call this post "Artificial Intelligence creates a watch dial." I present possibly the worlds first AI generated python code to produce an SVG graphic for a 30mm watch dial. First... I went to ChatGPT and asked it the following question. It responded with the following code... def generate_svg_watch_dial_with_markers(diameter, num_minutes_markers, num_hours_markers, hole_radius): svg_content = f'<svg width="{diameter}mm" height="{diameter}mm" xmlns="http://www.w3.org/2000/svg">\n' # Draw white circle for watch dial svg_content += f'<circle cx="{diameter/2}mm" cy="{diameter/2}mm" r="{diameter/2}mm" fill="white" stroke="black" stroke-width="1"/>\n' # Draw markers for minutes for i in range(num_minutes_markers): angle = i * (360 / num_minutes_markers) x1 = diameter / 2 + (diameter / 2 - 2) * math.cos(math.radians(angle)) y1 = diameter / 2 + (diameter / 2 - 2) * math.sin(math.radians(angle)) x2 = diameter / 2 + (diameter / 2 - 6) * math.cos(math.radians(angle)) y2 = diameter / 2 + (diameter / 2 - 6) * math.sin(math.radians(angle)) svg_content += f'<line x1="{x1}mm" y1="{y1}mm" x2="{x2}mm" y2="{y2}mm" style="stroke:darkblue;stroke-width:1"/>\n' # Draw markers for hours for i in range(num_hours_markers): angle = i * (360 / num_hours_markers) x1 = diameter / 2 + (diameter / 2 - 2) * math.cos(math.radians(angle)) y1 = diameter / 2 + (diameter / 2 - 2) * math.sin(math.radians(angle)) x2 = diameter / 2 + (diameter / 2 - 8) * math.cos(math.radians(angle)) y2 = diameter / 2 + (diameter / 2 - 8) * math.sin(math.radians(angle)) svg_content += f'<line x1="{x1}mm" y1="{y1}mm" x2="{x2}mm" y2="{y2}mm" style="stroke:darkblue;stroke-width:2"/>\n' # Draw solid black circle in the center svg_content += f'<circle cx="{diameter/2}mm" cy="{diameter/2}mm" r="{hole_radius}mm" fill="black"/>\n' svg_content += '</svg>' return svg_content import math # Diameter of watch dial in mm DIAMETER_MM = 30 # Number of minute and hour markers NUM_MINUTES_MARKERS = 60 NUM_HOURS_MARKERS = 12 # Radius of hole in the center in mm HOLE_RADIUS_MM = 1.5 svg_code = generate_svg_watch_dial_with_markers(DIAMETER_MM, NUM_MINUTES_MARKERS, NUM_HOURS_MARKERS, HOLE_RADIUS_MM) print(svg_code) I saved this as 30mmWatchDial.py Next a ran the code (using python of course). python 30mmWatchDial.py >30mmWatchDial.svg ... and here is the result displayed in Inkscape. Here is a png of the .svg .. and the .svg saved as a .svg.rtf is attached to the bottom of this post. Save it as .svg and you can open it in Inkscape. Some things to bear in mind when playing with this idea. The free version of ChatGPT can only write short snippets of code, so don't try to get too fancy or you will get incomplete results. Image generating AI will produce arguably more interesting watch dials, like the one below, but they wont be in SVG format. ChatGPT is available here -> https://chat.openai.com/ DeepAI image generator is here -> https://deepai.org/machine-learning-model/text2img Have fun. 30mmWatchDial.svg.rtf Just for fun, here is another AI generated watch. Spooky stuff.2 points

-

I can confirm from my experience what @RichardHarris123 said, if light scratches then you can clear them with an appropriate grade scotchbrite. If heavier then you need to polish the deep scratches out then brush again from the start. Tom2 points

-

2 points

-

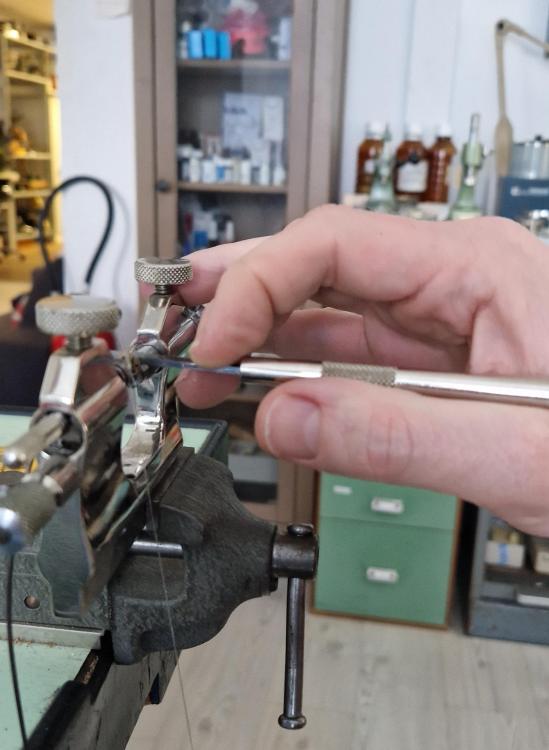

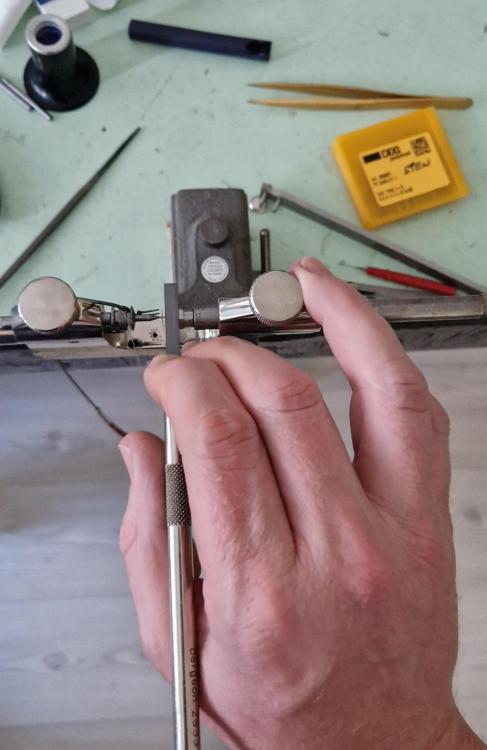

Just to note- I know folks who can put the pedal to the metal on Jacot use who don't anchor with ring/pinky, or even have a similar overall grip on the burnisher. But this is how I was taught, and have demonstrated to absolute greenhorns who within minutes are successfully using the tool. Honestly I think the burnisher "grip" is less important than getting your head away from the tool and going on feel and sound. I just did a really short length balance staff (1.95mm) with 0.07mm pivots and it was with me sitting normally and going on feel and sound. Wouldn't do it any other way. Loupe to line things up, sit back, and go. On that staff it was like 8 strokes.2 points

-

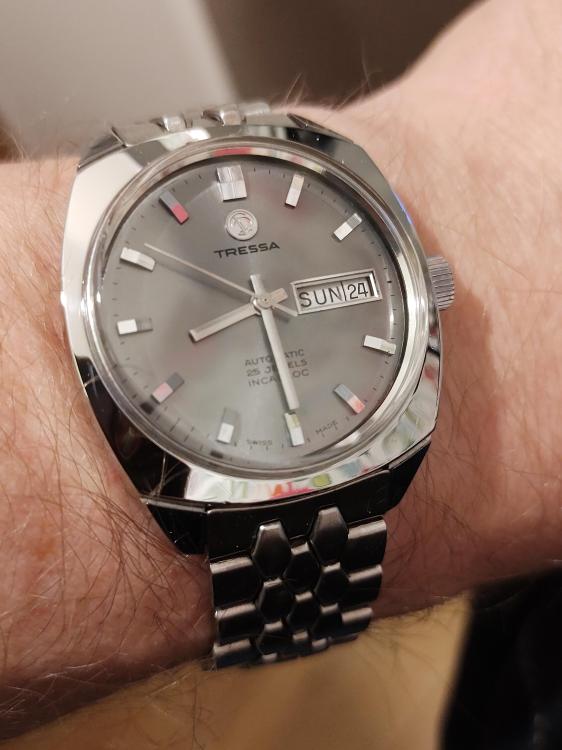

Ricoh has a similar pallet fork Tressa 1970s ETA 2788 Unusual Grey Sunburst Dial all original except for the crystal Running really well for its age, + 0.5 SPD, 300 degrees amplitude horizontal after 12 hours. I have another crystal arriving next week with a wider tension ring that I hope can hide the gap between the dial and case (XAC 321.577). Wide tension ring crystals appear to be few and far between so if anyone has any tips for a good source then that's most appreciated. I did look at ATCB range from Sternkreuz but they seem a bit higher than I would like based on the dimensions.2 points

-

1 point

-

1 point

-

if the screws hole is threaded through the bridge then push the screw from the opposite/underside....1 point

-

Latetothegame has posted about this watch before, it just might be a lot easier to replace the works than repair that post, your movement looks to be quartz, the Chronosport I saw had an ETA 555.11? so could be ETA, Ronda, I do not understand why a movement model number or picture of said works is scarce?, one can only help with more info or drill the post out and go from there.....1 point

-

Welcome Adrien. Great times ahead for you if you carry on. I started, aged 72, not even knowing how to open a watch. I knew it needed a battery or needed winding. That was it. Followed the YouTube video's then decided to do the course. Best thing I ever did for my watchmaking. Advice? Spend some time reading the posts from people like me who started from basics. Ask questions. Still learning nearly every day. So enjoyable. Ross1 point

-

Hi. Moving the fork higher creates a shallow lock which leads to fluttering ( skipping teeth on the escape wheel) giving the appearance of the clock gaining. Likewise the lower it gets ithe lock gets deeper and will eventually stop th clock. If you intend to work on these clocks it is almost imperative to have at hand Terwilligers book on 400 day clocks . The 400 Day Clock Repair Guide cost around £30.00. The latest is the tenth edition. The book gives you the relative positioning of the fork on most of the known models of this type of clock plus a lot more. Definitly worth the money1 point

-

Hello there! I've been repairing watches and clocks for years as a hobby. I've been on many residential courses here in the UK with the British Horological Institute and really enjoy repairing items taht are sentimental to people. Over the years I've collected quite a lot of tools and equipment and the variety of pieces that people give to me to look at generally means I keep learning constantly. Every now and again I come across something that stumps me and I can't quite see the problem; having access to the wealth of knowledge that exists on this type of forum is invaluable in those circumstances! Anyhow, I hope to be a useful member of the forum and look forward to reading posts and helping where I can! Andy1 point

-

3 in 1, sewing machine oil, or any thin watch oil should be fine - just not anything silicone based.1 point

-

I've liked Tressa since i started collecting, i compare them to the unusual design of Rado, apparently there is some connection between the two makes.1 point

-

You should be OK to wash the circuit board with high purity isopropyl alcohol (not the 70% stuff). IPA is commonly used in electronics manufacture and repairs and is safe on most such materials. Use a soft paintbrush if needed to remove any stuck dirt or flux, keeping it wet with the IPA. Then dry it somewhere warm to avoid condensation as it evaporates. I'd treat just the tips of the battery contacts with Deoxit using a cotton bud to apply it; or a very fine trace light oil if you cannot get deoxit. It will help prevent tarnish and maintain good contact with the battery. For a dial or date ring, I'd not use anything other than deionised water on a cotton bud, with very little pressure, and only if there is no lume. I'd rather leave them alone if practical.1 point

-

The new guy here.... Just saying hello from Kansas City. I hope to learn and contribute. This looks like a nice community. Hope everyone is having a great day. Joe1 point

-

There might always be exceptions but generally mechanical Seiko hand holes are all the same so finding replacements shouldn't be an issue. Finding original model specific hands might be trickier but sometimes Seiko used the same hour and minute hands for divers and dressier watches and everything between. You can find some info here http://cgi.julesborel.com/cgi-bin/matcgi2?ref=SEK_CS^6106-7589 The julesborel hand codes don't make sense. Your watch should (judging by Google) have wide rectangular baton hands but there seem to be many different types with the same code.1 point

-

Good and well done it's not that easy. You want to take out and English fusee clock spring, French clock springs are nothing.1 point

-

Not sure but I would think that if the brushing is undamaged, then brushing over would be OK. If scratched, remove scratches and rebrush. Someone with more experience will either confirm repudiate this.1 point

-

I don't have small hands, I suppose they are normal size for a 183cm/6ft man? Tip of finger is right in the middle of the burnisher (width-wise). Middle finger is there, kind of in opposition to the thumb, but not really doing much. Tensing up is probably more an issue of your hand being in an unfamiliar position. I shot some arrows last week with some watchmaker friends; never got into archery but had a cheap fiberglass bow as a young teenager, so like 35+years since I held a bow. I was surprised how spastic I was! Arrow flopping around on the bow, a mess. I did finally manage to make some good shots, but I imagine it would take a number of sessions before the motions become natural. One thing that watchmaking schools (used to) do that's great is making you spend hours and hours filing and sawing, eventually turning in the lathe with handheld gravers, making your own tools. The dexterity and muscle memory from the increasingly fine work really does translate over to things like the Jacot, or manipulating hairsprings. I can tell the fellow in the vid linked (I Shoot Watches) hasn't done much filing, haha!1 point

-

1 point

-

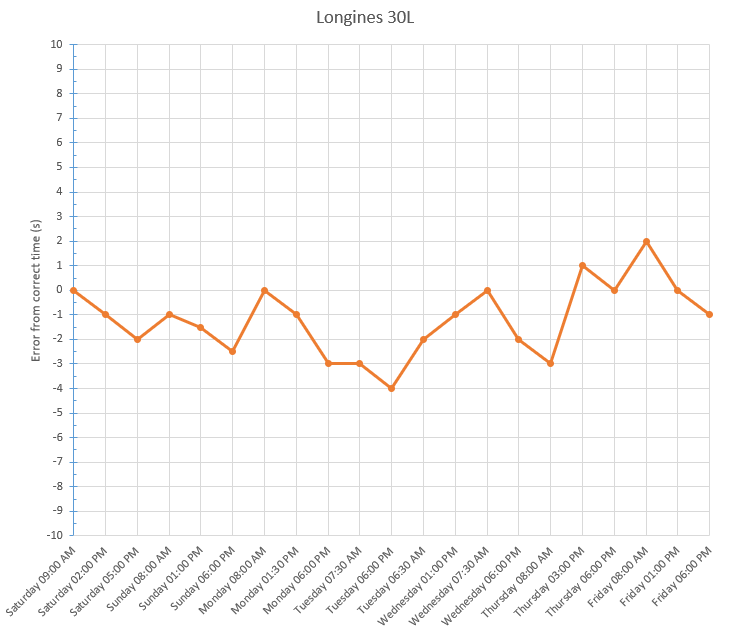

You did better than me, I broke a pivot Just to finish the thread @VWatchie. The pivots on the new balance were just as flat, I assume to make horiz and vertical rates more equal. As I posted elsewhere, I stopped short of perfect balancing, but got close. After a weeks tweaking the timing the results look good to me. I wind each morning and wear for about 10 hours a day, recording the error from true time 3x/day. After 1 week I'm with 1s, and the error was never more than 4s. When on the timegrapher fully wind DU, it's about -3s, which goes to +ve after about 24h. Which goes to show that the timegrapher is just the starting point.1 point

-

My point is that there is usually little difference in construction between 'high end' and 'standard' movements. It's usually better quality balance/hairspring, finishing, jewelling etc. Certainly nothing you would notice when learning to work on watches. I have watches which cost me £30-£50 with the same movements (eg ETA) as 'higher end' Tudor, Breitling etc, but as it doesn't say that on the dial, they cost 1/10 the price., but give similar performance. I go on the movement, not what it says on the dial. If you were learning to rebuild engines, working on a Ford would give you the same skills as working on a Ferrari engine, only a lot cheaper. I'm just timing a Rotary with a Peseux 330 movement I bought for £19. After 24h it's within 1s. And looking at the quality of the parts, I don't see much difference between it and any of my Omega's. Good luck with the new balance. Overcoil hairsprings are notoriously difficult to manipulate - probably the thing I least like doing.1 point

-

Oh yes, it works! I've practised this approach and technique now and it works very well, better than anything other I've tried. In the beginning, it feels very scary, much like crossing a busy road with your eyes closed, but after a while, you start to trust the process. Without having analyzed it, it also seems to be a safe method. I spent a great deal of yesterday practising and didn't once destroy or damage any wheel pivot (knock on wood). One question I have is if you have unusually large hands. I think it looks like that. I tried to hold the fingers of my right hand in exactly the same way as you do but noticed that my hand became quite tense. You probably have to adjust the way you hold the burnisher to some extent depending on the size of your hand. It's crucially important to be able to be relaxed, like with everything else when working on watches, and you look super relaxed. I'm also wondering if you hold the tip of your index finger right in the middle of the burnisher and if the middle finger is hanging freely in the air, or if the index finger is slightly to the left on the burnisher to make a little room for the left side of the middle finger so that the middle finger can support (press on the right side of) the burnisher? Watching the video it's a little hard to tell. (OT: Should we be crying or laughing?! I mean no disrespect.)1 point

-

1 point

-

there is some other things that you didn't say like how often do you run these watches? For instance if you only bring about once or twice a year to wear them and then put them back someplace safe then I really wouldn't worry about it. but if you're running them every single day then I would think about servicing them. The timing machine doesn't show everything that's happening in the watch. Like all of the metal on metal let's rubbing for instance the keyless parts the winding and setting components you won't know you're having a problem until you have a problem and then it may be to late as things disintegrate.1 point

-

Hello community! found this interesting forum and joined because I want to learn. Mainly I am a silent reader but have some questions sporadically. Basics are at the beginning the most interesting. I am interested in watches since 9 years and been generally interested in technics/cars. In my normal day I am working with IT so I love watches because they are mechanic and something different to all the software which is everywhere. My friends sadly dont like watches so I am often reading in forums. I hope to learn here a lot and you can read/understand my okish english1 point

-

Hey guys. I've been into watches now for about the last 20 years or so. Started modding some watches a few years ago, and then started building some for friends. Now I'm fully invested in servicing and repairing. My easiest service is think was a UG ultra thin, and most difficult has been an Omega 1140 that had water damage and rust. Currently I'm doing some repair work for a local Jeweler, and I'm working on a Seiko 6138 chronograph. I love the ritual of disassembly and the radical change a watch can make with a service and a new crystal. Ill do my best to help out with questions, and also I'll have my own!1 point

-

Yes, a service is always a good idea. Even if running well, the lubricants may be dryed up or evaporated, causing wear to the various components.1 point

-

Hello I'm James from Yorkshire England. Over the past few years I've found myself buying more and more watches. After visiting a watch and clock museum in Germany last year I've become fascinated with the workings of them and have started taking apart and servicing some of my older watches. Nice to meet you all1 point

-

Hi, I always liked watches, and now I have some time for a hobby, I started watching videos on youtube, and later bought some watches on a flea market, and start trying to reproduce what I saw on the videos, two years later, dozens of watches serviced, some books and a lot of more videos, I am completely into this rabbit hole. I read a lot of post here that help me a lot and now I want to be part of this group of people that love watches.1 point

-

I think the movement is genuine, the dail being made in Thailand. Put a screwdriver under the head of the screw and apply slight upward force.1 point

-

you don't because the file size would be too big for the message board. It is also not one of the supported file types. That means you can upload it to YouTube because I think anybody can have a YouTube account and just upload anything they feel like or you find some other source or location to put your video file it and give a link for people can download it.1 point

-

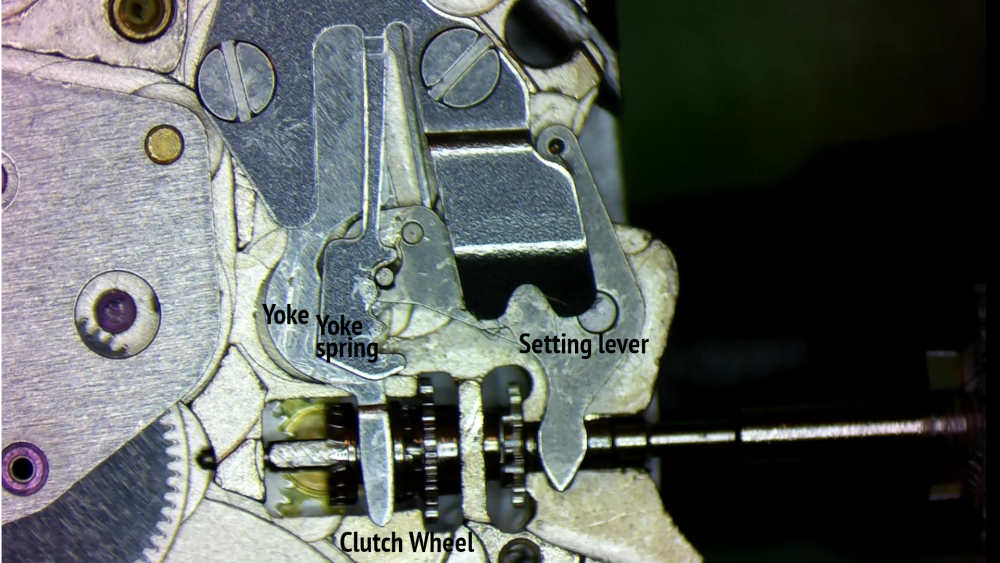

Well, I disassembled most of the dial side and sure enough the yoke lever had slipped out of the clutch wheel. I tried to nudge it back but wound up taking apart most of the movement side to get to the setting lever, yoke and yoke spring, all of which I had to remove to reset the yoke into the clutch wheel. What a pain but a good learning experience. I've attached a photo and also did a short video for anybody who might run into this who, like me had no clue what lay ahead. Please pardon the video, or actually audio quality; I have lots to learn if I'm to ever be a watch repair "influencer Here's the URL for the video:1 point

-

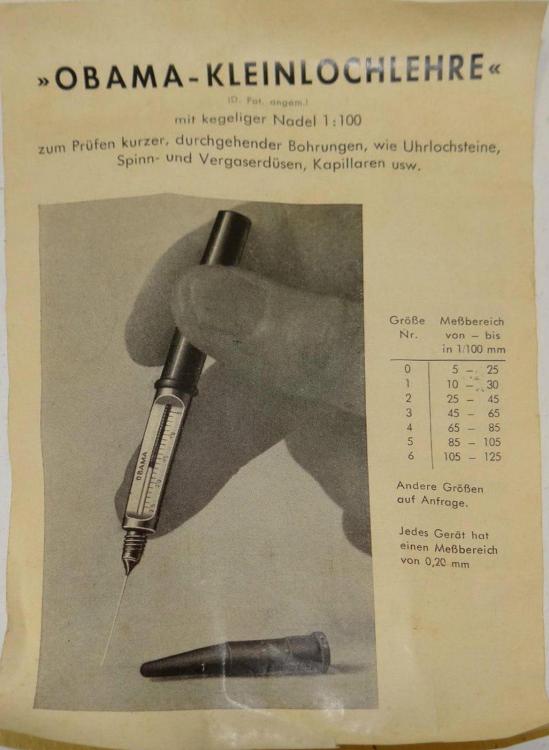

There is a tool for this, if you can find one. It's called an Obama Jewel Hole Gauge. It consists of a finely tapered pin which you push into the hole as far as it will go. The pin then pushes back into the body of the instrument until the jewel is against the tip. The hole diameter can then be read off the scale in 0.01mm increments down to 0.05mm. If you could find a suitably fine tapered pin there's no reason why you couldn't improvise by marking where the jewel sits on the taper and then measuring it with a micrometer. In practice though if you are replacing a jewel you could always just measure the pivot that is going to run in it.1 point

-

The pivot has broken off. Watch supplies might be able to help, you will find some at the top of this page click on Resources and just follow. As this is your first post we like new members to make an introduction telling us a bit about yourself and where you life also interests if you wish.1 point

-

Hi Andrew, this sounds like how seiko’s NH3X movements work, the bit that disappeared when you pulled the stem out is the setting lever. With the stem fully in press on the visible bit with a small screwdriver or tweezers and pull the stem out. as always with this stuff, minimal force to perform the action Tom1 point

-

Hi difficult to see from the picture but the obvious thing to do is to pull out the stem and look for the release nib coming into view as some watches have it hidden untill the stem is pulled out1 point

-

For me, a bit of a "kinky" side step; two partially broken vintage quartz watches no less ! They do run and the chronograph functions do work, but, from both, the small chronograph seconds recorder (1/10 sec) doesn't reset and they don't run I've found some instructions on how to reset the small seconds recorder, but it doesn't say whether the recorder hand should run, or not, after a battery change; "Resetting the Chronograph to Zero: If your chronograph and 1/10 seconds subdial hand are not aligned after a battery change, do not worry as this is common and easily fixed. Simply make sure the crown is in normal position (pressed in against the case), the push Button C (bottom left) twice. The second hand will move, press C again. Pull out the crown to time setting mode. Now you can adjust the two misaligned hands: Button A will advance the central second hand forward, Button B will advance the 1/10 second hand forward. Push the crown back in." So, since both of them do have the same problem, it could be simple and the seller didn't know how to reset, or there could be more to it? Is it a coincidence that both movements do run (cal. 3510 + cal 3530) and do have the same problem ?? They added thrill is that these Citizen / Miyota 3510 movements (12 jewels ! ) are discontinued and apparently (very) hard to get (??). Perhaps one of those: "There is a thin line between a Hero and a Zero" Anyhow, without further ado here some pictures of what should be in the post;1 point

-

Thanks for that. To be honest, I was thinking the same thing and just keep it. For the money I paid for it I may as well just buy another, use the 7718 for the cap jewels and the 7719 for the wheel train although I find oiling them a lot more easier than those pesky cap jewels Also, although I've never seen a genuine Bergeon oiler I wouldn't be surprised if they're all the same from the same factory as the packaging, labeling and instruction manual all look to professional to be a cheap clone.1 point

-

Yes you can. You have to thin the metal just in front of where the two halves of the tweezer are spot welded. About 2-3 cm length. The amount to grind off will be by trial and error and personal preference. I have some that are very light and some that are heavy.1 point

-

1 point

-

Hi this book by Henry B Fried goes so way to explaining magnetism it’s als worth a read. Electric_Watch_Repair_Manual.pdf1 point

-

1 point

-

Update: Installation of tips. One of my suppliers, Esslinger.com, suggested a pair of specialty pliers (#1 Conner Bead Setting and Stone Setting Pliers 4) to install the metal clips. The metal clips are sold separately from the tips should you damage one during installation. The countersunk holes on the tweezers help to center the clips onto the studs on the tips.1 point

-

1 point