Leaderboard

Popular Content

Showing content with the highest reputation on 12/06/23 in all areas

-

"The gasket had just been thrown loose inside the back of the case"... I bought my wife a quartz Tag Heuer watch as an eternity gift over 18 years ago. She wore it all the time (in the shower, swimming etc) so I have always left the battery change to the dealer who gives us a pressure test certificate after each battery change. Over the years they have charged us a few times for gasket changes and even a replacement crown and stem (I have the old one!) but always done the work in shop and not gouged us for the service.... This year they said it failed the pressure test and would need to be sent off for a new gasket (at a cost of $150+). We declined and she stopped wearing the watch daily (knowing she would forget to take it off). Instead she has been wearing a Citizen Automatic Mickey Mouse watch which is a restoration project I did on a watch she chose! I ordered a pressure tester from Ali express and decided to have a look at her watch. When I opened the case I found the gasket had just been thrown loose inside the back of the case! I inspected it and could see a it had little damage to it so I replaced it. I put it in the tester and it comfortably passed with no leaking bubbles at 3 BAR. She is now under instructions not to take Tag watch on beach holidays and go from the hot sun into the cold water, but outside that I am confident it will continue to survive her normal abuse and I now own more kit!4 points

-

A friend showed me their beautiful Jaeger Lecoultre Chronograph from what I assume was the early 60s? Unfortunately they had left it in a pair of jeans and it had gone through the washing machine about 10 years ago. I believe at the time they chose not to have it fixed when they were told the price and that it had been living in a box of rice and sawdust for the past 10 years. Anyway it appeared to work. I was brutally honest with them about my success rate and told them I wouldn't even be comfortable opening it! Problem solved!3 points

-

As well as a compulsive horological problem, another itch that gets scratched occasionally is the yen for yet another microscope. When I last checked in the mirror I still only had two eyes, but I have enough close up viewing apparatus around the place to satisfy the optical needs of the average spider. Despite this obvious fact, I threw a few more of my hard earned coppers (six pounds and ninety nine pence worth of British pennies to be a little more precise) at this little "beauty". Yes, it is a little ugly, and seems to be partially in kit form, but I think it is more or less complete and probably relatively old, possibly late Victorian. I think it would most likely fit the description of "field microscope". Much cleaning and polishing of glass and brass, and possibly a little repainting and/or re-plating will no doubt be needed to bring it back to a serviceable condition. Sadly it didn't come with the camera adapter.3 points

-

According to the Jules Borel interchange site they're not interchangeable, in fact the 2846 pallet fork and escape wheel appear to be unique to that caliber.2 points

-

Like you, I've been approached to work on upmarket watches. Well, for me, they are upmarket. Bulova, Jaeger Lecoultre, Kronos. I am capable of doing the servicing. However, thinking about the aspects has given me the outcome that I will not pursue such. I recently watched 'Kalle' on 'Chronoglide' discussing the reasoning for doing private work. Made me realise the pitfalls. Whilst the people who wanted the servicing done on their watches, to me they are watches, to them they are heirlooms, memories, treasures. Not that it would, but what if it did, go wrong. I have their promise that they would be no come back. But a promises is just that. Therefore I asked two of the possible friends if they would sign a memo to the effect that there would be no actions if I did make a mistake. Both said yes. After Kalle's videos I looked into the possibility of litigation. It would appear that even if such were signed, an action could be brought against me. Providing a service, any form of payment is a 'contract'. Therefor I would need insurance liability to be set a £10 million which is standard practice for todays employment. I like what I am doing to much Upmarket. No market for me. Friends and relatives watches, usually under £100 ish value. Fun2 points

-

A very difficult question. If you will enjoy working on them, then you don't really need paying for your time, parts only, maybe as said before mention a nice bottle of something. Explain what is involved and that you can't guarantee anything, if the relationship was soured, it would be on them not you. I don't get bothered about repairing watches very often but on the occasions I do, the above is how I handle it. I friend is sending me a watch, little monetary value and not a heirloom, his wife just likes it. So I explained and he accepted my explanation.2 points

-

I will do jobs for friends, neighbours, colleagues etc. on the understanding that "I'll have a look at it, but if I decide against it, I'll hand it back in a day or two, no charge. If anything needs replacing, then even if I can get the parts, they could be very expensive. If I encounter anything I don't feel ready to tackle, I'll put things back as they were, no harm done." That broaches the subject of cost, and you can start to have a conversation about the amount of time and effort actually involved. Most people don't have the faintest idea. Regarding liability, I don't tackle anything I'm not confident about (e.g. recently rejected the chance to work on an Accutron), and I try to be extra careful with other people's property, so no problem so far. If I know I couldn't afford to replace it if I broke it, then I won't touch it. For reimbursement, I usually work for upmarket alcohol; whisky, Belgian beer, wine, not cash. Something personal, with a bit of prestige, a treat I might not get for myself. Decent people will do the decent thing, if they understand the value of what you are doing for them. A neighbour gave me one of his pocket watches after I'd serviced part of his collection, which was a lovely surprise. If you don't feel sufficiently valued, just reject the next approach. In the end you have to weigh up what it is worth to you in terms of practice, experience, goodwill etc. A newish Rolex might be worth less to you than a Poljot chronograph and carry considerably more risk. If you don't feel comfortable reject it, explain why, and don't be shy about telling them what a professional job is likely cost and how long it will take. We are hobbyists in the end, amateurs, and we don't pay taxes, have liability insurance or guarantee our work. In my opinion, you can't charge, not even "mates rates". If you're anything like me, you have far more jobs lined up than time available, so why take on anything you wouldn't want to do for your own pleasure and satisfaction?2 points

-

2 points

-

Yes, I found it in a Local Shop, for Local People... I wonder what percentage of the WRT audience are now completely confused....2 points

-

2 points

-

Agree, had this issue a few time recently and cannon pinion was to blame each time - you can try tightening it if you have the equipment, otherwise see if you can find a donor movement.2 points

-

actually what would be much nicer to do with the fingerprint is figure out how to transfer it and put it someplace else like at the scene of a crime perhaps. Although the watch does qualify as a crime scene now.2 points

-

Not broken. The missing part is attached to the winder (button) above the tube which is part of the case.2 points

-

OK, I made some videos to show that drilling hardened still is normal thing, when tungsten carbide drill bits are used. Actually, this is the same as turning hardened steel on the lathe - this is normal practice in watchmaking. On the video with clock spring - this is 0.35mm thick spring, as hard as a spring can be. There are two interrupts in the video - that was for sharpening the bit. On the second one, which was at the end of drilling, the tip of the bit chipped. This happens, and for avoiding it, something must be put under the piece, with close hardness, and the piece should be pressed to it. The video with the old rusty filler gauge shows that it is much easier to cut. The gauge is 0.3mm. This gauges usually are made of spring steel, which is something totally different from normal carbon tool steel, and annealing it usually can't bring it as soft as carbon steel. See, heat treatment of steel is another, not simpe skill, craft... Annealing always leads to burning carbon int the steel and not only, then hardening and annealing can easy ruin the still and make it really crunchy if overheated. It usually takes many hours of practice to learn how to heat treat, and every different kind of steel has it's own ways and rules. So, this is much much easier to use readily heat treated steel and shape it in this state. Shaping is easy with carbon dental separators on the dremel tool, then fine with diamond files.2 points

-

At least you know who did the work, a fingerprint is better than a signature and will hold up in court, ha ha.2 points

-

Thanks By "eye" the collet may be a bit off the horizontal, but I've to see when mounted. It all may need to have a little tweak left / right / up or down, but in general the hairspring looks to be in a much better shape than before. As for the amplitude; the balance pivots are in a bit of a mess too, so we have to see ........ one step at the time2 points

-

So, it's not escaped my friends and colleagues that I am working on watches and up to now I have managed to escape the "oh I have an old Rolex in my draw at home you could fix..." conversations, but it's becoming increasingly difficult to come up with excuses as to why I cannot work on their treasured family heirlooms. I was just wondering if anyone out there had any 'pearls of wisdom' on how they handle this situation. My issues are that: If I junk the watch, am I on the hook to replace it? Even if I'm not on the hook financially it could sour the friendship if I junk a watch with sentimental value, and it would just feel weird getting a friend to sign some kind of financial waver?? It takes time to service a watch, I would feel bad charging a friend the going rate, but then is it fair for them to expect me to devote hours of my time for free and risk the above Of course lifelong 'give you my kidney' close friends and family are another matter, I'm talking more about the guy who sits 3 desks down from me or friends of friends etc. Could/should I charge them for my time, I don't think many people outside the watch maker world understand the time it takes to service a watch, most are used to dropping a watch into the local jeweler for a 5 min battery change, so are expecting a pint to cover my time (or a fancy Starbucks coffee at work). Don't, get me wrong, I would actually like to work on their watches, but the baggage (see above) that comes with it really puts me off the idea, but it's getting harder and harder to come up with excuses. I think it would be easier if it was a complete stranger, as they would be expecting to pay the going rate without 'mates rates' or free so this would cover the occasional junked watch and no friendship to sour etc. The reason I post this is I have a work colleague who WhatsApp-ed my last night saying that he is bringing two Tag's home from Australia for me to fix for him - no mention of cost or anything, so I assume he is expecting me to fix them for fun (ie free) or at best a coffee and muffin on our coffee break I am sure all of you have come across this issue, so any advice will be greatly appreciated.1 point

-

You guys talk as if you see no difference working on a Chinese ST and a Rolex. If so why ain't you adjusting escapements at JLC, the pay must be good and JLC wont let you go. With all respect. Pick one, your choice.1 point

-

Try here. You first select the maker, then the caliber, then the part. It will then show you all the other calibers that use that same part. I tried it both ways, first checking the 2824 parts which turn out to be common to a lot of other calibers, but not the 2846. Then I tried the 2846 and it seems that there are no other calibers that use those parts, so I guess they are uniquie to the 2846.1 point

-

I find it's an essential site : http://cgi.julesborel.com/?_ga=2.99547678.1292671413.1673701735-126716363.1672876102 Use the " Search for parts for manufacturers" down the bottom1 point

-

1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

1 point

-

1 point

-

There's always been a difference between pretend tradesmen and real tradesmen. Most often you only find out which one you've had after the work's been done.1 point

-

Hey again watch peeps. Finding a really good repair book can be a bit hit and miss, and when a recommendation comes along it can get quite expensive. So here a little discovery i made yesterday that should only cost you a few quid. I've had this book on my shelf for about 18 months, its not a big book around A4ish size with 200 pages and old, almost a 100yrs for the 1st edition. Now most of us have heard of Aegler, basically the manufacturer that put Rolex on the map, without Aegler they might not be what they are today. They had a very long partnership starting about 120 yrs ago, from what I've read more or less in each other's pockets since the 1920's, slowing blending together to finish as one company in 2004. The Aegler family also included the Borer family, through marriage ? The Borer family did buy out Aegler in the late 60's who eventually sold it to Rolex. One member of the Borer family was heavily involved with Rolex's design and technical department creating the Rolex Perpetual among others during his time, he was also on Rolex's board of directors this would be Emile Borer. I only realised yesterday after some reading that the writer of my book E.Borer being the same guy. For a few quid must be worth a read is it not ?1 point

-

I managed to cobble together something myself, maybe you can make use of it Seiko Operating Instructions.pdf PM me if you want the word version and I can email to you as I can't post .docx files here1 point

-

1 point

-

Both are very delicate. The first one someone has bent the minute hand. The second one to change the time its the center square. You must change the time by letting the watch chime and strike each time other wise you might foul up the movement. I expect they both need a good service. These must be repaired by someone who is advanced in repeater work.1 point

-

Its about time some one told the idiot you do not handle batteries with your fingers. Wear finger cots or use plastic tweezers. Have you tried extracting D N A to see if its human origin.1 point

-

@Neverenoughwatches i just ordered a copy Rich, got to be worth a punt for a fiver Tom1 point

-

out of curiosity did you remember to remove the power before you disassembled? Then which bridge did you remove first? the problem here is disassembly in the wrong order looking for unknown problems. Which of course leads to thinking you can reassemble it after everything is shifted out of place. it's extremely hard to reassemble a watch if you really can't see what you're doing or/and don't quite grasp what you're doing anyway. Plus reassembly is a lot harder when the pallet fork is still in place and the balance wheel is there that makes things much more interesting.1 point

-

Thi is still not clear if the pivot is broken or not. Make picture of the wheel from aside, not from above.1 point

-

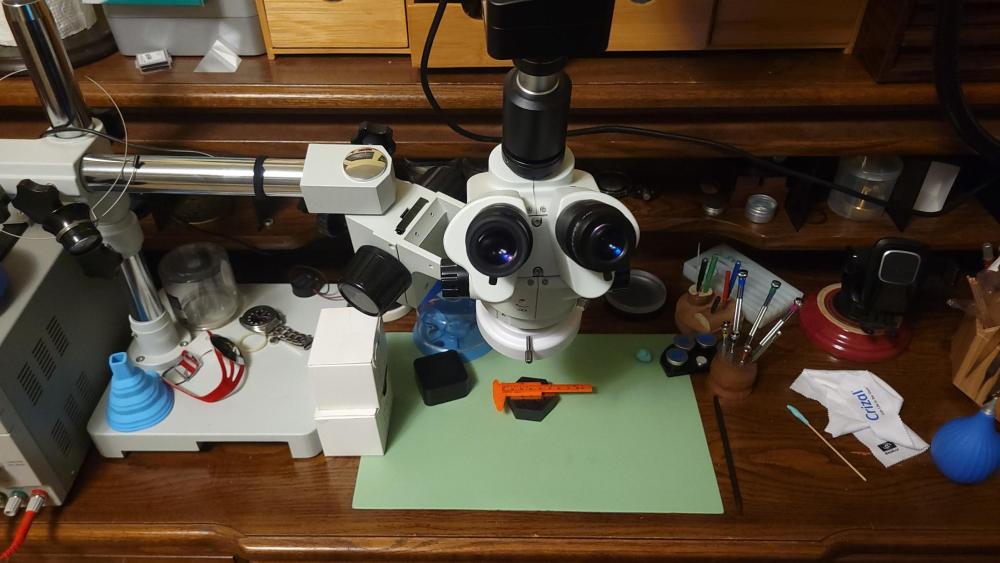

I have an Amscope SM-3NTPX, and of course you all got me wondering about working distance and FOV and such, so I did a little testing. The objective is 0.7x-4.5x zoom, with 10x/20 eyepieces from the factory, and an 0.5x Barlow, giving an effective magnification of 3.5x-22.5x at the eyepieces. I added an Amscope 16MP USB 3.0 Color CMOS C-Mount Microscope Camera with an 0.5x reduction lens to the trinocular port. Here's the setup: Working distance is about 16.5mm between the subject and Barlow. With the factory 10x eyepieces at the lowest 3.5x zoom, field of view through the eyepieces is 60mm. The camera's FOV is about 35mm: With the factory 10x eyepieces at 22.5x zoom, field of view through the eyepieces is 9mm. The camera's FOV is about 5.5mm: I recently bought a set of 20x/12.5 eyepieces, which increase magnification to 7x-45x at the expense of some field of view, but doesn't seem to affect the working distance. I like them a lot, especially for things like jewel inspection. They're also super quick to swap out. The camera sees the same thing as above of course, but when looking through the eyepieces: Field of view at 7x: 36mm Field of view at 45x: 5.5mm Any other questions or measurements folks are curious about, let me know! I love science.1 point

-

1 point

-

He's planning on following in my footsteps and doing Mechanical Engineering - pint sounds good!1 point

-

Yes indeed! Thank you! I got behind a VPN based out of Japan and now am getting proper search results.1 point

-

the problem with a lot of the watch battery places are a perception of easy money and no skills required. Plus definitely no real knowledge of watch repair required. Not only do you get a nice fingerprint but whatever else was on his fingers is possibly floating around inside the movement. Quartz watches really don't like bonus material floating around inside.1 point

-

Well, I've made some changes to my Eakins microscope. Dust Cover - The one that came with the microscope is rather useless. It is too big to cover the head and too small to cover the whole microscope and stand. So, I printed some eyepiece covers. That's really all that I need. I got the STL file from https://www.thingiverse.com/thing:5956643 Head Tilt - The Eakins only came with one handle to tighten down the head tilt, while the other axis uses an allen head screw. The Amscope comes with two handles. I managed to find an inexpensive handle that works. Now, it is much easier to change the head tilt. I bought the M5X40X50 handle, but a M5X40X40 would do as well but either way you need to cut the screw down to a suitable length. I cut mine down to about 35mm thread length, but I used a couple of thick washers to make sure that the knob was making good contact with the round piece it tightens against. https://www.aliexpress.us/item/3256804968135919.html Camera Field of View - I bought a 0.35X C mount camera adapter to widen the field of view for the camera. Field of view is definitely better than with the 0.5X camera adapter, but I still have a much better field of view through the eyepieces. Is it possible to get these field of views to match more closely? I don't see an adapter less than 0.35X. I'd like my videos/photos be closer to what I see through the eyepieces. As it is now, I cannot see the whole movement for a modest size wristwatch through the camera but see all of it and more through the eyepieces. https://www.aliexpress.us/item/2251832823671184.html1 point

-

1 point

-

1 point

-

1 point

-

Not sure why all of a sudden I am winning a bunch of 404's, but I'm up to my 4th one recently. Diamond tooled? Tropicalized? I assume that means water resistant. The scuba diver would allude to that. This one at least has 17 jewels to it. Non-runner though. From a bit of info I found online, it may have a Soviet movement.1 point

-

Switch is unlikely the problem. Bypass it to prove. I suggest you remove the earth ground that you added and see what happens.1 point

-

1 point

-

Looks like the escape wheel upper pivot is broken. At least it is what I see on the picture. One of the leafs of the esc. wheel pinion is not seen, but not sure if it is so or just light effect. Also, the reverse wheel upper pinion is under question, but not seen good enough on the picture. See, assembling watch movement is with no force, and no screws tightening before absolutelly sure that all pivots are in the holes. Otherwice this happens...1 point

-

I think I will do something with the hands though as they don't look great1 point

-

Hi there , an ETA 959.001 is a 9 ligne , expensive movement .ETA 210.001 is also 9 ligne you can get these new but are around 160-200 USD .Only other suggestion would be go the 8 3/4 ligne and go with a spacer . There is a good book called Quartz watch retrofitting by wesley r. door .This book has loads of information and good to have in situations like yours ,there are many measurements to determine such as thickness for the fitting into the case,dial feet position , hands .But there is most of the time a work around for theses problems .Hope this helps1 point