Leaderboard

Popular Content

Showing content with the highest reputation on 07/07/22 in all areas

-

3 points

-

This clock should have "automatic" beat setting (beat is the eveness between the tic/toc); you pull the pendulum as far as it will go in one direction and release it, and a friction clutch at the pallet shifts as the pendulum's amplitude decreases putting it in beat. It's not a foolproof system, sometimes you need to manually adjust it some more, but if the movement is otherwise in good shape the auto-set should get it running. These modern German movements defy the concept of "German quality". Typically after a decade or so they will need a number of bushings installed and pivots polished* to get them to run correctly. *many are not even heat treated, just plated, and when the plating flakes off that's about it unless you repivot2 points

-

with this track history you definitely have a pattern of there's something you're not doing or you're not doing it correctly. So the movement purchased for Mark class is running because it was always running so that tells us you're not doing anything destructive when you're trying to service the watch your just not doing anything that improves nonrunning watches. in other words you still haven't learned how to properly service a watch. Seeing as how you keep having the same thing happen over and over again we need to stop and look at one watch pick one probably not the Seiko is based on JDM's remark of your not there to that level of perfection might yet so I pick a Swiss watch. Let's get a breakdown of where do you put the lubrication's? Then why did you replace all the components did you perceive that there are bad in some way? Fortunately you're dealing with modern watches of this had a bin vintage that would've been your problem right there because vintage watches parts don't interchange usually not without adjustments I suppose you should finish doing the watch are currently doing a will see what happens otherwise let's start with the ETA 2789-1 and see if we can figure out what the problem is.1 point

-

Hi LWS. They are quality clocks and worth a bit of effort in fixing. The only problem is the pivots they are glass hard and don’t suffer abuse. Is the pallet jewel Ed or polished steel, Some on the brocot escapements were ruby pallets , very fine. Ithink we all were careful growing up, we were the same although the garden and the chickens helped a lot never hungry.1 point

-

I can speak only about Seiko. First, they normally run with a reduced amplitude by a at least 50 deg compared to the Swiss. That is because they have excellent industrial desing and strict mass produced tolerances, so to can use less mainspring energy (amplitude) to delivery the same timekeeping performances. However due these strict tolerances if any thing not 100% perfect in the hairspring and escapement, they will do exactly as you noticed. And that is also why they are not a good choice for beginner, and even avoided by some so called professionals. There is no margin of error when you want a cheap Seiko to run good. At the factories that made (and still makes) thousands of pieces a day, the ones that don't perform are scrapped and crunched and nobody knows about.1 point

-

Two have new stems. 1 has new escape wheel. 2 have new balance replacements from movements (ebay). 1 has replacement barrel bridge. All parts a cleaned with lighter fluid. I have cleaned all mainsprings by hand and replaced by hand (with cots). I have mobeus 2010, D5 and Molykote DX. I oil as per instructions from members and pdf's. Watch movements ETA 2789-1. Replacement parts from 2789-1 and 2789 movements. Seiko 7S26. Replacement parts from 7S26A movement Seiko 7009. Replacement parts from 7009A movement Seiko 6309. Replacement parts from another 6309 movement. Seiko 6319. Replacement parts from another 6319 movement. Every watch eventually works, but when running are low amplitude by sight. All stop after a short time. The only thing I am not comfortable with, and have only attempted once, is removal of the balance jewels. Did it for the ETA 2789-1 and spent three weeks getting the spring back in. The only one that works correctly after reassembly is the new movement ST3600 I purchased for Mark Lovick's course. I have dissembled a Citizen 8200a. Cleaned and made ready to reassemble. Don't hold out much hope, but will let you know on this one. Ross1 point

-

1 point

-

To raughly check the amplitude (and to verify the app) you can take a slomo video of the oscillating ballance with your cell phone.1 point

-

in your background history did you service this watch? In other words you receive the watch was not running or was running and then you service did and now it doesn't run at all? Did you clean the watch how did you lubricated and did you change the mainspring? then the wording is interesting other words you put back the parts that were originally in the watch or you replace them? typically no hairspring seemed to last forever. most common reason for something like this is problems with the balance pivots. Or the balance jewels if there are any at all in this watch.1 point

-

1 point

-

pick one ear watches that isn't running well give us some pictures of what the phone app is showing us. Now I really would try to get a Chinese timing machine 1000 at the minimum 1900 if you can afford the money. The reason I say this is it measures amplitude it doesn't look like for the link I have that yours does. The problem with apps in watch repair discussion groups is often times the people a been led astray by faulty data and they really don't work that well. So basically we could waste a lot of time if your app isn't perfect and your app has a problem of what's the amplitude https://play.google.com/store/apps/details?id=com.watchaccuracymeter.app then let's do an experiment? As you have no way of measuring amplitude let's calibrate you. yes the wording may seem strange but we don't know if you're actually calibrated to correctly read the amplitude at all. It's one of the reasons I bought it newfangled digital timing machine was so I didn't have to figure this out as often times it's really hard for people to grasp what they're seeing now that number may be too low for us but I have a video. Let's pretend you're going calibrate a timing machine. In other words you look at the video and get a clue as to what 180° look like if your watch can't hit 180 you have a really really serious problem. https://youtu.be/-Xgcck692js then this is why I usually tell people to start with the Chinese 6497 clone. You start with a running watch you know where you stand and it's usually a good way to go. How do curiosity are you trying to fix broken watches? In other words the watch wasn't running in the first place and still is it running because of that's what you're doing that the problem may be the watch needs more than just cleaning. May case went to give us a picture of the watch are having a problem with her one of them it helps of we can see a picture of what you're dealing with. Then a picture of the timing app results would be nice1 point

-

1 point

-

I think the best thing you can do for your hobby now is to get a Chinese timegrapher, like the wei Shi 1000. If you are sure that the amplitude is that low in all the movements you’ve worked on, you really need to inspect all the pivots on the train of wheels, and the balance wheel, and the jewels. In a movement without lubrication, but is otherwise fine, the amplitude at full wind is normally at least 240deg… I would normally investigate the end shake as well, but it seems unlikely that the end shakes are all out in all your movements.1 point

-

Welcome to the forum Jeet. As you can see you've come to the right place for help1 point

-

Hi I should make up a board as a stand and fit the clock mech to it and fit the leader suspension and pendulum as setting it up like it is is nigh on impossible., all that is required is an L shaped board with 4 holes to accomodate the movement clamped to the bench with enough clearance for the pendulum to swing. set the movement level (use spirit level) thsn listen to the beat. As OH said the crutch is friction fitted and able to be moved left or right. then adjust the pendulum for an even tick/tock. as Stopping in this position could be a depthing problem with the pallet and escapewheel check the escapewheel teeth are good and have no burrs or are bent slightly it doesnt have to be much to stop a clock.1 point

-

That is nice to know that you have all the parts. It is most likely the clock is not in beat, it needs to have an even tick tok. The green arrow pointing to the crutch is friction tight. With all the parts assembled and the pendulum swing the pendulum lightly if it sounds out of beat move the crutch a little one way until you hear an even tick if it sounds odd move the other way it is a trial and error. This is a set up that needs to be done with all clocks that have a pendulum.1 point

-

There is no direct 'adjustment' for amplitude, as that's simply the result of a myriad of both intrisec design constraints that can't be altered, and physical errors, imperfections, or plain faults that range from quite severe to very small. That being said if the balance oscillates very little, and stops regularly the fault should be large enough to be immediately discernible for an experienced repairer. Unfortunately I know well that is not the case as for hobbysts, beginners, which includes myself BTW.1 point

-

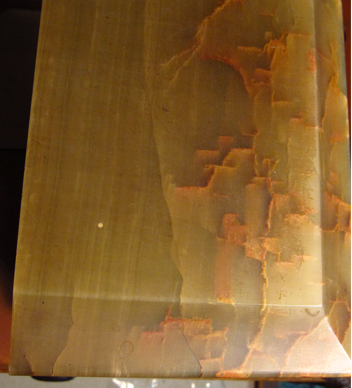

It isn't going to work properly with that stone. I don't see the suspension spring? You need that and the correct pendulum. The leader is also missing. All parts should be oiled I always recommend Windels clock oil. Do you have these parts or are they missing?1 point

-

was it running before you started practicing on it? oone of the problems with starting on something like this is it's not really the best thing to start with. On most watches you could take the balance wheel out you could check for power on the pallet fork you could take the pallet fork out see how the gear train spins but this is kinda like all or nothing. how worn out was this? The unfortunate problem of dollar watches are they were made to last forever.. So did you look at every single pivot and see how smooth and nice of looked at all the holes looked perfectly round. If you wind it up to push gently on the balance wheel does a pallet fork snapped nicely or is it seems sluggish. It be a lot easier to see this of the balance wheel wasn't in. Where the condition of the balance pivots like? There is also screwed to adjust that so they has to be enough play so it can move effortlessly. how did you do the lubrication? Did you unpin they hairspring we took the balance out? If so did you put it back exactly where you found is so the watches in beat?1 point

-

llooks like a weird version of a Waltham car clock. Now is the car clock the back would unscrew off the movement but I can't quite tell from the pictures whether that's going to be true or not.. iif it's the car clock it's just a really big pocket watch. A very large pocket watch that I'm not a fan of.. But if it is the car clock you should be able to remove the stem that should come out like a standard pocket watch them.. In the movement comes out however it's mounted and then you can see how it comes out of the case..1 point

-

advanced amplitude adjustment is not a beginner's field requires a special tool. You can only obtain the special tool once you complete the special test and complete the form all 100 pages of it is submitted in triplicate to. I wish it was that simple yes that would be simple if that's how you adjusted amplitude. If your watches truly running 100° you have a very very serious problem. If you had an Omega for instance at the end of 24 hours some other watches they might accept 160° only for those keeping time. Simplistically your watch running sucks there isn't sort of an adjustment for the.. It's basically back to the beginnings of did you change the mainspring, have you properly lubricated, could we have a picture of the watch they are talking about so we can see what you're talking about. This is where a real timing machine would be really nice. Because with a real timing machine like the Chinese 1000 or preferred 1900 it would really help for diagnostics. If you amplitude is really running at 100° now how long until the watch stops Kennedy even run overnight? so in order to run 100° mainspring set although even a set mainspring will run a watch better than 100° at least was fully wind but it would die really really fast. ssimplistically basically everything the watch can be a problem with the running that while. Nine then yes there are escapement adjustments but let's get a picture the watch that you talking about.. Start with the basics give us the history what have you done to it. wwhat exactly do you do with your android phone in your watch?1 point

-

Those balls work well and at only a £1 in the local toy shop quite a bit cheaper than the ripoff Bergeon version.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. Please put you questions about your clock in the clock section and add photos. Then I should be able to help you.1 point

-

Check the mainspring. These pin lever movements need a lot of force to get going. Maybe apply some torque on the barrel gear (not the ratchet wheel) and see if that helps the watch run better. If yes then you need a new mainspring. I assume you've cleaned the movement? Ive worked on something similar which had cone shaped balance pivots. Very robust but easy to get gunked up as the working area is very exposed. The balance needs to be removed from the cock and cleaned thoroughly. Hope this helps. Anilv1 point

-

Post some pics when you get it. Like John said, there are many different configurations; looking at my Hardinge 1913 watch tool catalog they list 27 different collet types for watchmaker lathes . The most common is 8mm though, but there there are still differences. Without knowing what you have coming it might be fruitless to give advice on how/where to oil etc. But as for first work to practice, get some brass bar, maybe 3 or 4mm, and practice turning a nice cylinder. No taper, clean square shoulder. Then make a couple different diameters, straight, clean, no taper, clean shoulder. Then start hitting a specific size. Then go smaller, try turning it down to 1mm. You have to play with the graver, how it hits the workpiece, to find a position that produces an actual chip- usually a curly ribbon coming off the work. The position changes constantly as the diameter changes; keep making piles of chips until you are really comfortable moving the graver around. Then move on to steel. At some point you can try making a scaled up balance staff- try in brass first, then steel. The more time you spend turning the better your hands get at knowing what to do, your brain will go in auto mode.1 point

-

1 point

-

it should definitely be lubricated watchmakers lathes run on lubrication. But strangely enough a lot of people forget about the run their bearings dry in them they wonder why they have issues. definitely a good book and you can download a PDF for whatever version you like from the link below https://archive.org/details/watchmakerslathe00good unfortunately want a great deal until you get it. Then you have to be careful what the term watchmaker's lathe. You understand that if you look at the PDF of the book above because they come in variations. Some variations getting collets are practically impossible for instance. But still the design of them is quite rugged especially to survive typical watchmakers who forget the lubricate them etc.1 point

-

I went with the RELIFE 0.5 one listed below https://www.ebay.co.uk/itm/124311756895?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=PNBmY-cRSd-&sssrc=2349624&ssuid=cJqjENlHSBe&var=425201768463&widget_ver=artemis&media=COPY1 point

-

I took Kalanag's idea and ran with it. This works. One of the issues with the project is that the wound spring and housing does not sit inside the mainspring barrel before you press the plunger. This means the chances of the spring not seating well are high (as mentioned a few times in the thread). Kalanag's idea was to slightly eject the mainspring a tiny bit before trying to seat it in the barrel, now the spring can "set" in the bowl before you press the plunger. The chances of ejecting the spring too far and unleashing it are too great. I designed a "WinderSetBowl" to make this job foolproof. It is essentially one of Zero's barrel bowls, but set to be just 0.3mm deep. It should be sized to accommodate any winder in Zero's complete set. Instructions: After you remove the Winder Base from the Main Housing, place the housing in the "WinderSetBowl" and press the plunger. When you remove the housing, you'll notice the wound mainspring is now perfectly ejected exactly 0.3 mm. Now you can easily place it in the Barrel Bowl and eject the spring into the barrel. I am happy to place this in Thingiverse, but if Zero likes the idea, he is welcome to include it in his GitHub repository as part of his set. For now, if you would like, contact me and I'll email you the STL. I've already printed and tested this and it works great!1 point

-

Thanks @Paul80 - I now have wifely permission to pull the trigger on buying one of these Relife trinocular microscopes. There seems to be a large selection of Barlow lenses available - which one did you use here, please? Did someone say I need a '0.5' magnification?1 point

-

Red Dot Diver is a nickname and this is actually a Marlin. Based on the hands I'd say it was second generation and from 1984. Yes, you will need to lift the bezel and the crystal to remove the movement. I don't see anything wrong with the crystal that a good buff and polish won't fix. What is wrong with the movement? BTW - you know one diver leads to another...like this The diver upper right was the latest addition.1 point

-

I also experimented with winders either 3D printed (https://www.thingiverse.com/thing:3540660) or otherwise self made (see attached) and know the issue. I managed to insert the mainspring without loosing the bridle by pushing the mainspring out of the winder a tiny bit beforehand. Then I centered and firmly pressed the tool on the barrel before pushing the plunger.1 point

-

Welcome to the forum Tim! I will often point folks to this web page which offers a really good look at a mechanical watch using some very good animations. If you spend time looking at that you'll learn a LOT. Also, I agree with @watchweasolabout Mark's online courses, they're well done and his level 2 and 3 teach you a lot. Level 1 is also good if you haven't spent the last three months watching every YouTube watch repair guy fix watches - it is really basic.1 point

-

Hi Tim If you are truly interested you could do no better than enrol in Marks Online courses (information on this site). Mark will take you through from the basics to being competent in repair and handling. "Watchfix.com" will also take you to Marks courses. I have attached two documents for you to peruse to give you an idea what its all about. Hope you find it helpful. In the mean time find an old pocket watch and get some good screwdrivers, tweezers and a loupe and have a go, best get a working one so you know it was ok to start with and should work afterwards. good luck. if you need further information just post the questions we are all here to help you suceed. Cheers 1612608791_ToolsfortheHobbyist (2) (1).pdf TZIllustratedGlossary.pdf1 point

-

I purchased this movement some weeks ago and it wants to run. I haven't yet done anything with it because I keep fouling things up with washing the balance and destroying the hairsprings. I'm also still shooting screws all over the place but the new tweezers I got seem to be better (or maybe it's just me)? Anyway, I also got a macro filter to get me somewhat closer than my 100M28 macro lens. This is a focus merge stack of 12 exposures. I see some distortion around the text on the bridge and wonder if instead of 12 shots if I had made smaller focus adjustments and merged 48 instead. Will need to experiment. Also (as noted elsewhere) I pulled the trigger on a trinocular AmScope 7x - 45x boom stand microscope. The scope ought to allow me to drop one of my cameras into the third tube.1 point

-

This is very true anilv. I adjusted a couple of cheap ones when I started repairing. Spent a good hour taking the thickness out of the back ends of them. Made a big difference to the feel, but then acquired a couple of full sets of Dumont and a few others from a job lot sale. These are far superior to the cheapos that I was using. It probably is you G, but you just need to practice mate. Don't let it bother you, you will get better honestly. What specifically are you having trouble with ? Pin down the exact issue then work on that. I've strength trained for 15 years and did body building and martial arts on and off during that time. Researched and studied endlessly how muscle fibres, tendons and ligaments all work in synergy. Understand how our motor skills adapt and learn to cope and compensate for different situations. That process is less adaptive as we get older we have to accept that that is a part of aging. But I've trained with men and women in their mid seventies and it blows my mind what they were capable of, age is just a number, accept that number is never going to go backwards but not that it is going to hold you back. Believe that you can do much more than you think you can. Just practice G everyday with a good pair of tweezers, choose the set you are most comfortable with now and stick to that set, don't chop and change because that will disrupt your fine motor skills learning. Our motor learning takes on a similar path to our muscle memory ( we never forget to ride a bike, bit rusty to start with but we quickly improve ). It takes around 300 repetitions to get a form down, if those repetitions are of a crap form because they were rushed or we weren't concentrating on making them good to start with then we've got stuck with a bad habit. It then takes another approx 5000 repetitions to correct that form and make it work the way we want it to. Basically to save a shit load of time get it right first time. This applies massively to bodybuilding as an extreme of our physical abilities but it also applies right down to our finest motor skills. I think what you might be experiencing G is the bad habit of gripping your tweezers too hard in an attempt not to drop anything, unfortunately this has the effect of pinging tiny parts away. Do what I suggested a little while ago, slightly roughen the inside surface of your tweezers to give them a little surface friction, ask me what or how to use or do it if you are unsure. Then just practice everyday for half an hour picking up different sized screws, twist and turn your tweezers while holding the screw adjusting your grip to stop you dropping the screw. Keep your touch very light, never overgripping as this will pull you back into that bad habit that you are trying to get out of, it's far better to drop the screw in front of you than it is to ping it off into oblivion . It will take a little time G so don't get frustrated if it isn't working overnight but it will come and you will become really good at holding screws and springs etc without dropping them or shooting them off.1 point

-

1 point

-

1 point

-

1 point

-

Well I would definitely start with Moebius 9010 (for train wheels and balance endstones) and 9020 (for train wheels) if you are working on Pocket Watches. Moebius 9415 is a must for Pallet/Escape wheel teeth. A quality silicon grease. Moebius D5 is essential (barrel arbor, motion work). Molycote DX or Moebius 9501 grease for keyless work. Moebius 9501 or 9504 for high friction (e.g. Cannon pinion, Setting lever spring and anything at high friction). Moebius 8200 grease for mainspring. Moebius 8217 for barrel wall (automatic watches) It's a lot but at a minimum get 9010, 9415, D5 and 8200 I hope this helps. Recommended Lubricants for Getting Started.pdf Moebius_Oil_Chart.pdf1 point

.thumb.jpg.6610b6556afa25062bcb95a61aa7e1ba.jpg)