Leaderboard

Popular Content

Showing content with the highest reputation on 02/08/24 in all areas

-

I think that this should be our motto. It's the time keeping that counts.5 points

-

This is my reply to this clown. What a bloody shambles. Use the proper tool a clock mainspring winder. You should always measure the inside of the barrel for the correct height because the spring to be replaced might not be the correct one Why don't you use a bigger hammer you clown. You never cleaned the new spring or oiled it, no oil on the ends of the arbor. I have watched many of your videos and find faults with all. People what ever you do never ever follow what this fool shows you. He is a complete menace to clock makers. I have around 30 years experience working on high grade clocks. I wouldn't let him inside my workshop. I look forward to your reply, that's if you have to guts to do so.3 points

-

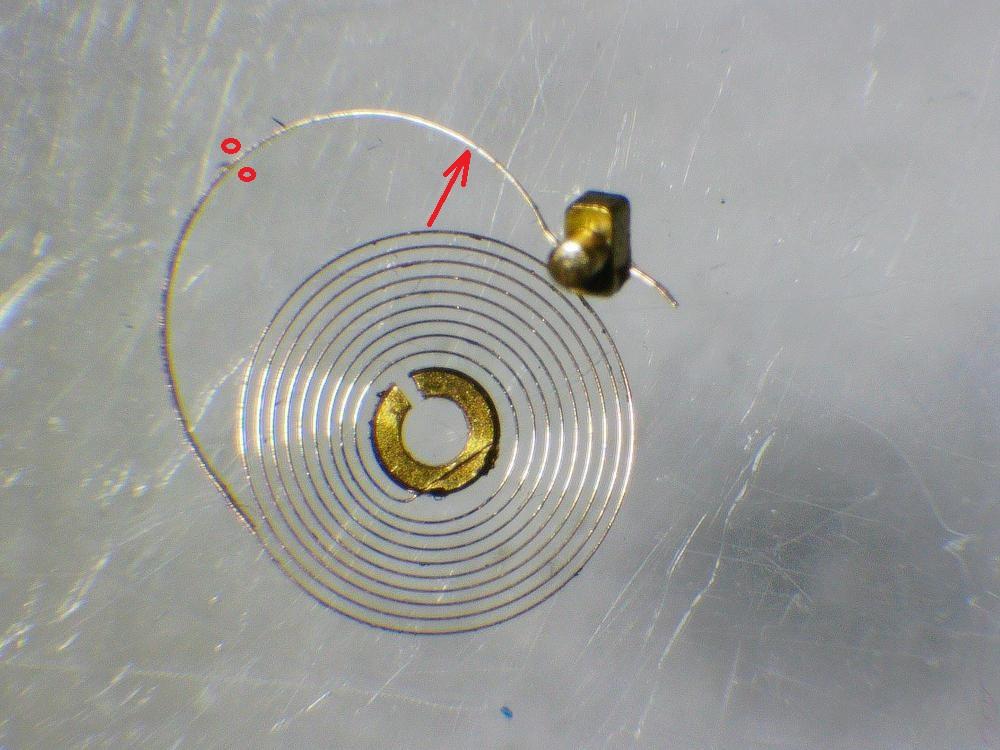

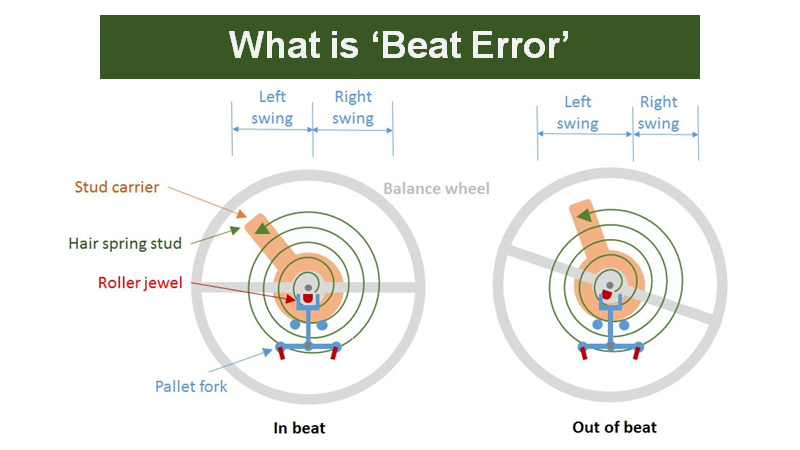

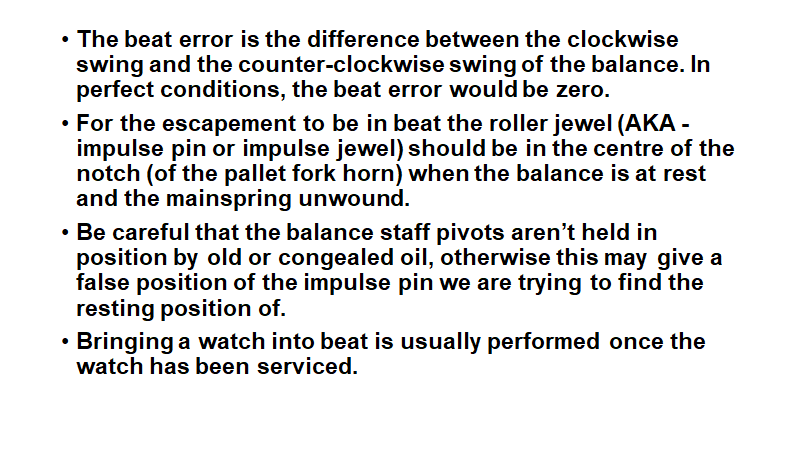

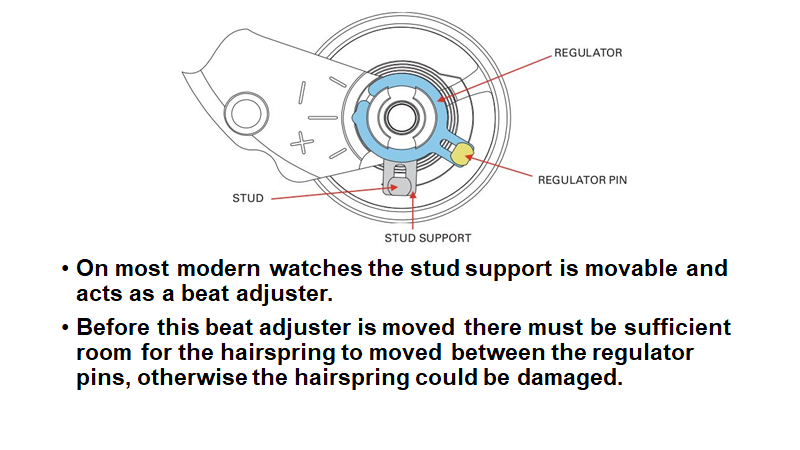

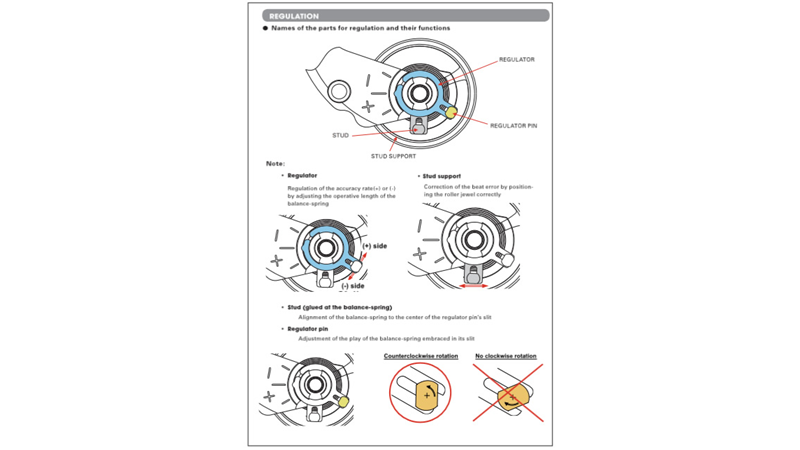

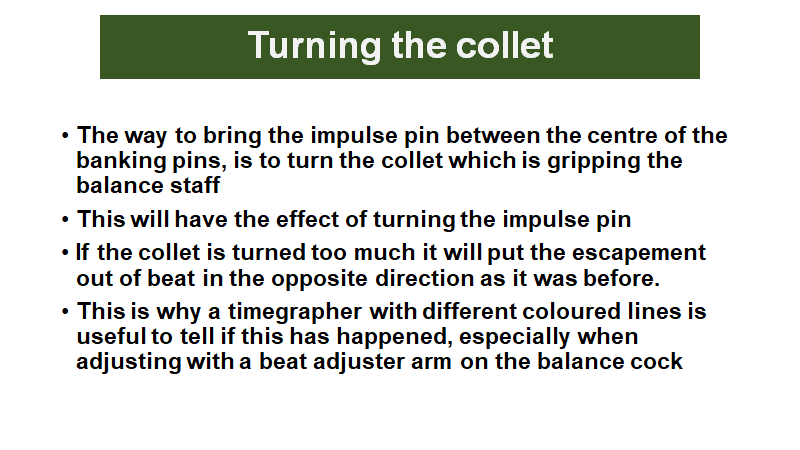

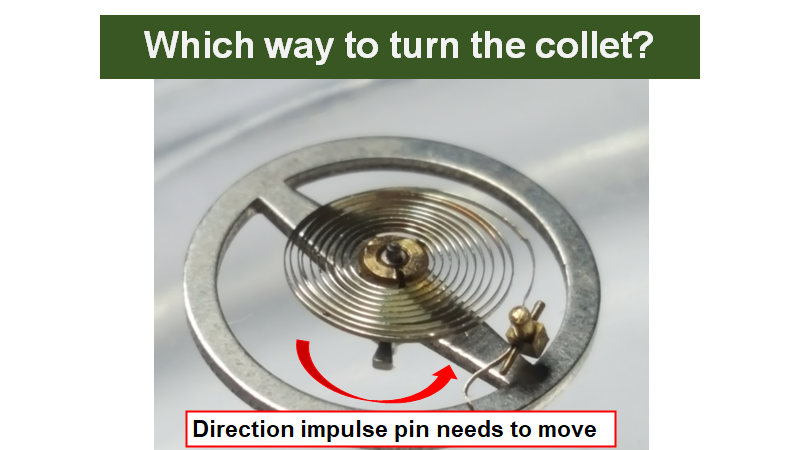

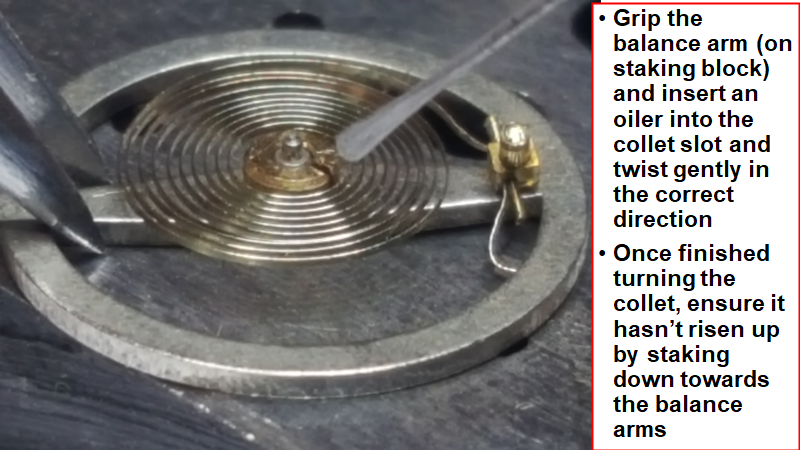

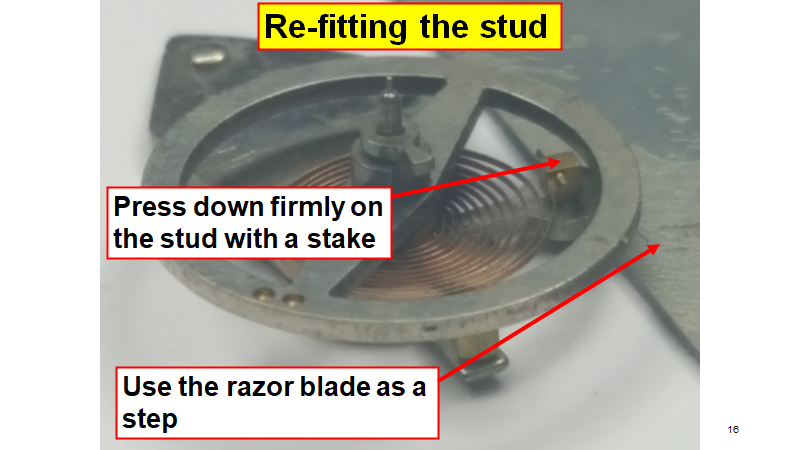

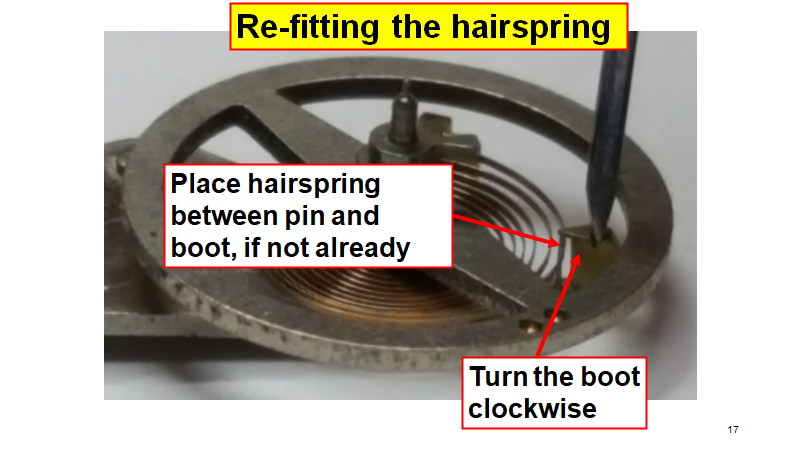

Here's a post that explains how to spin the collet to reduce beat error. These lessons were designed for those that were complete beginners, so I had them remove the balance and hairspring from the cock to do this task, but if one feels confident, the collet can be turned whilst in situ. You just need a balance tack the has a table for the balance to sit on and with an oiler going between the hairspring coils the collet is turned that way. If really confident, just a normal balance tack can be used. Also I roughly worked out how much to turn the collet depending on how much beat error there is. If a watch movement has a 300 degrees amplitude and it is an 18000 bph movement, that equates to the balance moving 1500 degrees in total in 1 second, which is 1.5 degrees of movement for every millisecond. An 18000 bph watch ticks five times per second, which is 5 times 300 = 1500 degrees. So, if your movement has a beat error of 5 milliseconds the collet needs to turn approximately 7.5 degrees. This is a rough estimate.3 points

-

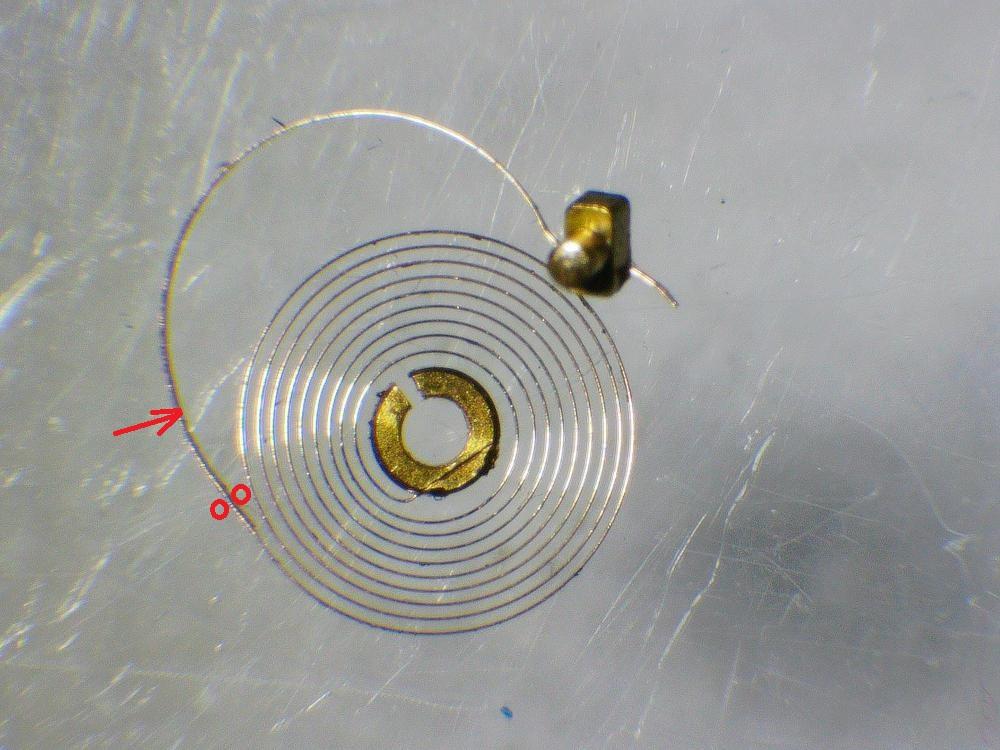

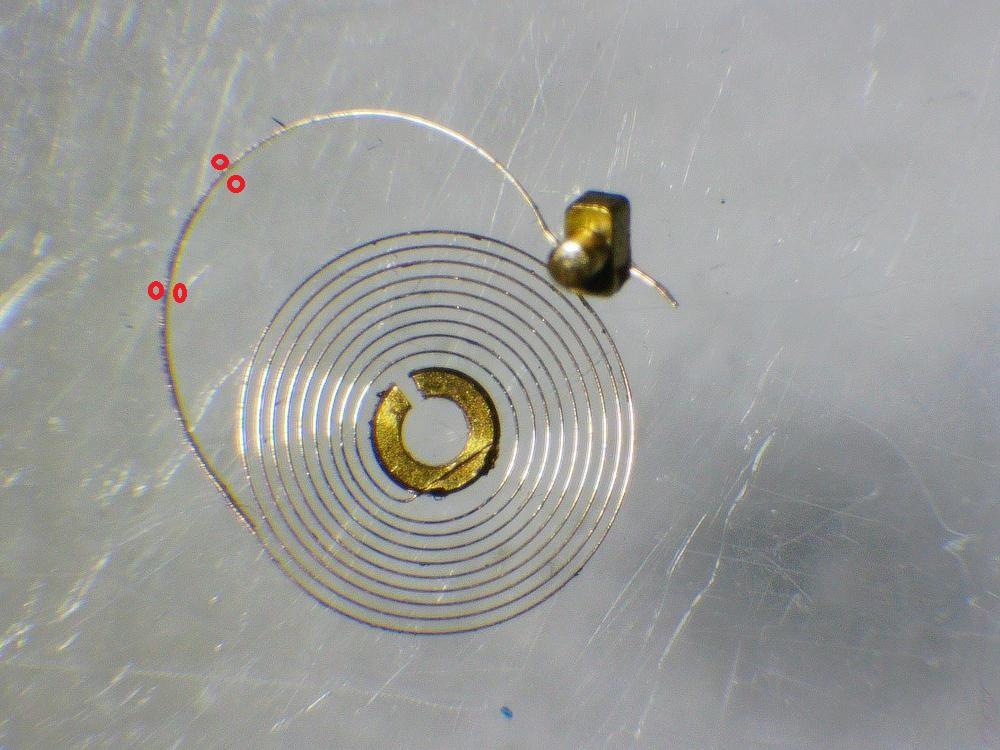

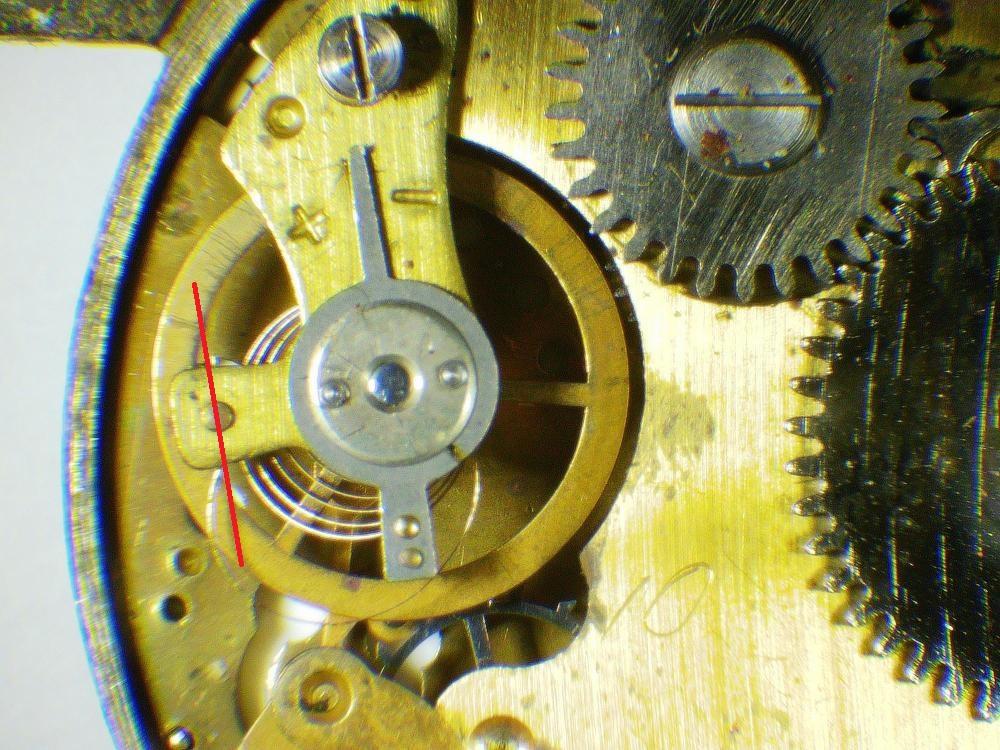

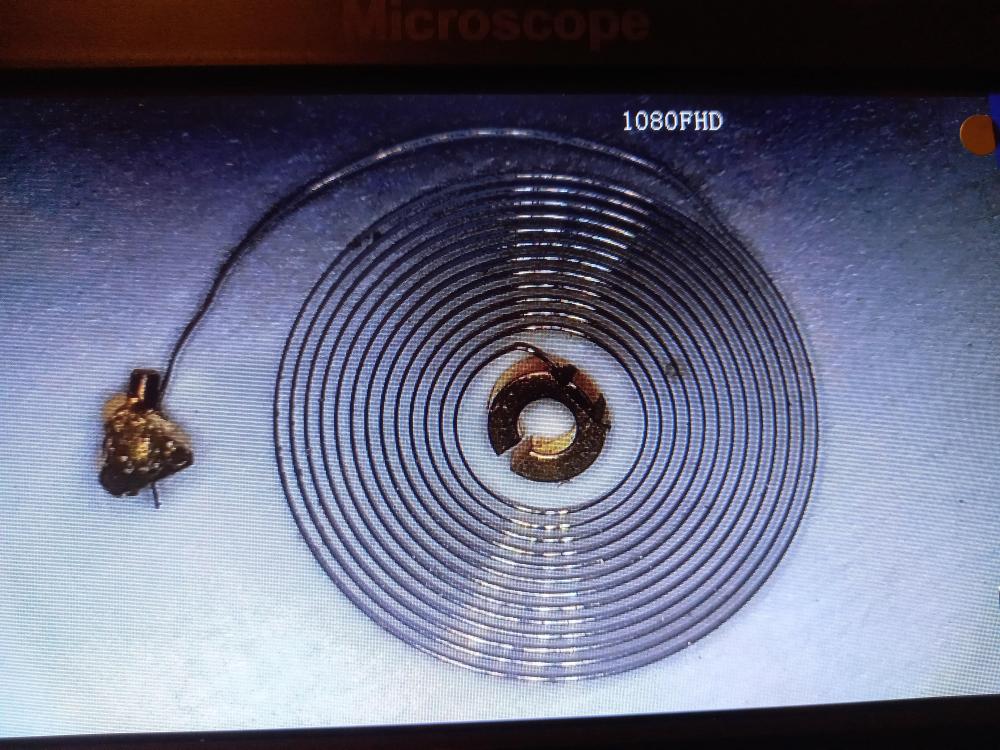

The first action needed is this: Here the small circles show where to grasp with tweezers and arrow shows where to push with something, e.g. needle or another tweezers, the aim is to increase the radius and bring the studd some little away from the sping body. The next step is this: The aim is to bring the outer coil closer to the spring body. It actually has to go paralel to the body and to keep distance about 2X the distance between the other coils inside the body. Try to do this as acurate as possible by bending in the manner with tweezer and needle. Next step is to bring the outer coil in one plain with the spring body. Here You must grasp with two tweezers and twist the portion between tweezers in manner that hte outer coil will get in the plain of the body. I am not sure about the points where the grasp mus be, as I don't have picture from aside, but hope I am close and You will get the idea. The next step is to put the studd in place in the hole of the cock. The studd must be oriented as per the line shown. The cock is upside down, hairspring up. Then, grasp with tweezers close to the studd and pish and twist as needed in order to bring the spring in place and paralel to the plane of the cock. Show the result at that point.3 points

-

Did somebody say "Parker 45"? Hey, I'm specifically trying to focus on watch maintenance/repair as a way to steer clear of my interest in fountain pens and other writing instruments, which just might have drifted across the line between healthy collector and obsessed hoarder. But then I'm innocently reading about watches when somebody triggers me!3 points

-

3 points

-

I just watched this video on YouTube. Scottie just bashed the spring into the barrel without cutting off the wire retainer, pre-oiling the mainspring and winding it into containment ring. Is this an acceptable technique? One can't even be sure that the hole end of the new mainspring is properly engaged with the barrel hook.2 points

-

About the mainspring, if the general ressorts one is the same thickness as the original then it should be of comparable strength. If I’m wrong I’m sure the professional’s will educate us both. It may simply be that the GS spring is just a little thinner than a Rolex original. Everything else you have shown looks very good. Personally, though not by any means expert, is you have met the Rolex criteria for proper function and timekeeping as folks have alluded too earlier, I would call it good and not go further for fear of introducing problems by chasing imaginary errors. Tom2 points

-

Only by adjustment of the collet that holds the hairspring. Its an interesting exercise for a beginner in how to trash the hairspring. Any way you can practice on something that doesn't matter first.2 points

-

2 points

-

You for sure are over-thinking. There is no problem with the esc. wheel bearings. The actual picture is different thow, the hole stones have convex outside surface, and the direction of oil drowing is actually to the other side than in the pictures. If something is really tilted there, it is the hole stonses, but it is not of any significance. The effect that You are trying to describe with the 'scenario 3' actually does not exist. This is correct, but I will try to point to something: You replaced the main spring, yes? What would the amplitude be with the old one? This is interesting to me. And, another thing - when amplitude is lower, this will result as reduced wear, at lease in the escapement and balance, and if the reason ie weeker mainspring, then wear will be reduced in whole movement2 points

-

Your oil concentricity on the escape wheel isn't robbing amplitude. Also, I've seen folks eat burgers with fork and knife in Switzerland . Funny, I have a friend who worked for rolex as an instructor, and they actually stipulate (or used to) to: peg jewels, and stick pinions into button pithwood soaked with benzine (lighter fluid) prior to machine cleaning. I had a zenith el primero on the bench with lackluster amplitude, tried this (pinions in pithwood), and dang if I didn't get a good 10 degrees. Maybe it was just the manipulation. Maybe it was the running a bit more. But Rolex does what books from 1905 say to do, must be a reason. But he also said they don't all hit 270+ full wind minus an hour. What they do do (gross!) is keep time really well. Your 24h amps are great and within spec, I would let this one go. Or, start adjusting the escapement (I do this all the time and I'm like the only watchmaker I know who does, haha).2 points

-

2 points

-

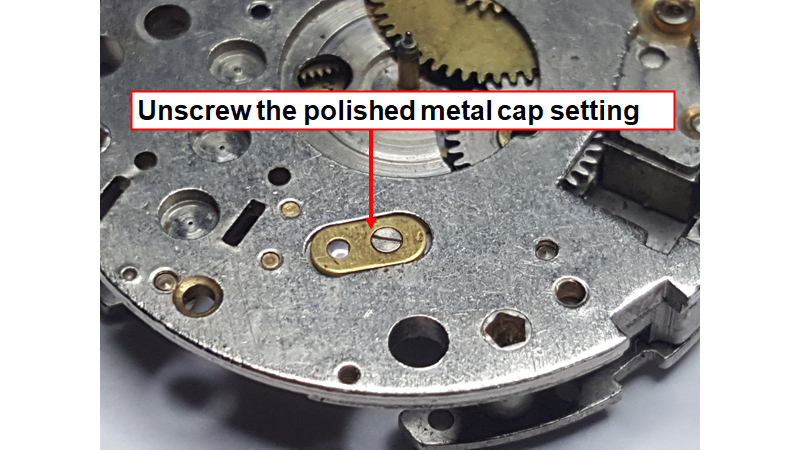

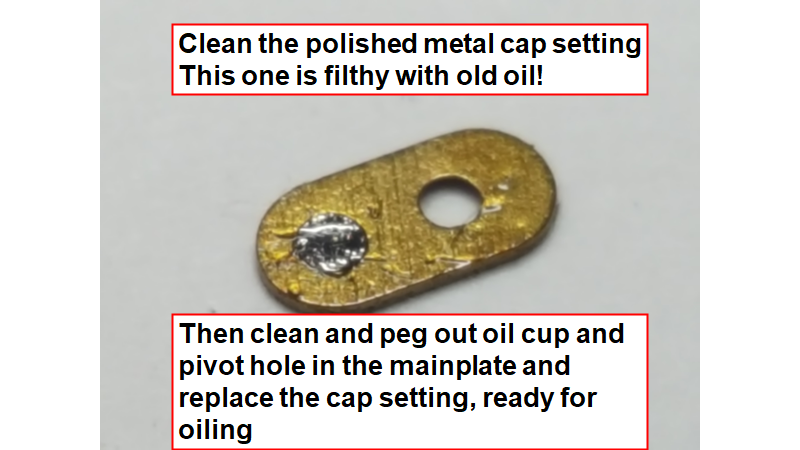

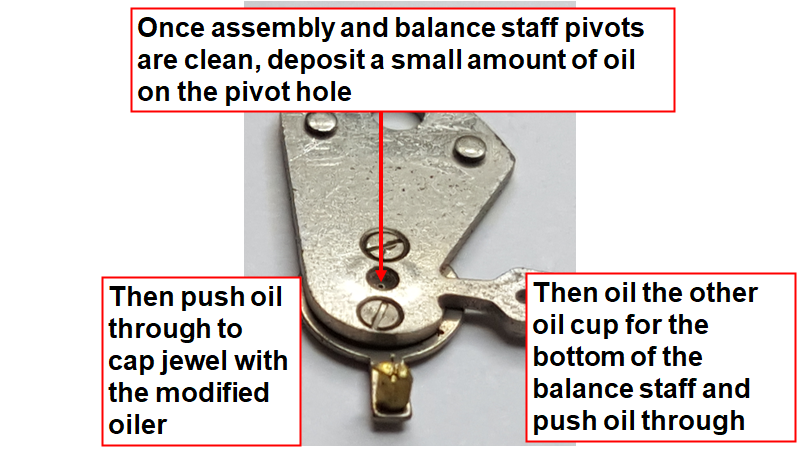

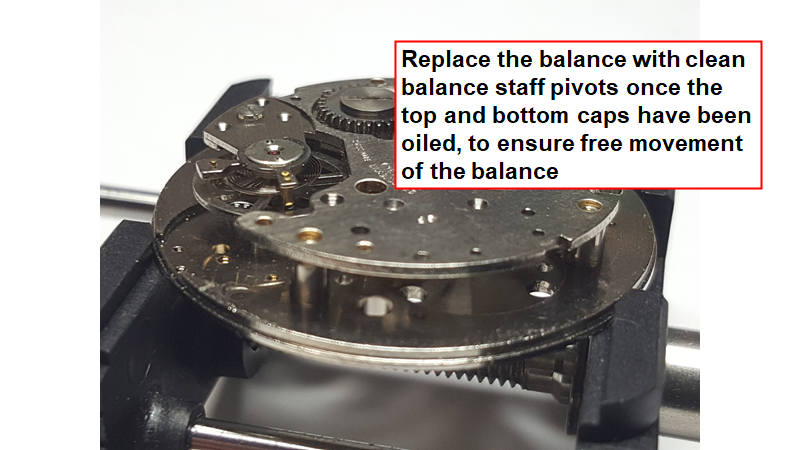

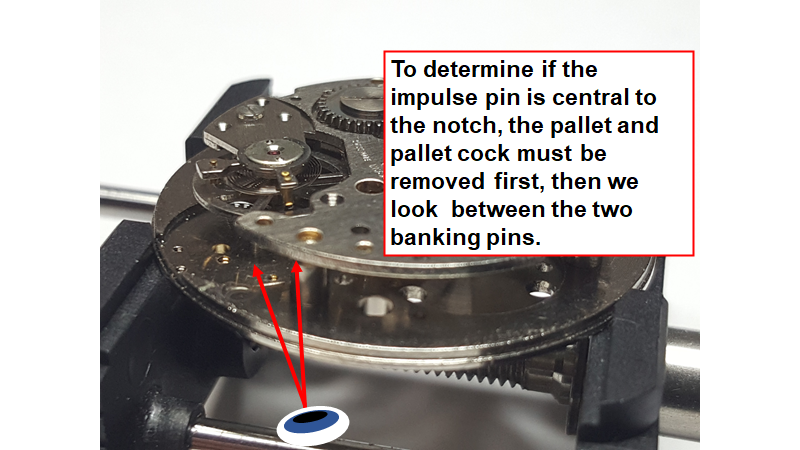

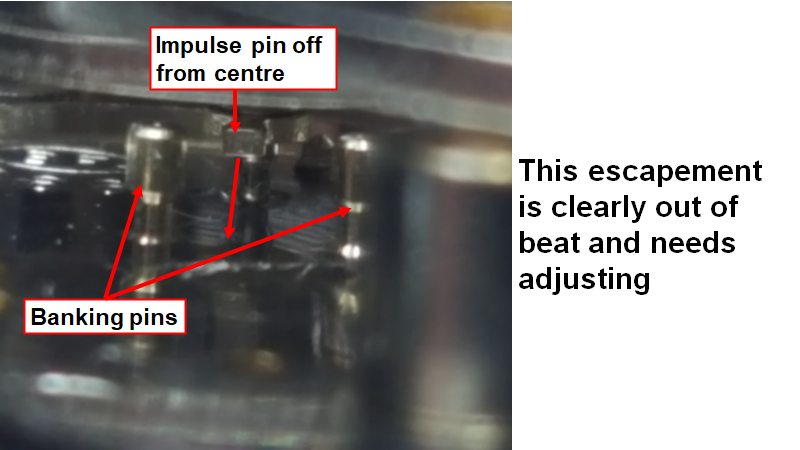

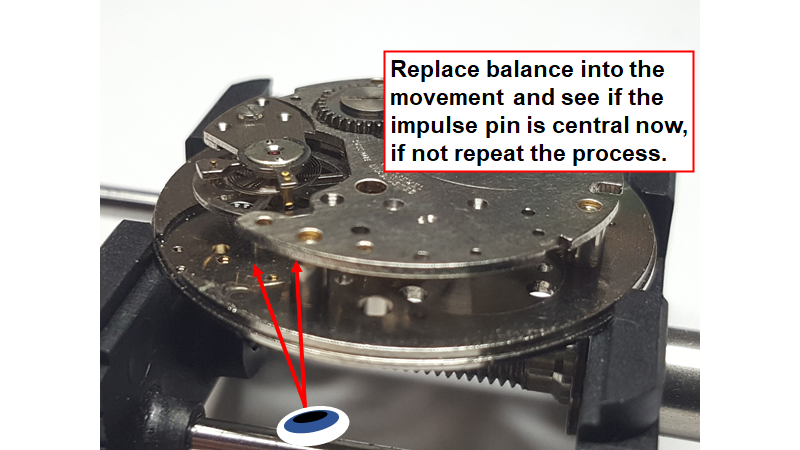

Hi, This is the third instalment on the Baumgartner BFG 866. I wanted to show how to bring the watch into beat On a previous walk-through of the BFG 866, I have described in detail how to remove the balance and hairspring to be able to oil the cap jewels As you look between the banking pins, the impulse pin is off to the left side slightly, putting the watch out of beat. The collet is turned in the opposite direction to the direction the impulse pin needs to move. So if in this case the impulse pin needs to move anti-clockwise to get it perfectly between the two banking pins, then the collet needs to be twisted in a clockwise direction You can attempt to turn the collet whilst fixed to the balance cock, but there is a much greater risk of damaging components, especially the hairspring. This is the way I teach my students, as it gives them the skills and confidence to remove the hairspring and balance from the balance cock and while removed they can oil the cap jewels as I've shown in this other walk-through on the BFG 866. I've got two more walk-through's on the BFG 866 that I'll post on the subject of adjusting the friction fitted minute wheel that is on the barrel and removing/re-fitting the centre seconds wheel and oiling the movement...1 point

-

They were actually designed for one purpose but now they can have two purposes. As you noted the watches cleaned entirely assembled if you are following a modern or some modern shops typically with Rolex for instance you will do a pre-cleaned cycle. This is where the watches left together the movement and its cleaned in that condition usually in a slightly shorter cycle the purpose of giving you a nice clean watch to evaluate. But the real reason for this is it's a faster way to service a watch. At one time they would make a substance it went by the name miracle lube or one step. There were others is also a dual lube method that did the same thing. The basic principle is you clean the watch assembled that saves that pesky time of disassembling. As far as lubrication goes I really like miracle lube as I think the miracle it works But? So I finally got to see a material safety sheets for one of these substances and basically it was mineral oil which is a high-temperature oil in your last rinse. So your watches all nice and clean with no lubrication and the last rinse has the high temperature oil dissolved in the rinse itself so now you have oil covering everything but don't worry the magic of capillary action. As the solvent evaporates the lubrication will migrate to all of the crevices like where the pivots are. So now your watch is 100% lubricated and yes that was the selling point you can increase productivity by quite a huge percentage because you don't have to disassemble a you don't have to do manual lubrication. Obviously there's a reason why this no longer exists but it didn't exist at one time and it was very popular with production shops.1 point

-

Then you accept that you will have possibly issues and I think that I will leave it at the mystery of how to change the balance staff which yes can be changed. Oh and yes you shouldn't practice learning how to do balance staffs on a watch that the balance complete cost more than the gross national product of some small countries. The problem with a little thinner is it to be a little bit weaker. Irony posted that Rolex had two separate springs for this watch the standard spring and a slightly weaker spring. Obviously they were concerned about too much amplitude. One of the problems I have with the general's mainsprings are in the case of my pocket watch springs which are aftermarket springs of course I'm noticing the quality doesn't seem to be there on a continuous basis. I have to remove the mainsprings from the ring to insert them into the pocket watch because the various ends they have and that allows me to see the back curve of the spring and often times that totally sucks or the spring even looks partially set and those things would definitely affect the running of a watch. Typically on the wrist watches you just push it in and assume that it meets the specifications and you never see the back curve or the actual of it. Which brings up the problem of we don't have some magical test of mainspring efficiency. In other words we can't put the mainspring barrel of the machine wind it up and measure how much torque to know if it's doing its thing. Yes that's another tool to buy I've seen a picture of the thing I'm sure none of us could afford it gets more of a factory thing so if the mainspring isn't right than the powers not right the power curve's not right and people might be unhappy because her amplitude sucks all because the mainspring isn't right. Even if the numbers seem right On paper this looks wonderful except? We still have no way of measuring if we have the proper power out of the mainspring barrel. Then we run into all kinds of other problems of well basically everything we don't know how the watch was cleaned we didn't hear what lubrication's were used and yes lubrication especially on the escapement is a key place more key than anything else in the watch we didn't get any of that and we have to assume that end shake was right because I asked but others are indicating maybe it's wrong? Oh and thinking about the wear and tear issue when was this watch last serviced? Because if this watch has a faulty situation which is causing the low amplitude it seems like a wearing of the pivots or whatever should have been visually noticeable? Then the other test is how many hours does the watch run until it comes to a stop?1 point

-

Hi @Neverenoughwatches I think it’s an m43. You may be able to get more info on. Heritage 1854 web site . They seem exclusively Timex. Have a shifty. As far as I know there is no manual And it was made in Taiwan.1 point

-

1 point

-

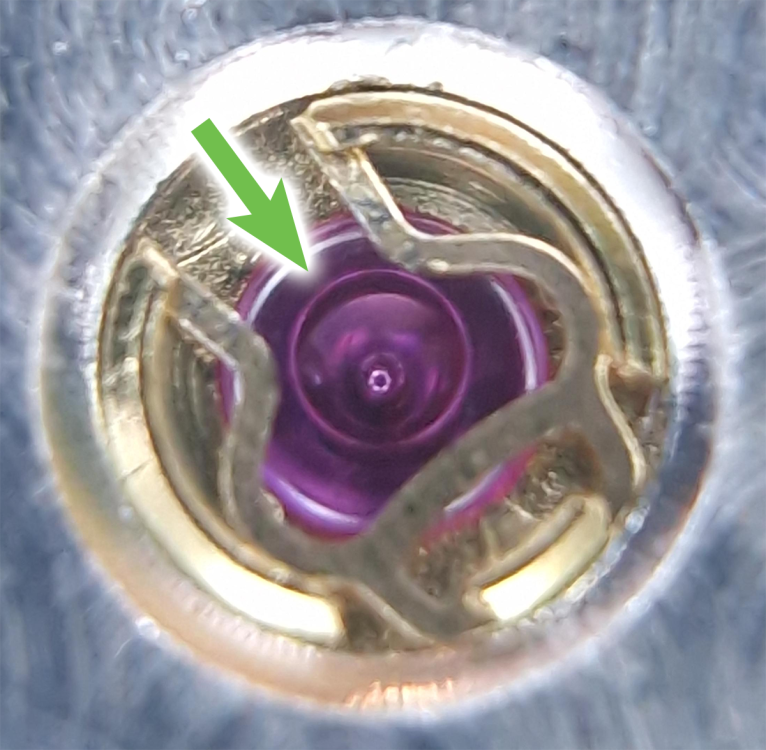

Two simple tests. With the shock spring closed, take an oiler or pegwood and lightly touch the jewel (and only the jewel) at the point indicated. If the oil bubble grows or moves, then the jewel is not sitting flat. Second "test" is really just an observation. With the movement running, does the pivot move around inside the hole or does it stay in the same position as shown. If the former, then you're fine, if not it may be touching the cap stone which means you don't have enough end shake (if any).1 point

-

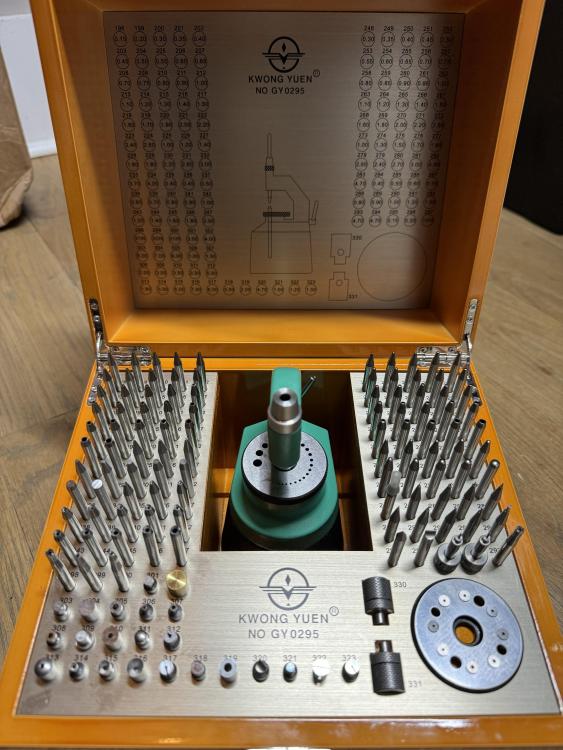

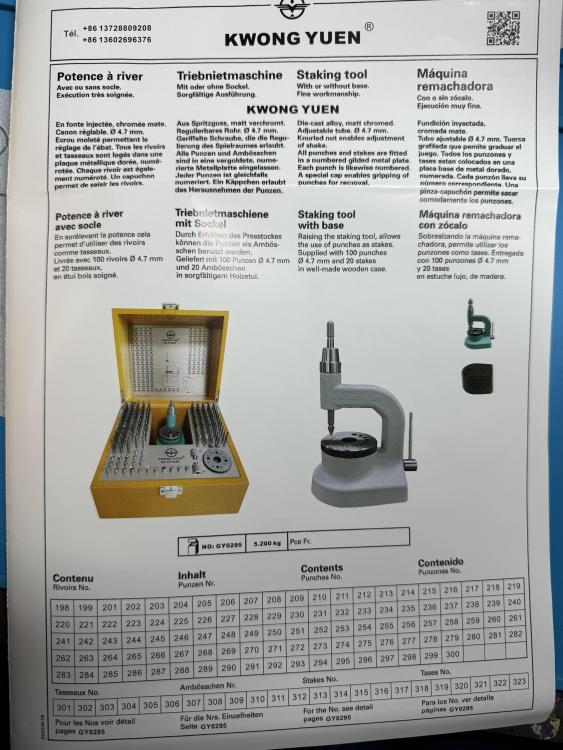

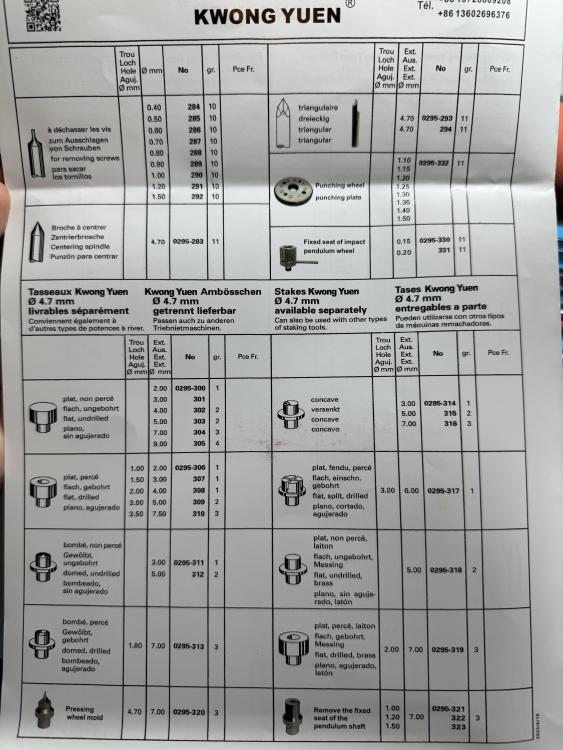

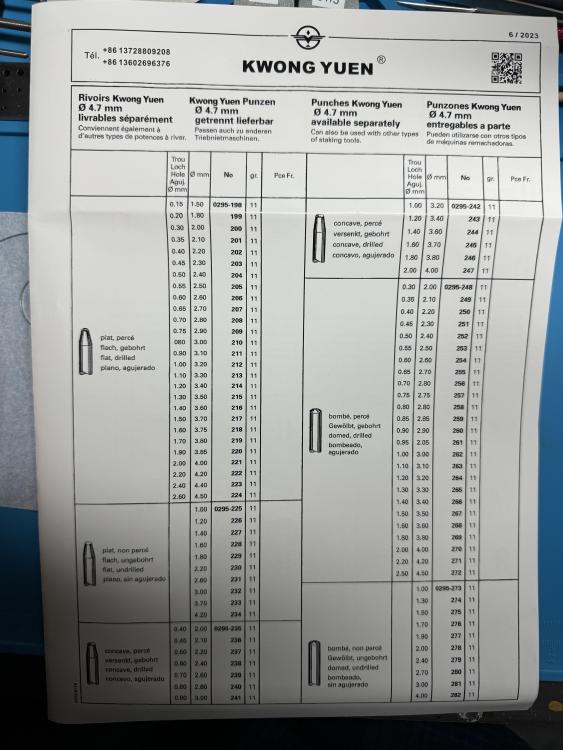

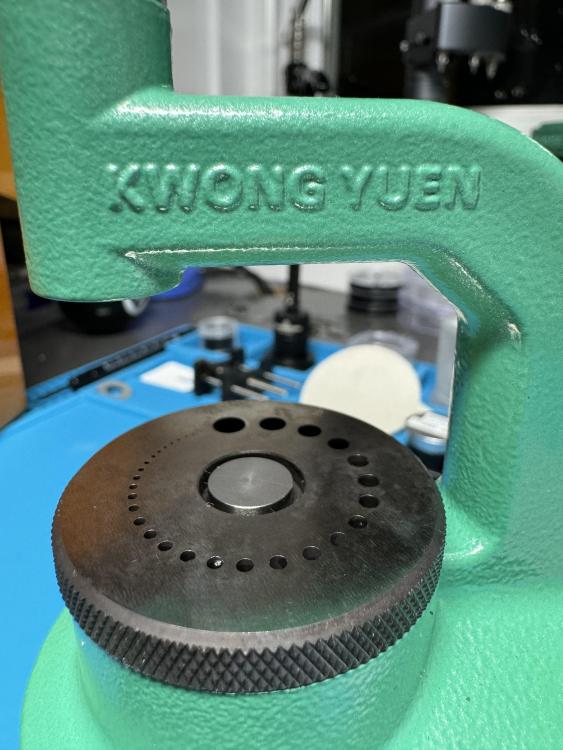

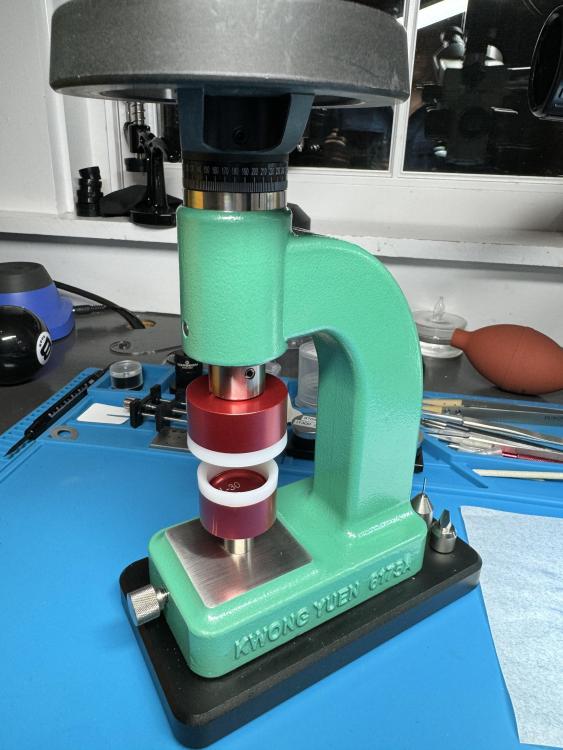

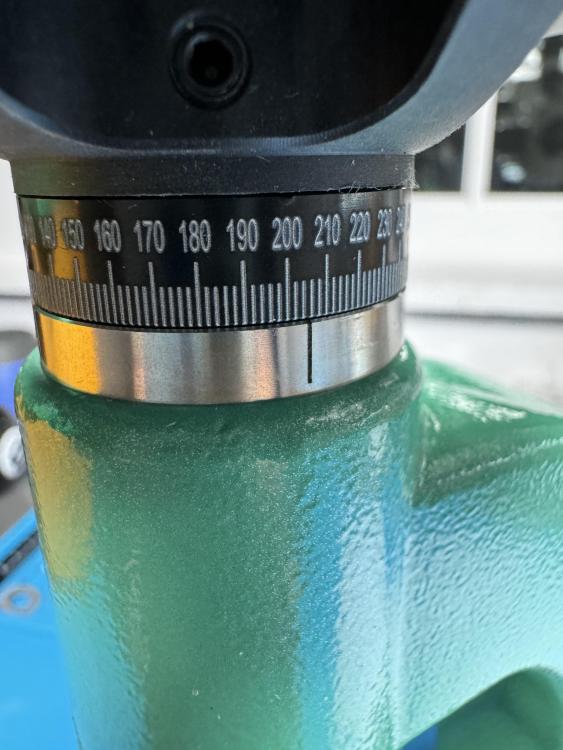

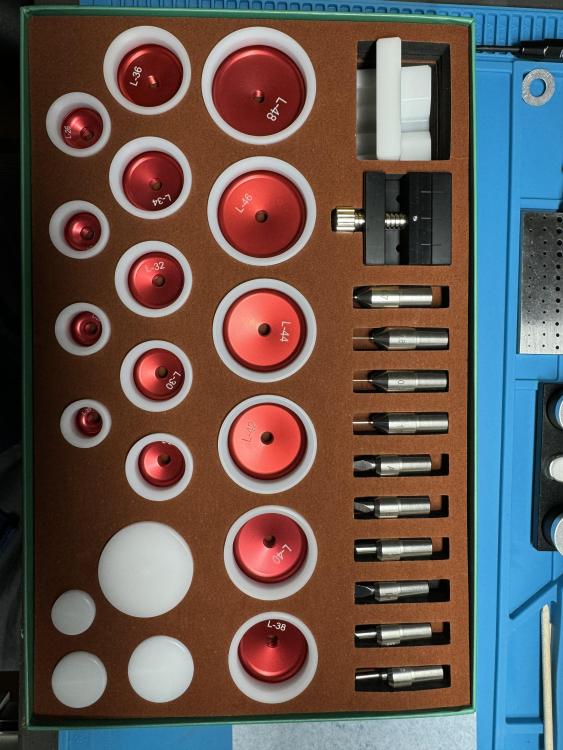

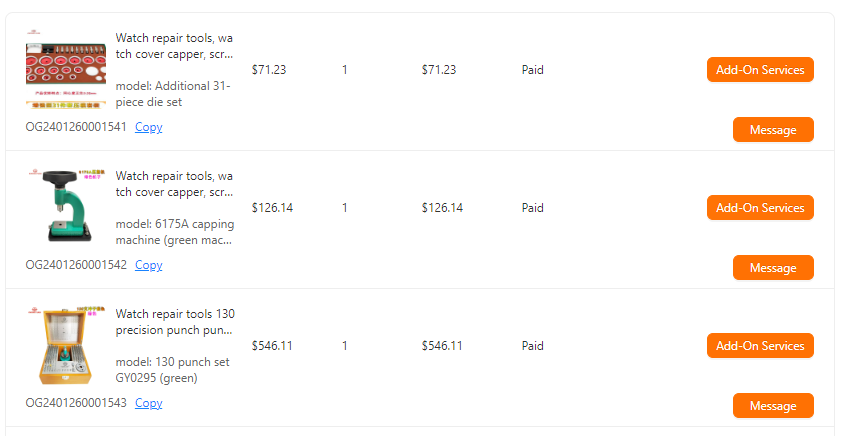

I think you have a few routes if you want the press and die set. It looks like you can purchase it via aliexpress https://www.aliexpress.us/item/3256805193943005.html?spm=a2g0o.productlist.main.17.7172vBFIvBFIE2&algo_pvid=36d147b7-c85a-4e96-98c3-91f5811bfcf3&algo_exp_id=36d147b7-c85a-4e96-98c3-91f5811bfcf3-8&pdp_npi=4%40dis!USD!137.00!137.00!!!137.00!137.00!%402101d69a17073978872681499e2fa2!12000032818712504!sea!US!4296785206!&curPageLogUid=ltM7m3b9GVRw&utparam-url=scene%3Asearch|query_from%3A I wanted two tools and wasn't happy with the shipping cost, so I ended up going a more convoluted route. 1688.com is the internal chinese version of alibaba. (It's owned by alibaba just like aliexpress is). Unless you're in China you can't order from them, you have to go some other route. Sugargoo is a 'forwarder', you put in the purchase order and they buy it from the Kwong Yuen factory via 1688, it gets shipped to them (for free) as their warehouse is in Shenzen, CN. They inspect, and then repackage together all items, and reship it using UPS or whatever from China to you. I had a good experience, but I'd hardly stake my reputation on anyone else going through this process. It takes a bit of a leap of faith. Here is a link to the factory store direct on 1688.com, sometimes theres more pictures and better descriptions here (I use google translate on chrome to understand the page): https://shop9984n72151764.1688.com/page/index.html?spm=0.0.wp_pc_common_header_companyName_undefined.0 Here is a link to the factory store (routed through Sugargoo), they will translate it for you. https://www.sugargoo.com/#/home/shopProducts?source=1688&shopId=2200742215132&sellerId=b2b-220074221513217c67 Here is a direct link (via Sugargoo) to the press, I added "6175A capping machine (green machine)" and "Additional 31-piece die set", https://www.sugargoo.com/#/home/productDetail?productLink=https://detail.1688.com/offer/701338329712.html And here is a direct link (via Sugargoo) to the staking set, I added "130 punch set GY0295 (green)" : https://www.sugargoo.com/#/home/productDetail?productLink=https://detail.1688.com/offer/732431432684.html As for what that tool is, I believe its used to punch out pins to remove links in a steel bracelet. Hope that helps.1 point

-

More specifically, the one that @GuyMontag has posted would be for Rolex microstella screws (not Omega co-axial). The code 03.670 on the packaging gives that away.1 point

-

I never fancied doing it from a tack, I used to do it with the cock stuck down on its back or its side and pull the balance wheel out to reach in to the collet. Until i tried it , i prefer doing it whilst hanging from a tact now. I made myself a big seven foot one from a sunshade base and 2 inch steel tubing, i have to be quick though, my arm gets tired and i fall off1 point

-

Oooohhhh shiny... me want!!! Maybe we should set up a penaholics support group.. In addition to the fountain pens, I've got a bit of a Rotring and other technical writing instruments problem.... Now did I see a couple of Parker 45 demonstrators in that lot... Where's the "ebay" button on this keyboard.1 point

-

If You are asking in which direction to wind the spring in the barrel, then place the barrel arbour in the barrel (in the correct way) and look at the hook on the arbour. It will show You the direction of the spring. If it happens to wind the spring in the wrong direction, then rotating the arbour in winding direction will lead not to winding, but to deforming the internal end.1 point

-

Thanks for your illustrations. I just tried to keep it simple (and I was lazy, drawing this up in Powerpoint...). Indeed, my worry goes mostly in the direction of your quote. I've cleaned it meticulously to remove any "mustard" :-D. Size-wise, the cap jewels fit perfectly into the chatons. It's weird, though, that BOTH jewel setting exhibit the exact same symptoms. If it was something bent or so, I'd expect this to be the case on only one jewel setting... I was afraid that might be the case. Rather than a manufacturing error (at Rolex?? ), I was afraid that it could have shifted through any of my interference -- but I can't really imagine how I'd have done so. But happy to hear that this wouldn't be too dramatic. Yes, I did replace it with a generic GR spring (named "2130-311" at Cousins). Sure, I acknowledge that a genuine spring would be better and that differences may exist. I have no indication, though, that it would be the intentionally weaker "311-1" spring equivalent. Possible, though. If so, my overall results of amplitude and timekeeping would be great. Yea, but this logic hinges critically --as you say-- on the the reason for the lower amplitude. If it's due to a weaker mainspring -- then yes. If it's due to bad lubrication (or so) -- then no, wear would be increased. Thanks! I really prefer doing it this way. It greatly removes the risk of causing any damage to the movement when putting it into those spring-loaded holders of the Weishi TG. It can slip out, etc. I do adjust the gain setting to maximum and I've not observed any issues in picking up a clean signals. As far as I know, Rolex balances have a special collet that can't be removed. So apparently replacement is only possible with a balance complete (~500USD)... I inspected them thoroughly and they look very good under 40x magnification. As far as I can tell.. Of course, I drew a ridiculous side shake! I was really just trying to make a point for illustration. If I had drawn to scale, all three pictures would probably have looked the same, hahaha. I did check endshake and sideshake of the balance and they seem fine. I don't have much experience with "feeling" microns, but nothing was really off. I used the eccentric screw of the balance cock to try increase and decrease endshake by small amounts, but put it back to the original adjustment afterwards (it seemed the best). I did check endshake everywhere. Again, I don't have a sophisticated feel for it yet, but all endshakes were absolutely minimal and nothing was "stuck"/"squeezed".1 point

-

These clocks are high quality, first class design and easy to work on. The only weakness I have found is with some platforms in the real older types they are not fully jeweled and you get wear in the pivot hole of the escape wheel. The really old Elliott movements are very dark in colour. Good job Rixy.1 point

-

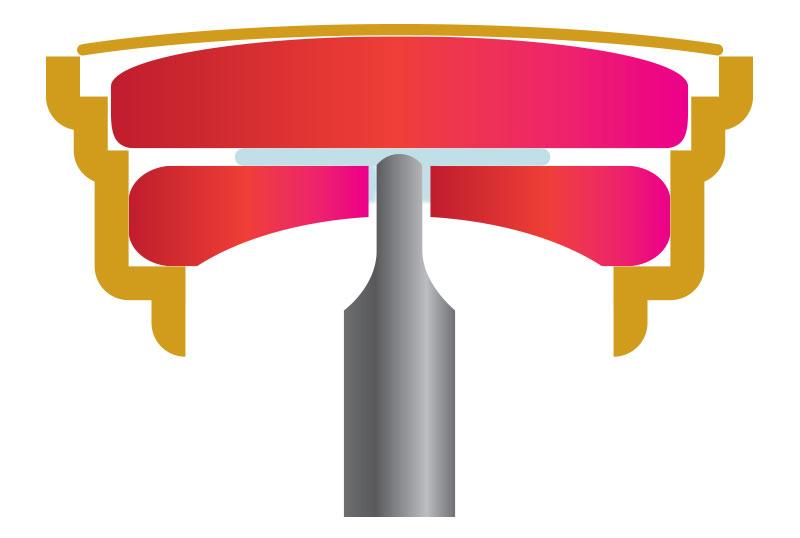

Eating burgers with a fork notwithstanding, here's what i think. The location of the oil droplet is for the most part a function a combination of surface tension, capillary action and where it's initially placed. Your diagram @Knebo is not taking into account the shock spring or the chaton. So let me provide an upgraded rendering. The lower jewel is fixed in the chaton while the upper shock jewel sits within the chaton, but not in direct contact with the lower jewel. The pivot end should not exert any pressure on the upper jewel and the downward force of the spring should keep the gap uniform. As long as the bubble of oil is surrounding the pivot and not extending to the edges of the jewels (too much oil) then you're okay. The only way your second and third scenarios would be possible would be if the cap jewel was the wrong size or the chaton was bent or damaged. (or you dropped a bit of mustard in the hole while eating a burger with a fork).1 point

-

These are made so that you can clean the entire movement(s) in one go, without taking it apart first, this assumes that the dirt/oil/debris etc cannot hide in any covered areas, and that you can access all areas after to lubricate etc.. personally speaking I don't think they are very useful for most members on this forum.1 point

-

@nevenbekriev gave us the key to this one. Pallet fork will keep the escape wheel from turning freely, that is its job. With the balance in place and oscillating, pallet lets the escape wheel, and thus the rest of the train, move in small steps. I think trying to install train wheel bridge with pallet fork in place is making it more difficult than it needs to be. Also runs the risk of dislodging a pallet stone if the escape wheel pushes down on it when trying to assemble. I think it will be much easier if you remove the pallet fork and its bridge before installing train wheels and bridge. Then you can check that the train spins freely. Stick with it, you'll get there. Eventually it will all just fall into place and you'll say "aha!" just don't force it.1 point

-

1 point

-

1 point

-

Hello Murks; If I were you, I would start to sort and take out all the screws. I would buy some compartmentalized boxes and put all the pocket-watch screws (3rd compartment from the bottom left) in one compartment and the smaller watch screws (3rd top compartment from the left) in another. Later, a box full of screws may come in very handy. From the balances which have broken pivots, I would take out the balance timing screw (top right) and cut off the hair-spring studs c/w fixing pins. These timing screw and fixing pins may come in handy. From all the train-wheels and balances, I would select the ones which are good and would keep those. These come in handy when to learn polishing pivots on the Jacot tool. I would keep the pocket-watch hands, to learn how to blue watch-hands and they may come handy as a replacement. Instead of trying to put things back together, I would scavenge the parts which may be of use later, the rest goes in the bin and I would start all over again. I would see this as a beginner mistake and swallow my losses; "learning money". I would start with a clean slate. From now on, I would buy only movements which are complete and in good shape. I would forget about all these "tinkered to death", "incomplete" & "rusted junk" movements. Waste of time and money. I would keep each movement that I strip in special watch-trays, like these; I would strip only one or two moments at the time and concentrate on these only, until I'm done with them. Too many projects at one time becomes overwhelming and I would lose track of which is what, what was the problem and which movement needs what? I would learn all the parts, their names, how to work systematically and precise. But that is if I were you ....... Perhaps other members do have different suggestions ...... Suc6 in this beautiful hobby1 point

-

All depends what you are working on. If the right mainspring is available and the money to buy one each time isn't an issue then a new one would be the best option. Downside is you dont get to aquire the skill of winding mainsprings. Which eventually if you work on a lot of old watches you will need. Yey old timer, my hero In my eyes leaving it in the barrel isn't an option, when I started i thought about it and i tried it. I soniced the barrel upside down in the hope it would clean it, it did but not to an acceptable level at all. No way are between the coils gonna get clean or all of the bottom of the barrel. You have to bite the bullet and just get stuck in, have it out and hand wind it back in if there's no option of a winder. Practice ,practice and practice and when you're done practicing......... you've guessed it , practice some more.1 point

-

thanks, guys; I really appreciate the help. I totally agree, too; it's far better to gain the experience first-hand. I'm a reader, though; I find it really helps me to study a subject in parallel to practising it.1 point

-

@watchweasol Sure no problem. As I said I couldn't get on with the wire holder for the loupe and had no chance of holding in with my face muscles for any length of time (how do they do that??!) so had an idea when I saw a cheap pair of £2 reading glasses in the chemist. I bought a pair and after taping up the lens with masking tape drilled a 25mm hole in the centre, I only had a wood drill bit so went very gently. I think it helped it was blunt or it would have probably broke the lens. I then ground/filed/sanded out the hole (quite easy as its plastic) until a loupe fitted through (about 27mm for mine). I then removed the other lens . The loupe is removed and changed easily and is comfortable to wear. Hope this helps someone else.1 point

-

1 point

-

1 point

-

Let us know how you get on with it. I bought a cheap one, and hardly ever use it. Unless you can hold the movement perfectly flat, there's no point using an expensive hand press. If you use proper movement holders, then it makes sense, but using normal movement holder, it's often hard to get the movement flat in the holder. I have no problem using hand tools under the microscope.1 point

-

Hello! Thanks to everyone who contributes here - I've been following and learned a lot. With a background in science and electronics, I've recently been drawn into watches and have serviced a few mechanical movements for myself. At first it was just to make the watches work, but the more I learn about the centuries of development the more I revel in the tinkering. So far I've always found answers to my questions without having to ask, but I look foward to contributing a morsel someday.1 point

-

Hello and Greetings from Germany! Long(ish) time silent reader of the forum, finally decided to create an account to ask for tips and advice at some point. I started looking into watch repairing as a hobby (and to improve my motor skills since I started surgical residency) in the onset of the pandemic and have been going at it since. By now I hope I have repaired more movements than I have butchered... I am looking forward for some guidance and conversations on this forum, thank you in advance! Chris1 point

-

Hello everyone. I am new to this forum and am I am new to hobby watch repair. I live in Panama. I am retired. For now I am mostly interested in manual wind watches. Most of the watches I have are fairly new. I have experience taking a caliber 6497 movement apart and lubricating and reassembling. I tore up a few movements. I have watched hundreds of you tube video watch repair videos. This is over the last several years. I purchased my basic watch repair tools on Aliexpress. I have a lot of Chinese watches. Manual type. Common manual movements. I like them. I like the Seagull ST5 for example. And, the Citizen Caliber 1800. These are both simple manual wind movements. Recently I bought a couple of vintage watches. They are not here yet. One is a Seagull ST5 from the early 80s. The other is a Citizen 21 jewel 1800 manual wind watch which is very similar to the HMT 0132 movement. I am going to need some help most likely in the future. I have no experience with snap on cases for example. Or, installing acrylic crystals. So I am here to learn. Thank you in advance for welcoming me to the forum.1 point

-

Watch this video. It show a complete disassembly of the movement. Have you serviced a quartz movement before? If you have, then do a full service. If not, just do the generator group. The parts in this movement are very delicate and I wouldn't recommend it for a beginner. I have serviced a movement with a broken generator rotor. I don't mean the pivot, but the arbor of the generator rotor was broken. Good luck.1 point

-

Awesome advice, I ordered an inexpensive demagnetiser today. Hoping that does the trick. Otherwise I've been happy with the performance of the set I have. The fit nicely in my hand and I can manipulate the parts well. Thanks everyone!1 point

-

I have cheap ebay tweezers from my first set. I do two things often. Demagnetise and keep them 'dressed', sharpened. The demagnetiser cost me £10. A honing stone cost me £3. that's it. Press the red button on the magnetiser, Demagnetise the tweezers by lifting them off the base ad going up. Release the red button. Repeat twice. Dressing. Using my magnifying glasses to confirm what I think I see. Shape and form the points. Dress all four edges and then gently removes burs. Job done. I use a pair of curved brass tweezers when working on an expensive watch that might show scratches. These were a massive £3 also. And, I do keep them dressed. Would I like high end tools. Of course, but to what end would it make my work better and this stage of my learning curve I ask myself? My standards are getting better by practice, not by high end tools. This is a great hobby1 point

-

The capacitor does not affect the rotor. If the rotor does not turn freely, it is usually due to the rotor bearing or the generator rotor. If the watch has not been serviced recently, the lubricants may have dried up and the watch will probably require a service.1 point

-

1 point

-

1 point

-

There are many ways to measure time. I've been observing this little brown, red, white and grey faced "watcher" for a over a month, and she has been watching me with equal intensity. She tolerates my presence, but I don't want to disturb her, particularly now that all that time sitting around on her eggs has finally paid off. The grey wagtail by comparison has already fledged with their dumpy little fellow (who was initially taking turns to sleep on the dusty path in the sun and hopping and flapping about indignantly waiting for mother to bring him lunch), now flying with ease. Mrs red legged partridge on the other hand seems to be leaving things a little late. Lets hope her offspring make rapid progress, as the summer here can be short, and unpredictable. So far it has been very pleasant. Warm without being too hot, and as a result there should be plenty to fill those hungry mouths. I suspect some more of my garden seedlings are likely to end up in those fluffy little bellies. Well you know what they say. "One for the mouse, one for the crow, one to rot and one to grow".. well in this case, maybe not the crow, but the partridge instead.1 point

-

1 point

-

It is possible to produce an iconic brown dial, but it is a tricky task. In my opinion the troicalized Omega Speedmaster hits the spot a bit better than the Rolex.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.0cfe95df32edde1c2cad6dddc1fe0d1b.jpg)