Leaderboard

Popular Content

Showing content with the highest reputation on 03/23/24 in all areas

-

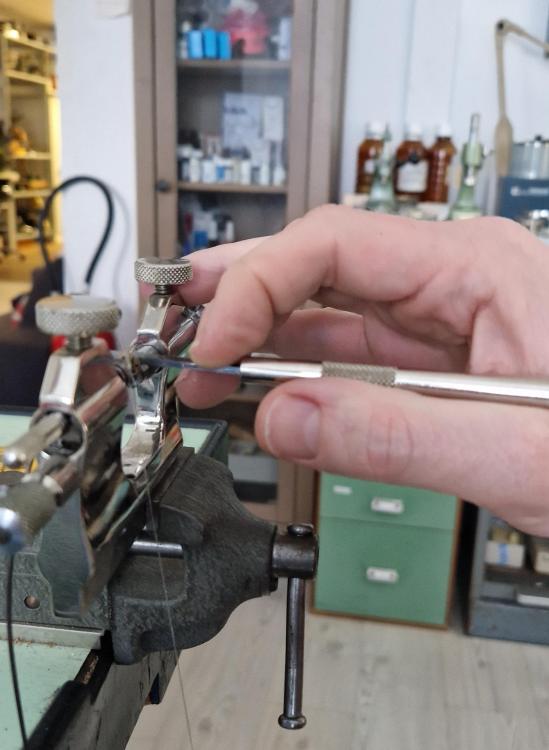

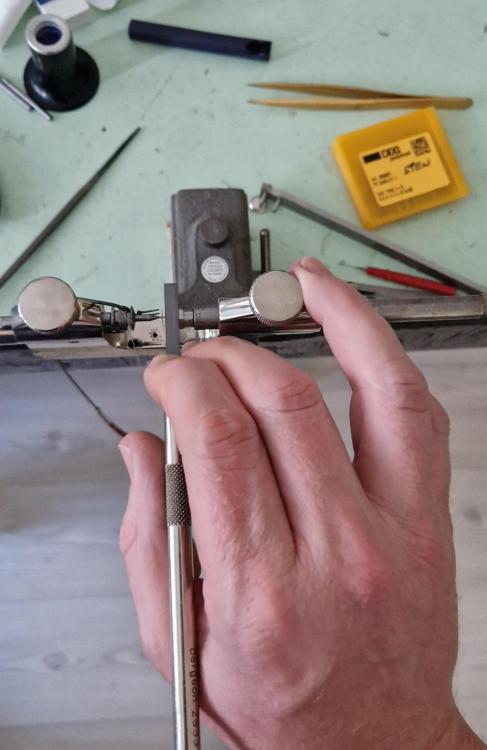

I don't have small hands, I suppose they are normal size for a 183cm/6ft man? Tip of finger is right in the middle of the burnisher (width-wise). Middle finger is there, kind of in opposition to the thumb, but not really doing much. Tensing up is probably more an issue of your hand being in an unfamiliar position. I shot some arrows last week with some watchmaker friends; never got into archery but had a cheap fiberglass bow as a young teenager, so like 35+years since I held a bow. I was surprised how spastic I was! Arrow flopping around on the bow, a mess. I did finally manage to make some good shots, but I imagine it would take a number of sessions before the motions become natural. One thing that watchmaking schools (used to) do that's great is making you spend hours and hours filing and sawing, eventually turning in the lathe with handheld gravers, making your own tools. The dexterity and muscle memory from the increasingly fine work really does translate over to things like the Jacot, or manipulating hairsprings. I can tell the fellow in the vid linked (I Shoot Watches) hasn't done much filing, haha!3 points

-

3 points

-

@nickelsilver Thank you very much for clarifying in such detail. It’s extremely valuable to me and I’m sure to many others.2 points

-

Oh yes, it works! I've practised this approach and technique now and it works very well, better than anything other I've tried. In the beginning, it feels very scary, much like crossing a busy road with your eyes closed, but after a while, you start to trust the process. Without having analyzed it, it also seems to be a safe method. I spent a great deal of yesterday practising and didn't once destroy or damage any wheel pivot (knock on wood). One question I have is if you have unusually large hands. I think it looks like that. I tried to hold the fingers of my right hand in exactly the same way as you do but noticed that my hand became quite tense. You probably have to adjust the way you hold the burnisher to some extent depending on the size of your hand. It's crucially important to be able to be relaxed, like with everything else when working on watches, and you look super relaxed. I'm also wondering if you hold the tip of your index finger right in the middle of the burnisher and if the middle finger is hanging freely in the air, or if the index finger is slightly to the left on the burnisher to make a little room for the left side of the middle finger so that the middle finger can support (press on the right side of) the burnisher? Watching the video it's a little hard to tell. (OT: Should we be crying or laughing?! I mean no disrespect.)2 points

-

Add a picture of the balance parts so they can be assessed. Dont assume that everything else will be ok, its very likely it wont be. Take it step by step with help from here.2 points

-

Ricoh has a similar pallet fork Tressa 1970s ETA 2788 Unusual Grey Sunburst Dial all original except for the crystal Running really well for its age, + 0.5 SPD, 300 degrees amplitude horizontal after 12 hours. I have another crystal arriving next week with a wider tension ring that I hope can hide the gap between the dial and case (XAC 321.577). Wide tension ring crystals appear to be few and far between so if anyone has any tips for a good source then that's most appreciated. I did look at ATCB range from Sternkreuz but they seem a bit higher than I would like based on the dimensions.2 points

-

Trying to resist saying I told you so. A beginner with an overcoil hairspring = 90% disaster. We all start with confidence that we can fix these things, but we have all made these mistakes, which is why we suggested practicing on cheaper movements. Or as @JohnR725 suggests, keep going on expensive movements then you will remember your mistakes more2 points

-

The stem has a clip fixing rather than a sprung setting lever; it's not the hole.. See around the 6th reply in the article here: https://www.watchuseek.com/threads/removing-the-stem-on-a-vintage-timex-quartz.1837898/ I've not found the movement name or number yet, but this one on ebay appears to use the same basic movement, though with calendar. https://www.ebay.com/itm/1757637576722 points

-

there is some other things that you didn't say like how often do you run these watches? For instance if you only bring about once or twice a year to wear them and then put them back someplace safe then I really wouldn't worry about it. but if you're running them every single day then I would think about servicing them. The timing machine doesn't show everything that's happening in the watch. Like all of the metal on metal let's rubbing for instance the keyless parts the winding and setting components you won't know you're having a problem until you have a problem and then it may be to late as things disintegrate.2 points

-

Yes, a service is always a good idea. Even if running well, the lubricants may be dryed up or evaporated, causing wear to the various components.2 points

-

Just to note- I know folks who can put the pedal to the metal on Jacot use who don't anchor with ring/pinky, or even have a similar overall grip on the burnisher. But this is how I was taught, and have demonstrated to absolute greenhorns who within minutes are successfully using the tool. Honestly I think the burnisher "grip" is less important than getting your head away from the tool and going on feel and sound. I just did a really short length balance staff (1.95mm) with 0.07mm pivots and it was with me sitting normally and going on feel and sound. Wouldn't do it any other way. Loupe to line things up, sit back, and go. On that staff it was like 8 strokes.1 point

-

Sorry, I didn't realise you have worked on such cheap (crap) movements! I would never have touched them. I never buy anything unless it has at least 15 jewels and a Swiss lever escapement. If you do that, you shouldn't go far wrong. There are dozens of different Swiss manufacturers with some excellent movements for very little money, and if you stick the the 'more popular' ones, parts are easy to find and cheap. BTW In marketing watches, the same techniques apply as in selling cars. Good advertising to get a reputation of quality (Rolex, Omega, Mercedes, Audi) and restricting supply (e.g. Rolex, Ferrari) means they can sell at a premium. In reality, Mercedes, Porsche and Audi are down the bottom end of the reliability lists. So for pretence of quality, Audi is apt (but not BMW as I drive one )1 point

-

1 point

-

There are countless movements of this type about, but they are not universal and it is highly unlikely that parts from a movement will fit others.1 point

-

I have seen tons of these types of parts( used) in my late watchmaker's stuff, unidentified , guess he knew them just by looking. Need full measurements to look for what you need. Rgds1 point

-

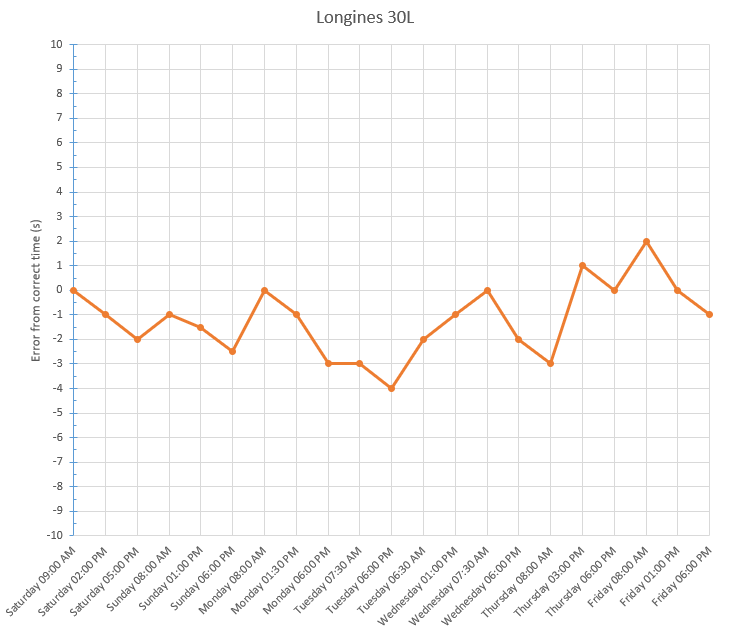

You did better than me, I broke a pivot Just to finish the thread @VWatchie. The pivots on the new balance were just as flat, I assume to make horiz and vertical rates more equal. As I posted elsewhere, I stopped short of perfect balancing, but got close. After a weeks tweaking the timing the results look good to me. I wind each morning and wear for about 10 hours a day, recording the error from true time 3x/day. After 1 week I'm with 1s, and the error was never more than 4s. When on the timegrapher fully wind DU, it's about -3s, which goes to +ve after about 24h. Which goes to show that the timegrapher is just the starting point.1 point

-

My point is that there is usually little difference in construction between 'high end' and 'standard' movements. It's usually better quality balance/hairspring, finishing, jewelling etc. Certainly nothing you would notice when learning to work on watches. I have watches which cost me £30-£50 with the same movements (eg ETA) as 'higher end' Tudor, Breitling etc, but as it doesn't say that on the dial, they cost 1/10 the price., but give similar performance. I go on the movement, not what it says on the dial. If you were learning to rebuild engines, working on a Ford would give you the same skills as working on a Ferrari engine, only a lot cheaper. I'm just timing a Rotary with a Peseux 330 movement I bought for £19. After 24h it's within 1s. And looking at the quality of the parts, I don't see much difference between it and any of my Omega's. Good luck with the new balance. Overcoil hairsprings are notoriously difficult to manipulate - probably the thing I least like doing.1 point

-

That's fantastic - thank you. I've read it, and also have favourited it so I can come back to it!1 point

-

I once wrote an article on WUS. Perhaps not exactly the same as on your watch, but you should get the drift ..... To read the full article, hit "see more" https://www.watchuseek.com/threads/how-to-change-hands-dial-on-a-vostok-24xx.5311825/1 point

-

According to one ebay seller, it's a "B64" movement, though I cannot find any other reference to that..1 point

-

1 point

-

If you have a MG, it's for sure a fun watch. Sometimes (or often) the "sentimental" value of a watch exceeds the commercial value. And, once completed, it will be a reminder on your first watch-repair ever Why do you want to lift the crystal? Doesn't the movement wants to come out from the back? First, you have to pull the stem. Not being able to see the movement from up close, but the is a chance that if you press with tweezers in this hole (arrow) you may be able to pull the stem. I would assume that after that the whole thing drops out(?). As JerseyMo suggested, look for a replacement movement. Judging the screw-heads, it looks like that somebody had a go at it with some garden-tools. CousinsUK has "millions" of quartz movements, in different shapes & flavors. eBay could be another source. You may want to swap the crown on the winding stem to keep the watch "original". The most important things to watch for is that the replacement movement, next to the same movement diameter, has the same pivot diameters for the hands as your old movement. Therefor it would be nice to identify the old movement and to find information of it. To fit the dial, you may have to do some "Mickey Mouse". There are again "millions" of video's on YouTube how to pull the watch hands, the dial etc, so you have to do some work yourself ..... Also read the beginners section, your questions have been asked, here we go again; a "million" times before. Since I've been talking so many times about "millions", I'm now going to check my bank account, maybe something funny has happened Suc61 point

-

1 point

-

I am guessing the roller table is at the wrong height, so in dial down position rubs on the fork horns because it has move down by gravity, in dial up position roller table moves away from the horns, thus doesn't rub and can works . Are you set up to show a side view of the roller table and fork , in DU & DD poistions?1 point

-

These movements were made on the French Swiss border and there are no I D for makers, date from 1850 to 1900.1 point

-

You first need to read all this thread You need to understand, that every time You punch the staff out, the hole in the balance arm gets bigger, thus the chance that You will be able to rivet the new staff gets smaller.1 point

-

Hi. Would you apply the same logic to your car? Dirt ingression dried up oil Deteriorated oil all good reasons to dismantle and clean a watch.1 point

-

How about other gears in the MINUTE TRAIN? haha. @MartinOfPrague There are walkthroughs on this caliber on WRT, where you might find a pic of the minute train, good to make sure you have the right gears as far as the Number of teeth. 781 Is originally an ETA with a host of calibers whose parts interfit. Worth a checking In case you found no gear teeth slipping. Finally a vid in slo mo of the train might be needed . Rgds1 point

-

12:36 then 10:40 ratios, looking at the photo. /3 the /4, so correct 12:1 reduction.. It must be something slipping or skipping due to allignment?1 point

-

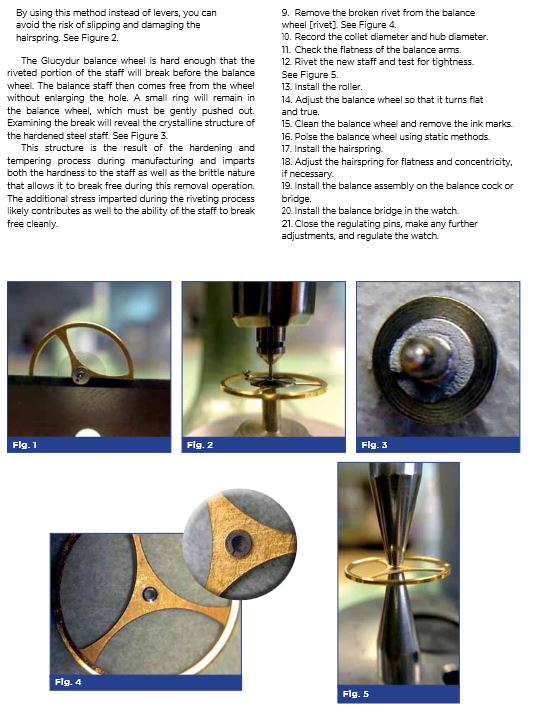

Haven't posted for a while as I've had family visiting and then sick with a cold . but did manage to work on this Gruen (AS 5203) watch which has really grown on me. It also has a cool escapement setup, and an even stranger keyless works (no sliding pinion!). Picture of pallet fork (stock image): Here is the before shot: Movement with and without automatic works: Here is the dial side showing the complicated keyless works without a sliding pinion Here is a closeup on that pallet fork in the movement: showing only 1 banking pin The image below shows the mechanism where the hands setting wheel is not horizontally brought into position, instead it engages and disengages vertically, rather than use a sliding pinion (stock image): And here is the finished watch with its new strap and crystal (original was cracked):1 point

-

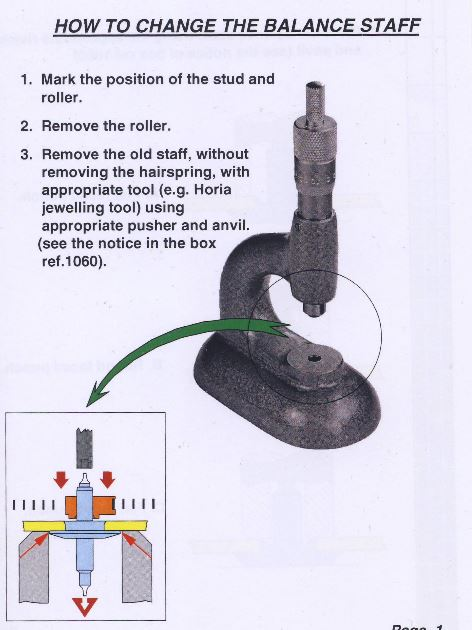

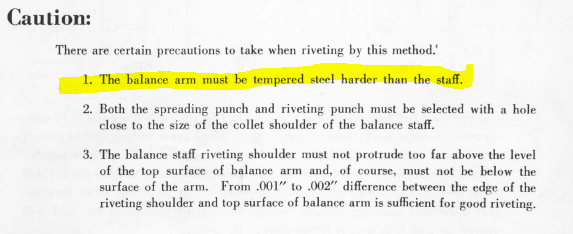

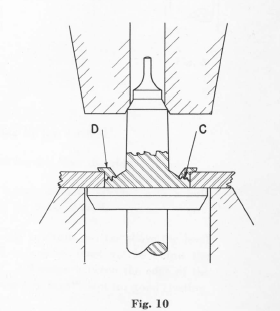

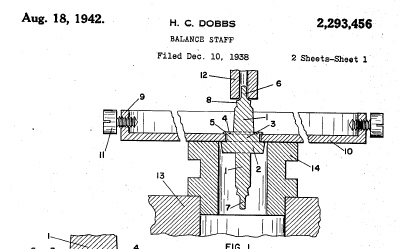

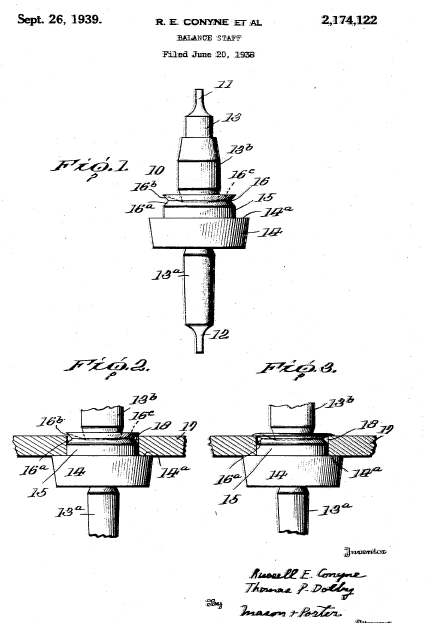

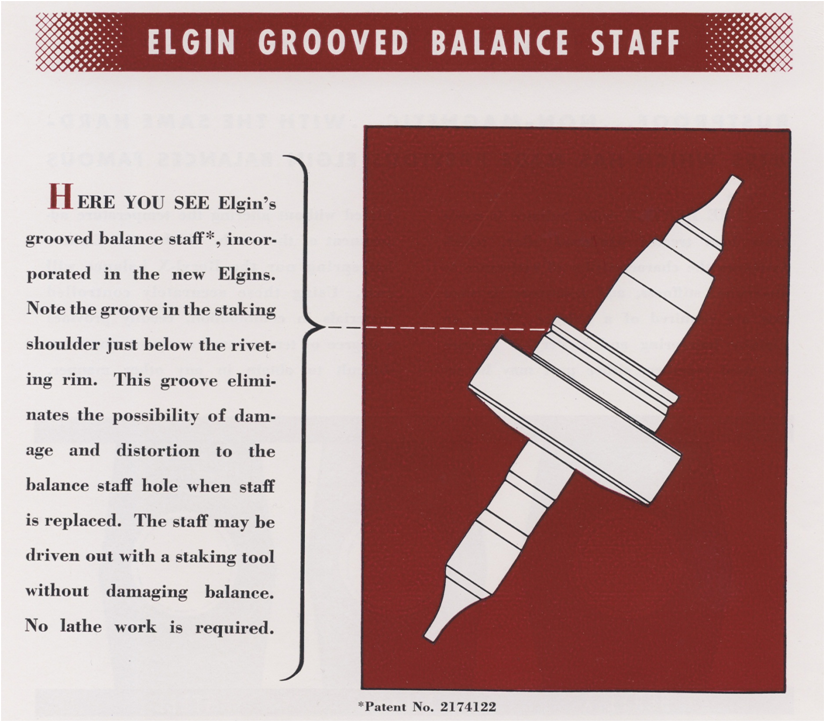

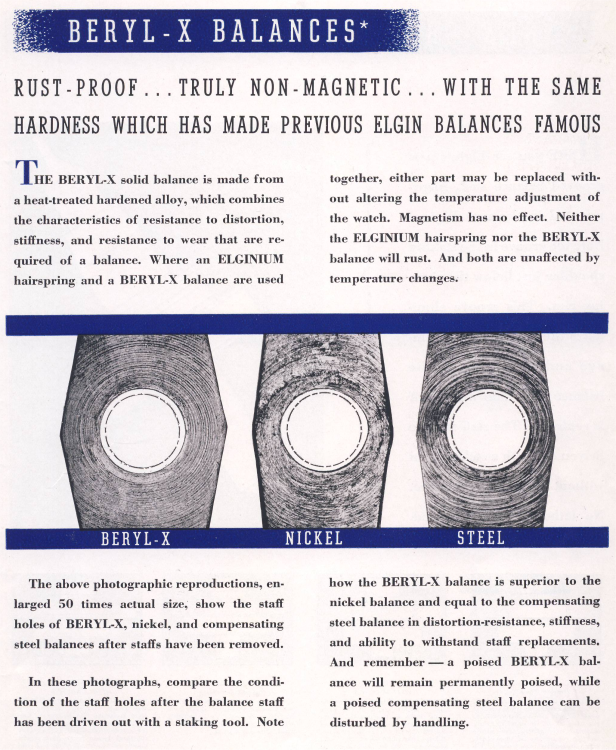

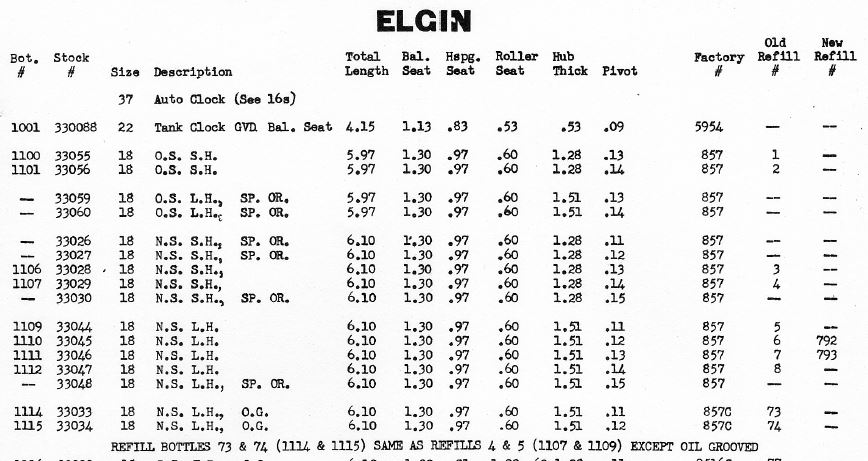

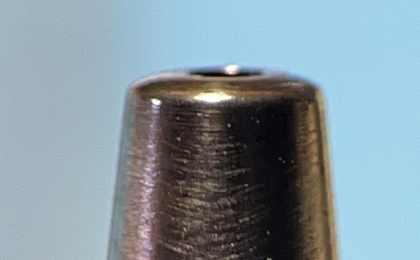

yes one of the problems with the group is it can't stay on track and were going to discuss all the theoretical first which I'm going to do to because everyone else does it and then we'll get back to the problem of your watch. one of the things I like locally as we have the remnants of well at one time it was in AWCI chapter but we left them and still are functioning. One of the people who's given a lot of lectures was the head watchmaker of the service center for chain of jewelry stores it has stores all up and down the West Coast and a few other places. So he would comment share the knowledge from people like Rolex. So Jeff demonstrated a particular Rolex that we found or I found quite fascinating. The particular Rolex you could not remove the hairspring there was no way to get it all. He remove the roller table by using a lathe and holding onto the roller table and just rotating the balance of removing up that way it was the easiest way. Otherwise he may have used razor blades or something to get the table off don't quite remember because that's not what I was impressed with. So how to get the hairspring off the Rolex how to get the staff out easy it's designed very specifically designed exactly what I quoted above.using the Horia tool and all the special bits and pieces that came in a really nice wooden box and probably cost a small fortune. And asking everybody to be really quiet in the room he started pressing and then the rivet sheers off with a pleasant pop. Then he picked up the rivet part that popped off and walked around the room and showed us there is a beautiful ring were the rivet just sheared right off because it's designed to do that with the only way that you can remove the staff is that as the staff has to be pushed out of the hairspring collet it's designed to work this way. then here's a snippet from a AWCI magazine from 2014 and how exactly are they removing the staff here's something that Rolex has so punching out is the work of the devil but yet Rolex and AWCI says pushing out is there a difference or is there something else going on that were not paying attention to? I always find the term in school interesting? the reason for this is schools can vary depending upon the instructor if you start gathering up people to specific schools and asked specific questions he begin the wonder if you even went to the same school at all because of various instructors how people were taught etc. etc. so for instance my first school the instructor liked to weaken the rivet as he called it. Balance staff in the latest that he would just take a little whiff of metal off and then using either the two methods quoted above knock the staff. Then later on in the other school we had this really nifty tool that just ground the hub off in the staff fell out which worked perfect providing it was set correctly for the particular size watches we were all doing. Then this discussion has occurred somewhere else in the universe remember the person Jeff I mentioned he was annoyed with the discussion somewhere else in the universe and get a lecture for us. So in his particular lecture he totally watch that he had been at whole bunch of balance staffs for and I think he staff did at least 10 times and drove the staff out every single time with no problems at all done. So what does this demonstrate? Now to understand better we have to go back to a previous lecture yes Jeff is given lots and lots of lectures. In a previous lecture Jeff and Doug gave a staffing lecture on Jeff did modern watches and Doug did pocket watches. Too long ago to remember the exact details of everything but the general consensus was you can not the staff out as long as it's not in super tight. in other words with a rivet is over the arms or something else is going on and tapping is not going to take it out you're going to have to cut things or something else? One of the lectures I think the last one especially if it's the beryllium copper balance wheels or brass you just remove your hairspring roller table and then use alum and dissolve the staff out after all it's still in the rest of it's not it can be safely dissolved out. now we're back to the interesting problem of balance staff? Do we have one procedure for everything across the board with no variations of course not that assumption would be extremely stupid which is the problem with some of this discussion. The Hamilton watch company the Elgin watch company and Rolex have all designed specific staffs that will break. They've specifically say in their literature you can knock the staff out Elgin even goes so far as to bring up the balance wheels themselves. I'm attaching a PDF from the Hamilton watch company replacing a balance staff. it's an interesting handout explaining of that somebody skilled in replacing a balance staff shouldn't have an issue but those starting out or going to have issues which is why they have a handout. like everything else in watch repair requires practice and knowledge of what you're doing. on the first page there is some cautions let me snip out the image because we get something really interesting that I've highlighted? notice the reference to the balance arm simplistically it has to be harder than the staff itself which would either be steel in this particular case which brings up the problem of watches with brass or soft balance wheels. The unfortunate problem of variations another major problem to watch repair one method doesn't necessarily work everywhere now on the second page you are reading the second page are you not? Sometimes I think when I attach PDFs no one bothers to read them at all. They show weakening the rivet and gently tapping the staff put. Which means using any one of the tools for driving a staff out work just fine as the rivet should be weakened and it should come out. then notice on pages 3 and 4 explain in detail about their new staff designed specifically to do what and explain how to put it in how it looks etc. and basically we end up with this picture the staff is designed to be driven out safely without problems. while looking for the Elgin balance wheel issue here's something interesting if you're ever looked up watch patents I'm convinced that everything has been patented at least once every single aspect of everything which of course presents challenges for other companies at the time. Here's an interesting image the taxes interesting it basically says a multi-method assembly method with one aspect being used for disassembly or basically break the rivet when you knock your staff out here's an Elgin patent as the patent was granted obviously it has to be somehow different than the Hamilton yet achieves the same goal a way of disassembling your staff from the balance without destroying everything Elgin was even so happy with their staff they had a handout with a talk about its wonderful features and how to use it identify it etc. here's something important for Elgin their nifty new balance wheel which basically Hamilton has also pointed out if the balance wheel arms are harder than the staff itself you can drive the staff out. now hopefully everybody grasps that everything is possible all the methods can work and all the methods can fail. There is no perfect method as usual and watch repair their lots of different ways to achieve the final goals and lots of ways to destroy the balance and everything else in the watch. identical? let's repeat the steps of replacing a balance staff as we are now aware it's 100% identical it was made by the Elgin watch company with the correct dimensions and it's perfect and yet it doesn't work let's just review anyway? in the procedure especially on vintage always best to use a micrometer and measure the old staff and the replacement staff the dimensions have to exactly agree. It would also be nice if they agreed with whatever you perceive is supposed to go in this watch. Which is easy we only have one balance staff so says the pocket watch database how many mistakes could they have? so as you can see only one balance staff one balance staff number and there's a note? This by the way is my favorite balance staff because how many balance staffs are there? All with the same part number of all of variations and for this discussion we can explore all of that because the balanced seat is 1.30 mm to all the staffs should work they just won't be the right staff but they should still rivet just fine. in addition to the specifications above is the replace of balance staff actually made by Elgin or as an aftermarket and is the shape of the riveting shoulder the same as what the original had yes there can be other sizing variations then in this entire discussion this is the only picture I see like this and we really need a slightly different angle to see what we need to see because this despite its curvature looks almost concave a little bit at the critical part and if not it's flat with the curvature and is that what is specified for doing a balance staff? Yes I see images above and they don't quite correspond do they? then this is a interesting picture isn't it? I have to go and find another balance staff to look at but definitely you haven't push the rivet down at all and I don't know I just don't like the look of this. Hamilton technical data number 129 replacement of broken balance staffs.pdf1 point

-

Great advice. I found an old scrap balance to practice on, and re-dressed my cheapo burnisher, I too was making the mistake of trying to work looking through the microscope. Following your advice - once set up, sit back and feel and listen to what's going on. You can feel and hear what's happening. I found shaping the end quite easy - as the pivot is sat in a hole in the disc, there's no chance of the balance escaping and getting damaged. I was so pleased with the pivot end shape and finish I'm not going to bother getting the Bergeon tool.1 point