Leaderboard

Popular Content

Showing content with the highest reputation on 11/24/23 in all areas

-

I think you’re on the right train of thought, you don’t need one till you need one. If you’re working on recent movements that are not very old then it is probably last on your list. From what I have learnt here and elsewhere the K&D vintage sets are the best overall, I’m sure folks will pipe in with their ideas too, hopefully. Don’t get hung up on it right now, you will know when. Unless you’re like a lot of us, we seem to be tool junkies then watch junkies Tom4 points

-

4 points

-

If all the vintage tools that watchmakers are currently using were to disappear because it's a museum piece watch repair would cease to exist. Vintage means nothing to a watchmaker that is a very usable tool.4 points

-

3 points

-

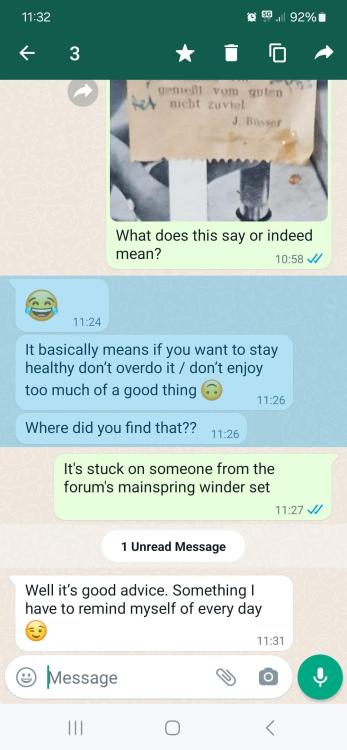

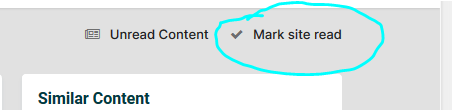

The reason you're seeing this as a new conversation is it is new for you. For instance when I come to the message board I click on the unread content. Go down the list and see what's interesting. But as you're relatively new here everything that you've never looked that will be considered unread new content even if it's vintage. I circled something in the image below may be clicking on that will help so you only see the newest stuff. Occasionally I run in the something like this where I'll see something of interest click on it and end up in the middle of a very long discussion. Because of someone replies to a multipage discussion and there at the end the message board will not take me to the end but it will take me to wherever I last was reading on that multipage discussion. So yes odd quirks the message board. Then discussions like this are interesting and basically a waste of time to purchase a paid in because look at the original posting person? Only did six messages and was last here in 2022. Often times with newbies variety reasons they don't get whatever they want and they don't stay very long. That means trying to help newbies out can be a waste of time if they're not going to stay.2 points

-

You will likely need a staking set at some point if you will be working on vintage watches. Finding a good set can get expensive (vintage or new). However, if you are just starting out in watchmaking, I'd place getting a microscope ahead of a staking set. I just got one and am kicking myself that I wasted time and money by not biting the bullet and getting one early on. So much nicer to use for servicing a watch than loupes, visors, or digital microscopes.2 points

-

Seeing as how most of my tools for jeweling and staking were purchased from antiques dealers this is wise…2 points

-

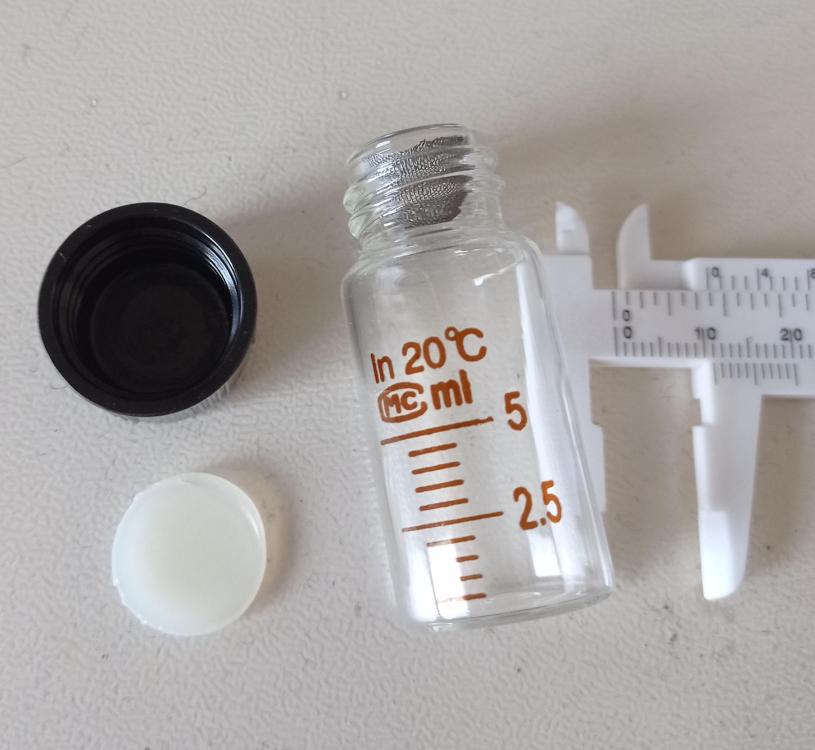

Well I have worked out the language thing on the Aliexpress pages. For some stupid reason when I was not logged in to Aliexpress the settings all came up weird. Only able to fix it by registering and logging in. Pages still don't load any pictures though. Even the most recent links. Not sure why though? I am going to go and get all my cookies now and clean them out and see if that helps at all. There are days I just hate computers.2 points

-

Thanks guys for the advice - I've since had a look at the gasket edge under my microscope and there is a chamfer that could be an insertion point for a thin blade. I'll try first using a razor blade and hopefully get it apart.2 points

-

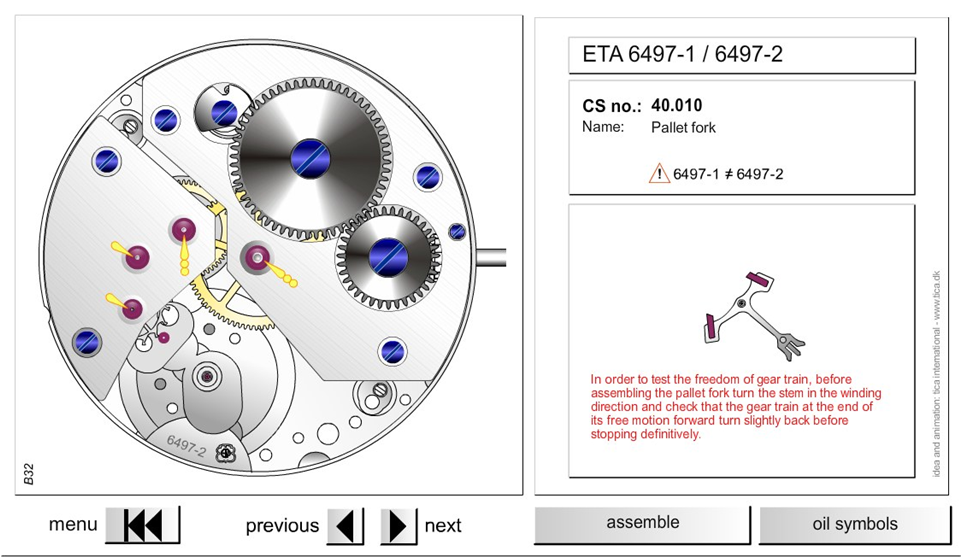

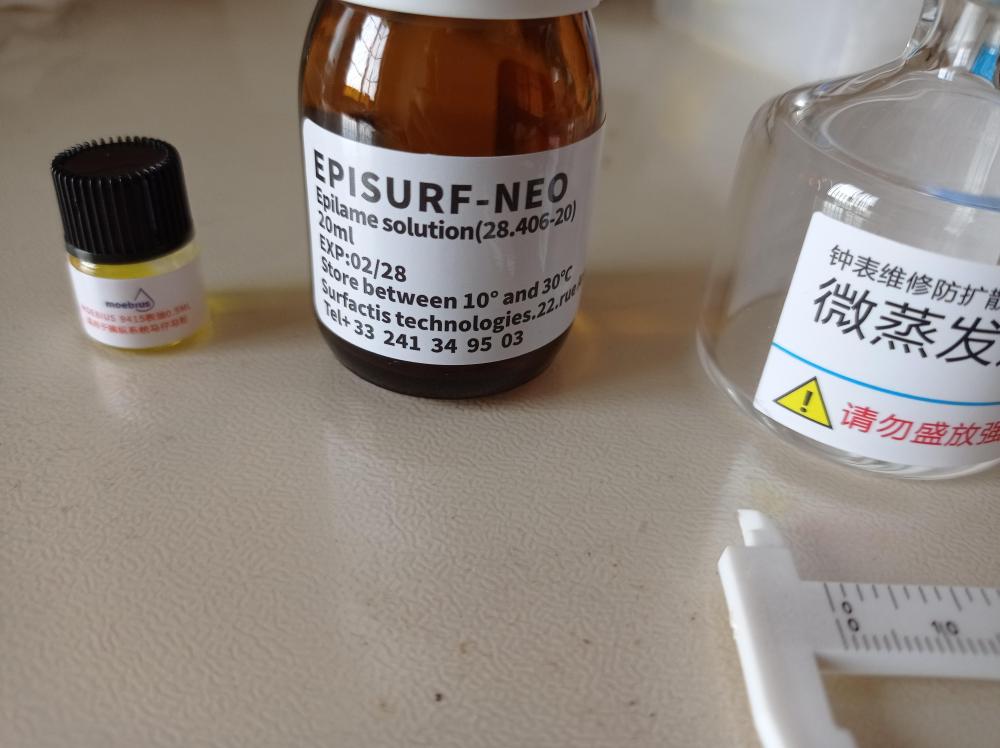

At one time Swatch group did have something which was step-by-step walk-through of several watches. Unfortunately as it involves moving graphics they made use of flash which is been phased out. But otherwise was a step-by-step of disassembling and reassembling four different movements. For instance this is a sample of one page of a pocket watch. Swatch group is interesting in that some stuff is available at least some of the modern ETA quartz and mechanical technical sheets. Vintage technical is interesting because often it was only scanned for parts availability and often times will be missing servicing information if it even existed at all. Watch companies have the silly notion that anyone working on their watch should know what they're doing so a lot of times service information was not available. I have the links below are you can find some technical information for the watches you seek. https://sellita.ch/index.php/en/movements https://shopb2b.eta.ch/en/2 points

-

I yet may take you up on that generous offer.2 points

-

You first have to determine whether the tubes are screw-in or friction fitted types. Look inside the case to see if there are any signs that the hole is threaded. If the tube is a screw-in type, wedging in a slightly tapered rod and turning it might work. WD40 and heat will help loosen it. Worse case scenario, you might have to carefully drill/ream/file until the remnant of the tube disintegrates. If the threads end up getting damaged, then you would have to thread the hole for the next bigger size pusher tube. If the tube is a friction fitted type, there are specialized tools to push it out. But spending money for an expensive tool for a one-time job doesn't make sense. Consider sending the watch to a competent watchmaker. https://www.cousinsuk.com/product/pusher-pendant-tube-fitting-removing-press-horotec-swiss2 points

-

Try heating the case to break any threadlocker, followed by soaking in Coca-Cola for 24 hrs. You can buy micro screw extractors or shape an old screwdriver into a wedge shape.2 points

-

Hi. From your description it’s the set up of the escapement that is out of beat. Take all power off the clock and make sure the movement is level. Observe the pallet in its rest position and the positioning of it on the escape wheel with the leader and pendulum hanging straight down with no power, is the pallet even within the teeth if not avhieve that by adjusting the the leader this is a friction fit , by moving the leader far left / right you are able to move the pallet In relation to the leader. Once having achieved the balance next set the depth of the pallets locking on both faces by moving the bridge / cock. When done apply two or three turns of the key and start the clock.2 points

-

It's 100% Bergeon. Well.... Bergeon had it made. I've owned probably a dozen sets of these, some marked Bergeon, some no name, but clearly from mid 20th century. Identical. There are little nuances, also between Bergeon sets of the same period. Definitely Swiss in any case. The big change on these was when they started making "Nivaflex" sets. The only real difference is instead of a hoky (usually too long) hook, the hook is "internal" to the arbor. Basically machined in, on a spiral, like a real barrel arbor, instead of being whacked in raising metal with a punch. I think it was to accommodate some of the unforgivingness of modern alloy springs being stretched out. Caliber specific winders soon followed, as the trend became to make barrel arbors smaller to allow more spring length, and the old standard winder arbor diameters proved to be too large. I might have this identical set- will check tomorrow when in the shop. I like that a lot of folks back then wrote the date purchased under the lid, I think the set I use most is marked 1943 .2 points

-

Many beginners are tempted to use a tweezer to grip the edge of the barrel and press down on a hard surface. DO DO THAT! That would end up damaging the teeth of the barrel. The trick in opening a barrel is to press on the edges of the barrel, without putting any pressure on the lid. It helps if you have thick skin on the tips of your fingers. Some people use their fingernails to press on the teeth of the barrel. I have also read of people who get a thick piece of perspex and drill a hole to fit the barrel in it. I also saw a video on YouTube recently, where compressed air was used to pop the lid off. Winding by hand is something that every watchmaker must learn. I have five different sets of winders but there will always be some deviant mainspring that won't fit any winder. I just had to hand wind a mainspring 2 days ago. Winding by hand can be painful. For a professional watchmaker who services 5 watches a day, that can really take a toll on the fingers. But for a hobbyist, that shouldn't be a problem. Good luck and press on!1 point

-

Interesting point and correct but all we can do, is try to help and hope that they will learn and stay on the site to help others in the future. I'm still an amateur and always will be, but thanks to this site, I've learnt enough to of at least help newbies from time to time. Thanks to all, my knowledge is still lacking but I started not knowing what a crown was , let alone a stem etc. Being of help is good enough for me.1 point

-

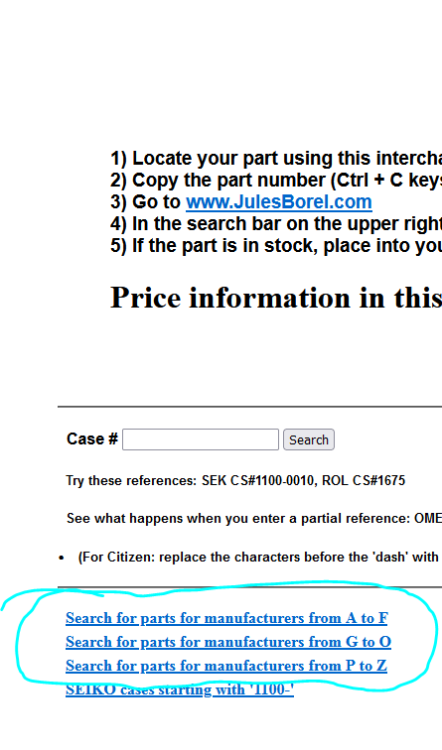

You're not going to find anything on your case back as the database won't have anything. In order to use the case back search you have to have a watch that you actually know who manufactured at it has to company that had parts listed for their cases like Seiko Rolex Omega and others yours does not fall under that category I snipped out an image for you notice I circled something that's where you want to go click on one of those links see where that takes you1 point

-

…of the vintage watches I work on 8 out of 10 cats need at least the barrel arbor play addressed and usually the center wheel too. In hindsight a staking set would have been after screwdrivers and oilers but before winders… A new set will be a hard and expensive endeavor. Get in line at Cousins…or study the auctions for used. I think I was lucky as the set I have is well loved but the bloke before me thought of everything I may need. Thanks mate…1 point

-

Found a video with a similar Chronoswiss. Seems as if the bezel was screwed on. Will try it tomorrow… Service of Chronoswiss Opus1 point

-

At some point in your time at watchmaking you will certainly need a staking set. Only you will know when that will be.1 point

-

@Michael1962 Clear your cookies. Your cookie thinks you're in some French speaking territory with some weird import/export settings on the seller side.1 point

-

I usually use a butane microtorch for heating seized screws. Depending on the type of threadlocker used, sometimes the parts need to be heated to 150°C before the bond is weakened. Before applying heat, make sure that any heat sensitive parts are removed, like orings, gaskets, etc. Although it might have a right hand thread, it usually helps to turn the part in both directions to break the adhesive bonds.1 point

-

1 point

-

1 point

-

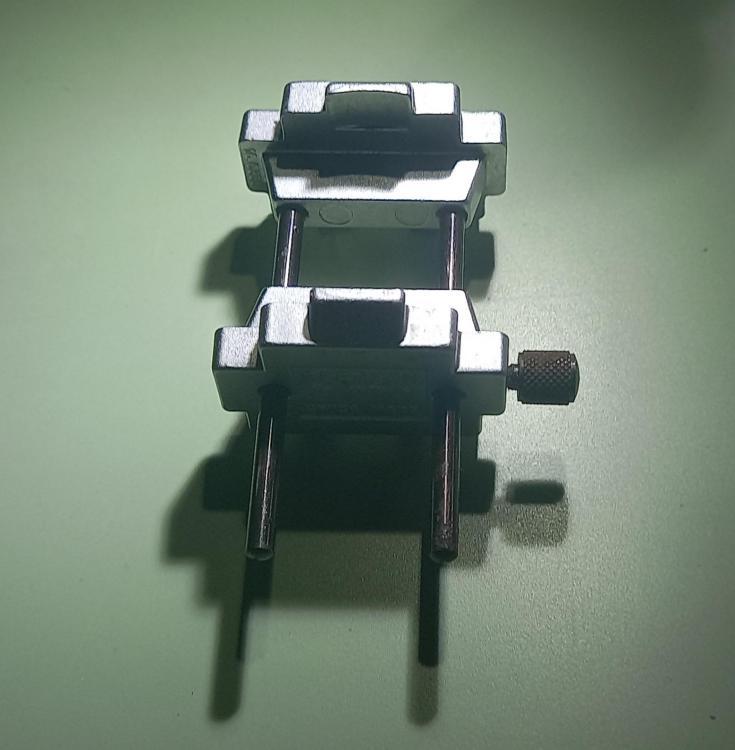

@Neverenoughwatches Rich, I think you were looking for a cross slide for your Wolf Jahn. Maybe worth keeping an eye on. Tom https://www.ebay.co.uk/itm/155899513887?mkevt=1&mkpid=0&emsid=e11021.m43.l3160&mkcid=7&ch=osgood&euid=3b9de3898c7b4b598298fa3642b9644b&bu=45234913067&ut=RU&osub=-1~1&crd=20231121052329&segname=110211 point

-

Assuming it isn't a one piece case try taking the back off so that you can remove the crown and stem, the replace the back and force air into the pendant tube with a syringe or a case pump to pop the crystal off.1 point

-

1 point

-

I can't see any way of removing the crystal without removing the bezel but I could be wrong.1 point

-

1 point

-

I ordered something for one of my daughters when they both lived in Melbourne from a Melbourne distributor. For some reason Oz post routed it Melbourne > Adelaide > Melbourne Tom1 point

-

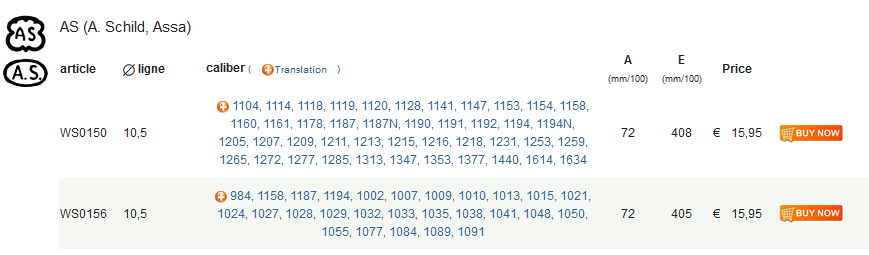

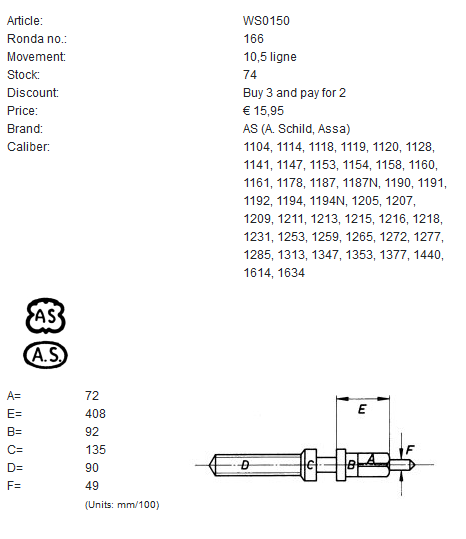

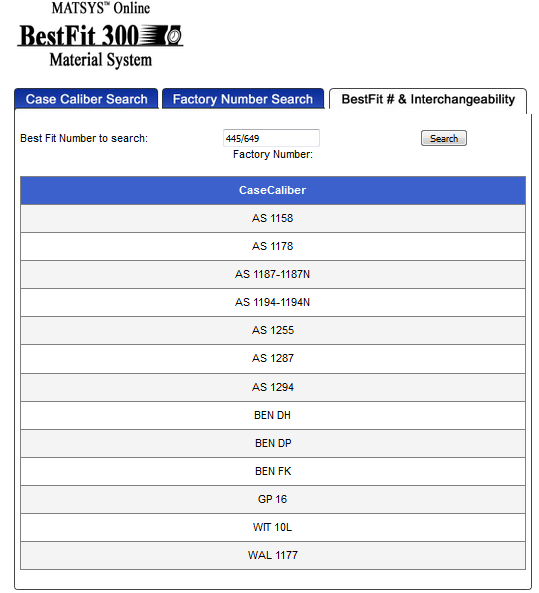

Spare parts unfortunately will always be a problem for one reason or another. Even if you 100% identify watch especially of its vintage there may be no spare parts available anymore. r have a mystery watch and try to find another one on eBay Howdy describe your mystery watch to see if anyone is selling another mystery watch that you can purchase for spare parts that becomes quite a challenge. Then since we believe we have identified the base caliber what about seeing if it actually matches the base caliber parts? You can look in the bestfit book because they do the same thing as the website. Such as this website https://www.windingstems.com/product.php Normally you using it if you want a stem or their other part the staff the other thing I use it for its a quick way to get dimensions where you don't have to look in the bestfit book which does list both of these by dimensions in addition to caliber numbers. So you know or think you have a caliber number you can look up your stem get the sizes and see how closely your stem matches. Then the setting parts of the peculiar thing where their unique for identification purposes to the company's get together and decide on that or did it just happened because of? But you start going beyond the unique parts how many parts will interchange in a watch with anything else? For instance the stem look at all the watches that use the same stem and I classic we have a variation but not much of a variation Now we get the dimensions and yes a lot of watches use that particular stem Now let's go to a different website in addition to bestfit online which you have to pay for is another free site. Which for the most part has exactly everything the same but not always and if you find a part here you can go to the main site and see if it's available for purchase sometimes it is http://cgi.julesborel.com/ Oh now we get to another problem certain movements set up and made over time will have variations. So depending upon the parts you need you need to be aware of exactly what you need. For instance balance complete there are four of them. Or the cannon pinion they came in different heights looks like six of those. The escape wheel is interesting because it comes in four separate types and the references to the type of pivot it has what is a conical or straight pivots. So all the various combinations are here so if you order and escape wheel you have to get the right one or it won't fit. Then one of my favorite parts the pallet arbor. Yes when you break the pivot off the arbor can be replaced providing you have the right tools to push it out and push it back in again and put it exactly where it was before. Pallet arbors are interesting because look at how many use the exact same one. So there are some parts that interchange with almost everything in the universe and then other parts that are unique to your watch. More than likely what we're seeing is depending upon who is manufacturing the movement conceivably they outsourced parts like the pallet arbor which was made by somebody else. You go down the list far enough that even looks like a couple of Rolex watches use the same arbor. So not only do you have companies manufacturing OEM movements conceivably you have them purchasing OEM components from other companies. This would definitely apply to a lot of the specialty things like the jewels or the mainspring or apparently pallet fork arbors. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=[^}D_Es Four of them are listed.1 point

-

1 point

-

Hello Ray, i am from Switzerland and the above mentioned eBay seller is more than ok. i bought many Movements and other Parts from them. But, if it has to be a Swiss Movement, i would buy a Selitta from them ( i have 2 x SW200 and 1 x SW220 from them). for the start i would suggest to buy Seagull Movements from Aliexpress or eBay, the ST2130 is equivalent to the ETA2824-2 and Selitta SW200, i pay about $58 for a ST2130, but for a SW200 or ETA2824-2 you pay between $200 and $300 depending on the Quality Grade (Standard / elabore / Top / Chrono ) hope this helps Ernst (And yes, many Years ago i was a Biker too, but different Bikes than yours)1 point

-

So maybe the Tissots won’t get here today. According to the tracking, the parcel first came to Sydney from the UK. Cool. Then Sydney to Melbourne. Cool. Then logically, one would expect the last 90kms to Geelong. Nope. Parcel has now gone to Brisbane for some odd reason. These watches will have travelled more of the world than I have by the time they get here.1 point

-

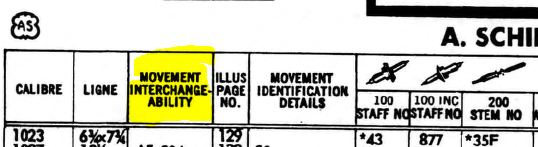

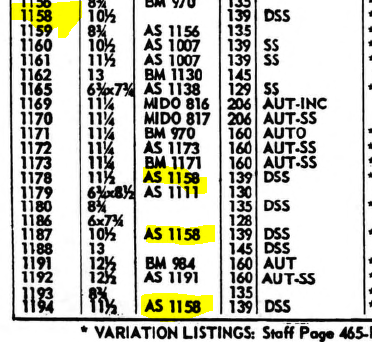

People collecting or repairing watches often are very confused by who made their movement. I was a lecture where somebody was giving the history of the Gruen Watch company and there is something quite fascinating. The collectors for being fascinated with who actually made the Gruen movements. What I was fascinated with is the company who made the movements who else were they making movements for who else needed high grade movements? Then some of the key players like their OEM company so much they purchased stock in the company with one of them finally purchasing the company as their own in 2004. You can see the sales price at the link below and you probably be surprised with who the company is you probably thought they made their own movements. Well they do now comes the own the company. The other thing of interest in the lecture was for OEM type movements when you have several high-end companies purchasing to make their movement look different they change the plate layouts and took out a patent. They still have people having the same movement but the plates will be laid out differently. This is why in the Gruen lecture he said there's still trying to figure out who made some of the movements and then be comparing with other companies to see if they could figure it out similarities and things. https://www.watch-wiki.net/doku.php?id=aegler So back to the problem of your watch identifying it? So yes the identification seems simple look at setting parts if they agree we have a number or do we? Why did companies like bestfit come into existence? So for instance we've identified the set bridge a key component in identification of your watch but have we identified the watch yet? Let's look at the top of the bestfit book noticed what it says gives you the caliber number the size the page where we can find the setting parts the part numbers and movement interchangeability? Let's go to the bottom of the page and we see that the 1194 as a base caliber of 1158. Notice in a few other movement still use the same base caliber? Now back to why do companies like bestfit exist? Even in this example we see in that a lot of parts will interchange and then we end up with a lot of other companies conceivably purchasing the movement putting their own name on it some companies like Bulova would possibly sell their own parts and soon you can end up with hundreds of parts packets considerably all containing the exact same part. Or maybe the company doesn't even have parts than you don't get that many parts at all. But then companies like bestfit come along they help you to identify your watch they give you part numbers and then you can hopefully purchase parts. Or maybe you do something a little different digital bestfit is online at makes it a lot easier to do things like this for instance that unique set bridge that identifies your watch I wonder who else is using that set bridge?1 point

-

Hi. I have a British made one National. Made in Manchester that has them mounted on the motor plate also.1 point

-

Hi V W. From my correspondence with the Gentleman Israel he comes across as a genuine person, if you do make contact he is in Manila and responsible for several tower clocks he has made as well as watch repairs. A man I would like to meet myself but unable to travel these days with my medical baggage.1 point

-

Eyup watch peeps hows we all doing. On my way to making my first watch part, this is a Kasper 700 setting lever around 8mm long made from an old feeler gauge. I still have 4 holes to drill 3 pins to fit and a hole to thread yey and its taken me 4 hours to get this far shaping it and polishing the edge although i did make a miniature diamond file as well. It is still in its hardened state, so that needs addressing before i can drill out and tap one of the holes for the set lev screw. Its not perfect but I'm fairly pleased with result, and I've learnt a lot with this first go. Getting into the knack of holding it and working around it with a file and a degussit stone and under a microscope took some time. If you think you have the right shape with a magnifier or a visor then think again, try x40 magnification, the cut from a 2000 grit diamond file looks the teeth of a 10 tpi hand saw1 point

-

1 point

-

1 point

-

1 point

-

Hello and welcome to the forum. Pictures of the watch in question would be helpful. Thanks1 point

-

1 point

-

1 point

-

Welcome to the forum, enjoy. Assembly is a skill that becomes easier the more you do it. For balance staffs the best I have found is: https://www.balancestaffs.com/product.php1 point

-

Ok, Im not sure if this is appropriate for this forum so, mods, please remove it if it should not be here. But, I made a strap! I recently bought a "nice" watch from Japan and wanted to put a decent quality strap on it. My only problem is that Im not sure what constitutes "decent quality" for any given price point. So I figured how hard could it be to make my own?! A few YouTube videos and a peruse of ebay and I had the equipment and (hopefully) the knowhow to give it a go. Now, don't get me wrong, it is rough, and I have no idea if it will hold up but it is my first attempt so I still consider it an achievement!1 point

-

0 points

.thumb.jpg.ef814f9379edc6c96e2f59156f3988e2.jpg)