Leaderboard

Popular Content

Showing content with the highest reputation on 12/05/23 in all areas

-

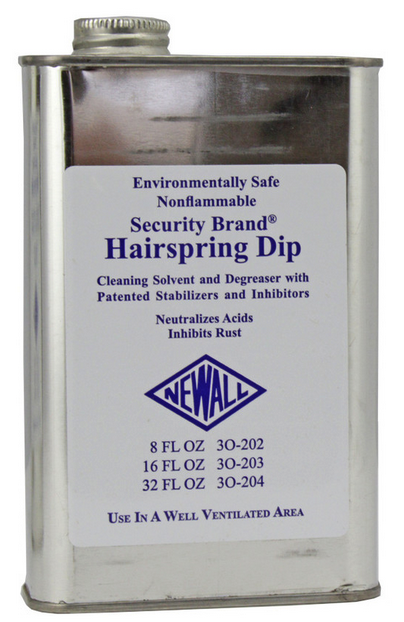

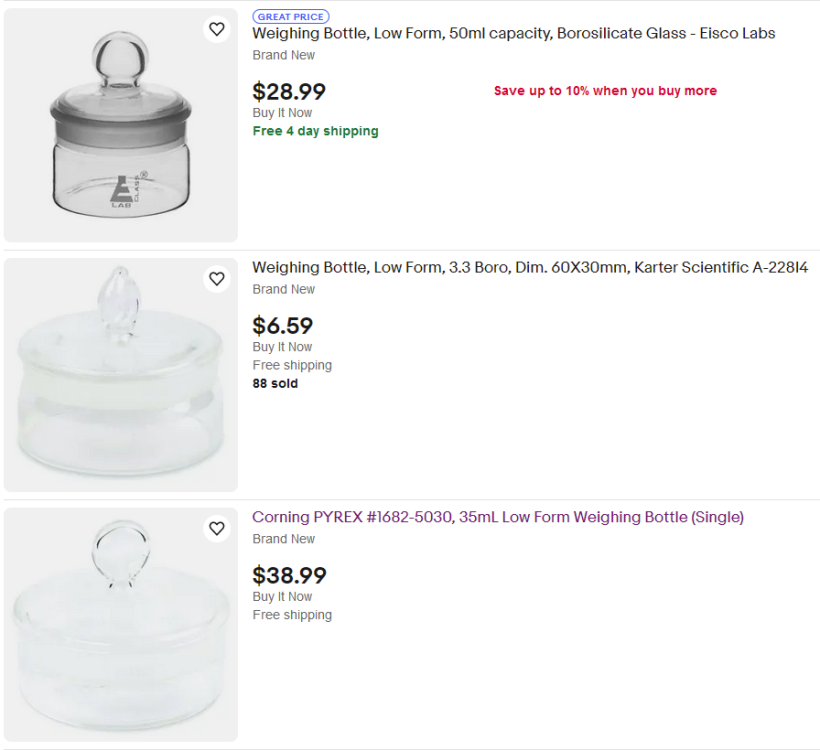

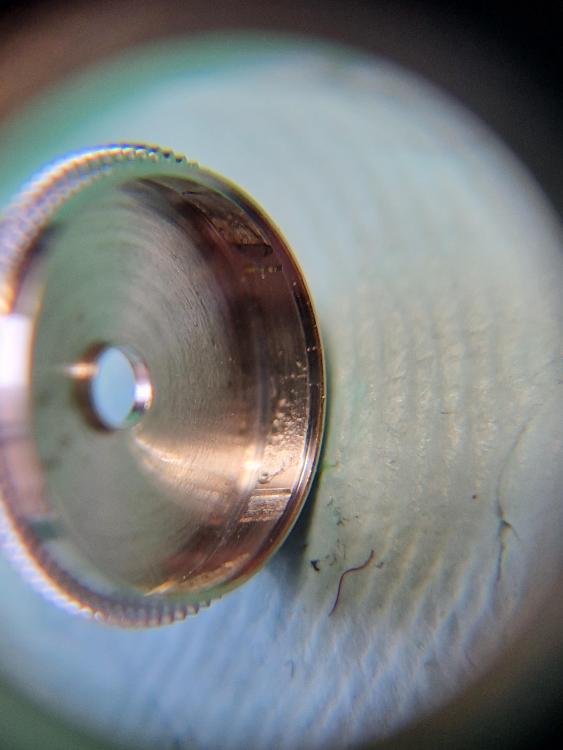

For most of my cleaning I use an ultrasonic with L&R chemicals, but I still like to clean my balance and jewels separately. Like most of us I think, I started with this inexpensive glass "alcohol jar:" Which works okay, but it doesn't have a flat bottom, it's kind of big knocking around my desk, and the lid doesn't seal at all, which causes my expensive (but effective) hairspring dip to evaporate very quickly. So I briefly thought about upgrading to the Bergeon benzine cup until I saw the price tag. This guy was a little too fancy for me... I did a bunch of searching around for benzine jars, then I decided to look on the scientific glass website and found the magic search words: "low form weighing bottle." Even the made-in-USA Pyrex one is a third the price of a Bergeon. Just wanted to share for those like me who are happy to pay a premium for quality, but not happy to pay a premium for a brand name.4 points

-

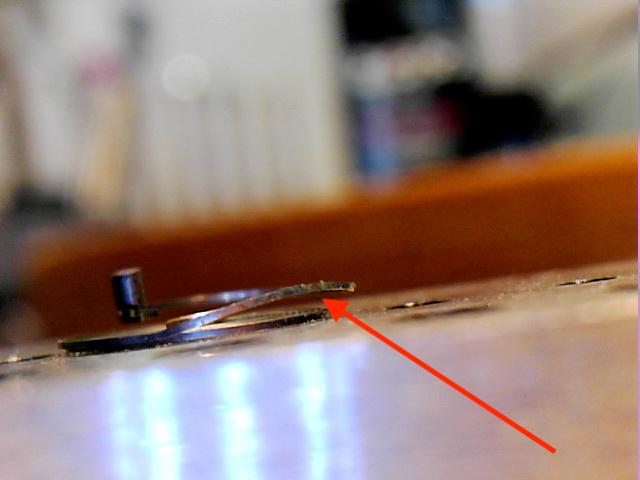

Getting there, the terminal end sits pretty horizontal and the regulator ark runs over the 10th coil from the center jewel. Like @nickelsilver said, final tweaks once mounted on the balance wheel and in the watch. BTW; with two tweezers (I used 2x Dumont N˚7) under the stereo microscope, due to limited depth-of-field, one wrong move and the hairspring turns into a ball of spaghetti ...... To be fair, somebody warned me Thanks all for your help3 points

-

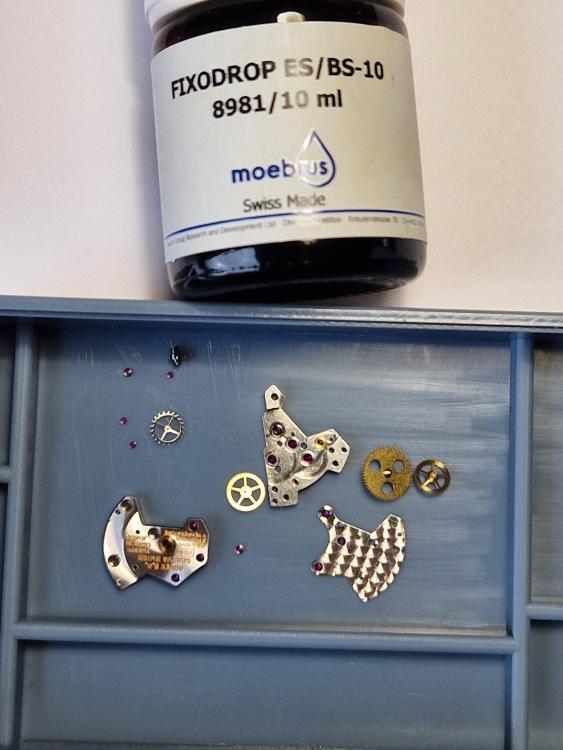

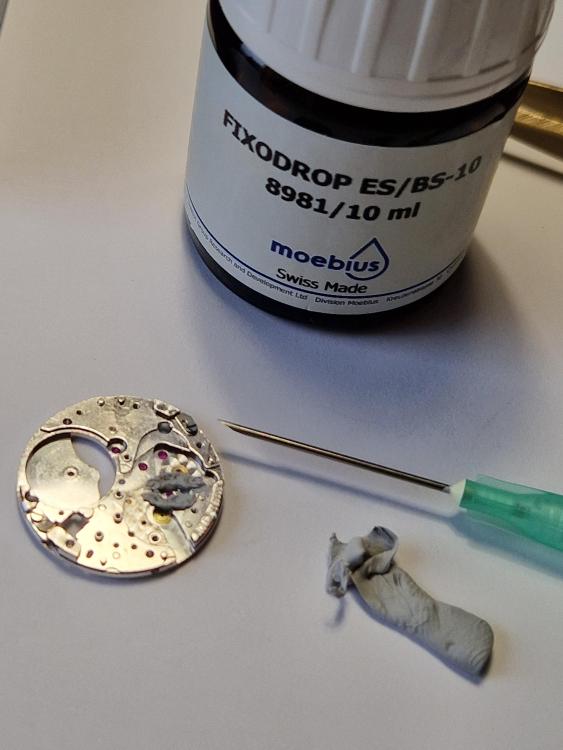

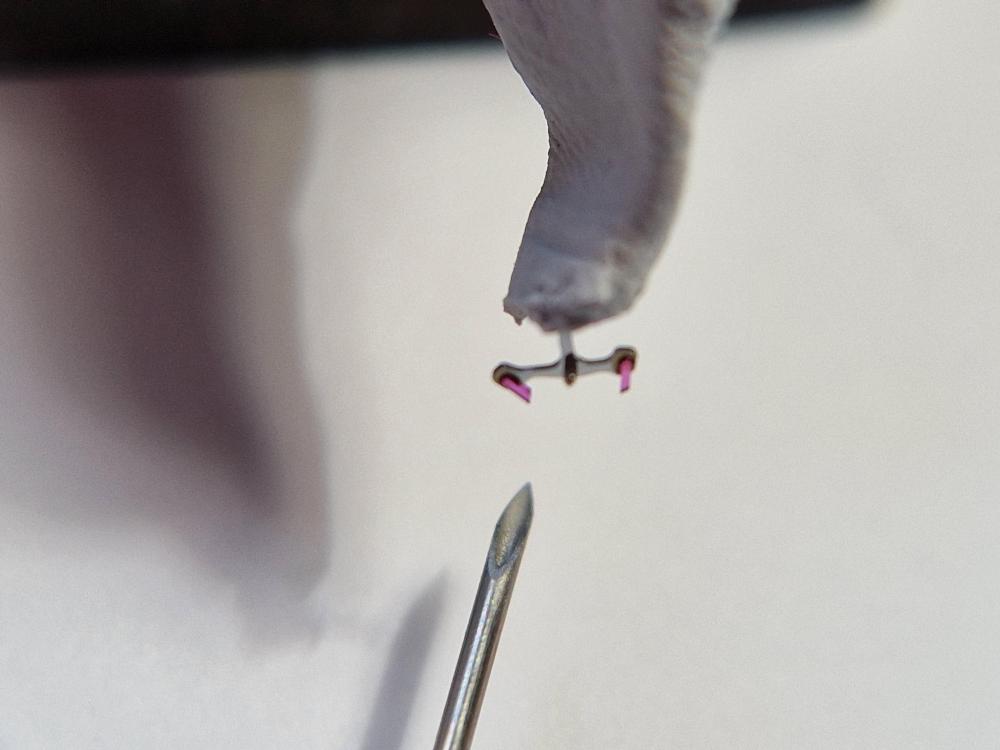

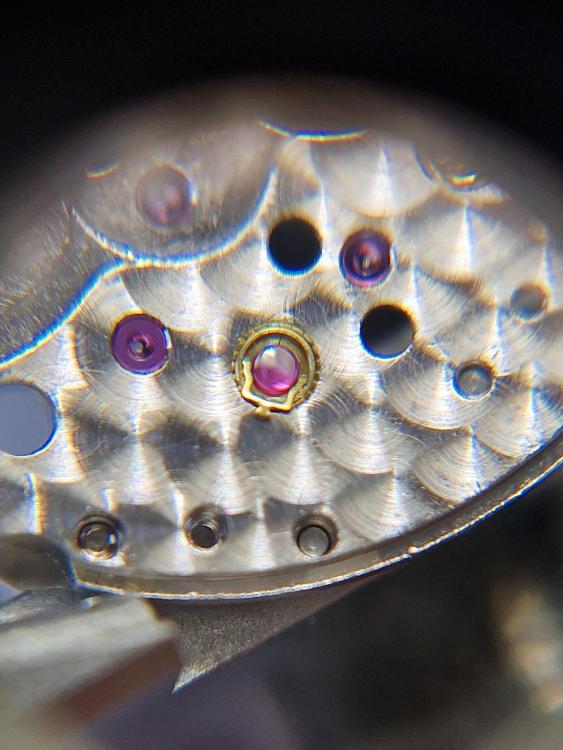

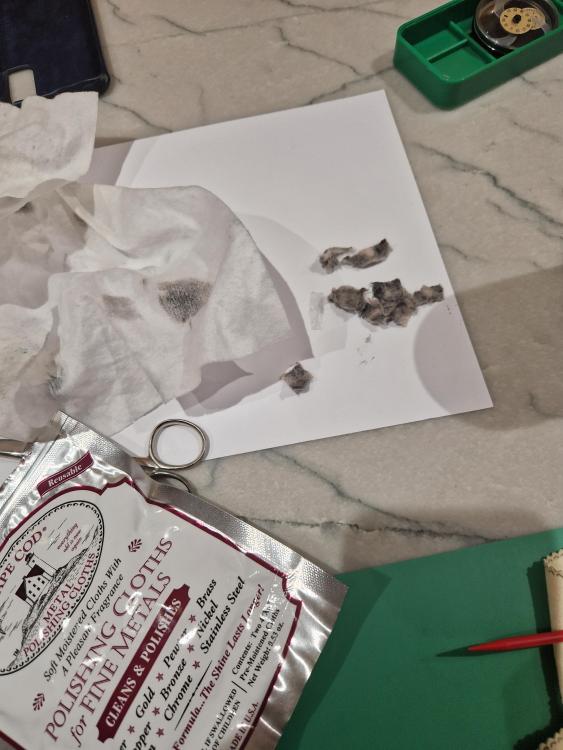

Some updates: 1. Cleaning done. 1 cleaning and 2 rinsing cycles of 8min each in my ultrasonic cleaner. 2. Epilame treatment (new reversers are on order and will be treated when I get them). After soaking in Fixodrop, I put them in a deep jar with some watchmaker paper to absorb the excess liquid and the use a blow-dryer on slow speed and low heat to dry the pieces. When treating the mainplate with individual drops of Fixodrop applied with a syringe, I stick some Rodico around the pallet fork jewels to avoid that epliame gets there (not sure that's excessive precaution, but want the jewels to stay without any residue). For the pallet stones for, I suspend the fork with some Rodico so that it hangs downwards and dip the stones into a drop at the tip of the syringe: 3. 8217 breaking grease on the barrel wall: 4. The escape wheel has shock setting in the Rolex. Note that you simply need to push (and somehow lift) the single pin, not take out the two holding ones. 5. Some work on the case and cleaning out the gaskets (ultrasonic cleaning afterwards). Next is assembly/lubrication, but still waiting for a replacement capstone (that I mysteriously lost...Note: all four capstones are the same).3 points

-

I just wanted to add to this goldmine of information as it has been really helpful for me. I've had my machine for a few weeks and was having trouble with foaming, related to the fact I'm using Elma Red 1:9 (water based cleaning fluid) and the fact that the rheostat isn't particularly sensitive on my machine (Pearl). I bought the same (overpriced) wave breakers as this chap. They're very flimsy stainless (I hope) steel and it was a bit fiddly to get them into the cleaning jar without bending them out of shape but they're a game changer on 2 fronts: 1. No more foam, whatsoever. The reduction of the amount of foam means I can now spin off the excess fluid without creating a foamy mess and in my view, as I'm not spinning the parts in foam, the quality of the clean is better. 2. Rheostat works better. The baffles/wavebreakers create more resistance in the fluid meaning the rheostat works as it should, allowing me to control speed in the fluid from very slow to very fast. Of course, the motor still spins like a maniac on meth when it's out of the fluid but there's very little I can do about that.2 points

-

This is worth a look. https://www.ebay.co.uk/sch/i.html?item=325913045129&rt=nc&_trksid=p4429486.m3561.l2562&_ssn=time_wize2 points

-

Ok. That is a shaded pole motor. Check that the welds of the copper shaded loops are still intact.2 points

-

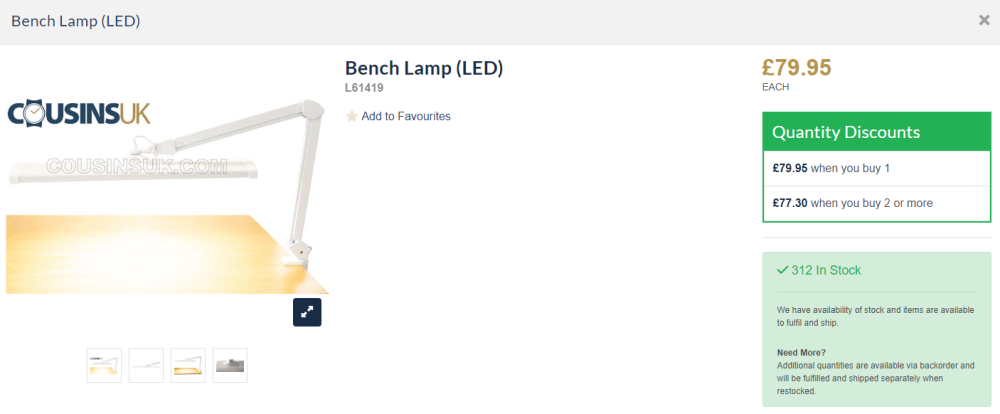

Ian, I would go for a bench light, I have the combo magnifier/light version and find it pretty useless for watch work. It gets used now only as a light and very occasionally to inspect a case or bracelet. Only my thoughts and opinion. Tom2 points

-

2 points

-

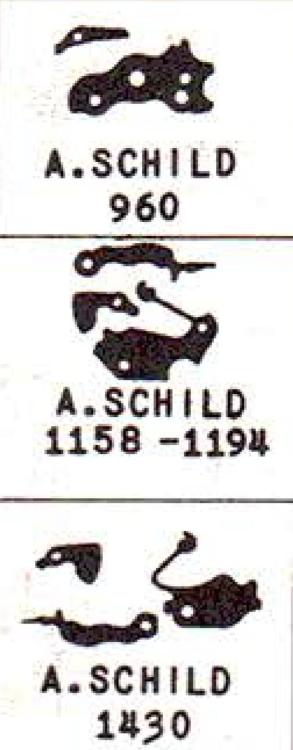

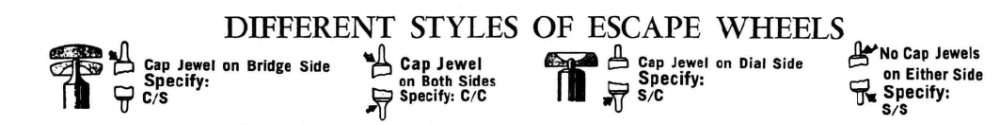

you didn't and I didn't but everybody else did we have to go back to page 1 of the discussion where it was ruled out so now we have to find something else let's go back to this webpage is it's not right by the way http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&AS_1194 the end stone on the escape wheel is not an issue the balance protection system is an issue sort of but not really let's go somewhere else http://cgi.julesborel.com/cgi-bin/matcgi2?ref=AS_1194 so here we get the parts list for the 1194 for which I have the feeling I've just done this the other day oh wait somebody else I think we did do this the other day it's a common movement with variations like on the parts list. Like for instance three different balance completes one of them with a well just like the link above a balance protection system another one with over coil hairspring which probably does not have a balance protection system the watch came in evolution of variations to your base caliber is probably this when you take the dial off someday you'll find out. oh and before we leave how many different escape wheels you have there's four of them how can that be how can you have forced escape wheels for one watch it make it really complicated watch unless of course there were variations. know what she should do should ask of someone would be nice and give you a link to the bestfit book you can download it for free but seeing as how I paid for mine I don't feel like telling anyone where to get it for free just one of my weird little things normal L Tilley about anything but somebody else will help to tell you where to get the bestfit book for free. Because the bestfit book has things like the fingerprint system which could be used to identify the watch once the dial comes off or it could be used to explain why four separate escape wheels exist for one watch in a way so what happens when you identify a watch is you you end up with the base caliber and like this watch has been around for quite a while lots of variations here's the meeting of the different escape wheel pivots basically every combination you can have so the watch had lots of variations more than likely your watches the 1194 or some minor variation2 points

-

I didn't, calib 1194 is ofcourse the most probable answer. just that I wasn't 100% sure. You have said it " taking the dial off " only then we can be sure. Plus the orientation of the balance cock is real confusing , both clock & anticlock orientations were made. Newbies might not that lots of similar looking calibs were made. Rgds2 points

-

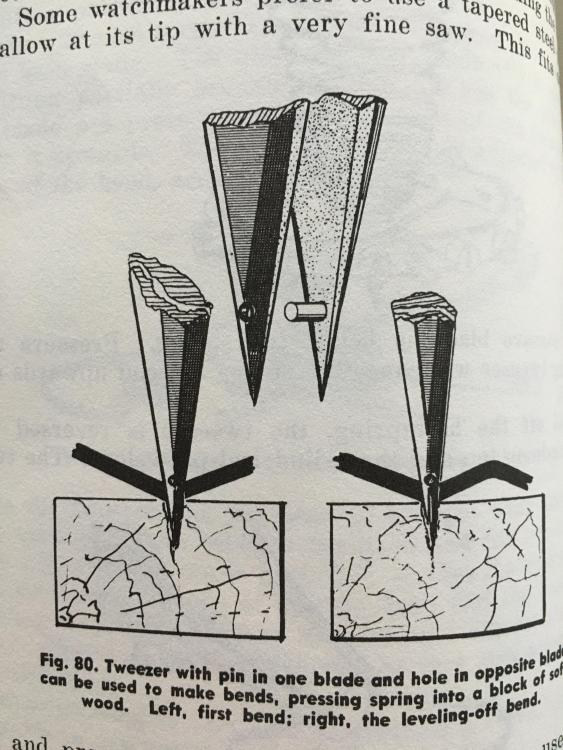

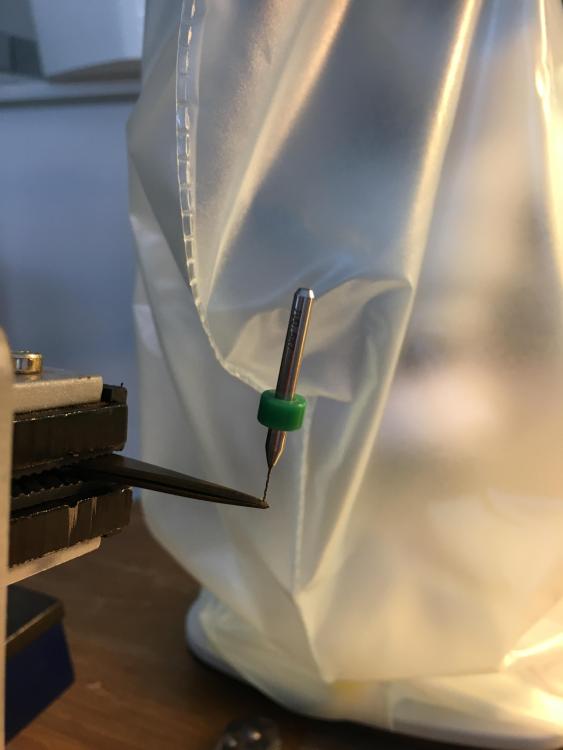

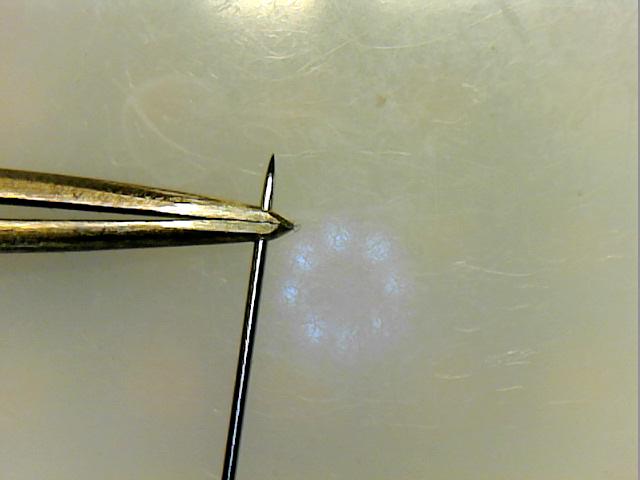

Yesterday I did several bending attempts (with "normal" tweezers) on a small (ladies-watch) hairspring and the results were poor at best. I noticed that while pushing the tweezers in the wood that either the hairspring slipped upwards in the tweezers, or that the tweezers would suddenly "sink" in the wood and bent the spring beyond repair. The soft-wood I tried was everything but consistence in its resistance. At a certain spot on the wood one had to push hard to penetrate the tweezers, on a spot next to the previous, the tweezers would sink in deeply when applying the same force. I decided to make an attempt to mimic the tweezers depicted on page 68 ("Bench practices for Watch repairers" by Henry B. Fried) For that I took some some pointy brass tweezers. The "pin" chosen was the thinnest needle I could find: 0.6mm Hand drilled a 0.5mm hole through both legs, close to the dressed tweezers tips: With the needle inserted; I could have trimmed the needle off, but as it turns out, either end of the needle do act like a safety, preventing the tweezers from "sinking" too deep into the wood. I also started to use another, more homogeneous "hard-wood", offering a more consistent resistance. I did a few more test on another PW-hairspring and the results were very good, very controlled and producing consistent bends. The bend produced is, due to the relative large radius of the needle, not as "sharp" as the first bend, but it does the job very nicely. Because the needle extensions are starting to "rest" on the wood, the bending goes very controlled. I'm not done yet with my hairspring, but the second (down) bend sits in without damaging the "one-off" hairspring. Adrenaline back to normal levels On the picture it looks like that the 2nd bend is a bit "over-bend", but that's only when you take the twisted continuation of the spring as a reference. In reality it's spot on, back to horizontal Next is to sort out the terminal curvature ........2 points

-

1 point

-

Hey, This doesn't help your focus issue but your mount is upside down. Take the scope head off and flip the focusing rack upside down. That fixed ring you have mounted above the horizontal bar goes below the bar, that way you can loosen up the mounting screw for the horizontal bar and swing it out of the way without your scope head crashing to the bench. You need to put your scope head in the middle of the focusing rack range, place a work piece under the scope and then find the correct rough working height of the scope so you have room to focus up and down, then lock the cross bar height. Then trouble shoot from there. There's no point in trying to figure anything out with the way you have the boom stand set up right now. Good luck, Darren1 point

-

The usual configuration that I have seen for watchmaking is with the 0.5X Barlow lens and the 10X eyepieces. That gives a pretty good working distance to use screwdrivers. Though, I agree with @spectre6000 that it may be nicer to use a 0.3X Barlow lens to give even more. I do notice that Amscope offers a 0.3X Barlow. Though, having a stand that allows the head to tilt could lessen that lens smudging issue. As for the camera, I am hoping that a 0.35X camera adapter will get the field of view through the camera to be closer to that I see through the eyepieces. My microscope came with a 0.5X adapter and the field of view is much smaller for the camera. I have a 0.35X camera adapter on order, but it is taking its sweet time getting here.1 point

-

What about a thin nato type strap threaded through pins/original strap?1 point

-

If you mean the one that screws on the main lens to reduce magnification and increase work space then yes that is the Barlow Rich. Tom1 point

-

It looks like a good alternative but it can't truly match being worn on the wrist. Your wrist is in almost constant motion in multiple directions and doesn't always move smoothly. It's amazing how often you touch your face without realising it.1 point

-

This is the one I use https://www.aliexpress.com/item/4000004784736.html?spm=a2g0o.order_list.order_list_main.125.755e1802brNoLK You have to mount it on a wall, otherwise, it won't wind the watches in all positions as it would on the wrist. You can't go wrong for £30 including shipping!1 point

-

Flaming heck Tom! £11.72. Good job I'm not going into business and it's just for fun. Would be another tool purchased.1 point

-

@VWatchie plenty of choice here from really cheap to “how much! https://www.aliexpress.com/w/wholesale-Watchwinder-professional-.html?spm=a2g0o.productlist.search.0 Tom1 point

-

1 point

-

Hi Marc, I'm in Singapore too. Welcome to WRT. What model and calibre watch is that? We like plenty of photos at WRT. It makes giving appropriate advice easier. Laser welding would not work if the tube is made of brass. Anyway, fabricating a new seconds tube is not that difficult. Start a new thread about the advice you seek. Members will be along to help you shortly.1 point

-

Switch is unlikely the problem. Bypass it to prove. I suggest you remove the earth ground that you added and see what happens.1 point

-

Same as Tom i have a big magnifying glass/light combo, use it quite a bit for case polishing and initial decasing and some disassembly. I increase magnification with it by using +4 reading glasses, for anything more detailed i pop a x5 loupe on the glass of the magnifier . It gave enough magnification to rough out an 8mm setting lever. But for bench lighting i have a diffused 2' fluorescent light ( £10 ) mounted under a shelf on the general workbench and a couple of anglepoise lights on the watchbench. One is really small but i can bring it right up to the watch and direct light inside it.1 point

-

https://carbootdirectory.co.uk/car-boot-sales-near-me/ http://www.carbootjunction.com/ Also look for "junk" shops, charity shops and local auction houses. You can find all manner of stuff at these places. It seems with the advent of online shopping, and post covid that in some areas there are as many charity shops as genuine retailers.1 point

-

there is more than one type of watch Winder there is the type you purchase to impress your friends that comes in a nice wood box. Many times there programmable sling will not over wind the watch but they're not going to do what you wanted to do it at all they typically look something like this http://www.julesborel.com/s.nl/it.A/id.40732/.f then if you are commercial watch shop this problem comes up all the time so you have a watch Winder like this. I'm pretty sure the Chinese clone it. So basically outlines the watch in multiple positions slowly rotates around and it's what all the shops use or something equivalent. http://www.julesborel.com/products/tools-watch-winders/bergeon-7802-115-v-new-final then of course there is the other way but? the other way is you would have a nifty which he timing machine that times watches in a multiple positions and he gives you a number equivalent to if it ran in all those positions. In the absence of that timing machine which is dreadfully expensive they have a PDF we could do all the calculations yourself. But as you've already found out instantaneous timing on the timing machine even with a equivalent number of multiposition timekeeping is still an instantaneous of what the watches doing now does not represent what it does over 24 hour's which is why the shops have the auto winding device up above. an alternative to you wearing the watch is to give the watch back to the owner and let them run it for a week and see what happens. witschi X-D-DVH-Di-Im-N_EN.pdf1 point

-

1 point

-

I don't think so. Have you noticed how robust and hefty those clamps are? Take a look at those tools in action and you'll understand. Take a look at similar tools from AliExpress. They are made by Kwong Yuen, which is one of the better Chinese brands. Kwong Yuen Watch Repair Tool Rolex Watch Strap Removal Tool Watch Joint Removal Strap Tool Watch Strap Removal Tools https://a.aliexpress.com/_mK31JSc1 point

-

I second that, I ended up donating mine to Mrs W's quilting room and opted for the cousins bench light which I 100% recommend: It's expensive, but throws out a huge amount of light - I'm sure the occasional 747 wanders off course when i switch it on. Being LEDs it doesn't cook you either. It is dimmable and you can change the type, (blue/daylight, warm/yellow etc.) so suit your needs also it clamps to the desk so frees up valuable desk real-estate! One of those few tools you end up saying "how did I manage without it!?!?"1 point

-

Depends where you are going waggy. Check for local carboots in the area you are visiting usually very busy in summer, tend to have more clocks than watches . Birmingham has a watch fair a few times a year and Yorkshire and Lincolnshire have plenty of antique fairs placed throughout the year.1 point

-

Yes that is genuine all right. There is nothing that tells me its a fake. If you look closely it all fits.1 point

-

1 point

-

1 point

-

Not as many as there used to be. They all seem to have gone up market, and the prices reflect this. Phrases like "Upcycled" and "new to you" seem to add an extra zero on the price. There are car boot sales though, which often have some interesting stuff.1 point

-

1 point

-

1 point

-

As mentioned earlier by myself and now Joe the setting components of the movement such as the setting lever ( pull out piece ), the yoke ( clutch lever, castle gear wheel lever ) set bridge with setting lever spring ( sometimes called a jumper spring ). Usually 3 pieces can be used to identify a make and caliber, sort of a finger print . These components can be checked against a documented list, books that contain these lists are the Bestfit watch material catalogs ( American ) Flume ( German ) Catalogue Officiel ( Swiss ). As far as i know these list systems finished sometime in the 70's.1 point

-

Some hints: - position the hairspring blade perpendically to the grain. - pushing too deep can be avoided by the laughed upon hammer taps. - the hairspring will slip up if the tweezers is too weak. Else: congratuations on your progress! Frank1 point

-

Because I didn't actually know the address or website I just searched for the word and the model number of the watch and there was a link. Just as when I went to the website I couldn't even figure out how to do a search for anything were typically in the past the only way I found the website was by searching for something and basically stumbling across it and then being in the weight with the whole thing I prefer other sites for cross-referencing parts and things1 point

-

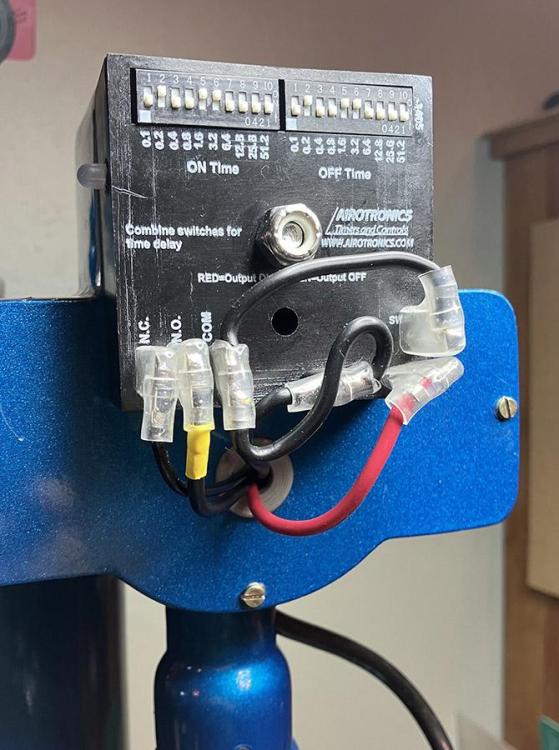

I finally got around to taking photos of my changes. Full setup. For baffles in the jars, I went the L&R route. I did a 4-wire variant of the original circuit. It does have a minor drawback where switching to "forward" while the red light is on will pass current through both windings for a few seconds which isn't so good for the motor. Creative soldering is required to get 2 wires on each spade connector. This is the 21EW91 switch set for 5 second intervals. Plenty of room for the motor with the right-angle connectors. 3D printed TPU grommet. I managed to relocate the LED so I can see it from the front. Potted circuits are a pain! Master switch and fuse. Also a 3-wire cord that properly grounds the body, plus the really good jar seals. I hope the helps someone out.1 point

-

I always thought it was anodized aluminum but that's just what I thought It's always interesting what I find lurking in my computer vintage service guide just in case you don't have one. Then you Need to be careful about a standard operating procedure of demagnetizing as there is a magnet found somewhere in this watch. You'll see is a reference to used for the breaking of the sweep second hand. 2030-2035 rolex tech.pdf1 point

-

On a roll this weekend and did another 404, this time a Shelton Cal BF158 which came as part of a job lot so cost £2.22. It was a runner, but couldn't get a timegraph trace, but when I finished it got it to -12 s/d, 248 degrees amplitude and a beat error of 1.6. As this is a pin pallet I decided to cut my losses and be content with those figures. I used some flitz to clean up the case and it took all the gold off instantly leaving me with a two tone watch with a silver case and gold bezel which I actually prefer to the original all gold finish. The dial was made of a card almost like paper, so used a pencil eraser to clean it up and it worked a treat! Here are the before and after shots : And here is the finished watch:1 point

-

1 point

-

I've used the articulating type at work, and I didn't like them as much. With the long arm, they vibrate. And don't stay as steady as you adjust the focus and magnification. The dual arm design and rotate and slide on the bearings, allowing it to move in the X-Y plane easily, to move the view around the workpiece while the Z axis, and thus the focus, remains constant. The the arm design is free to move in all directions, so it doesn't stay in focus as you move it around as easily. To give you an idea of height, with a 0.5X barlow the vertical distance from the eyepieces to the desk is about 17". 0.5x is the most useful working distance and magnification range.1 point

-

Correct, tube not split, just loose, well it was, not anymore :) I put a couple of dots of adhesive on the underside, and all good :)1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.39a5caffa306c63ad67a22bc41e65e03.jpg)

.thumb.jpg.7432ac45408ad3d1ba326c9569c53020.jpg)