Leaderboard

Popular Content

Showing content with the highest reputation on 12/24/23 in all areas

-

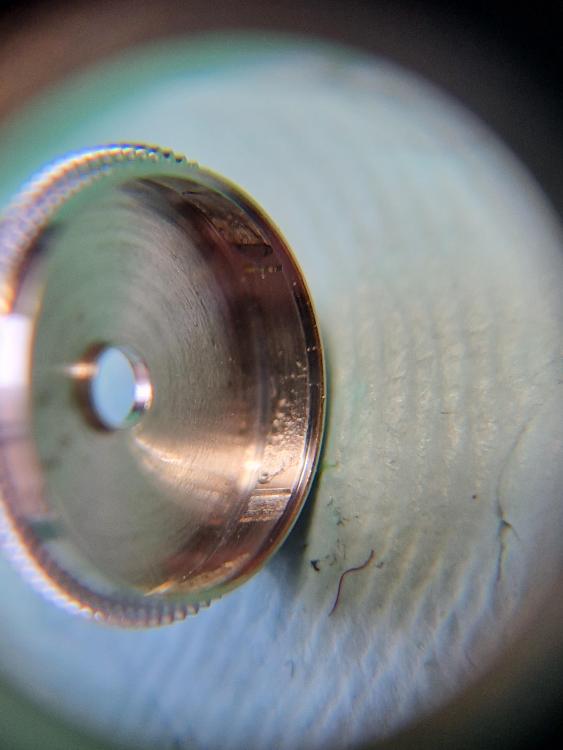

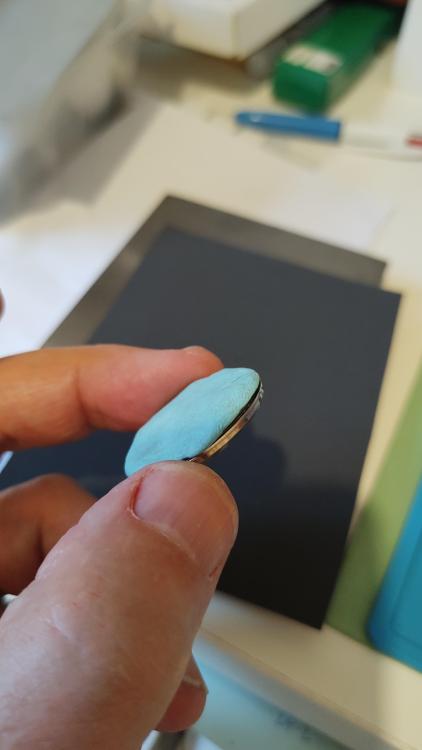

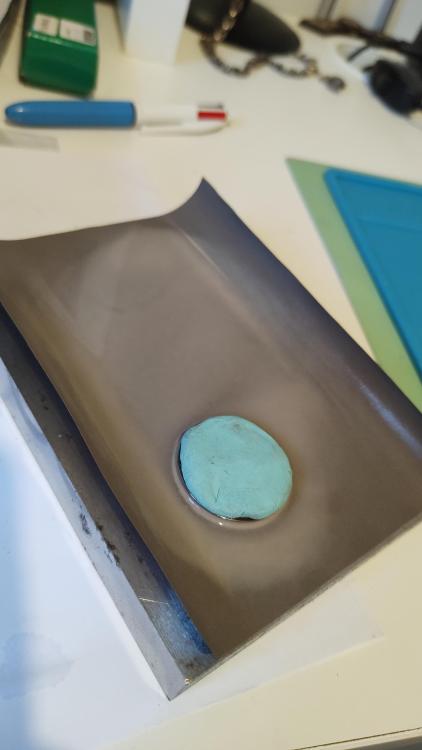

Hi, just wanted to share in case it helps anyone. I made my first attempt at glass polishing recently and was very impressed with what I achieved as a first attempt. Equipment used - Flat machined steel block approx 100 x 150mm. Consumables - Silicon carbide grit paper, grades 600, 1000, 1500, 2000, 2500, 3000, 5000, 7000. Also diamond based polishing compounds, 2.5, 1 and 0.5 micron. I started off with the 600 paper on the metal block slightly wetted. I used some used rodico on the inside of the glass to protect from any stray abrasives. I spent less than 2 minutes rubbing in a circular motion while periodically rotating the glass by 90 degrees at a time. A milkyness would appear on the paper and that was the abraded glass particles. Then I moved on to the next finer grade. Between grades I would wash the glass surface and also wash the new piece of abrasive paper to get rid of any stray abrasives particles. After each finer grade the translucence of the glass would be improved. After 7000 grade there was a certain kind of speckled textured when looking into the light through the glass. At this stage I used the 0.5 micron diamond paste on a small cotton Dremel wheel and ended up with a bit of a fine orange peel effect. Nicely polished but not what I wanted. I reverted back to the 2.5 micron paste and then used the 1 micron followed by the 0.5 micron and this gave the result I was after without any orange peel. Looking back I think that the 1 and 0.5 micron pastes didn't add much to what was achieved with the 2.5, maybe they made the glass just a bit more reflective. If I was to do it again I would try and find some finer grade papers than 7000 and try and use those instead of the diamond paste to keep everything optically perfectly flat. Also I would try to minimise the glass loss of thickness as much as possible by using the harsher grades as little as possible (I ended up at 1.38mm from 1.45mm that I started off with, just under 5% loss).TBH though I am very happy with the results that look pretty much perfect to me.4 points

-

3 points

-

I'm not one that celebrates Christmas in fact I hate it. For the many that love this time of year I wish you all a Happy Christmas & New Year. Lets hope for piece on Earth.2 points

-

Yes it is possible to grind in a bevel edge to a flat glass. I made an attempt a couple of months ago at removing some chips from a bevel. I used a diamomd plate and some fine grade wet and dry . Revolved the glass by attaching it to a sucker in a bench mounted drill. https://www.ebay.co.uk/itm/153447915747?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=nB_-9zebTVG&sssrc=4429486&ssuid=tBiLZaCfRb2&var=453396631343&widget_ver=artemis&media=COPY2 points

-

Cheap is, as cheap does! If you buy some Bergeon or another known brand finger cot the result is obvious compared to something like Anchor finger cots, which should be thrown in the bin. If you prefer nitrile gloves, go for it. I don't like my whole hand sweating inside a glove, as I'm using cots for eight to ten hours a day and regularly take them off to let my fingers breathe. I use Bergeon black finger cots. Large ones for three of my fingers on my left hand and an extra large for my thumb, as the large ones fell a little tight on my thumb. I don't like wearing finger cots on my right hand I use for screwdrivers and tweezers, as I don't have the tactile feel of the tool and generally don't handle parts with that hand2 points

-

Even if a replacement is available it's still a nice feeling to say I did that myself. Well done2 points

-

The julesborel.com Basically has two sections the website the parts we can look up the part numbers and the other part where you can look up to see if the parts available. So if we had a pallet fork arbor number for instance we could go to the link below and yes it's available. Of course have the price comparison with the pallet fork that you purchased pallet fork was a better deal and of course you need to have the tools to put. But just remember you have to take the part numbers to the other side to see if the parts are available. http://www.julesborel.com/s.nl/it.A/id.26968/.f1 point

-

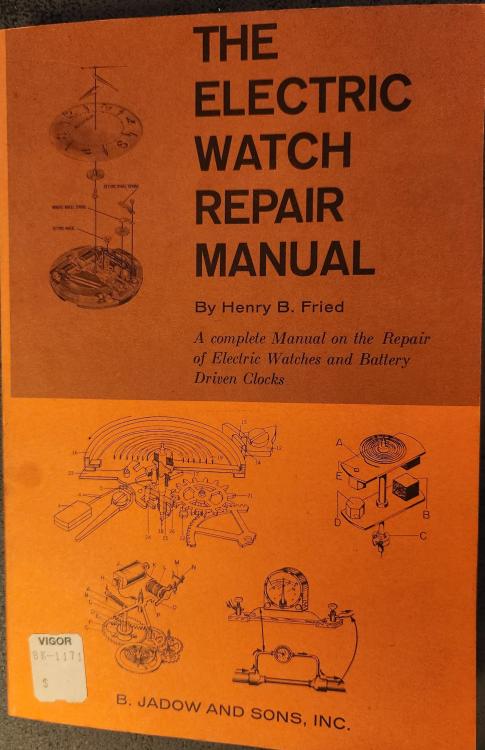

Antonio from Madrid (Spain). I am passionate of watch repair about a year and half ago, although always mechanical systems, and specially clocks, got my attention. I am telecommunication engineer, so quartz clocks might be my preferred ones, but not, there is a kind of hypnotic attraction on a beating balance that has been blocked several decades. I have rescued so far some pocket ones and two wrist ones. But have many more waiting solution of problems above my actual skill. I hope this will change with some help.1 point

-

1 point

-

1 point

-

Steve. Thank you. This post now marked in my favourites/Watch Repair/ Learning tips1 point

-

1 point

-

1 point

-

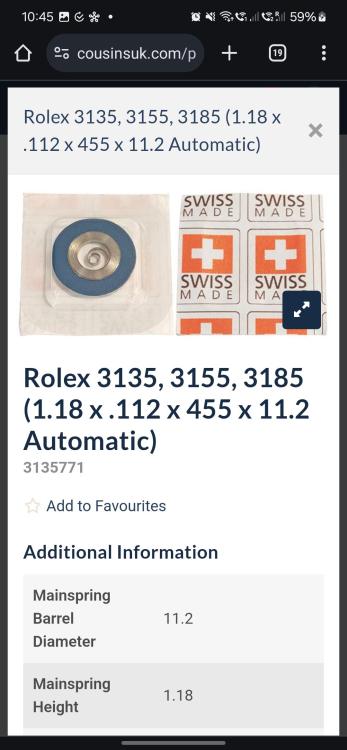

Thanks, that's a very useful input! I fit a generic Generale Ressorts mainspring specifically meant for thr 3135. Screenshot below. I unfortunately didn't take a picture of the quantity of breaking grease applied. But I took pictures of a recent cal 2035 and I'd say that I put an equivalent (not equal, because the barrels are not the same size) amount. The picture should give an indication. I applied 5 blobs and then spread them out rather thin to avoid that putting the mainspring would result in pushing the blob down to the barrel floor. Last thing the point out, it really only takes 1min for the amplitude to settle at 300-310.1 point

-

My best guess on the size at the moment is L- 3.55 some of the cylinder is buried in the balance wheel. I have a feeling the cylinder lengths dont vary too much, any discrepancy would be adjusted within the tampon depth. The diameter is 0.75. I saw a good selection of tampons a couple of months ago on ebay, i was tempted to pick them up but then i thought nah I'll never use em . Are you sure ? I'll buy them from you. I'm only playing around , unlikely this will ever be cased, but I'd like to see it run. All I'm doing is testing myself to see what i can do. I have a shed load of staffs and stems so anything you need in that way i can return the favour.1 point

-

If you post the dimensions, I may have one to fit. The cylinder with tampons attached.1 point

-

1 point

-

Most vintage dials will survive the soldering. It's the modern ones using water slide decals and toner transfer that could be problematic. And because I served in a medical unit in the army and was trained to go in hot and come out fast.1 point

-

Unfortunately that won't work. By the time you align the dial foot to the correct spot, the dial would have reached room temperature. Unless you have a walk in freezer where you could actually work in subzero conditions. But I my experience, it's not necessary. You just have to go in hot and fast. Don't try temperature controlled soldering irons or hot air guns. The heat produced is not fast enough. Trust me, I've tried. Use a microtorch or a carbon electrode, with a low fusing solder. And use copper wire and not brass for the dial feet.1 point

-

Nothing frightfull, just the proper punch and anvil needed. Do You have it? Do You need explainations? Making new tampons is not a problem too. The down side one is OK, but it has sunk a little. Must be pushed out till the plains of the tampon and cylinder coincide. The pivot will strighten with the tool in the other topic.1 point

-

Langendorf. I have some complete cylinders, long shot but maybe something if use.1 point

-

Postage not included, I doubt if any of these seller understand English International shipping rate is or was $50 up to one kilogram, so multiple purchase and combining shipping saves $. I have a arron boy who do the international shipping to you. You can also ask the sellers for discounts.1 point

-

I have a cut-off point of 335 amplitude. Anything below that is not going to knock. Anything that goes above that is usually going to start knocking. As this is an automatic it is generally going to be at full wind and full torque, but after a day or so it might settle down. It does seem quite a high amp for a 3155 to be honest. What spring did you fit? I find that at the total full wind for a 3135 it will be about 300 to 310. Did you put enough braking grease on the barrel walls? It might be slipping way too late.1 point

-

There is a Moebius oil called TH7-SC specifically designed for the lubrication of plastics: chrome-extension://oemmndcbldboiebfnladdacbdfmadadm/https://www.moebius-lubricants.ch/sites/default/files/security_sheet/tinf_th7_en.pdf However, on an ETA chronograph such as the 7750, there is a part called an hour counter lock made of plastic that isn't lubricated, as it is made of nylon, therefore lubrication isn't needed. Alternatively, you could use silicon grease that won't degrade the plastic. It has to be pure silicon. Alternatively, vaseline will work.1 point

-

Check out the variation list matey. Page 509.1 point

-

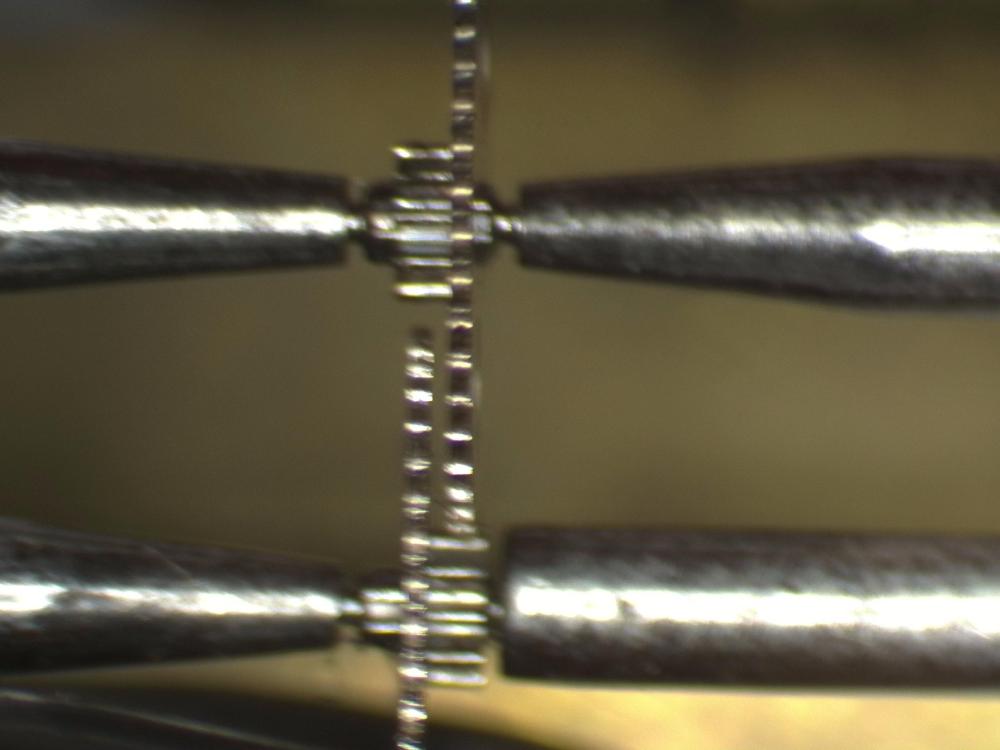

I'm not entirely sure, i wasn't able to find any instructions, but that is how i came to do it in end. I could see the register arm lifting up and down, which surprised me as the arm has to bend to be able to move up and down. I think it was just designed for balance staffs, i had a bent escapewheel pivot on a restoration from a while ago that had been put aside so i thought why not give it a go, its my first time using it. I've literally just gotten around to casing up the movement, busy sorting out a load of old movements i bought and making washing machine devices. Here we have it running dial up and crown down an hour after a full wind, i think the pivot survived the ordeal and is doing well.1 point

-

1 point

-

1 point

-

I guess I'm another old bugger. I must have gorilla hands; all the cots I've tried were so tight as to be almost painful. I've invested in good tweezers, good screwdrivers, good pin vices and tool holders, and good movement holders. Even before cleaning, I touch the parts as little as possible, and after cleaning - not at all. I will put on cots if I cannot do something without finger-manipulation, but I've been practicing with my tweezers and I believe I'm getting pretty good. Learning to dress them right helps also. But I do have a K&D winder that I like very much. And I always have the Rodico close by. And I know how to oil these things. So I am hoping for a measure of absolution too.1 point

-

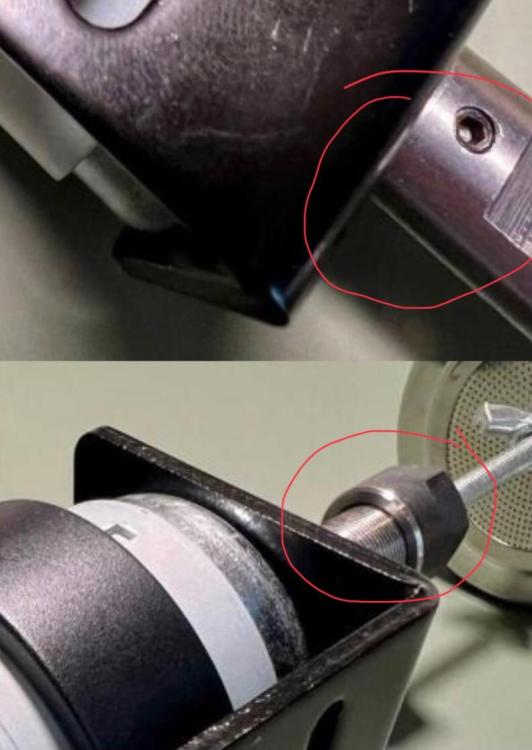

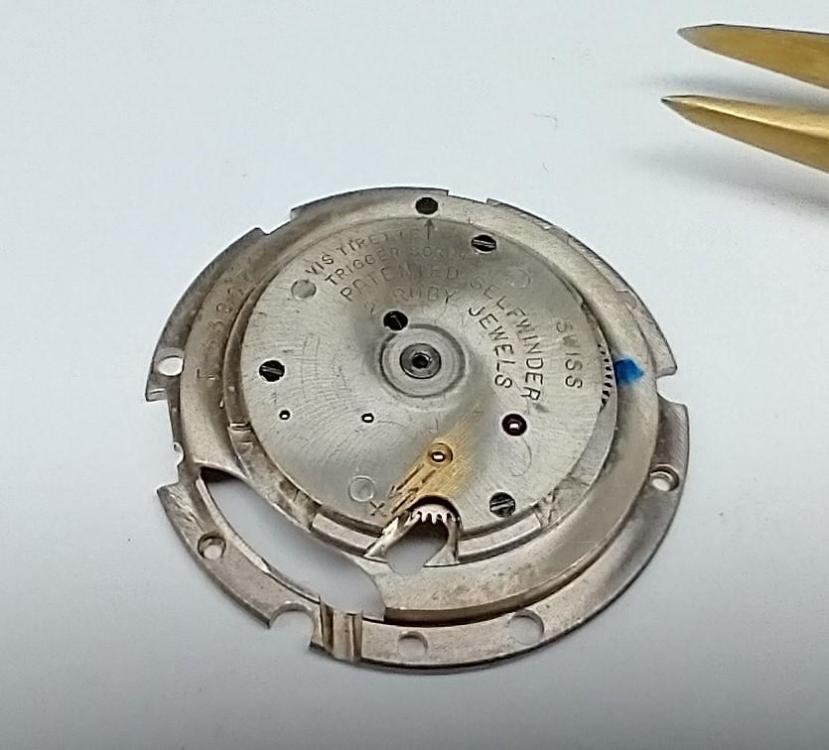

My tutor never wore finger cots, as he was 'old school' but he did handle parts from the sides and was constantly washing his hands like he had OCD. I never once saw him handle parts like Times Radical, therefore he could never etch his fingerprint into the plating. Here's the dial side of a Rolex 645 I serviced this week with a finger or thumbprint beautifully etched into the rhodium plating. That will never come out. Probably the same fettler who scratches the arrow and 'W' on the rotor to denote which way it wound and more than likely the same guy who files down the replacement bush on the upper auto bridge. Genius! Incidentally, they had set that bush 0.06 mm to one side throwing one of the auto wheels out, as you can see from the photo. I used my depthing tool to work out where it should have been in the second to last pic. I know I've strayed a little off-topic, but it highlights what fingers on bridges can do and if that's acceptable, then what's the harm in scratching marks into the rotor and bridges and filing the top of bridges? Then the watch ends up on someone else's bench and the customer wonders why it costs so much to rectify the previous lash-up. Rant over! The last pic is of the movement minus the auto works or rotor in place1 point

-

Of course, but this was a Seiko metal framed bonded glass from the 1970s and was unobtainable. With a fully polished bevelled edge. I did look for a glass with polished bevelled edge but couldn't find that also. This has got me thinking now. How easy would it be to grind and polish a bevel onto a new piece of flat circular glass? I'm thinking Dremel tool, some kind of flat metal disc to stick the glass to with a thin post on the back to go into the Dremel chuck. Could shellac be used to stick the glass in place?1 point

-

1 point

-

Hi NEW the one I made was put on the forum in Oct 2029 I believe in the tools section if it still exists. If you can’t find it let me know. It’s quite simple and almost fool proof.1 point

-

Hi NEW. If you want to build a dial foot machine they are quite simple and very effective, I built my own using a battery charger for the power source as it had over current protection it does a good job. I will dig out the plans. Or if you look at the NAWCC. Of AWCI the creator of the machine was Wesley R Door. Look him up.1 point

-

Perhaps this article could be of some interest? https://www.great-british-watch.co.uk/how-to-polish-a-watch-case-and-bracelet/1 point

-

Neither.. You need to have a dedicated mop for each grade of compound. If you try to use different compounds on the same mop your results will always reflect the coarsest compound and you will never get a proper finish.1 point

-

Yeah already watched almost all of his videos, but there's no information about the polishing dicsc he uses Anyways thank you!1 point

-

Im really going off sapphire crystals. All my watches that have sapphire crystals I have stopped wearing. I just don't think they add anything to a watch (apart from scratch resistance ) I have been designing and building a number of my own watches recently, and do you know what isn't on my list of must have features? You guessed it....a sapphire crystal. They are just soulless in my opinion. Practical yes, romantic no. And I want a bit of romance in my watches. A bit of tradition. Im very lucky to have a rolex submariner in my collection (don't judge), with the ceramic bezel and the sapphire crystal. I haven't worn it in ages, but I got it out the other day to give it a clean and check everything was in working order. What struck me was that after a quick wipe down it looked like new. I went through a period of wearing this thing every day, all day, no matter what I was doing. I spent a good deal of my working day under cars, or inside engine bays, fabricating stuff, welding, etc etc. Through it all I wore that bloody submariner, and there still isn't a scratch on it! On the other hand I finished building my new favourite watch about a week ago. I specced it with a big old high dome acrylic crystal because I just think they are special (almost as special as domed, flat bottom mineral crystals). Ive never seen a watch that doesn't look better with a high dome acrylic crystal on it. This evening I glanced down at it to check the time and noticed it was covered in scratches. I grabbed the poly watch, gave it a quick buff and it looked as good as new. NO, it actually looked better that new! I don't know what it is about acrylic crystals but the more you polish them the better they look. And you know what? Sitting down buffing that glass I bonded with that watch. I had to put some effort it and look after it, and now I can't stop looking down at the beautiful reflections on the glass when the light hits it in just the right way. I think I never really bonded with the submariner because it was too easy. I never had to put any effort it. It left me cold. I just don't think ease of ownership makes an item special. Out of all the cars I've owned my favourites certainly weren't the most reliable ones. Sometimes I think we appreciate things more when we have to look after them. It feels like something that is perhaps being lost in more recent times. Everything feels a bit more 'throw away' than it was when I was growing up. When I was younger it was common to spend your free time taking care of your valued possessions, because you worked hard for them! Whats wrong with polishing your shoes every morning, and waxing the car on Sunday?! Sapphire crystals are very convenient, very practical. But I think ill take a pass.1 point

-

For scratches in steel I use wet and dry stuck to wooden sticks (Cousins sells them), so I can keep sharp edges. For deep scratches I'll start with 240, them move to 400,600 grit (800 for finer scratches), before using Dialux orange, on a hard felt wheel on the Dremel. I finish with Dialux white with a soft felt or cotton mop - which I also use for gold.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)