Leaderboard

Popular Content

Showing content with the highest reputation on 12/14/23 in all areas

-

I concur with Neven, this is just a retaining clip.3 points

-

This has nothing to do with antishock. Just cap jevel fixed in place by the spring. In Rolex too.3 points

-

3 points

-

I just got all the bits and set it up a week or two ago - I am waiting until I have a candidate watch to try it out on. When I set it up every watch I opened was missing dial feet, now I have the contraption I haven't had one...typical I think I should try the electrical system first, then if I hit any problems I can revert to the electrical-less option and use direct heat. But now I write this, I'm thinking it would make more sense to try it out on a scrap dial before going at the real thing. I'm on holiday from Friday for a week so will fire it up when I get back and see which mode gives the best results3 points

-

Might be of interest: https://www.watchrepairtalk.com/topic/1967-how-to-open-a-victorinox-watch-case-back/ The older versions of this watch used to mimic a srewed on Rolex case back. In your case it‘s a screwed on back very likely though! https://youtu.be/b8PrKJNZIdE?si=9g4MIHdMUEYmhJmI The cheapest way of screwing off these backs is glueing on a big nut with super glue and using a normal wrench. After opening you can dissolve the glue with aceton (or nail varnish remover).3 points

-

The jewel is press-fitted, just like the jewels in the plates. This is for all contemporary watches.2 points

-

Stephen dont ! I nearly laughed . Horrortech. Well my order is in, how about the rest of you2 points

-

This one has never been riveted and used, but the spare parts latest production in post USSR Russia was on lo level of quality. You can burnish the pivots a little after riveting the staff and that's all.2 points

-

The problem would be resisting licking it to see what happens Your work area looks great Ross and you have all the workaround ideas to compensate for the lack of space you have. Like i said ingenuity mate.2 points

-

I wonder how many types of tool are out there... probably the number to types of tools outnumbers the number of watches out there. Especially with people like us making their own tools on a daily basis2 points

-

Hi Waggy. I built my own as well some years ago using a car charger to supply the power. If I can find the picture I will post it for you. Like yours it can be used with a torch or arc, the arc is the quickest and less chance of burning the dial. Good set up best of both worlds.2 points

-

So, after finishing up a pocket watch, I decided to go to the other extreme and service my first ladies watch. It is a Russian Yanka pendant watch with a Chaika 1601A movement from about the mid 1980's. Boy, talk about nerve wracking! Such tiny parts. Both balance cap jewels played hide and seek at different times. Found one in the wheel train. The other was leaning on the side of my desk pad. Trying to get those shock springs back in took a lot of patience. So glad that I now have a microscope to see such small parts instead of using loupes. The keyless works had some unusual characteristics (at least unusual to me). The yoke spring had a cam screw holding it. Adjusting that screw would change the engagement of the sliding pinion with the intermediate wheel. Instead of having a setting lever screw it was more of a pin with a groove around the end. A spring with a fork in the end fit into the groove. I wouldn't say that it is an accurate timepiece. A good deal of positional difference when checked with my timegrapher. I didn't see any real problems in the movement. Pivots seemed good. Jewels in good shape. Though, I did find two shims under the balance cock. Screws are quite soft, so hard not to mar the screw slots. I adjusted the timing the best I could, focusing on crown down position, which is the position it would be in when hanging from the chain. Got it down to about +45 seconds per day. This is going to be a Christmas present for my 18 year old niece. Kids these days don't normally wear watches (well maybe Fitbits and smart watches) but she's into jewelry, so I know she will like it.2 points

-

For watches with high water resistance (300m as in your case) they tend to really crank on the case backs making them difficult to open. Water resistance is a whole other topic as 300m does not mean 300m, but I digress. So it's not surprising that the ball didn't have enough grip to open the case back, I would also avoid using any budget wrench type tools as this is a good way to scratch up your case back. You may have no option but to open it with a heavy duty tool like the one below, these are expensive - especially if you are only looking to open the one watch, so maybe you could try and talk a local watchmaker into opening it for you with their tool? Chronoglide YouTube channel did a video on tools to open watch case backs, so may be worth a look. Here is the tool I was talking about above: Here is the Chronoglide video: Just a word of caution, some watches fake screw on type case backs. They make snap on case backs look like screw on backs, they even have fake dimples where you would use a tool to unscrew them - I assume that this is to make them appear more premium?? Just to be sure, please double check around the rim of your caseback where it meets the body of the case to see if there isn't a small slit/recess where you can insert a case knife.2 points

-

I'd like to revive this thread with the tale of my recent descent into madness. My friend asked me to service his '60s Longines Flagship. It had been sitting in his drawer for the better part of a decade as he wanted to start wearing it again. The crystal was yellowed and badly scratched, the stem had more rust than thread, and the watch would stop intermittently. No problem, I thought. I ordered a range of crystals, a NOS stem, and fixed the centre wheel's tendency to rub on the barrel. Skipping forward a couple weeks, parts had arrived and I was delighted to see that the tension ring crystal fit the case perfectly. My problems began when casing the movement, though. A movement ring is fastened to the movement with two tabs and rests in the case on a shallow lip. Above the movement ring, a brass tension ring shaped like a C is forced into a slot in the case to hold the movement firmly in place. Here's a picture from disassembly: Although fiddly, the process of installing these components didn't raise any red flags... Not until I realized that the movement sits around 1 mm deeper in the case than I'd expect. This is obvious when looking through the crown hole -- the stem would have to jut out at an angle to fit into the keyless works. Cue multiple days and several hours of fiddling and head scratching and, admittedly, some swearing. This small misalignment didn't make any sense, and I was starting to doubt my sanity. Eventually, eureka. I had picked up the wrong case from my drawer. The case I had in my hands was for a Certina movement. Many stars must have aligned to mock me, because the crystal diameter for these two cases is identical to within 0.1 mm, and most of their internal features like lips and slots are very similar. If it weren't for the slight discrepancy in movement resting height between the two cases, I would've never realized that I had goofed up. Lesson learned: stay organized. Label everything.2 points

-

interesting experiment how about we take a commercial watch cleaning fluid such as L&R with ammonia which is what my favorite is. Rather than cleaning the recommended four minutes maybe five let's do your experiment in go 30 minutes in the ultrasonic. It even better if you could elevate the temperature although usually 30 minutes and ultrasonic depending upon the machine it will usually get warm anyway. So the ammonia which does a beautiful job of making things bright and shiny after a certain point of time which is way less than 30 minutes I actually did it at school in a machine at 10 minutes will frost all the brass parts. So a little cleaning is good a lot of cleaning can be bad even commercial fluids. But as of yet I don't think we got any answer back as to what exactly was done for cleaning in this watch? oh and then there is the other little problem we would actually have to look at the material safety sheets for the particular lighter fluid because the additives vary. Like somebody once asked about charcoal fluid for starting charcoal fires like for barbecues and whatever that was it had all sorts of very undesirable stuff. I think people think that lighter fluid is pure and it's not it does have additives with additives varying per brand.1 point

-

Notice OH doesn't speak of Ronson and shellac in ULTRASONIC. Do your own experiment, run for 30 minutes a shellaced part in Ultarasonic usinig Ronson. See for yourself that no shellac has remained, all washed away. So @ekv81 did you clean fork and balance with Ronson in Ultrasonic?1 point

-

What holds the impulse jewel in place on the roller if there isn't any shellac?1 point

-

Like the endpieces that were marked up on the fhf that i did. dont know why, but i know which i prefer removing and fitting.1 point

-

I meant a plate holding the cap jewel.1 point

-

1 point

-

Test Shellac + Ronson in Ultrasonic, then show us if any shellac has remained. lol I wouldn't be surprised if the outer coil jumps behind the stud when breathing at high amplitude. Rgds1 point

-

Well, it is not well focused, but with few clicks on the picture it gets big enough. But the next pictures confirm what I suspected.1 point

-

The hub looks a bit rough and the pivot doesn't seem particularly polished but that might just be because the photographer seems to have taken the picture with a potato . . The rivet still looks like it has its shape though.1 point

-

----------- Further observations: The Accutron 218 movement holder (I inherited) is far better than a conventional movement holder. It clamps on to the movement very secure. Second, I do not know how anyone could work on one of these without a microscope. I have the Bulova microscope but I am using my stereo for this work. Using a battery installed on the test set. Yes, I read this but forgot it. I will revisit this issue today. The couple that I have looked at also corroborate this.1 point

-

Apologies if you already know this, but the recommended procedure is to seat the collet all the way down and bend the post back or forwards to raise or lower the jewel. My experience has been that the index wheels are always out of round. This can make it challenging to get it to run smoothly. In this video of a 218 I did, you can clearly see the wheel pulsing back and forth: And in this video of phasing a 219, you can see it fully stopping at the high points: Are you phasing with the battery, or with a variable power supply?1 point

-

1 point

-

That is rough. Someone has with out taking care knocked that out of an old movement. Don't buy that one.1 point

-

I use an old sharpened oiler on these - it's useful for all sorts of things1 point

-

Hi Waggy in one respect it is live as you complete the circuit with the anode, but as it’s for no more than two seconds and lov voltage. Twelve volts no problem. The heat is at the point creates the arc and melts the solder. Job done. You can use a 12v bell transformer for the supply. Hi NEW. wouldn’t adapt the manual one as everything is isolated and the cathode is attached to the post that holds the wire the carbon anode makes the circuit when placed on the foot wire, the table is also isolated. Took me a day to make mine including a bit of lathe work1 point

-

Give me Bergeon any day. Horotech are swiss made and they are not in India as far as i have found out, so this is more like another India rip off.1 point

-

That looks like a tricky bugger. Curious that the bottom prong looks longer than the top one. I don't have any experience with these, but if it were me I'd try to get the two prongs free of the slot, then try to push the whole spring to the right of your picture. Either that or prize up the top spring with a fine tweezer point and work it around to the left. I think you'd risk bending it this way, though. In either case, I'd have plastic or Rodico over it. That looks like a prime candidate for the Swiss Space Program. Probably not. I'd warm up the mainplate to evaporate it.1 point

-

1 point

-

1 point

-

1 point

-

Still in awe. However for me it is a no go. I only have a 5ft x 3ft table. All shared with computer, printer, cabinets at one end for watches and spares. I move the Keyboard forward to allow my watch working box to be placed, moved from the top of the printer. Seat is lowered for ease of use. I do have a drawer cabinet behind the seat in which I keep the watch tools. Staking set, back openers, ultrasonic etc,. I suppose my only saving grace is that after every practice I return everything to its place. Nothing is ever left out.1 point

-

Its amazing the amount of ideas that pop into your head when looking for a solution. Make this make that, my favourite by far is a micro dimond file from a nine quid dimond plate, i think i could make a hundred from one plate.1 point

-

Hi. The charger is of the old type. 12 or 6 v. Pretty basic. If you google Dirk Fassbender dial foot machine. Or Wesley R Door on the same subject both have simple designs for dial foot machines using a transformer and easy enough to build and they post how to do it. As well. I will try to post my set up. Try a search on the site for dial foo soldering, I put it on there when I built it it may still be there. It’s a black box with the posts on the top with a table.1 point

-

To mark up i used a needle point just to give me a center, i also scratched in a cross hair. I'm thinking of trying a round burr as well on some scrap. You need to make this your first job as the original position can dissappear when you clean up. 600 emery paper and then ipa, same on the copper wire, as with all soldering a good bond starts with a clean surface. A touch of self cleaning flux might help as well, not sure what flux is added to the low melt. There is a definite risk of damaging the dial finish, if it was a good dial my arse would have been twitching watching the bluing of the copper travel down to the dial. The Bergeon device has a cloth pad that i wet down first, i would suggest a damp leather pad to lay the dial on, bere in mind delicate old dials that might not handle water.1 point

-

1 point

-

Back at you Ross with your ingenuity, if i can do it anyone can . Its just about having a go to see what you are capable of. It took me another day and a half almost to finish polishing up the watch and crystal, lining up the dial was a pain as the other dial foot needed straightening out and reshaping, making a click spring that was missing, spent ages sorting out the hands that were loose, bent and kept catching and finding a secondhand hand that was also missing to broach out to the correct size . Its a battered watch that had a lot of dial damage and wear in the movement to correct but of good quality so i thought worth at least trying to fix it up. The dial foot has held up well all the handling which was the main reason for restoring it. You know when you start something and you just dont want to let it beat you. And the brand name is kind of funny, like its been misspelt . I tried this one a couple of times on scrap dials first, the low melt solder is a must. The bond feels strong, but get good clean shiny surfaces to solder to and definitely find a way to mark up permanently where the foot is to go. Unless you are super accurate with your placement there can be a little trial and error trimming up to do afterwards so do all your fitting up on a bare plate.1 point

-

1 point

-

Take care OH. Drink plenty of hot tea and go back to bed. Hope it's not Covid. Monitor yourself. I just recovered from another bout of Covid and it wasn't fun. There's another spike in the number of cases here. It happens whenever it's school holiday season and people go traveling and bring back all kinds of bugs. Mask up and avoid crowded places.1 point

-

All, thank you so much for your input. It's amazing how just talking about these things helps. Can I just make a schoolboy correction to my own notes so far on this. The wheel causing the problem is the fourth wheel (220) not the third as I have been saying previously. I have no idea why I said 3rd when it is as plain as the nose on my face Nicklesilver - you will be pleased to hear you hit the jackpot. Who ever had serviced this last time had put the fourth wheel in upside down. Putting it in the right way up gives plenty of clearance from the intermediate wheel and it runs like a dream1 point

-

Hi Andy. Crack on it’s your clock you have learnt a lot so far and help is just a post away. Have a look at Barrie Smith’s website there are some details on there and I believe a book as well on Smith’s clocks.1 point

-

Exactly, I have no intention of selling this clock. I bought a cheap movement to learn about clocks, followed up with a pendulum and suspension spring and after disassembly, cleaning and reassembly managed to get it working again, albeit not correctly. With advice given by all contributors I have a working clock of value mostly to myself, and learned quite a few things in the process. Not a lot of money changed hands for these parts so I don't mind if it is a Frankenclock. This is my first few steps into this field but not the last.1 point

-

Try searching "Omega Novochoc".1 point

-

Thanks, Jon. Always encouraging to get some praise, but especially when it comes from a pro!1 point

-

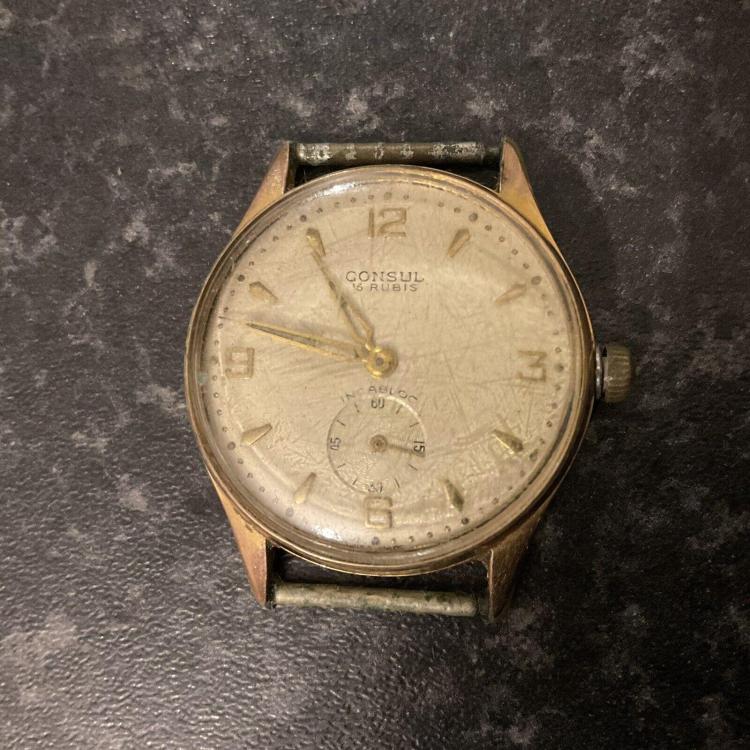

This 404 club candidate has a pleasing 1950s vibe to it. A Consul 16(?) Rubis. Incabloc, probably gold plated. It also claims to be that rarest of all beasts in the modern world, a 100% Swiss watch. Consul, based in La Chaux-de-Fonds, seem to have pitched themselves as a quality maker. They submitted some of their mechanical timepieces ("chronomètres-mécaniques") under the wristwatch category ("chronomètres-bracelet") to the observatory competition in Neuchatel, Switzerland ("Le Concours chronométrique de l`Observatoire de Neuchâtel"), that subsequently passed the stringent tests and became certified as observatory chronometers and therefore received a "Bulletin de Marche" from the observatory, even receiving a "1er prix" in 1958. This particular example has seen better days, and could certainly use a thorough cleaning, a service and a crystal (and possibly a new crown). The hands also look to need re-luming. I have no idea what makes it tick, as there were no movement shots. Another "mystery movement" watch. There is a good chance that it has an "in house" re-engineered consul branded AS movement, as a number of the other Consul watches I found online had these. There is even some speculation that they may have supplied Consul engineered movements to Girard-Perregaux.1 point

-

0 points

-

I've come across these in a few different Russian calibers. Used acupuncture needles in the past but the steel tend to be a bit aggressive for these little springs, they are quite weak as might be evident on yours, i dont remember the locating tabs being of different lengths. I now use a toothpick with a condom on the end ( dont ask !! Well actually maybe you should ) and a titanium probe which is more forgiving than steel. Dont release one tab and then try to draw the spring out, it will either ping on you or snap if you are unlucky. I find it best to release both tabs, and use the condom pick to hold it in position while you do this.0 points