Leaderboard

Popular Content

Showing content with the highest reputation on 06/02/22 in all areas

-

2 points

-

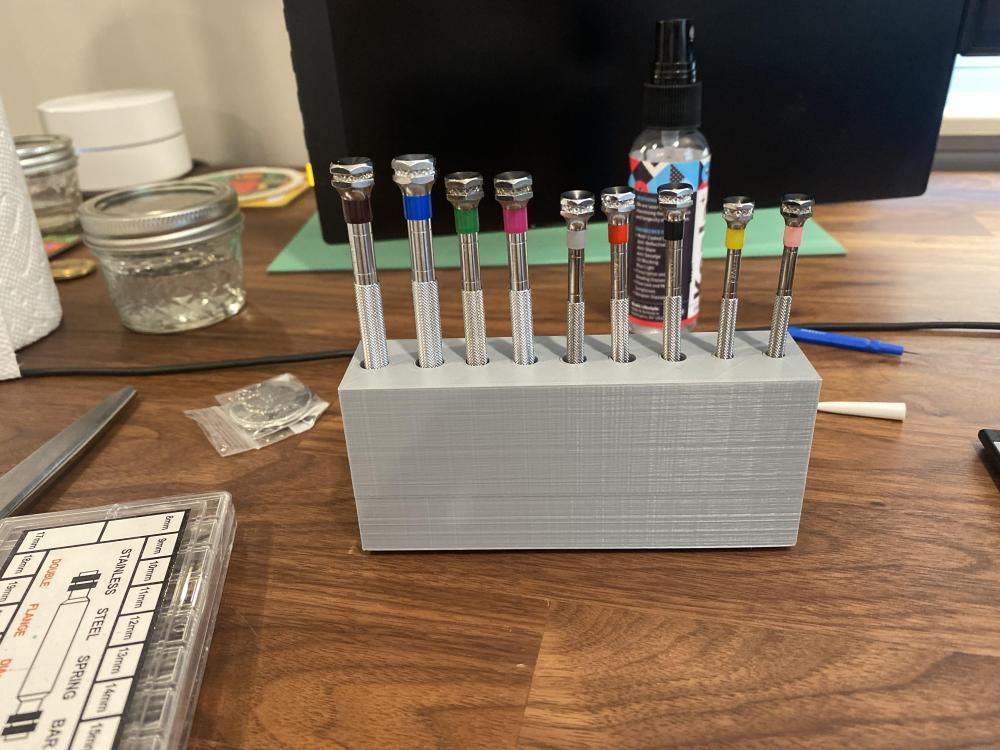

Great idea, well done. I might give that a go for "odd" sized barrels. I only have a small winder set, so I've made a couple of extra parts : I use the 10.8mm size most but often the arbor is too big for the spring. So using a bit of brass tube in the winder hole allows the next smaller arbor to be used. To allow left hand springs to be wound, I made a couple of new winders. It's not hard, I only have a Dremel type drill and hand file. It's all brass apart from the pin - where I drilled a hole, knocked a bit of steel in, and filed to shape.2 points

-

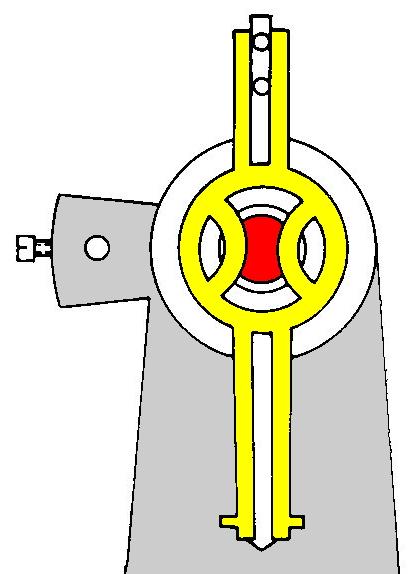

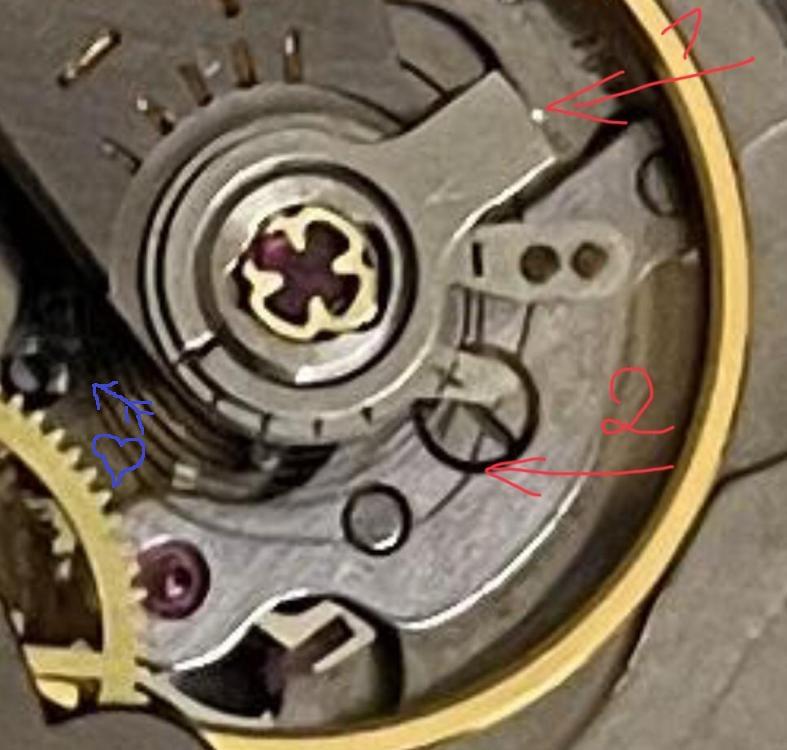

This is a rather high grade movement, I wouldn't recommend it for learning on. Parts will be unavailable, I would imagine the stem would need to be made. But if you want to proceed, the ratchet wheel should pull off the barrel arbor, it's held by the square, and kept from coming off by the barrel bridge. it could be a bit of a fight getting it off though, as it's been in place probably for decades. You would then grip the square in a small watchmaker's vice, and turn the barrel so that there is no pressure on the stop finger, remove the finger, then let the barrel unwind, noting how much pre-tension was applied. Most mainsprings will develop 6 turns of wind, and this stopwork allows 4 turns, so it would be typical to have one turn of pre-wind and then the stopwork will stop before the last turn, leaving one turn that doesn't get used.2 points

-

Tangerine Dream is one I like a lot, must have over 50 of their cd's on my PC.2 points

-

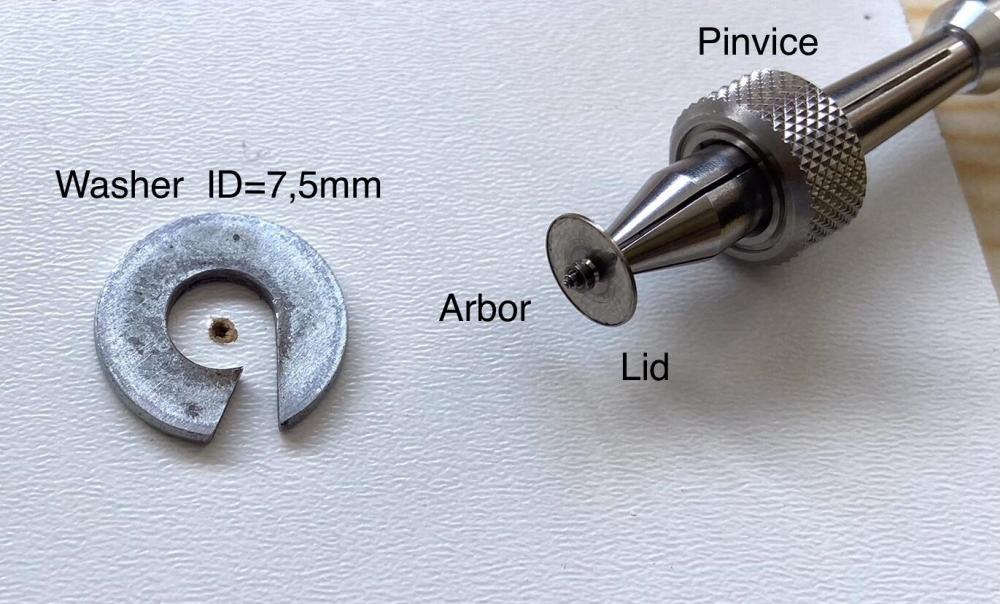

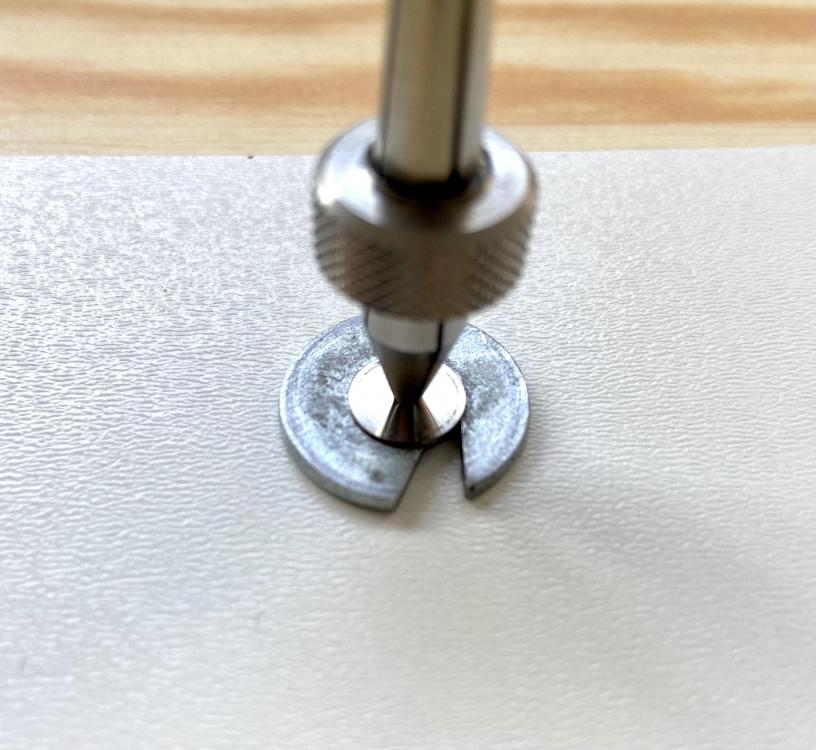

Inspired by the Mastercraft winder I tried to use its principle for a „quick and dirty“ mainspring winder. The spring I used for testing has an arbor diameter of 2,2mm (left wound) and the barrel has an ID of 8mm. The mainspring has a hight of 1,2mm. So I found a washer with the right thickness of 1,2mm, drilled it to 7,5mm ID and cut a slot in with my dremel. Then the washer was fixed to a board with three tiny drops of super glue. I used the original lid and arbor and my pin vice to complete the tool. The rest is selfexplaining looking at the pics. Any thoughts?1 point

-

1 point

-

Have a read below. Hoowever, the crystal seem to be curved on an axis only, so it can be replaced with a blank or one of approximate size, then cut to measure. Even 2000 paper still leaves an haze. One need diamond paste for a perfect job. Polywatch and it's equivalent mildb brasive compounds do little or nothing to mineral glass. They are made for plastic crystals only.1 point

-

I bought the cousinsuk one with the boom arm, camera Barlow lens and ring light. https://www.cousinsuk.com/product/cousins-microscope-with-articulating-arm-camera Tom1 point

-

Hi steve, Before spending money on mainspring and other parts, I would test if the oscilator runs without putting up a stiff fight. Build your oscilator, install the escapement and gear train without the barrel and turn a gear of the train to see if oscilator runs with normal amount of persuasion, in case it desn't cooperate, it might take a lot of work to get it to run. Good luck pal.1 point

-

That is never necessary. The formula for MS (or any other regular spiral) length is accurate https://www.engineeringtoolbox.com/spiral-length-d_2191.html Applied to watchmaking http://theindex.nawcc.org/CalcMainspringLength.php So you can keep the original part in case no replacement is available after all, future reference, or just out of respect to for non-destructive science.1 point

-

I need something relaxing, so (Sir) Van Morrison for me Tupulo_Honey1 point

-

Even if I invested in a priceworthy 10 sizes Chinese winder set I wouldn‘t be able to use one of these winders for this specific Citizen mainspring/barrel New main springs for this caliber are not available anymore.1 point

-

1 point

-

It also prevents the arbor from slipping off the mainspring.1 point

-

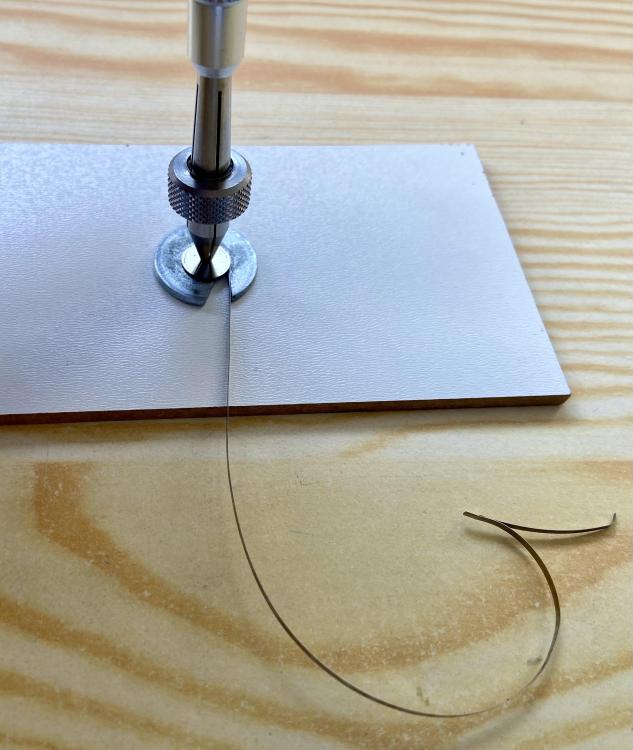

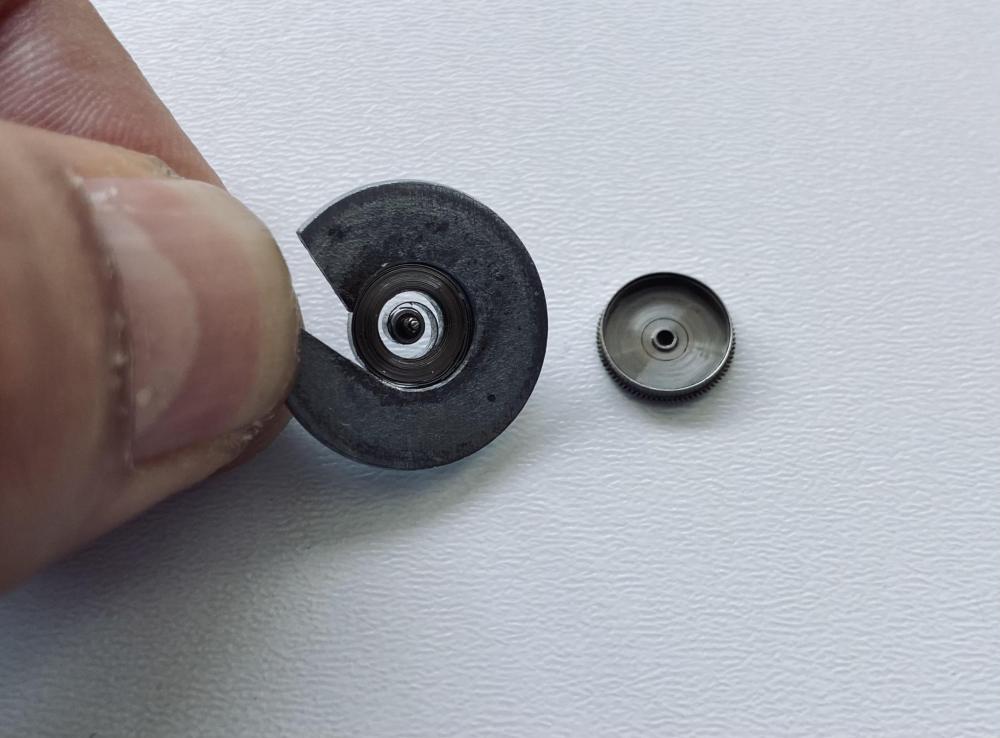

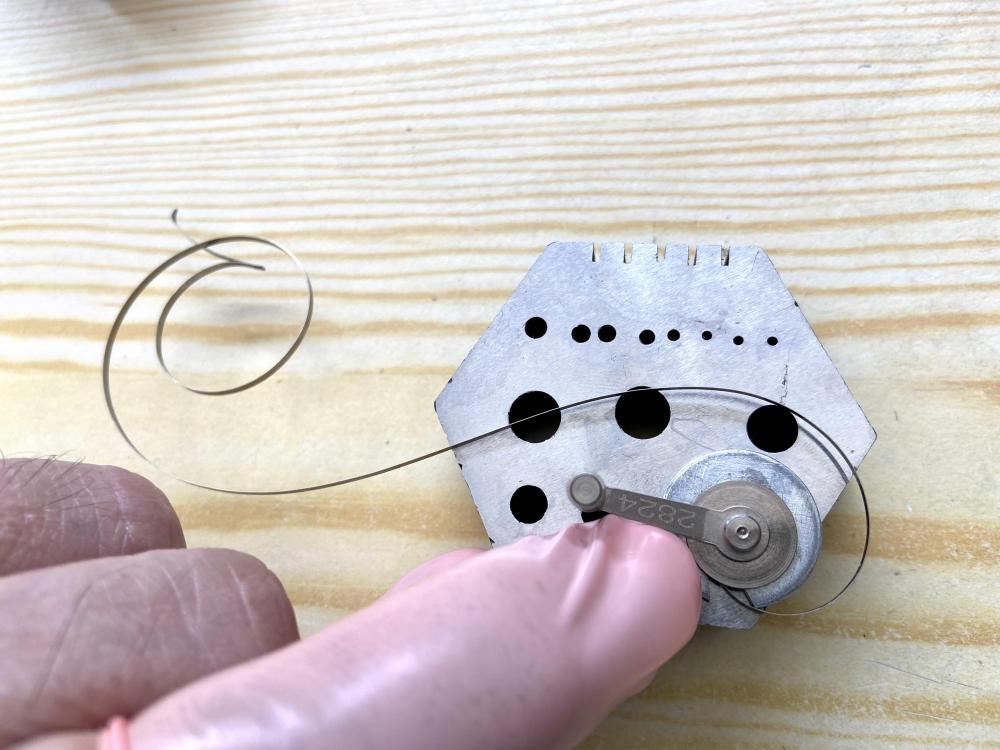

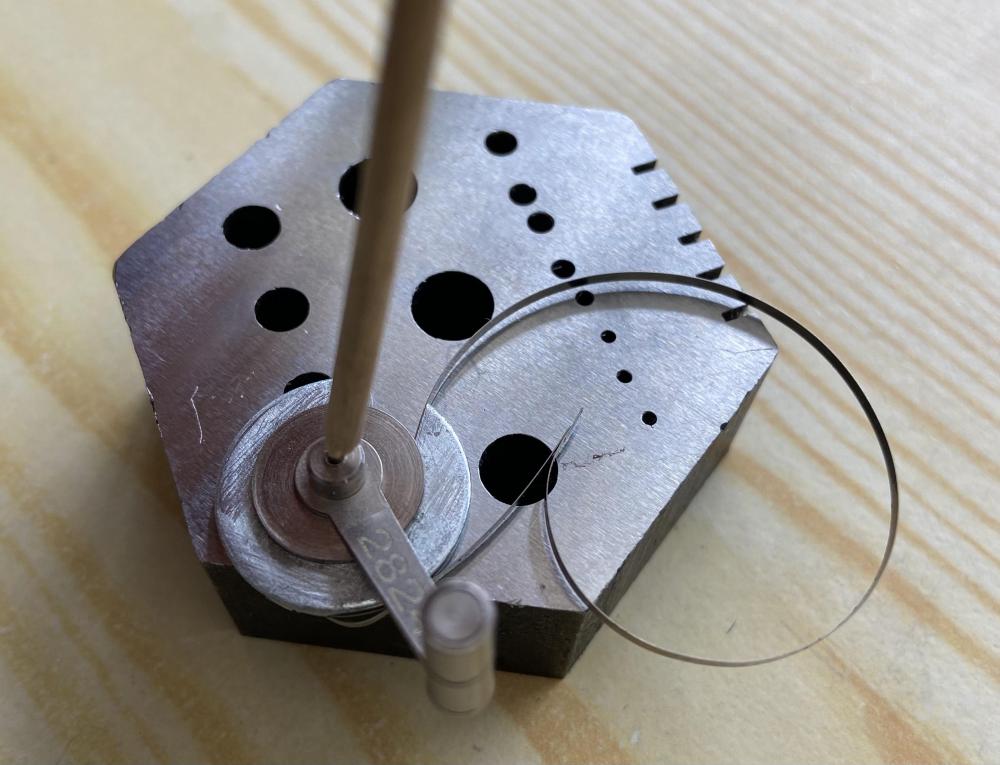

I‘m still experimenting with my „washer winder“ and the left wound mainspring of a tiny Citizen 6900 with an 8mm barrel and 2,3mm arbor. I have to confess that grabbing the arbor on the squared portion of the pivot with a pin vice might not always work. Having a single Chinese winder for ETA 2824 with a right wind 2,5mm arbor I tried to use this arbor (the barrel is to large). The advantage of the washer method is that you can drill the appropriate barrel diameter easily and that it doesn‘t matter whether your spring is left or right wound. You just have to flip the washer the right direction before pushing the wound spring into the barrel. Here are some pictures showing that it worked fine. Interestingly the washer was not required to be glued in place. I could prevent the free floating washer from spinning with some axial pressure or one finger easily.1 point

-

Nice! And thank you! Man, I couldn't find a new stem for this watch (it had broken stem and missing crown). I did see some on Ebay but guys wanted like $80 for it and shipping to me would've made it waaay more expensive than I paid for the watch (or what it's really worth). So I found a used stem (which, of course, was too short) and used a stem extension which worked brilliantly. Maybe something you can try for cheap?1 point

-

There could be something jamming the motor? They do tend to attract any steel particle or shaving, so you might have to remove it and inspect carefully. I agree that if it's moving at all, the motor might actually be OK.1 point

-

Excellent job and a nice watch saved! I have a few Tissots and like them a lot, in fact I'm wearing one today. Runs well around +5sec/day. Only issue is the push to reset crown doesn't work as the stem has been cut too short (Crown inner is free of dirt). Will get around to date eventually. Dial has some age spots but not so noticeable on the wrist. Anilv1 point

-

The movement has no sensor to find out whether the train moves or not. The only way is sensing the stepper current. Could be that the pcb feels to much current drawn by the stepper. To be sure that there is not to much drag in the train I would try to operate the stepper without wheels (or with just one wheel).1 point

-

1 point

-

Hi again and thank you for your help. I separated the centre wheel and cannon pinion (luckily my loupes had arrived on Monday). Things were easy to work out after that and it is ticking again. I’m so glad I found this forum (big smile).1 point

-

Hi Pastor, long time no see. Welcome back. What an interesting movement. I've never seen one before. I do not see the driver circuit for the stepper motor. Is it under the name plate? The fact that the motor is capable of twitching is a sign that the motor might be ok. If you can test the electrical resistance across the tracks of the stepper motor, you can confirm this. I would suspect that it's the driver circuit at fault. I don't see any pcb for the 2423.10 on ebay at the moment. Good luck. I just trawled eBay and found that there are 2423.11 pcbs. I'm not sure if it's compatible with a 2423.10. https://www.ebay.com/itm/265162608779?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=BbEol4SXTyy&sssrc=2349624&ssuid=v36TsHWBSw-&widget_ver=artemis&media=COPY1 point

-

Hi there, here is the manual for the movement in case you need it. Apparently the movement was made by Citizen and assembled in Switzerland for Bulova. Graziano 242.pdf1 point

-

So the oscilator might be out of beat. Heres a vid by Mark on the subject. Your oscilator might also be out of beat if stud position has changed as the result of sorting out the hairpsring coil. Replacing hairspring is not an easy option, as pairing a spring with a balance requires special tools and a bit of skil.1 point

-

1 point

-

Hello Drew and welcome to the forum, I have attached a little information to get you started. 1612608791_ToolsfortheHobbyist (2) (1).pdf TZIllustratedGlossary.pdf1 point

-

Speaking of streaming (something that can't easily or reliably be done on my internet connection), I used to do a fair bit of it. These days (owing in part to the aforementioned lack of communications infrastructure), my music is 100% vinyl. 6-8 hours a day playing in the background, just rolling through my entire collection. I'm also a software engineer, and spend too much time in front of a computer screen for my eyes, and glasses are a fact of life. I've found that the ~20 minute/side is the perfect interval to get up from whatever eye intensive thing I'm doing to give myself a break. I know the topic is re: music, but the form factor plays a part as well. Also, hi-fi audio has a lot of mental overlap with horology, and I've got a tube pre-amp project on the back burner... Well, it's been a bit more in the front over the last few days, but it's a relatively low priority due to the same desk hog project that's keeping the watches in the drawer.1 point