Leaderboard

Popular Content

Showing content with the highest reputation on 12/21/23 in all areas

-

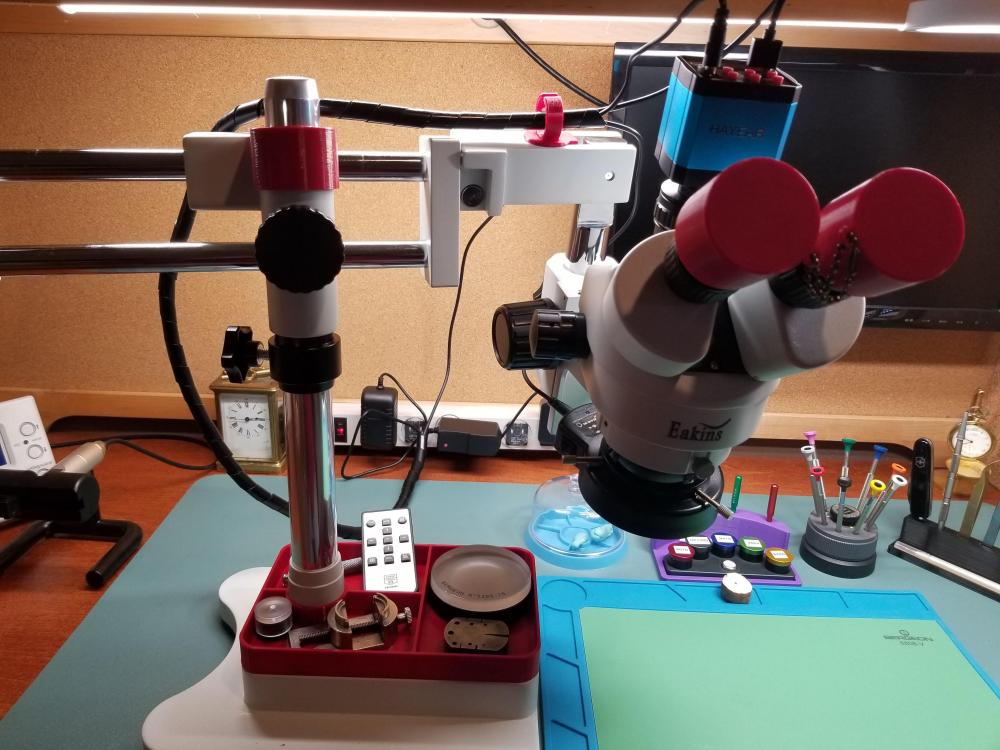

I've been adding some 3D printed accessories to my microscope. Found the STL files online and tweaked them to my liking. Though, I might do a bit more tweaking of the cable guides. I like the extra storage that the tray provides to make some of my commonly used tools handy instead of having to dig them out of a drawer. I happened to have a length of cable sleeve tube handy to also help tame the cords. I traded out the old thick and stiff HDMI cable for a new slim and flexible one.3 points

-

If I remember correctly, Blu-tack came out in the seventies. What did you use prior to that? I read somewhere that the Waltham factory tasked a lady to make a batch of dough every morning and that was used like Rodico. Maybe @Neverenoughwatches would like to make his own Rodico. Any extra can be used for making chapati.3 points

-

As I'm one of the old buggers that never used finger cots I always used Radico, always handled parts with tweezers and I couldn't get on using watch mainspring winders. I learned how to put a spring in its barrel without touching the spring by using tissue paper. I expect now I'll be sent to Coventry for the rest of my time on this forum. Happy Christmas.3 points

-

The thing for me is things move on, we didn’t use seatbelts in the ‘60s, not invented yet, should we go back to those days? I don’t believe so. As for finger cots they were not available for the most of the time watches have been made, does that mean we shouldn’t use them? Hell no! In my opinion, having been involved in the creation of the internet we enjoy here, things will progress, there is no such thing as “best practice “ only “best CURRENT practice “ Tom2 points

-

No need to be frightened of alum, but it will not dissolve the screws - they for sure are stainless steel. I guess that they are big enough, e.g. 0.8 mm in diam, so drilling them is normal choice, but do it carefully. If 0.8, then 0.5 drill bit (carbide) should be used. I do it by hand, the drill bit in pin vise. After the drilling, a tool like reamer shoud be pressed in the hole, then the tool gently forced in both directions - screwing and unscrewing, many times, untill the screw begins to move a little, when this happens - success is close.2 points

-

Ross you don't under stand us down here. This is what is meant when sent to Coventry. "Send to Coventry" is an idiom used in England meaning to deliberately ostracise someone. Typically, this is done by not talking to them, avoiding their company, and acting as if they no longer exist. Coventry is an historical cathedral city in Warwickshire2 points

-

2 points

-

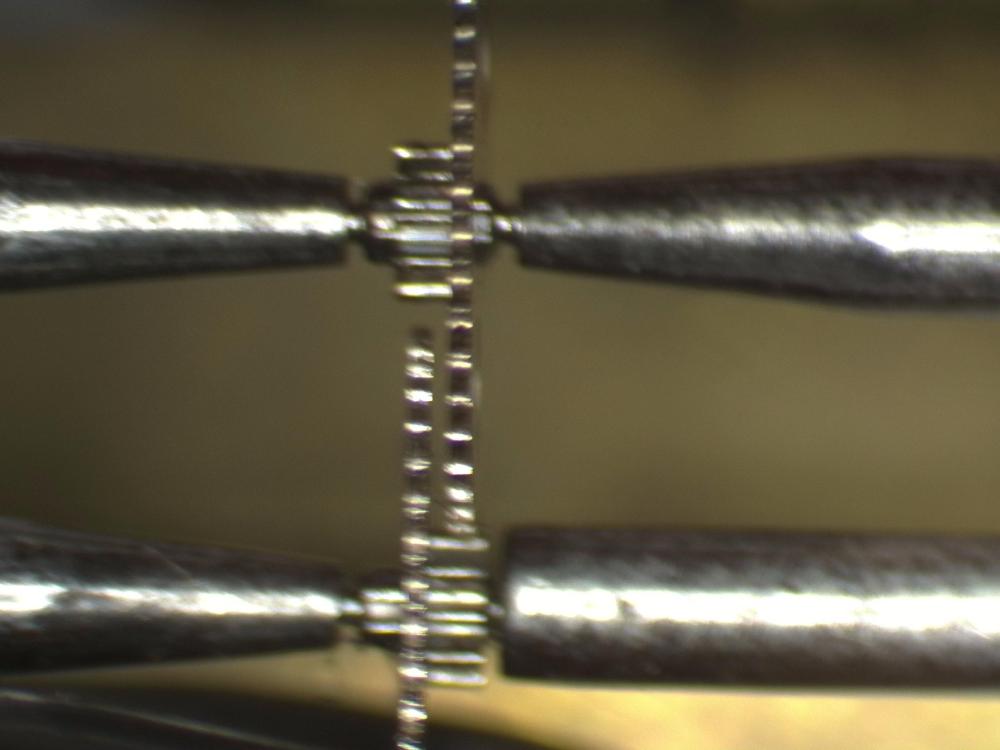

Yes the background history of some of the channels are quite interesting if they would tell us. I rewrote one channel or the person indicated I think basically he didn't have time to go to a school. On the other hand that unnamed channel has lots of viewers and seems a very popular and probably makes lots of money doing exactly what he is doing. But if you know what they're supposed to be doing then things get amusing. Which probably explains why I typically do not watch watch repair videos when I come home almost anything but that When I was in school and we went to BERGEON It was explained that this is made in Canada and they purchase the entire supply each year. I don't recall them saying what it is originally used for. Then its use becomes interesting depending upon who is talking about it. For instance in the American watch and clockmakers Institute magazine horological times they became very obsessed with not touching it at all because of course is going to absorb the oils in your skin. They became very very obsessed with its use and if I remember right they figured out a way of putting it into a brass tube so they can reject it out and cut it off in little pieces. Then you would sponge up whatever it was you are doing you would not wipe out all wiping was a sin and it was never ever reused. Yes they had some very clear defined ideas of its use which was quite amusing. My favorite though was in a BHI journal somebody reviewing their witschi watch expert timing machine excited about they could look at amplitude. In the midst of doing something they wiped the oil off the balance pivots with this miracle substance and lost amplitude so maybe it's not a miracle substance and maybe it shouldn't be universally used every place. Then the video is way way way too long I'm not going to watch all of it I skimmed over a lot of it and noticed some things which I'm a comment on out of order. Like at the end of the video escapement lubrication was not quite right and some of it may have been done in secret because he needed his loop but couldn't show us some not sure of what he was doing there. Then he winds the watch up super tight I don't recall Him demagnetizing Watch as it goes immediately on the timing machine and you can see what I view as the evidence of lubrication has improperly spread to the escapement which is why the waveform looks a bit rough. On the other hand he showed and talked about the spring for the sweep second pinion as to how tight it should be which I thought was quite interesting in a very clear definition of that. But the most interesting thing was a tool that he has I've seen it used before a YouTube videoAt 43:28 There's a box with interesting mini lathe and interesting fixtures the last time I saw this on a YouTube video the person did not show all the accessories or the box and I'm pretty sure this has to be Rolex tool purchased from Rolex. This is not the tool of a hobbyist even the knowledge of such a thing isn't normally found in their service manual's. So it appears to be that he's had professional training and has access to something that you normally wouldn't have access to. But his techniques are quite interesting and I really not going to watch the entire video to see anything else that distresses me.2 points

-

I'm a little confused here all the watch companies have hyped that their watches are outstanding. f you want to look at a ripoff look at a quartz watch for a couple hundred dollars. I see this all the time where I work with the changing batteries they bring in all these watches name brands and inside is a movement that cost bike $5-$25. Getting a five dollar plastic movement in a case for a couple hundred dollars doesn't seem like a ripoff versus a Rolex movement that's expensive and is probably chronometer certified in a stainless steel case Still seems like a much better deal than they quartz watch. But to a certain degree are right about the hype because of the hype a lot of the Rolex watches are now worth way more than what they cost brand-new. Then Rolex of course doesn't play games with artificial shortages which a course and bumps up the price even more some of the new watches on the secondary market cost more than they would if they were brand-new. But still it still a very nice watch inside.2 points

-

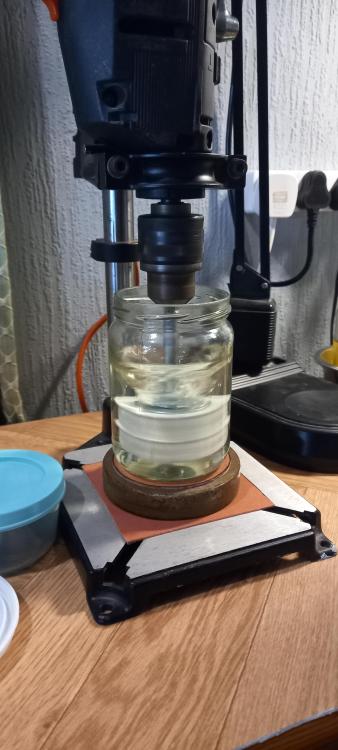

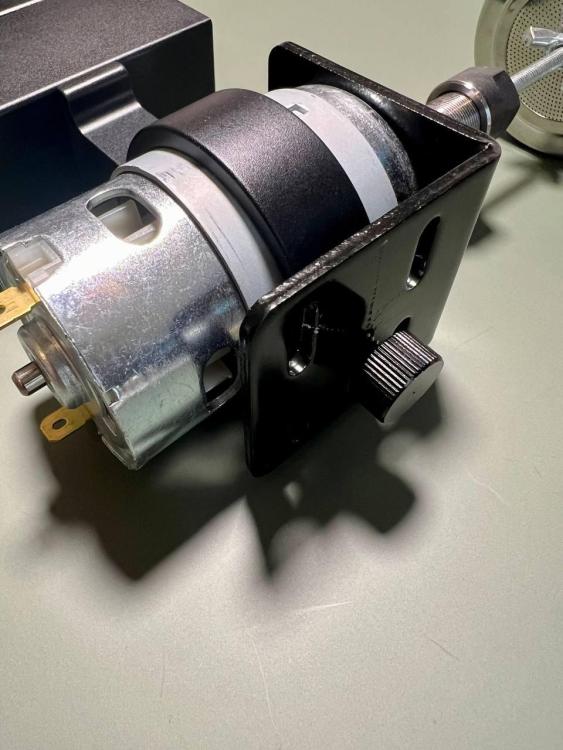

A couple more washers for those of us that like to potter around making gadgets. The small one just a a cheap dremmel type tool , this one is cordless which is handy. Mounted on a very cheap lab stand, i should have spent a few more quid really, the locking nuts and brackets are a bit pants, the clamp is sort of ok, but its completely stable because there's no weight to any of it and its extremely quiet when running. Another 15 quid would have got me a much better stand. But all in all i like it, the lowest setting on the dremel is perfect and a touch above that to spin off the cleaner. The big one is a drill and press bought this year at a carboot for a fiver. Very stable and the voltage regulator for 15 quid gives it plenty of speed adjustment. The travel on the press is 75mm which is perfect for lowering the baskets i made, i just had to remove the big return spring in the press and tighten up the travel mechanism. It took a little while to find all the right nuts bolts and couplings and some adjustments had to be made but not a headache. I was thinking of adding an impeller to the spindle of the drill but there already seems to be a bit of a vortex going but adding some wave breakers will be an Idea.2 points

-

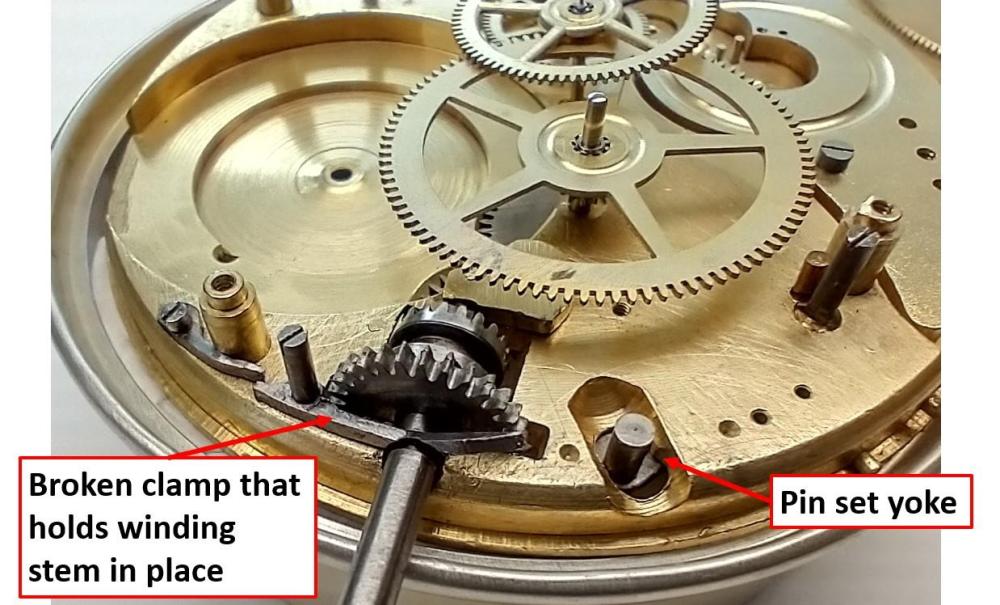

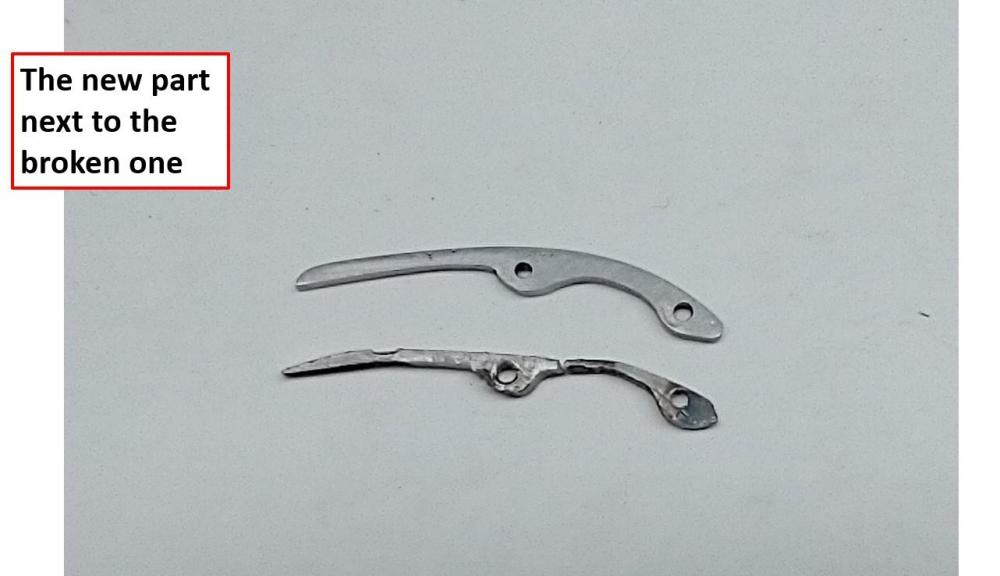

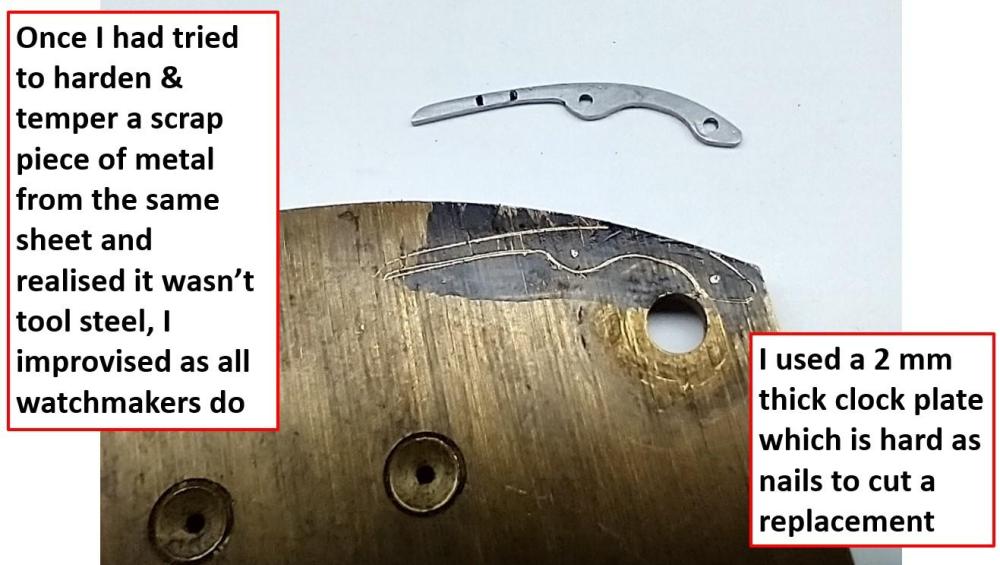

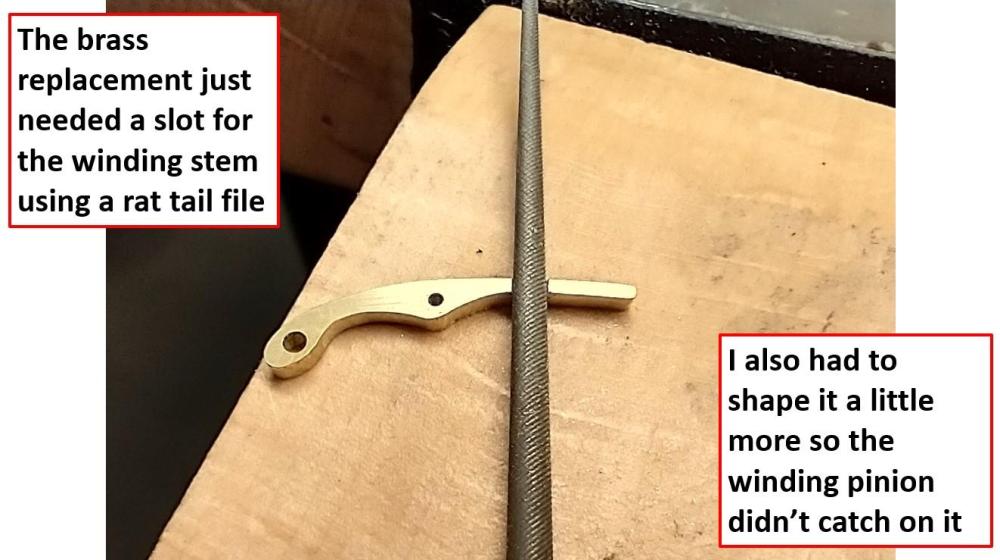

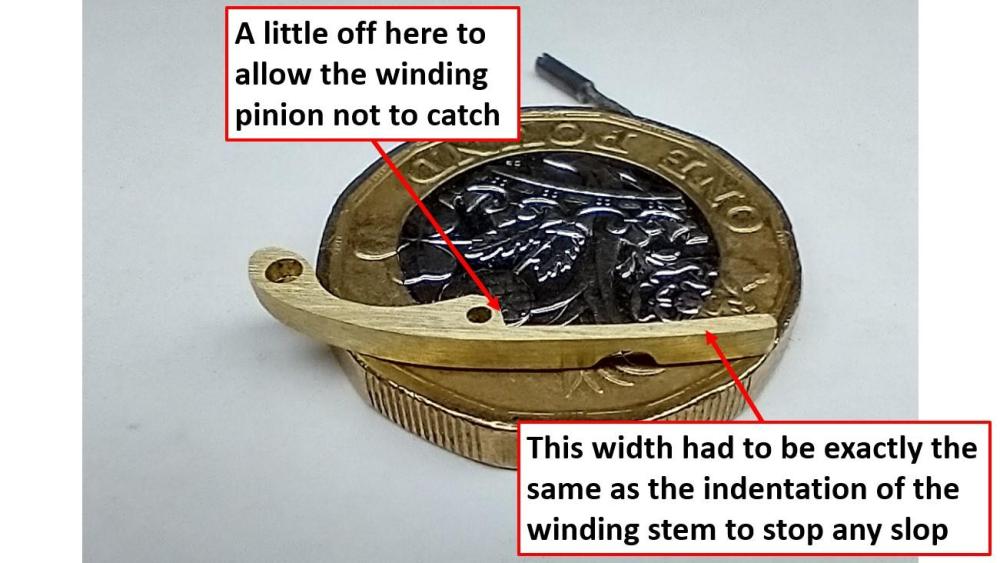

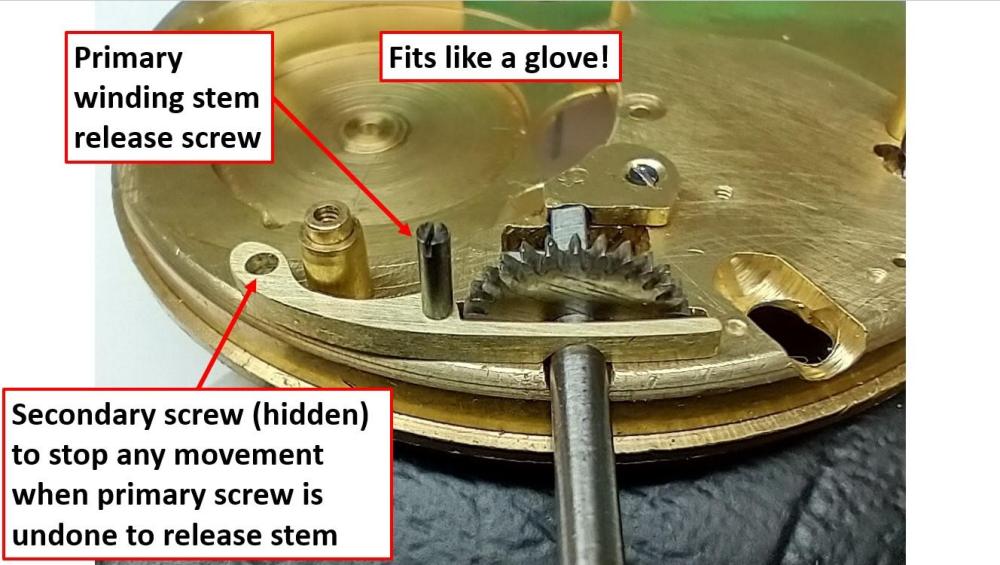

Hi all, I recently had an 8-day watch/clock to service and found that the winding stem fell out of the watch very easily. It is a pin-set movement, so the winding stem shouldn't be able to move. It should only wind the movement. My first thought when I was handed the watch was that there must be a part that was broken for this to happen. The movement doesn't have a setting lever, as the watch yoke is pushed toward the motion work to set the hands, but it does have a part that clamps over the indentation in the winding stem and is held by what can only be described as a winding stem clamp screw. This screw when loosened will allow the winding stem to be removed from the movement. Anyway, when I started to disassemble the movement my guess was true that the clamp that held the winding stem in the movement was broken. It looked like in the past someone had fabricated this broken part as a replacement for the original and had used metal that wasn't hardened and then tempered, so the inevitable had to happen and it broke. Probably when someone thought to set the hands that the winding stem should be pulled out and not realised that it is a pin set, or what is commonly known as a nail set watch movement. I decided to get out my tool steel sheet and fabricate a new clamp and then harden and temper it, only to find that once I had spent some time cutting the shape with a coping saw and filing it to the correct size and shape the sheet that I bought from Cousins wasn't tool steel, or what Cousins refer to as 'Carbon Steel' but some crappy sheet of mild steel that their Chinese supplier had ripped them off with. So, a word of warning here. If anyone is intending to buy a sheet of this crud from Cousins to make keyless work or tools etc. you'll be wasting your time and money.2 points

-

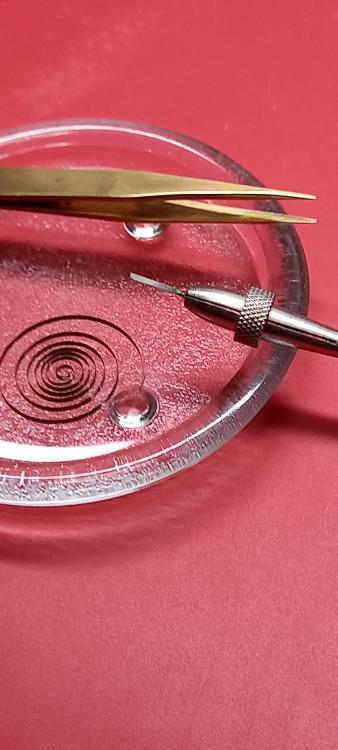

Hi All, I had some free time to work on a Pocket Watch I picked up a while ago. It wasn't running but it looked nice and appeared to be intact so I took a gamble. It came in a tidy Dennison Star case and the movement says cal. 529 although I could not find much information about it. I think it is a Cortebert but Im not an expert. Disassembly was straightforward and everything appeared intact (apart from a missing adjustment screw on the balance). Nothing seemed worn or damaged and a couple of runs through the watch cleaner to clear the congealed gunk and it came out nice and clean. Now I have this thing up and running Im not actually sure what Im going to do with it, Im not much of a waistcoat guy! Not terribly dirty but a lot of gunk on the pivots. And finally all clean and running!!1 point

-

Hi everyone! Here you can find an idea on how to build your own cleaning machine for less than 150$ using some stuff from Aliexpress (or Amazon). First - the video: Second - the stuff (all the wire connections were made w/o soldering - only crimping terminals were used; also 3 additional holes were drilled): Hope it will be helpfull to someone.1 point

-

I guess I'm another old bugger. I must have gorilla hands; all the cots I've tried were so tight as to be almost painful. I've invested in good tweezers, good screwdrivers, good pin vices and tool holders, and good movement holders. Even before cleaning, I touch the parts as little as possible, and after cleaning - not at all. I will put on cots if I cannot do something without finger-manipulation, but I've been practicing with my tweezers and I believe I'm getting pretty good. Learning to dress them right helps also. But I do have a K&D winder that I like very much. And I always have the Rodico close by. And I know how to oil these things. So I am hoping for a measure of absolution too.1 point

-

As I said the Timex of high grade watches. For which I'm not trying to insult Timex but they still mass-produce a very very high grade watch. But there's other of watches that are possibly nicer it better but they're not made in the same quantities. Typically they would cost way way way more money. They're not as well known. This is what happens for a A few key placements and movies for instance like who gets to have their watch in a James Bond movie although Omega has been there for quite some time then you really can't fault a company of that still has a lot a hype whether they're doing or not. The purpose of companies are to survive and if you want to survive you have to be on the tongue of every single person thinking about buying a watch.1 point

-

current update on this issue, I went out wearing the watch and it started working so I put it back on the auto winder and it stopped after 8 hours, I checked the mainspring and no power it was completely let down. I took the auto works apart cleaned it again put it back together still same issue. I purchased a used auto mechanism complete unit which came today, I have fitted it and the difference I noticed straight away was that my rotor had some resistance as it went round where as the old one when the rotor was on it whizzed round with the slightest touch really fast. fingers crossed this was the issue. I will let you know.1 point

-

How fine of grain sandpaper are you finishing with? It's important to "cross the lines", go in different directions, so you can see when you've really erased the last grit's grain. Then, if using a micromotor, you really have to go fine with the paper or it's going to be painful. This would go better with a large wheel (hard felt) on a buffer. You also have to change directions with the buffing. The polishing can actually augment remaining defects, which just get bigger if always going the same direction. And sometimes it just goes all orange peel and you have to go back to paper. Having the right paste for the metal is good, but there's a lot of voodoo superstition around that. Good technique is a bigger deal.1 point

-

Before the Brexit, I used ebay.co.uk and a company named GABIELI UK to BG that delivers from UK to Bulgaria goods bought by bulgarians from Ebay. Now i use Aliexpress, delivery is from China and takes about 3-4 weeks normally. The drill bits are the same as what You have, I order normally 1-2 times per year and have ordered more than 10 times till now.1 point

-

Are you sure there's no contaminants either on the wheels or in the Polinum itself?1 point

-

Marc Like your site https://watchmender.wordpress.com/, especially the eta 2789-1. This movement was my first attempt. 3 pivots broken, 'pings' everywhere. Did not photograph anything. 1 month later began Marks course and found out where I went wrong. Ha!1 point

-

1 point

-

Marc. Wrong metal? I think you are correct. When I look a the broken stem it really does shine. Cannot mark it with tweezers or screwdriver. What I do have, as a Christmas present to open in a few days time (woohoo) is a screw removal tool. Not sure if it would work on a sealed end product like the crown. But, who knows?1 point

-

Following up on @gpraceman's take, go for the Eakins. There's probably a good year between production of our two scopes, which I imagine accounts for the minute hardware differences (the Eakins grub screw was 2mm, AmScope is probably 3mm). The hole in the Amscope is kinda dumb, and I'm not sure how to attribute that. For the cost though, the Eakins wins hands down. I think the difference between the two is something like 50% ($400-something vs. $600-something for like setups) I have a feeling, having paid attention to this topic for a while now, that the top of the heap will change over time given the nature of Chinese white labeling, but for now, it's not really a contest. The 3D printed accessories are super cool. One of these days, I'll get my printer operational again, or I'll sell it and get another. Actually... I think I'll take advantage of the holiday season and get it on FBMP this afternoon... What am I waiting for? I initially got a Canon mount for mine because I had an old but decent DSLR. Unfortunately, I have no idea how to use it, and photography is its own domain. I'm full up on domains right now with some of yesterday's other activities @gpraceman weighed in on. Messing around a little with his camera was somewhat inspirational. It was super easy to use, and plugged right into an old computer monitor I happened to have sitting nearby. I don't know that it'd be preferable to work on it like that, but my nearly 4yo daughter and son (found out yesterday right after @gpraceman left) in progress will be able to watch over my shoulder. Watchmaking of course, but also soldering electronics, fixing toys, micrometeorite hunting, and whatever else comes along. The 0.3X Barlow gave me more than enough working room to tackle some clunky stuff (thinking toy repair), and normalizing the microscope and working in such a manner will be great for both of them in the future. TLDR; Don't pay for the AmScope branding, go for the Eakins. Also, get the dedicated camera unless you're a photography buff.1 point

-

Keeper or not, just running isn't all, should see ON TIMEGRAPHER how HEALTHY its running in various positions, specially that a balance screw is missing. Your right its a cortebert, you know Russian Malnija copied cortebert Malnija 3602. I am not sure if balance screws off malnija fit your watch. Rgds1 point

-

It's unusual that you had no luck with this method as it's a well established technique for dealing with the removal of otherwise inaccessible steel casualties from non-ferrous parent material. There are a couple of possible explanations for this though, the first of which is that the stem was made of stainless steel (alum doesn't dissolve stainless steel), which would be unusual but not impossible; the second is that it was the wrong kind of alum. Technically "alum" refers to a range of compounds (see here). It may well be that some alums are better than others for dissolving steel. I believe that the one to use is potassium alum KAl(SO4)2·12 H2O. This has always worked well for me. I think I'd be more worried about the potential for damage from a slipping or breaking drill bit, or the drill bit actually impinging on the threads in the parent material. I'm pretty certain that the alum won't stain or otherwise damage the gold, however, a simple experiment with an otherwise redundant gold plated item would answer that question.1 point

-

1 point

-

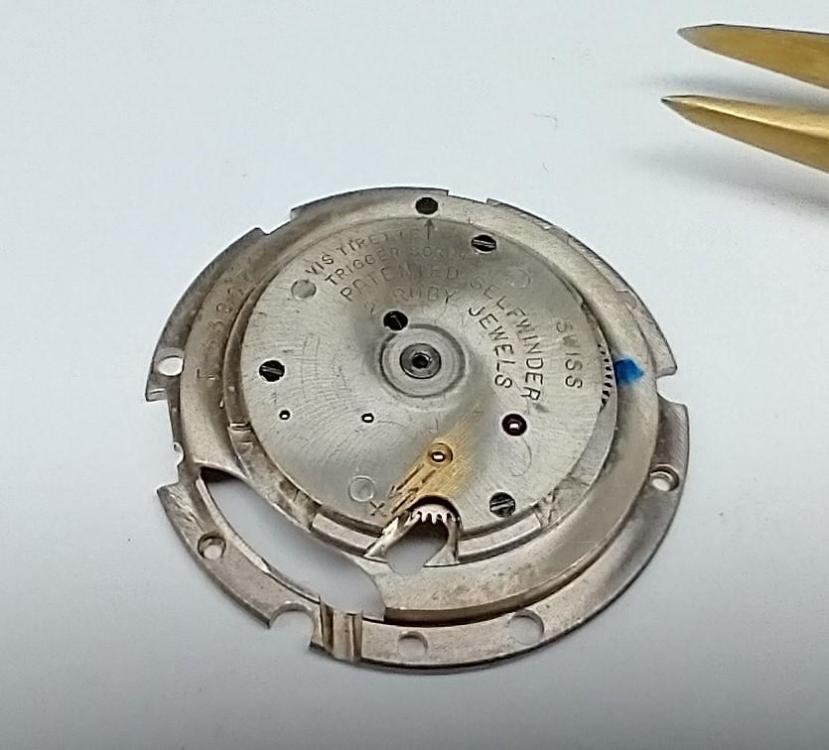

My tutor never wore finger cots, as he was 'old school' but he did handle parts from the sides and was constantly washing his hands like he had OCD. I never once saw him handle parts like Times Radical, therefore he could never etch his fingerprint into the plating. Here's the dial side of a Rolex 645 I serviced this week with a finger or thumbprint beautifully etched into the rhodium plating. That will never come out. Probably the same fettler who scratches the arrow and 'W' on the rotor to denote which way it wound and more than likely the same guy who files down the replacement bush on the upper auto bridge. Genius! Incidentally, they had set that bush 0.06 mm to one side throwing one of the auto wheels out, as you can see from the photo. I used my depthing tool to work out where it should have been in the second to last pic. I know I've strayed a little off-topic, but it highlights what fingers on bridges can do and if that's acceptable, then what's the harm in scratching marks into the rotor and bridges and filing the top of bridges? Then the watch ends up on someone else's bench and the customer wonders why it costs so much to rectify the previous lash-up. Rant over! The last pic is of the movement minus the auto works or rotor in place1 point

-

Because of the concern of water here I use 1 percent Liquinox and deionized water, change the IPA rinse every time and into my dehydrator with the fan. No rust. The cost savings, no offensive odors and cleanliness are too good to pass up1 point

-

1 point

-

Just because a so watch repairer on youtube using it to clean watch parts and plate and bridge thought to give it a try.1 point

-

1 point

-

Three things with this sort of dial. 1 you leave it be, but the movement will more then likely pick up what is peeling of the dial so the movement will probably stop. 2 you pay a lot of money and have the dial restored. 3 you look for a replacement dial.1 point

-

Apparently this is how he's made a living for the last 15 years. I watched a few more, he constantly moans. Yes his practice is very poor considering its his profession.1 point

-

1 point

-

Well, here I am again. Doing an update. It's been 24 months since I began my journey on this watchmaking hobby. Where am I at, what have I achieved? Looking back, time has gone quick. Covid has been and gone...ish. Although I, like others of my age group are still reticent about mixing in a large community situations. This hobby has been a godsend. Something to do, but most of all a change of life direction. Achievement is the name of the game, and to do something that uses acquired physical and mental skill gives great well being. That's what it has done for me. The internet has allowed me to study and to practise physically from visual and audio stimulation. Like most beginners, I started without direction. Youtube videos, 'I've only been doing this two weeks and I fully serviced this vey intricate watch with many complications'. Oh bloody ha ha. I believed it and started. Ebay sold me a cheap kit (still use most of it) and I purchased watch movements that needed repair (idiot). If they need repair it's because they are broken and if they are broken how can you fix them if your don't have the skill? They are still there in my storage. I had no idea what I was doing. I do like Seiko's so I tried unsuccessfully to repair some. But I did watch Mike's 'My Retro Watches' who suggested that a course would be a good base, and mentioned Mark Lovick. I was lucky and got a 40% Christmas reduction. At last, guidance!! How did he know that everything I had been doing was wrong? Hmmmm. I have mild dyslexia in that I have great difficulty in assimilation of written instruction. I react to physical and visual stimulus. Exactly what Mark offers. So began the extended learning curve. Overcoming the history of broken pivots, springs , lost items and other breakages, I learned system and most of all the skill to practice. An hour or two every day gives a good depth of skill in use of tools. Where am I? I can disassemble most watches with basic complications, day and date, not yet chronographs. I can assemble all the watches and service them to be better than prior to disassembly. I have a plethora of tools and thanks to members even know how to use them. Am I where I wanted to be after 2 years. No. I was going to do a service on my own Breitling chronograph purchased by me for my 18th birthday in 1966. But I don't want to do so just yet as confidence is not there. Soon. Maybe. Am I enjoying the hobby? Oh yes. Will I continue? Oh yes. The biggest help has been 3 fold. 1. Me, getting off my backside and making the effort. 2. The internet. Courses and YouTube. 3. The membership of this forum. Made good friends and got good guidance. 24 months on. Merry Christmas and a Happy New year to you all. Ross1 point

-

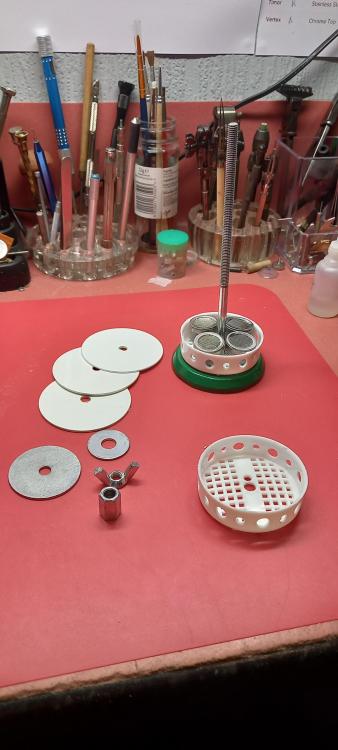

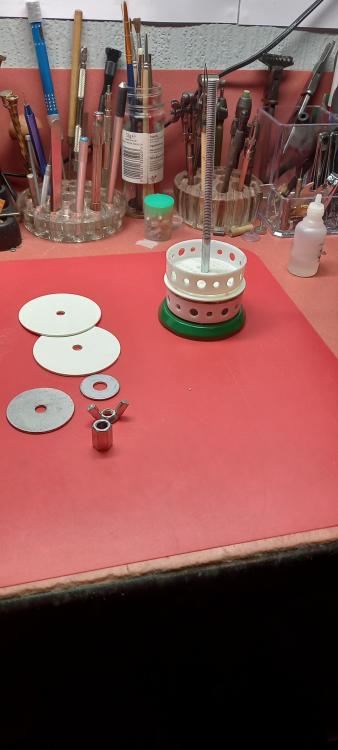

Another upgrade for you Ross. The little plastic baskets from cousins, the center post is too flimsy to spin the basket outside of a neatly fitting tin as per previous post. So i did a little customising to make it more stable. Remove the center post of the basket completely and drill out a 6mm hole in its place. Add in some more holes around the side of the basket to your liking. The base is just the lid off a sauce jar, i might change that or do away with it altogether but it does make the assembly more stable and creates a stand for the basket, you could add some holes to it if you wish, i probably will. The driveshaft is a bolt that connects kitchen worktops together it was just the right length and is an m6 thread size,you will need an m 6 wingnut for the top locknut. The plastic disks are cut from the outer skin of an old upvc door panel, just cut with a holesaw and then spun in a drill to clean them up, probably add some holes to these too. I think the pictures are self explanatory, i have some bits and pieces coming in the mail plus some odds and sods to make up the drive for the basket and a heater. Ideas are an electric drill with a seperate speed regulator, a striped down 2 speed cooling fan, these are great if you can adapt one to fit into some kind of jig ( very quiet induction motors and they run forever ). Also in the mix is an old drill press, a cheap laboratory stand with holding arms and dc car windscreen heater. Enjoy , i have too much time on my hands at the moment so theres more to come For some reason the pictures didn't add here they are.1 point

-

There are older watchmakers who never saw much less used a finger cot, but you get trained to handle parts with tweezers not fingers- even if they are about to go in the cleaning machine. It gets tricky with the barrel, especially if you are obliged to wind the spring in by hand, but again good technique is to use a winder, if you don't have one that works for that barrel, you get one or modify another. If you look at old vids of people working in factories, they do handle mainplates by the edges and so forth, but definitely avoid handling parts with fingers. They used to make a soap that acted as a skin barrier to prevent our naturally acid ph skin from affecting finishes or causing rust. Also I heard from old guys there was a total ban on eating citrus fruit during the workday including breakfast as the oils can be hard to remove from skin and can stain plates and bridges. I won't pass judgement on this guy, vid is way too long to watch even at 2x speed, but a quick scan shows he does seem to know what he's doing- but I wonder if his pieces end up at another watchmaker a year later...1 point

-

We would really need to see the crown positions all four of them to see if you have a poise error of the balance wheel. Then gravity is interesting it influences the hairspring in the crown positions when it pulls they hairspring down it causes the hairspring to rotate the balance wheel ever so slightly causing a beat error. Although 0.6 seems a little higher than usual but if the watches keeping time I probably wouldn't worry about it. People often times get way too obsessed with trying to make watches keep perfect time which can lead to interesting consequences and not necessarily make the timekeeping better.1 point

-

So, I did pull the trigger on the Proxxon Micromat 230/E, and I'm super happy with it and can wholeheartedly recommend it. It's truly a night-and-day difference between my Proxxon and the lousy tool I got from Cousins. The vibrations are minimal and it's so quiet it bothers no one. IMO, worth every penny!1 point