Leaderboard

Popular Content

Showing content with the highest reputation on 02/06/24 in all areas

-

IPA is pretty safe with any shellac. Methylated spirits (also known as denatured alcohol) on the other hand is a different story. Methylated spirits is about 90% ethanol and about 10% methanol and this will dissolve shellac really quite quickly. I also it to remove pallet stones and any shellac before setting new stones with new shellac. I also use it for removing old lume from watch hands I always leave a balance on the mainplate without the cap jewels and chatons in place and wash the movement through #111 L and R cleaner for five minutes and two rinses of #3 L and R rinse. You can't do that with non-shockproof balances though, as you have to take the cap off and the whole assembly is then in pieces. I never put a pallet fork through a cleaning machine, but that's my personal preference. I clean it by hand whilst everything is going through the cleaner, because I don't want to damage it, especially vintage pallet forks which could happen. I also clean caps and chatons by hand because I know they will come out really clean because I use new cleaner and rinse. If you put them through a cleaning machine they might not be as clean as you would like unless the fluids are new, as well as a possibility of mixing them up. Sometimes a cap jewel/chaton will be much bigger on the balance than the mainplate, but sometimes they are very similar size and sometimes they are identical. Washing them and putting them in separate pots marked top and bottom, a mistake to their position can't be made. I have put them through cleaning machines before with good results, but again, I prefer to hand clean them whilst everything else is going through the cleaning machine and it only takes minutes. Again, just a preference that I have. There are more than one way to skin cats... IPA isn't as good as a dedicated rinse in my experience, otherwise all watchmakers would be saving a lot of money using it instead of a rinsing fluid. It's about £17 for 5 litres and L and R #3 rinse is about £55 for 3.8 litres. Some 4 jar watch cleaning machines will have IPA in the last jar, but that is after the the rinse.4 points

-

I find IPA and rinse are pretty similar with their evaporation rate. I keep a small jar of IPA on my workbench to dip my tweezers in when they get a bit sticky from lubricants on movements I'm disassembling then push the tweezers into pithwood.3 points

-

It sounds like the contrite wheel is not at the correct depth to the escape wheel. Make sure the teeth on the contrite wheel are good and make sure it has hardly any end shake. Cleaning and oiling the platform is needed, The screws that hold the platform to the movement gives you opportunity to also adjust depth.3 points

-

The thinnest discs suittabe for dremel can be obtained from dental clinics supliers They are called 'separators', and 0.15mm is the thinnest ever, but 0.2 is what they offer as standard thinnest. https://www.shop.mipis.com/en/separating-discs/1242--22-04.html#/302-thickness-0_2_mm3 points

-

Hi Guys here is a little reading. some may find it interesting some may find it usefull so help yourselves 01-OFFICIAL CATALOGUE Of Genuine Swiss Watch Repair Parts_1949_Main Document-Introduction.pdf 02-OFFICIAL CATALOGUE Of Genuine Swiss Watch Repair Parts_1949_Main Document_A-Z.pdf 03-OFFICIAL CATALOGUE Of Genuine Swiss Watch Repair Parts-Supplement N°1 - 1953.pdf 04-OFFICIAL CATALOGUE Of Genuine Swiss Watch Repair Parts-Supplement N°2 - 1959-1A.pdf 05-OFFICIAL CATALOGUE Of Genuine Swiss Watch Repair Parts-Supplement N°2 - 1959-1B.pdf2 points

-

Cleaning procedure Since I began I have learned how important it is to clean the watch parts. I can't afford a cleaning machine. I have made my own variation. My system on disassembly. Pegwood and fibre brush if needed. Large items into base of lighter fluid holder (No. 1 jar). Place all items into baskets then add them into the lighter fluid jar. Ultrasonic for 6 minutes. Remove shellac items and dip into Isopropyl alcohol for 30 seconds and blow dry. Place all other items into isopropyl alcohol fluid jar (No. 2 jar) Ultrasonic for 6 minutes Remove all baskets and items and blow dry in warm air from nail drier for up to 10 minutes Place all item back into parts holder and check items individually. Reassemble2 points

-

Whilst grounded post Covid I am goling through my store of information in order to tidy it up and posting such documents you guys might like. If not Ignore the posts TM9-1575-War-Department-Technical-Manual.pdf2 points

-

Until oldhippy gets back to you have a look at this it will give you an idea what needs doing Servicing a Platform.pdf2 points

-

2 points

-

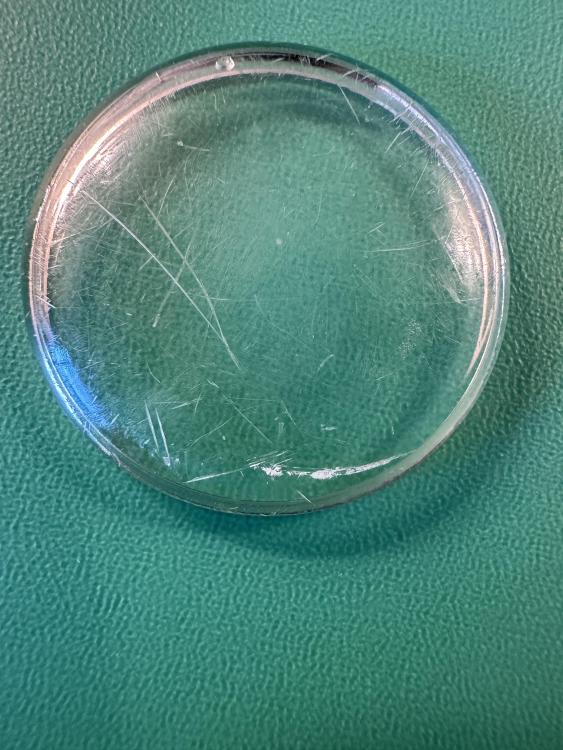

Is that a flat or curved dial? Benrus and Hamilton both made GG-W-113 watches using a movement from the ETA 2750 family, but Benrus generally used curved dials while many Hamiltons were flat. Your hands look more like a Benrus model, so I wonder if the dial is a mismatch for the case, which could complicate the fit and seal of the crystal.2 points

-

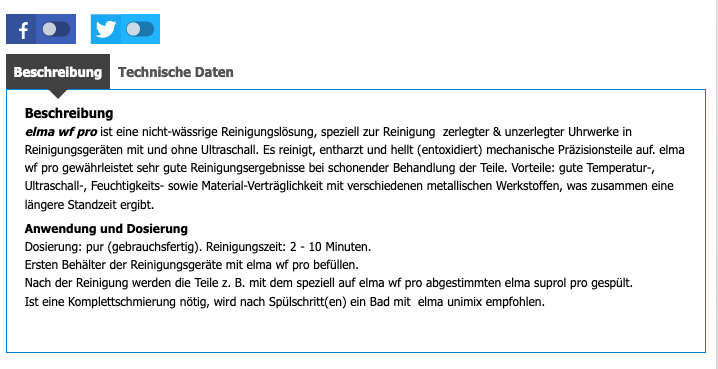

For years I've been using Zippo lighter fluid. I recently bought a 2nd hand Elma S15H ultra-sonic and purchased Elma WF Pro cleaning fluid and Elma Suprol Rinse. https://www.cousinsuk.com/product/elma-wf-pro-cleaner?code=R37683 https://www.cousinsuk.com/product/elma-suprol-rinse What a world of difference these Elma chemicals make. My big regret is that I've should have purchased these products years ago2 points

-

If you don't have a watch cleaning machine. Clean all the parts with Ronsonol lighter fluid, after cleaning put the parts on some tissue and use your watch blower to dry the parts. If jewel caps can be removed then do so. Pocket watch oil fill be fine. Oil the pallet jewels and every other tooth on the escape wheel but do not over oil.1 point

-

In Europe, Lidl have these workshop benches. The height is adjustable in three steps - 85, 95 and 105 centimeters, personally I find the 95 cm height ideal for me. The bench is very sturdy and has a wooden desk, which is not the best quality (not surprisingly, for 150 EUR), there were some gaps and cracks I did not like, so I did some easy filling and grinding job before I started to use the bench. I am a newbie, but so far, I am quite happy with the result. https://www.lidl.de/p/rikta-werkbank-hoehenverstellbar-b-135-x-h-85-105-x-t-60-cm/p1003485001 point

-

As we get numerous questions regarding the escapement of swiss and other watches I thought it would be useful to, post this 370433519_WorkingSwissEscapement.pdf1 point

-

Exactly my process, too. With non shock I disassemble and use hairspring dip and a brush for the wheel/spring and...lighter fluid for the jeweled plate jewel cock-haha1 point

-

It could be the penetration of the of the sliding gear to the finger. But first off check that the minute counter is totally free, and its jumper is working correctly. It should advance the wheel but not with too much tension on its spring. Later models have the spring integral with the jumper and if not messed with give little trouble; on yours the spring is on the escape cock, and could easily be overtensioned. With those things sorted, then check the depth as Neven mentioned (the eccentric is actually the one just to the right of his arrow). You want the sliding gear wheel to engage with the finger, as deeply as possible, with the limit being that the finger can touch the next tooth after the jump, but not enough to make the minute counter move (just brush by it). If the engagement is too light the finger can butt on a tooth, stopping the watch.1 point

-

Your response popped up for me this morning so I went to look for the thread I saw re: the Stella crystals. I didn’t find it but this thread may have some insight on the dial differences and best crystal options… https://www.watchuseek.com/threads/hamilton-gg-w-113-questions.35726/1 point

-

Dont down play your knowledge or level of skill Ross, besides people on here who do you know that can do what you do ? Your contributions on this forum are huge and just as valid as anyone's. If all is original it really does sound like a worn down upper pivot. Thats the first thing i would be looking at to eliminate it from the list of causes. If its not obviously worn then to varify from inside the watch if the pivot cone is riding on the jewel or the opposite pivot is almost free.1 point

-

If you look at your balance jewels that's what the jewels should look like. If there plastic they should be soft enough to be scratched with steel like corner of a screwdriver tip. Then if it does scratch like plastic I'd keep it out of the cleaning fluid as you have no idea what kind of plastic it is. Then the Swiss do have another form of synthetic Ruby called Polyruby. As far as I know the only place you find this is in pallet forks I don't think I've ever seen or heard of it being used as a bearing jewel. on pallet forks you recognize it as pink colored stones that are not transparent.1 point

-

We still need to know is the axial free play normal in any combination of settings/enstone position. I will not be so amused if the free play will be normal when both enstones are put upside down... Well, the fact that when dial side endstone put rouned side to the pivot makes the balance work correctly, only means that the pivot is short for this setting, nothing more. I mean, it is not proven that the pivot is worn. The pivot may be OK, but the setting may be not original. Then, the balance itself may be replaced. Or, someone may have worked on the pivot and then rounding it's head for some reason... For sure will tell, that if a pivot is worn in a manner that it has got that shorter, it's head will not be rounded as it should, but will be flat and even riveted. Furder more, no reason to expect this exactly pivot to be worn. Such wear of pivot one can meet in a pocket watch which has worked 40 years on the table or nightstand lying dial up, but in the hairspring side pivot. So, what we really need is good pictures of the pivots. When using smartphone camera, search for macro mode and find out how to lock the focus (e.g. press the area of the image and hold untill locked padlock symbol appears) and then find the distance from camera to pivot where the image of the pivot is on focus.1 point

-

Observation on this post Just so interesting Not that I could do the level of work that you are all talking about, it is very interesting none the less. It is as a result of these types of discussion posts that allows us learners an understanding of the use of the relevant tools needed, and applications how to use them. Together with the observations and comments of the members, because no one criticises or ridicules, just offers information, all we learners have is great learning opportunity. Thank you to all1 point

-

It’s not just Seiko Chris, to be fair we probably have more information on Seiko parts than most manufacturers. Unfortunately no global parts list exists for anything in watchmaking. Tom1 point

-

1 point

-

I’ve watched some. I like the guy but he talks too much. I sit there thinking “just get to the point” I know of him, and his mentor the late George Daniels. I could just knock on his door and ask for help removing my broken arbor screw I suppose1 point

-

Well, this is not another problem, but still chronograf part needs to be regulated as it should. The engagement depth of finger that switches the minute counter must be regulater as deep as possible (but still one position ahead per finger turn). The excentric that regulates the depth is here. But, as Henty Mencken once said, “For every complex problem there is an answer that is clear, simple, and ... wrong.”, the things are more complex and complicated. Did You already try to regulate the depth and if so, what hapened?1 point

-

The stud is press fitted into the hole in this fixed stud holder arm , can be pushed/ punched out of the hole. OR You might unpin the hairspring.1 point

-

Movement is marked Hamilton. Dial edge is domed. I ordered a Stella 24 1/2 crystal. I'll let you know if it fits.1 point

-

I just serviced one of these…. A different board suggested a Stella 24 1/2 was the ideal replacement so I ordered one on the Ebay but received the wrong one so I refurbished the old one. I was concerned the replacement wouldn’t secure things- I suspect that’s what you’re thinking as well? Here’s some pics of the original- to me looks like an ordinary hi dome or something but there isn’t a large edge… Here’s what mine looked like in the case… This one was inherited by the sister of a deceased USAF pilot so definitely all original Hamilton. From your pic your dial does look like it may be curved…1 point

-

I took on Marks course and applied level 1 and 2 to my early learning. Level 3 seemed a bit to far ahead for me when I looked. Needed more practice. Even though I practiced, Still I needed more depth of knowledge. This has come form a YouTube weekly programme. Chronoglide. I'm sure you have heard of it . But in case you haven't. Chronoglide is like the breakdown of why Mark's course is needed? I began to watch about 12 month ago. As result of what they do, dealing mostly with disassembly and looking at problems that have arisen with use, and the reason why such has occurred, together with verbal and visual observations. I am now spending more time on Mark's level 3 as I understand what needs to be applied by his methods.1 point

-

1 point

-

Not exactly, all I have installed is the 2nd wheel with it's standalone bridge and the escape wheel with the pallet cock (using Seiko's terminology). Those two wheels spin. with tweezers. Installing the barrel next to check the spin of the 2nd wheel is JackRoss01's way of doing it and I think it sounds like a good second check of the 2nd wheels ability to spin.1 point

-

No not all calibres have a sheet to work from, age and release are a factor. Its seems you have a complicated mechanical puzzle to solve. Start with aquiring any information you can on the calibres involved. I think i would attempt to assemble all the calibres at once, starting as normal with the barrels of each one. A lot of it will be trial and error, i certainly dont envy your task ahead murks, wish you all the luck in the world. Think of it this way, i bet not many of us have done multiple assemblies at the same time.1 point

-

I agree on ditching the alternative chemicals and going with the "real stuff". Horror stories of ammonia stink kept me away from them for too long. I use L&R 566 and it is pretty apartment friendly. Non-ammoniated but there is a little ammonia like smell. I rinse with L&R #3 rinse and both are shellac safe. Finally a quick and harmless rinse in IPA.1 point

-

I gave things a couple of days and restarted. I took things down part way (same as I did before). The center wheel and bridge are still in place along with the Pallet cock, pallet fork, and escape wheel. I can turn the escape wheel with tweezers and the pivot looks fine, I can also turn the center wheel with tweezers. I want next to install the barrel and see if turning it turns the center wheel. My question is, given the above is it necessary to disassemble any further? I'll be using rossjackson01's tips as I go along.1 point

-

As far as I'm aware, both fluids are shellac "save". That's to say, I do no more than 5 min per ultra-sonic cycle. I have one (165ml) jar with cleaning fluid (Elma WF pro) and two (165ml) jars with Elma Suprol rinse. I give a basket filled with parts 5 minutes in the cleaning fluid (WF pro), blow the basket clean, then the basket goes 5 min in the first Rinse. After 5 min, I blow the basket clean and it goes in the (optional) 2nd rinse. Once that's all done, I hand-dip the basket in the IPA and quickly (especially with the pallet-fork and the balance) take the parts out of the basket and blow them dry. How to do the balance is still a bit of a question mark? I left the balance in situ c/w the anti-shock jewels, I also cleaned the balance separately and I left the balance in situ without the anti-shock jewels. All options went fine, but I'm not sure which of the three options is the best? With the anti-shock jewels separate, I experience this: https://www.watchrepairtalk.com/topic/28547-these-rubber-bellow-hand-blowers-do-suck-/#comment-240948 It seems, and to make sure that the anti-shocks are 100% clean, that one has to do the anti-shock jewels (by hand) separately in IPA. To me the Elma WF pro (cleaning fluid) seems to be the most "aggressive", but that may also be due to the ammonia smell. The Elma Suprol is to flush the Elma WF pro out, and to make sure, I use two rinses in two separated jars; Rinse 1 and Rinse 2. The 2nd rinse seems optional, but I do it anyway, just to make sure. I don't think that any of both Elma chemicals are directly "decremental" to shellac, or at least not so as IPA is. But as I understood from others, you don't want to leave any of the watch parts in the WF pro too long either. Up to 5 minutes cycles seem to be safe. Also these two Elma chemicals are non-water based. One has to make sure that there is no cross-contamination between the water in the ultra-sonic tank and the fluids in the jars. Perhaps other members may have different idea's or other cleaning procedures? I'm a bit experimenting too what's the best procedure. However, from what I've done so far, the results with these chemicals are very good ! Before; After; and the same results I get with the wheel-train, screws etc. Everything comes out sparkling clean If WF Pro was not suitable for ultra-sonic, why do they sell it in shops specialized in ultra-sonic? Perhaps, it is not a good idea in the ultra-sonic tank directly. That would be, due to the volume needed, quite costly too. But in jars .... ? I bought my chemicals by SKsonic in Germany: https://www.sksonic.de/ I do hope that your German is up to spec1 point

-

Hey Ross, the cleaning fluid is the equivalent of your lighter fluid and the rinse is the equivalent of your isopropyl. Tom1 point

-

Hi Ross. A sound method for cleaning and drying, the nail dryer is an ideal solution to careful drying process.as the heat is gentle not over powerful. Well done. Who needs a machine. Eh.1 point

-

1 point

-

1 point

-

1 point

-

Stamped either ST96 or FHF96 or ST-FHF96 or any modified version thereof, for example ( ST96-4 ) , a 18000 beater escape out of any of the above 96 calibers, fits your watch. Rgds1 point

-

YES, the BASE CALIBER is BASICally the same, made by FHF also by ST , in some cases you see a movement might be stamped ST FHF. All are of same BASE CALIBER. Then newer versions were improved by COMPLICATIONS like date, day etc. As long as they beat the same frquency say 18000bph they were said to be in the same family though might have been modified or have different settings or shock systems etc. BUT when frequency was improved a new family was created , all families constitute a generation. Go on to Dr ranfft site bidfun to see a sample of this breakdown. An escape wheel out of any variant of same family ( frequency ) fits you watch Rgds1 point

-

1 point

-

1 point

-

Hi Waggy. Ihave a custom made desk built from redundant kitchen units with drawers and a cupboard, not pretty but practical. I also made a desk top one with a drawer again from bits to use in the house in winter as the workshop has minimal heat and the fingers suffer. So it is quite possible a lot of members have the skills to do the same, it’s not rocket science by any means. Do you have a picture of your bench so others who may be interested can get an idea. Thanks1 point

-

It looks like the Venus 175 is based on the Valjoux 7730 however here is what I found. 1909_Venus 175.pdf1 point