Leaderboard

Popular Content

Showing content with the highest reputation on 12/07/23 in all areas

-

in the discussion all of this looks friendly and nice. You point out your hobbyist you cannot perform the same service as a professional does for variety of reasons and you're not going to. It be really nice the contract approach get them to sign off on a piece of paper that they give up all the rights to their watches ever seeing it again and no guarantee that you can even get it to run anyway. One of the reasons you need to have the they may never see it again is what if somebody breaks into your house now that they know you're servicing watches and they steal the watches I bet your homeowners insurance isn't going to cover that. this is perhaps better than the contract approach self liability you are responsible for their product. It's like where I work we taken work we ask the customer what is the item worth. occasionally somebody will ask why were asking we explain it's for insurance purposes. When you take somebody's item in exactly what is describing can you reimburse the person for whatever they perceive it's worth as you are the insurance provider. now this is where things get interesting we've already established that your client is cheap they don't want to pay for a real service but do they want a real service? As soon as you start taking money from people is an expectation from them that you're going to actually do something? Then are you going to shortchange yourself and all of this? Like why are you discharging for your time what about the investment of your tools the investment in yourself and learning how to service watches should you get money for that. Replacement costs for tools where the new tools that you would like to purchase what about the money for that. Often times people grossly underestimate how much they should charge and end up shortchanging themselves which is another reason people are happy to find hobbyist watchmakers who don't understand how to charge for what they're doing oh minor little thing from charging though your now running a business would that be frowned upon in your part of the world? Receiving alcohol conceivably it could be a gift. Although the IRS where I live does actually specify that you cannot receive a gift as a payment for something as a way of getting around paying taxes on that money. So little money occasionally probably know once the care but if you start running a little business on the side depending upon where you live they might care. Plus you are taking and money you should taken a suitable quantity of money to cover which are actually doing as opposed to just paying yourself your wages and even your wages you have to charge more than what you actually get for overhead like for instance? here is an example ordered replacements item that broke on the watch so there's $40 of your money now invested in this watch and time and effort to order the part our you to charge for this only a $40 or since you only need one but you had the order to are you only going to charge half that price and keep the other one? this is a very interesting paragraph I quoted. Needs to be read in its entirety as it's very important. So basically as a hobbyist you're having fun repairing watches you're not running a business and you receive a gift for helping somebody out a win-win for everybody. Although you're unlikely to run into this stay away from people that are running businesses themselves they will not do the decent thing as they will always protect their interests first. I will skip over the lessons I've learned on that one. But I will agree 100% stay away from taking money as soon as you receive money you're running a business are charging for something your customer expects something. With expecting something in paying for something it opens up a whole side of things that you really don't want to get involved with the fun of watch repair will be gone and they will introduce a lot of unpleasant problems.3 points

-

There isn't really any such thing as a universal main spring. This is the way to go. You need the height (width), the strength (thickness), and the length. The end is just a standard manual wind end. The most critical measurement is the height as this will determine how well it fits into the barrel. Then the strength, you should try and get as close to the original as possible, then length which is the least critical. Then if you go to a site like Cousins UK and input those parameters you should see all of the options that they offer, pick the most appropriate or make a note of the GR number and find an alternative supplier. If you just put in the height and the strength then it will give you all of the different lengths available for those parameters.3 points

-

Never work on watches when you are tired, irritable, frustrated, excited, grumpy, confused, cranky, gittery, hyper, annoyed, upset, fiery. I need to now question why i took up this hobby, I've just listed 99 % of my finest emotional qualities.3 points

-

I will do jobs for friends, neighbours, colleagues etc. on the understanding that "I'll have a look at it, but if I decide against it, I'll hand it back in a day or two, no charge. If anything needs replacing, then even if I can get the parts, they could be very expensive. If I encounter anything I don't feel ready to tackle, I'll put things back as they were, no harm done." That broaches the subject of cost, and you can start to have a conversation about the amount of time and effort actually involved. Most people don't have the faintest idea. Regarding liability, I don't tackle anything I'm not confident about (e.g. recently rejected the chance to work on an Accutron), and I try to be extra careful with other people's property, so no problem so far. If I know I couldn't afford to replace it if I broke it, then I won't touch it. For reimbursement, I usually work for upmarket alcohol; whisky, Belgian beer, wine, not cash. Something personal, with a bit of prestige, a treat I might not get for myself. Decent people will do the decent thing, if they understand the value of what you are doing for them. A neighbour gave me one of his pocket watches after I'd serviced part of his collection, which was a lovely surprise. If you don't feel sufficiently valued, just reject the next approach. In the end you have to weigh up what it is worth to you in terms of practice, experience, goodwill etc. A newish Rolex might be worth less to you than a Poljot chronograph and carry considerably more risk. If you don't feel comfortable reject it, explain why, and don't be shy about telling them what a professional job is likely cost and how long it will take. We are hobbyists in the end, amateurs, and we don't pay taxes, have liability insurance or guarantee our work. In my opinion, you can't charge, not even "mates rates". If you're anything like me, you have far more jobs lined up than time available, so why take on anything you wouldn't want to do for your own pleasure and satisfaction?3 points

-

The second to last photo looks like a screw on. Superglue a nut to the back, put in a case holder and use a spanner to turn the nut. The nut will come off with acetone. The other looks like a snap on, try a one sided razor blade and work around the case.3 points

-

2 points

-

2 points

-

Problem solved! In my attempts to remove the roller bearings I had displaced one of them very slightly (about 0.5mm) and they were binding a little when I closed the housing up tight. I reseated it firmly. Now everything is running very freely, and the motor has no problem getting up to speed. The bearings are noisy, so I think a replacement is due at some stage, but I'm just happy to have the machine running for the time being. Now to find out if it actually cleans watch parts! Many thanks to all those who tried to help so far. If anyone has any more questions about the machine or wants to add their own knowledge, please feel free to continue the topic.2 points

-

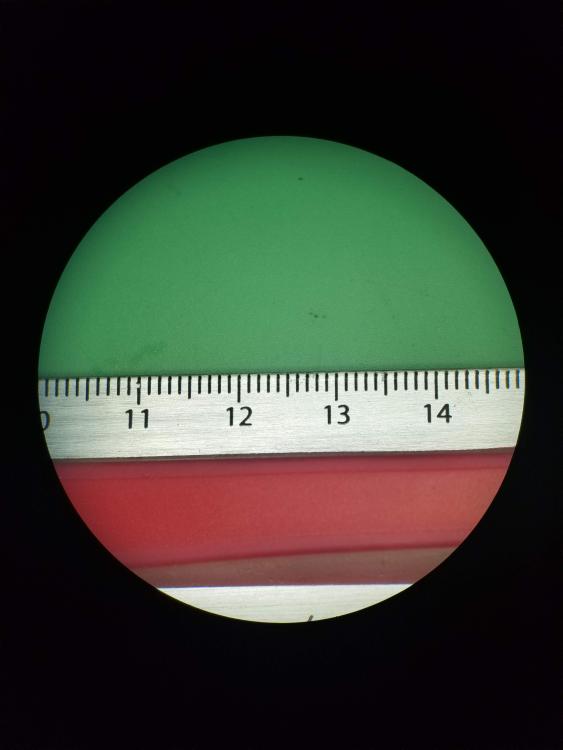

This is true. And with the level of magnification you got in your photos you should be able to tell 100%. If anything I might add the border of the circle of oil should be sharp and clear. In all of my services I check the lubrication of the balance jewels by taking photos of the jewels one photo after oiled but before final assembly and one after the jewels was fully assembled with the shock spring. I use a very cheap chinese USB microscrope thought I can see the circle even with just my 20x eye loupe. Here are the 2 photos I took from a Seiko I recently did and I don't think I have to mark the circle of oil because you can clearly tell: This photo looks like you've got no oil at all except maybe a tiny bit in the middle of the jewel. This one the blue circle looks indeed like the oil and looks like you got the perfect amount of oil here. In case you may still be confused, these are the photos I took when I was playing with my automatic oiler. I was adjusting the oiler to get more and more amount of oil into the jewels setting. You can see the circle getting bigger and bigger Yes I have a bunch of photos like these in my phone.2 points

-

Repairers used all sorts of practices/ ideas. What the customer couldn't see the repairer got away with.2 points

-

2 points

-

You don’t need excuses. Embrace ‘no’… I find the dad watch and Rolex in the drawer conversations go quite well when I educate about the costs, risks, and expectations. Sometimes the friends won’t want to bother sometimes it’s ‘do what you can I don’t care it doesn’t run now anyways’… So far no lost friendships.2 points

-

2 points

-

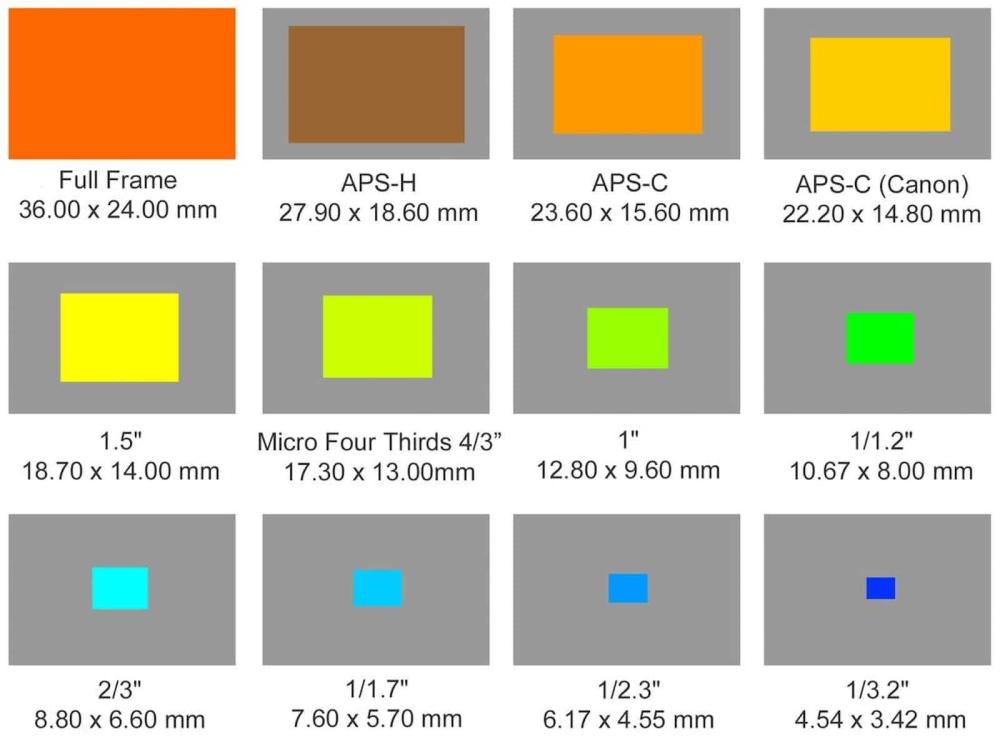

@spectre6000 said: I wouldn't say that I am unhappy with the camera. I'm just unhappy with the FOV issue. I did find out that my expectations are not realistic due to cameras having a rectangular sensor. I did not realize that camera sensor size came into play as well. I went on the assumption that a lot of people are using this same camera with that microscope, so it must be a good combination. If I had to do it over, I would have ordered a couple of cameras from Amazon, with different sized imaging sensors. Then I could have found the best option for the lenses that I have and returned the other. I ordered this one from AliExpress, so trying to do a return is probably not a good option. It is rather strange and confusing how the manufacturers state camera sensor size. My camera image sensor size is stated as 1/2.3 inch. See sensor size comparison photo below. The C mount adapter to use depends on the sensor size. https://www.microscopeworld.com/t-microscope_c-mounts.aspx I just did a test, which you can see in the photos below. With my microscope at minimum zoom (0.5X Barlow and 10X eyepieces), my width of field through the eyepieces is about 49 mm. With the 0.5X C mount camera adapter, width is about 21 mm, while with the 0.35X adapter it is about 33 mm. So, the 0.35X adapter was an improvement and I don't notice any vignetting in the corners. My cheapest option at this point is to give a 0.3X Barlow lens a try. I have one on order from Amazon (so if it doesn't work out, I can return it). If I can get a whole movement in the camera's field of view, then I'll call it good. Eyepiece View: With the 0.5X C mount adapter: With the 0.35X C mount adapter: Image sensor size comparison:2 points

-

When I graduated from dental school, one of my mentor's parting words, which was taken from Dirty Harry, was, "A man's got to know his limitations." This advice has stay with me throughout my career. Although I was certified to practice Implantology and Orthodontics, I have always referred my cases to more experienced colleagues. Just because you have taken a few online courses and watched a lot of YouTube videos, that doesn't make you a watchmaker. There is so much to learn in watchmaking. The more you learn, the more you realise you don't know. My advice to budding hobby watchmakers is to start small. Change batteries, watch straps, crystals, polish some cases and bracelets. Find an experienced watchmaker to be your mentor. In case you mess something up, he's there to bail you out. When you think you've arrived at a milestone in watchmaking, go get a Mumbai special and fix that. That will bring you back down to Earth. In the meantime, learn all you can and practice.1 point

-

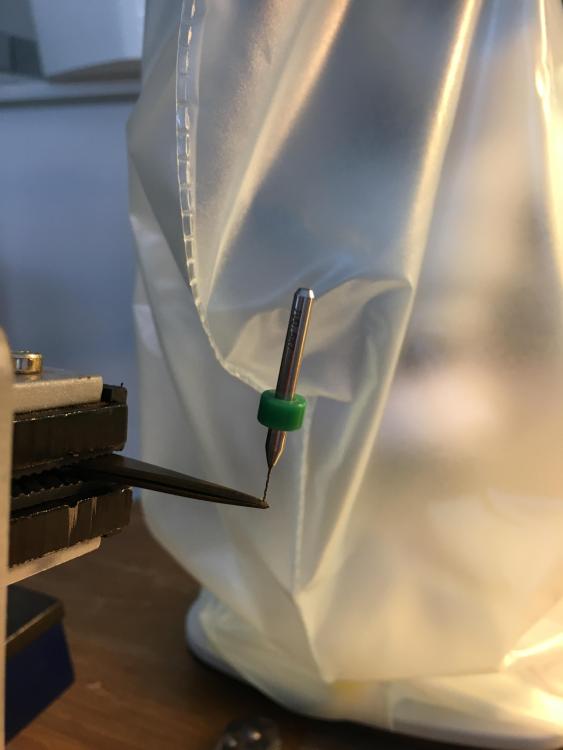

The tweezers are useless steinless antimagnetic swiss made nonsense, the pin is guitar string (pivot wire), I have drilled the holes and inserted the pin and formed the tips. Yes, I use the rubber on the handle instead of wood.1 point

-

They look the same as the Amscope and the swift makes. Quality could be different or just badged differently. They come from china but which factory and under what quality control. Unless someone here has and can recommend one, ive read good and bad things about all of them.1 point

-

It’s not necessarily as simple as you put it Richard, I doubt very much that that motor would be 5W, wouldn’t pull a kipper off a plate Tom1 point

-

Remove the balance and push on the fork, it should snap side to side. If not power isn't getting though to the level or the lock on the pallet stones is too deep.1 point

-

My theory is that while they of course want people to search the database, they don't want people to scrape or abuse it. I can literally try and search the db without a vpn and it returns garbage results and then turn on the vpn and get correct results. I can turn the vpn off and on multiple times, checking a search with it on or off, and it will fail with the vpn off and work with it on time after time. So there is clearly some IP shaping going on. The reason why I can't say for sure. I'm sure they scraped jules borel. I have noticed in the past that I've seen an error on JB that I've also seen repeated on EW, with the same kind of parts naming shorthand that JB uses. I've also seen results on EW that return the same results as JB, but with additional info. So EW may be adding some of their own info or scraping other sites.1 point

-

Yes, I actually tend to do that anyways. But this time I was blinded by the fact that the 4 cap stones (2 for balance and 2 for escape wheel) are the same Rolex part reference; and the 2 setting/hole jewels are also the same part reference. But you are right, even Rolex may have slight differences in the actual parts. That's a good point! It would be great if we could all agree on a particular number of degrees (e.g. 180°) and then be able to compare. But that's me dreaming, I guess .1 point

-

1 point

-

I'm disgusted at the way you opened the watch. If you do not have the correct tools you should have left it. What the hell would you have done if something went wrong. It would have cost you a packet, I don't expect you have insurance to have covered your work.1 point

-

1 point

-

1 point

-

Tried it many times and it has always worked. The nut needs to be clamped in order to get full adhesion. Obvious precautions to protect to crystal and front of the case. This is where another great use of the screw crystal press comes in. Afterwards fill the nut wuth acetone and leave for a couple of hours, you might need a sharp blade to get under it.1 point

-

I kinda find that hard to believe because it looks like everything they do on that website is to generate money and limiting your ability to search limits them on how much money they make. then I was looking at their database and it looks like it's identical to the one found here? http://cgi.julesborel.com/ then even more amusing was I looked for an obscure watch and both databases were identical but on their website I can try to order some parts but the big difference between the database is you can order the parts well not really. I was looking at obscure watch for parts relisted and it asked if I'd like to order the parts so I said yes and it just sat there and spun its wheels for quite some time is having a really hard time finding something that doesn't actually exist sort of. I know the part does exist but it's not available for sale anywhere but it did try and it never gave me an error saying it couldn't find the party just kept on searching just never to be found ever1 point

-

Now that I have had a second look at the pictures, I have just realised that it is the back of the dial that I misread as an out of place mainspring barrell. Silly me.1 point

-

1 point

-

Unless you know what you are doing and have checked everything to do with the escapement you should never play with the banking pins.1 point

-

was the watch running before you serviced it? Things like banking pins do not happen by accident somebody did it before you and did they have a reason why? Although a lot of times people have no idea what the banking pins are for and because of that they like to play with them which leads to problems.1 point

-

I've come across a few movements where the person before me has scratched in numbers on the plates, in a huge size... seeing this you know you are in for a rollercoaster ride of a repair/refurb.1 point

-

John, thinking a little deeper on your point above and comments of others, they all know I'm a non-professional doing this as a hobby, but I guess they think they can get something for nothing, or at least at a very reduced price because they think the cost of a professional is too much, and/or it's more convenient to give it to me than take the time and effort to find somewhere to take it. Thinking of it in those terms I suppose it is the same thing every plumber or car mechanic etc. faces, with friends expecting them to work for free or at cost. As @Klassiker points out, this is a hobby, so I have the luxury of picking what I do and when I do it, so as @rehajm says, I'll embrace 'no' unless it is something I want to work on and then point out the risks and cost of new parts and drop hints about the virtues of unblended whisky @RichardHarris123. Thanks to you all for your comments, this has helped me crystalize my thoughts on this issue Ross, Thanks for your comments, I agree with you that this hobby should be about fun, and getting liability insurance and making your friends sign waivers is the opposite of that.1 point

-

I agree. The .1 increments ensur the correct size for stock metal used in making parts etc. .2 increments may cause sizing issues.1 point

-

1 point

-

Happy to be corrected if wrong. My understanding (I have a lathe but too many other projects on the go) is that there is no wiggle room hence why we get 0.1 increments between collets, though most you will commonly see are jumps of 0.2mm. I think that it would be expensive for sizes a watchmaker would rarely use, e.g. the full current shaublin range of collets contains around 74. @nickelsilver and @jdrichard are probably our most prolific current lathe users and might confirm. Tom1 point

-

what exactly is the question in this discussion? for instance in this example they were told the price obviously they didn't like the price they didn't get the work done. now they're asking you to do the work, why do they think that you're going to give them a better price than the previous price? Is that what this is all about this discussion is cheap watch repair? coming up with excuses for what? In other words have you indicated to people that you're running a professional shop and that you're servicing watches? Why do you think people are ask you to work on their watches are they trying to save money do they think you'll do a better job, it's probably the money isn't it that's what thinking what I'm thinking?1 point

-

Pulling a disk from the center tends to contract the perimeter, so although you could get a good mechanical advantage with such a setup, I think it might make the mating edges of the case and back bind that much tighter... People have described pulling a crystal out from the center like this, in which case the shrinking of the perimeter would be helpful.1 point

-

1 point

-

Like you, I've been approached to work on upmarket watches. Well, for me, they are upmarket. Bulova, Jaeger Lecoultre, Kronos. I am capable of doing the servicing. However, thinking about the aspects has given me the outcome that I will not pursue such. I recently watched 'Kalle' on 'Chronoglide' discussing the reasoning for doing private work. Made me realise the pitfalls. Whilst the people who wanted the servicing done on their watches, to me they are watches, to them they are heirlooms, memories, treasures. Not that it would, but what if it did, go wrong. I have their promise that they would be no come back. But a promises is just that. Therefore I asked two of the possible friends if they would sign a memo to the effect that there would be no actions if I did make a mistake. Both said yes. After Kalle's videos I looked into the possibility of litigation. It would appear that even if such were signed, an action could be brought against me. Providing a service, any form of payment is a 'contract'. Therefor I would need insurance liability to be set a £10 million which is standard practice for todays employment. I like what I am doing to much Upmarket. No market for me. Friends and relatives watches, usually under £100 ish value. Fun1 point

-

A very difficult question. If you will enjoy working on them, then you don't really need paying for your time, parts only, maybe as said before mention a nice bottle of something. Explain what is involved and that you can't guarantee anything, if the relationship was soured, it would be on them not you. I don't get bothered about repairing watches very often but on the occasions I do, the above is how I handle it. I friend is sending me a watch, little monetary value and not a heirloom, his wife just likes it. So I explained and he accepted my explanation.1 point

-

I watched a YouTube post where someone did the superglue trick - I have 2 watches I can't open (one that looks similar to your second and the other a Seiko) and was planning on giving this a go1 point

-

1 point

-

1 point

-

Some hints: - position the hairspring blade perpendically to the grain. - pushing too deep can be avoided by the laughed upon hammer taps. - the hairspring will slip up if the tweezers is too weak. Else: congratuations on your progress! Frank1 point

-

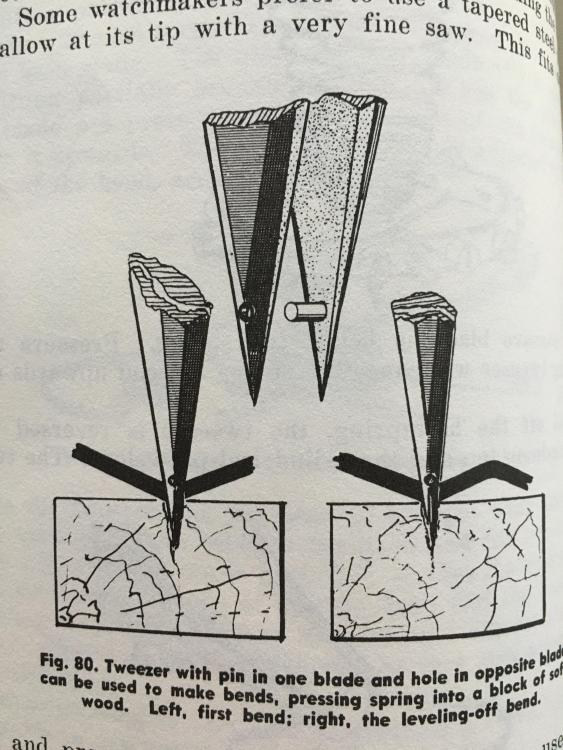

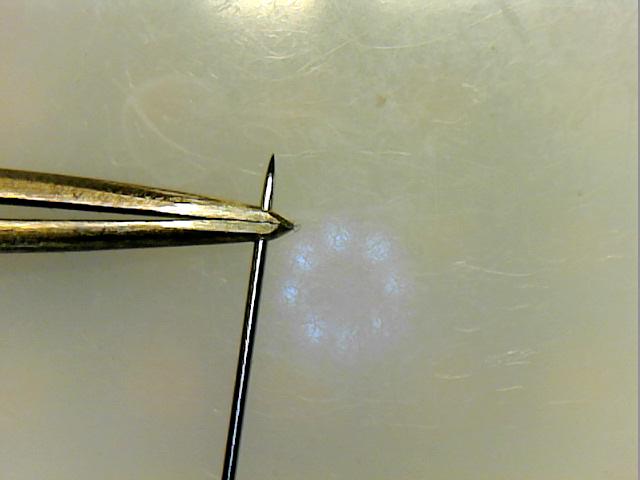

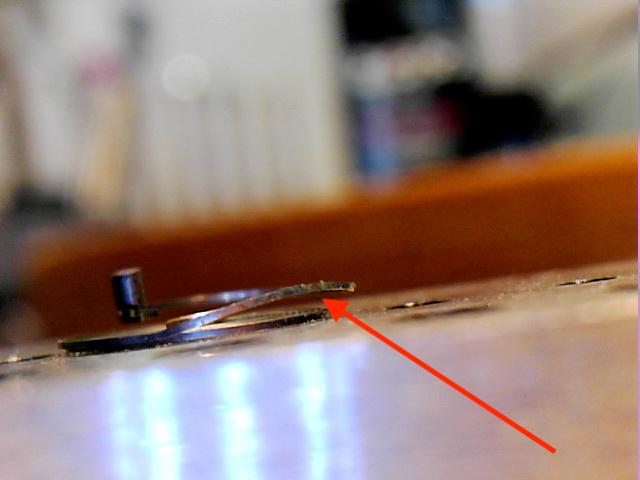

Yesterday I did several bending attempts (with "normal" tweezers) on a small (ladies-watch) hairspring and the results were poor at best. I noticed that while pushing the tweezers in the wood that either the hairspring slipped upwards in the tweezers, or that the tweezers would suddenly "sink" in the wood and bent the spring beyond repair. The soft-wood I tried was everything but consistence in its resistance. At a certain spot on the wood one had to push hard to penetrate the tweezers, on a spot next to the previous, the tweezers would sink in deeply when applying the same force. I decided to make an attempt to mimic the tweezers depicted on page 68 ("Bench practices for Watch repairers" by Henry B. Fried) For that I took some some pointy brass tweezers. The "pin" chosen was the thinnest needle I could find: 0.6mm Hand drilled a 0.5mm hole through both legs, close to the dressed tweezers tips: With the needle inserted; I could have trimmed the needle off, but as it turns out, either end of the needle do act like a safety, preventing the tweezers from "sinking" too deep into the wood. I also started to use another, more homogeneous "hard-wood", offering a more consistent resistance. I did a few more test on another PW-hairspring and the results were very good, very controlled and producing consistent bends. The bend produced is, due to the relative large radius of the needle, not as "sharp" as the first bend, but it does the job very nicely. Because the needle extensions are starting to "rest" on the wood, the bending goes very controlled. I'm not done yet with my hairspring, but the second (down) bend sits in without damaging the "one-off" hairspring. Adrenaline back to normal levels On the picture it looks like that the 2nd bend is a bit "over-bend", but that's only when you take the twisted continuation of the spring as a reference. In reality it's spot on, back to horizontal Next is to sort out the terminal curvature ........1 point

-

You guys talk as if you see no difference working on a Chinese ST and a Rolex. If so why ain't you adjusting escapements at JLC, the pay must be good and JLC wont let you go. With all respect. Pick one, your choice.0 points

-

Oh noooo I should have just stayed away from watchmaking when I was tired last night. I broke one of the shock springs for the escape wheel... I will order two new ones (20 USD/EUR each + 20 for shipping ). Any advice on installing them without breaking would be much appreciated! On top of that shock (pun!) last night, I also realised that I somehow lost the intermediate crown wheel. It's still there on my overview picture of all parts. Since then, no idea how it could have been lost. It'll cost me an additional 30 dollars/euros. Just a really bad day0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)