Leaderboard

Popular Content

Showing content with the highest reputation on 12/18/23 in all areas

-

There are older watchmakers who never saw much less used a finger cot, but you get trained to handle parts with tweezers not fingers- even if they are about to go in the cleaning machine. It gets tricky with the barrel, especially if you are obliged to wind the spring in by hand, but again good technique is to use a winder, if you don't have one that works for that barrel, you get one or modify another. If you look at old vids of people working in factories, they do handle mainplates by the edges and so forth, but definitely avoid handling parts with fingers. They used to make a soap that acted as a skin barrier to prevent our naturally acid ph skin from affecting finishes or causing rust. Also I heard from old guys there was a total ban on eating citrus fruit during the workday including breakfast as the oils can be hard to remove from skin and can stain plates and bridges. I won't pass judgement on this guy, vid is way too long to watch even at 2x speed, but a quick scan shows he does seem to know what he's doing- but I wonder if his pieces end up at another watchmaker a year later...6 points

-

4 points

-

Before the ‘Iron Curtain’ fall, in my country was not possible to buy watchmaker tools. There were no any. So, if one wanted to have, then he would receive them by inheritance or make them. And, my father was (unknown) poet and writer… This is my first lathe, I was 14-15 years old when I made it. The base of it is a Vernier caliper I am OK with Nev. No problem, will show pictures. Will make new tweezers to show how. Will try to do before the holidays3 points

-

@nevenbekriev you've blown my mind (again)! I believe every word and I'm not doubting your approach works for you, but I cannot see me making my own tweezers out of kitchen knives in this lifetime. For what it's worth; brass Dumont 1AM for me 99% of the time. I have some good quality steel No.4 & No.5 for hairspring work, opening shock springs etc. but picking up small parts with those in my hands is a recipe for disaster.3 points

-

3 points

-

I started servicing and repairing some six years ago. Since then I wouldn't be surprised to learn that I have spent an amount of money on tools, consumables, equipment, and accessories corresponding to the cost of a decent Rolex Submariner. Taking my first steps I thought: "How hard can it be?". Since then I've learned that it can be pretty damn hard. BTW, I just listened to a Swedish pod (Klocksnack) with a Rolex representative talking about "Rolex certified pre-owned", where I learned that the reason Rolex can provide that wonderful service for the customers is that Rolex watches a nearly indestructible and so much better built than all other watches. Having heard this, I'm surprised that the stem and crown pulled out of the watch. Are you sure it is a genuine Rolex? I mean, the real thing being indestructible and all.3 points

-

Not to despair directly, at least you have a nice goal to work towards to. As a mechanical engineer I serviced, as a novice, my Rolex Submariner too. However, before doing so, and knowing that working on (certainly by now) such an expensive watch, requires quite some skills. Next to watching lots of Youtube videos (https://weww.youtube.com/watch?v=nUZ3xB5fI-k), I acquired tools and trained myself (over and over again), next to some others, on two 17mm NOS ETA2541 ladies movements. What I'm trying to say, there is a chance that you can repair your Rolex yourself, but you have to acquire the knowledge, tools and skill first. If you are willing to put in all the time, money & effort, you may have, next to your Rolex fixed, an interesting hobby for the rest of your life. If you are not willing, or able to, and you value your 20+ years companion, bring it to somebody with lots of experience and has a very good reputation (preferably to an official Rolex service point). Yes, it will cost you, but you may regret it later if you bring your Rolex to some friend of a friend who's handy with cuckoo clocks. For sure, your Rolex won't be your first watch to have a go on .......3 points

-

So i was about to recommend this youtuber that initially looked quite professional, nice tools some skills good commentary. Watched a good hour of repairing techniques, then onto the assembly, then i realised I'm watching a full video where the guy doesn't know what a finger cot is. Fingers all over a full assembly of a mainspring barrel, more finger grease than barrel grease .See what you think. Times Radical - This rolex explorer almost killed me.2 points

-

So Nev, lets just call you Neville after my uncle Nev if thats ok with you ? You can call me Richard or Rich or I'll even let you call me Dicky or Dick when we get to know each other better . Ok so my mind is also blown and Intrigue has grasped me by the short and curlies. We all need to see a picture of your kitchen/ tweezer combo if you please.2 points

-

Thank you to members for the guidance to watch the video. As a novice I am intrigued to see what I could achieve. I was impressed by his knowledge and understanding of the movement. Some of his comments left me wondering what the owner of the watch under service would think. A 'this will do' attitude. As members say, finger cots? I use gloves, but still am careful. The oiling of the crown wheel? More than I put on as a beginner. And bending the third wheel? What? Scratching the part when using the burr removal tool? If I am ever lucky enough to work on a Rolex, I may consider that video for referencing if I couldn't find another.2 points

-

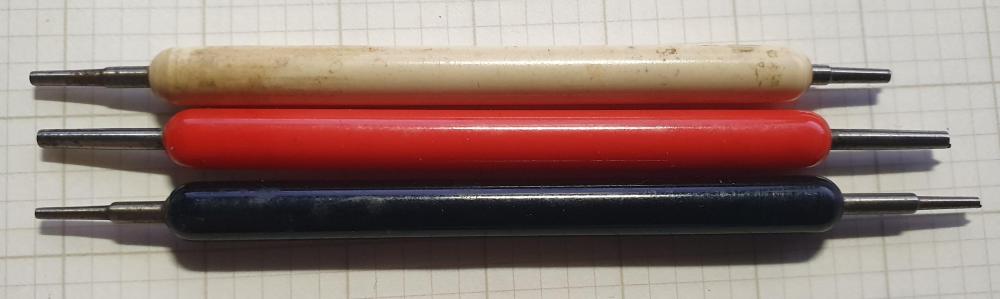

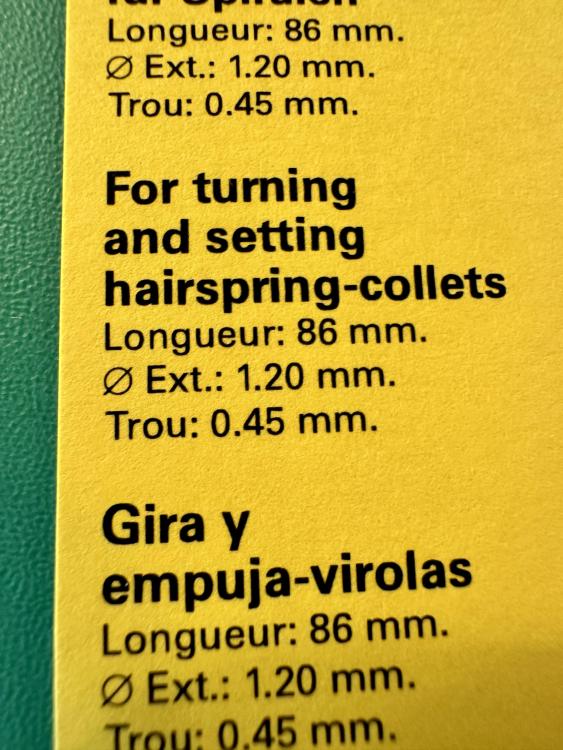

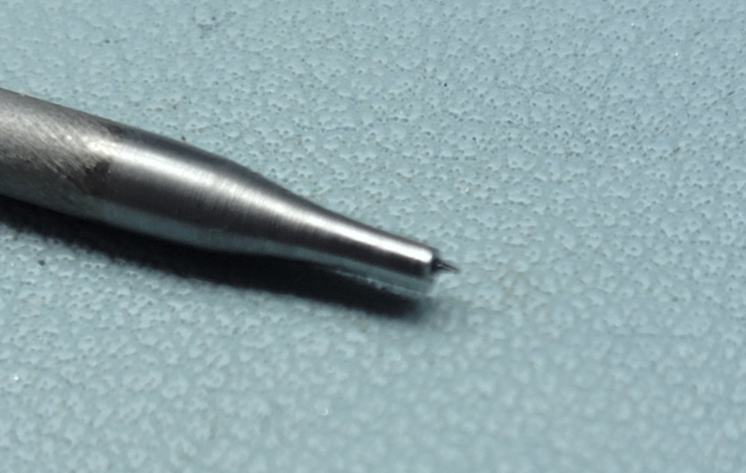

yah…to add.. …here’s my most used Bergeon size. ‘Trou’ is the hole size here but Bergeon sells them in .10 increments. In my mind you’re really trying to make sure it is similar to the collet width you’re working on so the tooth lines up with the break in the collet. To large or narrow and you risk slipping and/or snapping the upper pivot.2 points

-

2 points

-

Try an inexpensive dehydrator for your drying cycle. Parts baskets can be set right on the tray and you can set the temp and turn things over 1 time (or more) so you can prep the next step as the parts dry without having to stand over it.2 points

-

The round end with the tooth looks just like the Bergeon collet tool. I paid up for a couple of those but they have been quite valuable… …the flat end looks like the trowel in my shed. I suspect that end is for a collet adjustment while the wheel is still hanging on the cock, while the other end is easier when the wheel is removed and sitting in an anvil hole?2 points

-

After 20+ years the watch urgently needs a service. If it is done by an offcial Rolex service center all movement parts are exchanged routinely that show the slightest sign of wear (without additional costs). So the money for the service is invested well! Same here Except I practiced on a Chinese clone which was mainly identical to the original.2 points

-

One of the problems with watches especially Rolex watches are there sealed up and not visible to the user. A lot of times on Rolex discussion groups people are very happy that the inherited a watch and it's running perfect and why should they send it to the greedy watchmaker. Yes Rolex people like to complain about the cost of Rolex servicing. But that's sealed up watch has gaskets and over time they will disintegrate and conceivably moisture will get into the watch even tiny quantities. Moisture forms rust and of course lubrication typically doesn't last for ever and if you can combine rust of lubrication it's a nice grinding compound. So yes your watch is in good condition and worked well but is it really in good condition if it's having issues? There really is a reason why watches should be serviced approximately every five years. It would really be helpful to have a movement number? You'll find that out when you the back off or we can probably get it from the model number found between the case lugs.2 points

-

2 points

-

We would really need to see the crown positions all four of them to see if you have a poise error of the balance wheel. Then gravity is interesting it influences the hairspring in the crown positions when it pulls they hairspring down it causes the hairspring to rotate the balance wheel ever so slightly causing a beat error. Although 0.6 seems a little higher than usual but if the watches keeping time I probably wouldn't worry about it. People often times get way too obsessed with trying to make watches keep perfect time which can lead to interesting consequences and not necessarily make the timekeeping better.2 points

-

The fact that the watch is still ticking and the minute hand doesn’t move means that the sliding clutch and the hacking lever are out of position. You will not be able to refit these components correctly without removing the movement from the case, pulling the hands and get the dial off. Without experience in watchmaking and appropriate tools you will for sure damage expensive parts of your Rolex. As Nucejoe said…2 points

-

This video shows the complete process including heat treatment of the carbon steel: https://youtu.be/vCyPSjnNky4?si=K8BkG5XORIijcSS82 points

-

2 points

-

I dont get it, hes talking likea pro,doing 3 watches a day on top of this one. Why something so basic like preventing bare fingers from touching the movement. Not once in the entire 2 hour video does he handle parts wearing cots. Yet his mini lathe was really nice, just another bullshitter I'm sad to say. I wonder if the watch owner would ever watch it and understand the bad practices. I could pass for a rough arsed joiner if thats what you mean ? His comments if true, strongly suggest he does this for a living. In his defence he was fed up with working on it, but i didn't see anything out of the ordinary that a pro doesn't do day and day out. I like to make sense of things, this i can't.2 points

-

Oh, I'll definitely watch this video! The Rolex Explorers from the 1950s/60s are my absolute grail watch. I skipped into the video and accidentally landed right where he is doing the barrel assembly with his bare finger all over the barrel and mainspring. Crazy! PS: I'm not convinced by his oiling technique on the gear train... why oil the mainspring jewels before putting the wheels and why oil the other pivots before putting the train bridge?? Sound like asking for oil to run where it's not supposed to be, especially with the rather generous amounts of oil that he uses. Classical oiling of jewels when pivots are in seems better in every way.2 points

-

Well, here I am again. Doing an update. It's been 24 months since I began my journey on this watchmaking hobby. Where am I at, what have I achieved? Looking back, time has gone quick. Covid has been and gone...ish. Although I, like others of my age group are still reticent about mixing in a large community situations. This hobby has been a godsend. Something to do, but most of all a change of life direction. Achievement is the name of the game, and to do something that uses acquired physical and mental skill gives great well being. That's what it has done for me. The internet has allowed me to study and to practise physically from visual and audio stimulation. Like most beginners, I started without direction. Youtube videos, 'I've only been doing this two weeks and I fully serviced this vey intricate watch with many complications'. Oh bloody ha ha. I believed it and started. Ebay sold me a cheap kit (still use most of it) and I purchased watch movements that needed repair (idiot). If they need repair it's because they are broken and if they are broken how can you fix them if your don't have the skill? They are still there in my storage. I had no idea what I was doing. I do like Seiko's so I tried unsuccessfully to repair some. But I did watch Mike's 'My Retro Watches' who suggested that a course would be a good base, and mentioned Mark Lovick. I was lucky and got a 40% Christmas reduction. At last, guidance!! How did he know that everything I had been doing was wrong? Hmmmm. I have mild dyslexia in that I have great difficulty in assimilation of written instruction. I react to physical and visual stimulus. Exactly what Mark offers. So began the extended learning curve. Overcoming the history of broken pivots, springs , lost items and other breakages, I learned system and most of all the skill to practice. An hour or two every day gives a good depth of skill in use of tools. Where am I? I can disassemble most watches with basic complications, day and date, not yet chronographs. I can assemble all the watches and service them to be better than prior to disassembly. I have a plethora of tools and thanks to members even know how to use them. Am I where I wanted to be after 2 years. No. I was going to do a service on my own Breitling chronograph purchased by me for my 18th birthday in 1966. But I don't want to do so just yet as confidence is not there. Soon. Maybe. Am I enjoying the hobby? Oh yes. Will I continue? Oh yes. The biggest help has been 3 fold. 1. Me, getting off my backside and making the effort. 2. The internet. Courses and YouTube. 3. The membership of this forum. Made good friends and got good guidance. 24 months on. Merry Christmas and a Happy New year to you all. Ross1 point

-

1 point

-

Hi that’s the same set as mine. Mine must be 50. Years old..1 point

-

I don't want to stray off-topic, but credit where it is due. In the same situation I for one would not display a fraction of your creativity or skill in execution. Are you suggesting that this is normal in Bulgaria? And now you can acquire the commercial tools, but you prefer your self-made ones. How much of your time is spent making tools, and how much putting them to use?1 point

-

1 point

-

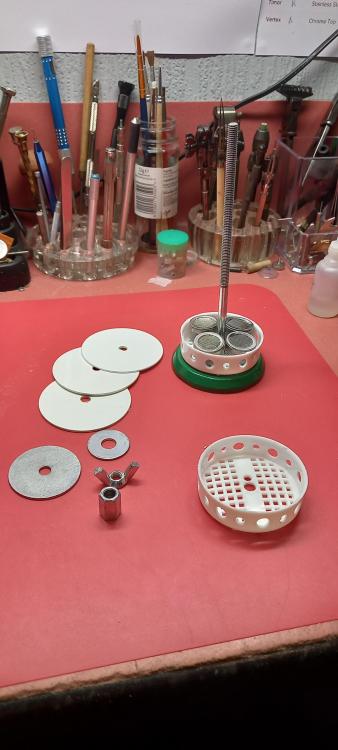

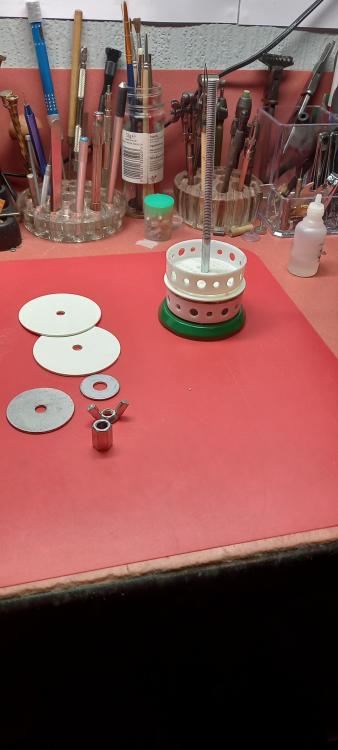

Another upgrade for you Ross. The little plastic baskets from cousins, the center post is too flimsy to spin the basket outside of a neatly fitting tin as per previous post. So i did a little customising to make it more stable. Remove the center post of the basket completely and drill out a 6mm hole in its place. Add in some more holes around the side of the basket to your liking. The base is just the lid off a sauce jar, i might change that or do away with it altogether but it does make the assembly more stable and creates a stand for the basket, you could add some holes to it if you wish, i probably will. The driveshaft is a bolt that connects kitchen worktops together it was just the right length and is an m6 thread size,you will need an m 6 wingnut for the top locknut. The plastic disks are cut from the outer skin of an old upvc door panel, just cut with a holesaw and then spun in a drill to clean them up, probably add some holes to these too. I think the pictures are self explanatory, i have some bits and pieces coming in the mail plus some odds and sods to make up the drive for the basket and a heater. Ideas are an electric drill with a seperate speed regulator, a striped down 2 speed cooling fan, these are great if you can adapt one to fit into some kind of jig ( very quiet induction motors and they run forever ). Also in the mix is an old drill press, a cheap laboratory stand with holding arms and dc car windscreen heater. Enjoy , i have too much time on my hands at the moment so theres more to come For some reason the pictures didn't add here they are.1 point

-

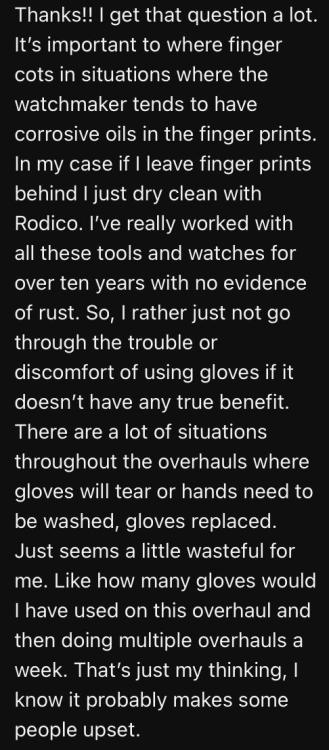

I completely get that, i hate wearing cots the difference in the use of tweezers and drivers is huge for me when i dont wear them. Ive worked with bare hands for 40 years and hate gloves, i adapted not to have to, handling glass is the only except and then i dont always wear them unless its 6mm plate or heavier. So i dont always wear cots and rarely use a cushion, if its in a holder i dont need to touch the movement and can spin it over if needed with wide tipped tweezer. Barrel assembly is different i need to use fingers to handle that and anything to do with the dial. If you watch him assemble the barrel his finger goes right inside all over the mainspring he just oiled, rodico goes no where near it afterwards, he doesn't reoil it and pushes the lid straight back on . Anyone watching his video can see his answer is false. Shame because he does seem to know his his stuff. I think with this guy he does know what he's doing but he doesn't actually care that much how he goes about it. Thats complete pants, " in situations where the watchmaker tends to have corrosive oils in his fingers prints ". Doesn't everybody always and not that long after washing them. Dry clean with rodico that ive just handled with my fingers, i think he needs to look at how much oil that rodico has absorbed from his fingers. How many gloves would i have used on this overhaul large bag of 650 cots for a tenner. If you wipe them with ipa before you start or reuse them the 6 will last the day out, thats 3 months by my reckoning. Maybe I'm having a bad day and just feel like ragging someone to pieces .1 point

-

My latest restoration/repairs. A really nice 1959 Sea King cal 11AFC and an equally fine 1962 Model 23 cal 10BZAC. While I love the looks of the old Sea King, the 11AFC movement is not my favorite to work on re: fixed pallet stud and a very delicate click/click spring configuration that really doesn't make any sense at all. On the other hand the Model 23 10BZAC is the a great Bulova workhorse movement from the past IMHO. Such a straightforward, robust design with good parts availability for vintage.1 point

-

I like to use tools made by me. Not that I don’t have fancy swiss made tweezers, but compared to what I use, they seem to me like from some child-adolescent set of tools… They are stainless and antimagnetic, and this features together exclude the feature ‘good’… I also like the straight hairspring tweezers, because if they are good for hairspring work, they generally are good for all other works. That’s why I have reshaped almost all tweezers I have in such manner, I mean pocket watch hairsprings. People usually have a pair of good hairspring tweezers that keep in a special box and use them only for springs, and handle them with extreme care. Not me, I use careless, not afraid what will happen if drop them on the floor and tips bend or something of the sort. Reshaping and sharpening is habit that must be learned and it takes no more than 5 minutes to bring the tweezers in perfect shape. My advice is to make tweezers this way: get 2 good steel small kitchen knife blades. Rivet them together by 2 rivets on one end, then use bench grinder to shape tweezers out of them. The kitchen knifes are usually stainless, but hot antimagnetic, as they are made of real steel. This is good, as they will be hard and will wear really slowly, and will not lose the shape. Magnetization is not frightful, as demagnetizing, when needed, takes 1-2 sec.1 point

-

I will check and report back The tip starts at 0.18mm and narrows down to a point. The hole diameter is 0.6mm. I would have gone for a smaller hole but didnt want to deal with breaking bits this morning!1 point

-

You nailed it. Bergeon 30017 has the same design on one end. Not the trowel however.1 point

-

Oh, I had no idea, thanks for enlightening me! I’m fed up with all YouTube videos and pods about Rolex watches (80 % of them?) I understand it, it draws attention, but it also makes Rolex stand out as exceptional and superior to everything else. It becomes a vicious spiral. Yes, Rolex watches are high quality watches, but the world of horology is so much more, and people in general miss out on it believing Rolex is the be-all and end-all when in reality it’s far from it.1 point

-

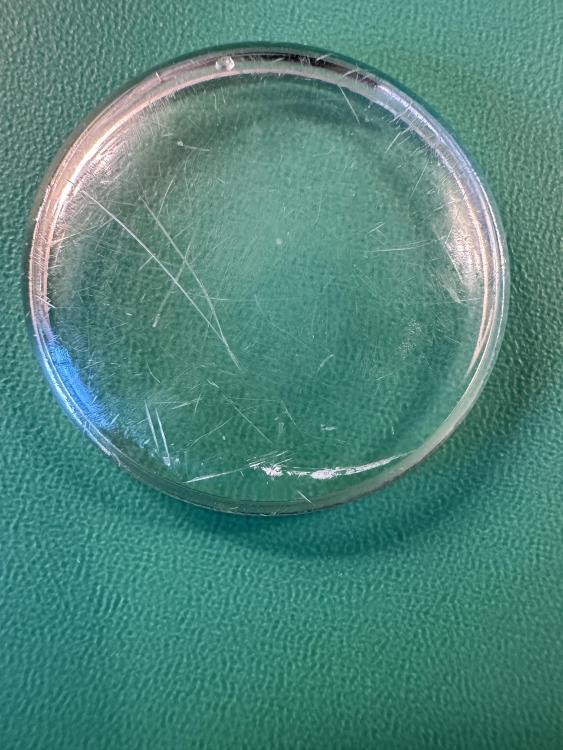

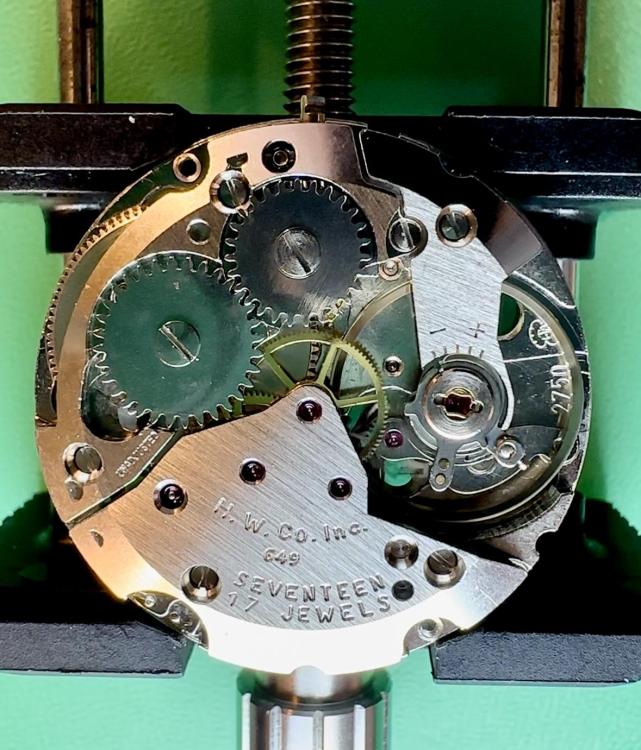

…so its looking good. No issues with the crown removal or the movement. No rust and looks to have never been serviced. Dried gunk. There’s that greenish glue holding the hairspring in the stud. The hole in the barrel bridge has been tidied a bit… …I’m waiting on a new crystal as the old one was cracked and not just scratched. A special Stella 24 1/2 says the interwebs. There's extra importance to the crystal here as it holds everything together so hopefully it’s the correct size…1 point

-

Number five the same brand as my number two is typically only used for hairsprings. I find any time I start to use them to grab a hold things they have a habit of flying away. So once I complete whatever task I'm using it for a occasionally when I'm putting gears in the watch I might use of the move some things around because the tips are finer than the number two's. But once I complete my task they'll back in the drawer to avoid things flying away.1 point

-

At home I have just the disc with jewels all the other bits and pieces are either missing or somewhere else. On the other hand when I was at work once with a bent balance pivot and not wanting to replace the staff The tool came in very handy and I basically didn't use the bits and pieces that are a guide. I started with the biggest hole and eyeballed it and it worked out really nice. Nice straight pivot didn't have to replace the balanced staff and everything was good conceivably depending upon things are probably break the staff and I don't remember if I refinish the pivot afterwords are not. I'm tending to go with I just straightened out and everything was fine then because the Swiss can they've upgraded the tool probably updated the price also. There is with the new version looks like and a PDF attached of how you're supposed to use the thing. 7135 7136 30350 new.pdf1 point

-

I use feeler gauges for the steel. There's a discussion on annealing here1 point

-

Videos didn't open on my device, see this walkthrough helps any. Go on to similar post on top of posts column, click on ETA 2472 - Disassembling the automatic device Lack of end shake is the likeliest issue. Good luck1 point

-

I must say that I used to watch a lot of channels and have unsubscribed as I have learned a lot more from here. There seems to be more well edited videos out there than genuine teachers. Also whilst I applaud anyone having a go with watchmaking and a YouTube channel I get rather cautious when bigger channels laud them as watchmakers. I know, I’m a grumpy old git but I hate people pushing sloppy practice out there as marvellous. Nice tools don’t make a craftsman, I’m pretty sure Rich I could give you a crappy old chisel and you would be able to sharpen it quickly and perform a good job. We do have to consider that a lot of these folks do not have a background in watchmaking, but surely they could try and learn best current practices. Tom1 point

-

Do You know what is axial free play, how to check it and judge it is OK or not? Seems that the sweep second wheel has no (axial) free play. This probably means that the stone above the wheel has shifted. The stone has hole, but it is not real hole jewel. It is rather a axial jewel for both 2nd ant 4rth wheels and can shift when the minute hand is pressed. First of all, take off the 2nd wheel bridge and look at the stone I speak about. I guess You will need to press it until it goes down and it's surface is level with the bridge. Then, put the bridge back and check if the 2nd wheel turns free and axial play is not too much. Then put (only) the 4th wheel and again, see if there is some free play and turns free. Enlarging free play of 4th wheel leads to decreasing free play of 2nd and wice versa. So, by shifting the stone, You must ensure the both wheels feel good1 point

-

1 point

-

Consider investing in a microscope! It makes fault finding so much easier!1 point

-

A couple of things I would check: side shake and end shake for the sweep second wheel. Also for the third wheel.1 point

-

Hello and welcome. Yes, the wheels aren't free, they would carry on running for a while without power.1 point

-

Welcome to the forum, enjoy. Looking the vids there is something binding ie the first vid shows the wheels moving but not freely.. At a guess a bent pivot.1 point

-

I noticed the date jumper spring is not positioned correctly, you can see through the opening window in the date bridge that it is not perpendicular to the jumper and more at an angle, it might seem like it does not matter but that issue could be causing too much resistance on the date wheel and maybe shifting the date wheel tooth just enough out of the right position for the date trip arm to strike the date wheel tooth, also on these models the tension on the canon pinion drive wheel could be too loose to carry the trip arm all the way through on its own,, but it should still work with a manual hand turning of the stem, I hope this helps, just more to check on1 point

-

This involves hands, dial plate, date disk removal to gain access to the keyless and while there to check the minute train as well. The least would be keyless has misaligned, and what caused it, and likely to need a part replaced with new. This is a fine jewel, best to entrust it in experienced hands. Rgds1 point

-

0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)