Leaderboard

Popular Content

Showing content with the highest reputation on 11/18/20 in all areas

-

Hi Mike I used the same stuff (typeclean) when servicing typewriters may years ago for cleaning the type heads once it was used up and dirty it went in the bin. The old stuff from using on watches can be reused for holding parts on the bench when measuring or other like tasks but the bin is where it usually ends up. Premium Rodico is likly to be an altered formula designed to remove money from your pocket it will be a bit more tacky so it collects more dollars/pounds .2 points

-

Just in case I am preaching to the converted, I appologise, There are several company catalogues available from material houses in the UK namley, Gleave and Co which contain a lot of useful data as well as the usual lists of parts, Free on application. Cousins uk also free and available for down load, Clocks there is Meadows and Passmore, on line or application, A.G.Thomas Bradford also on line. This information is probably aimed at New starters rather than the seasoned Hobbyist/repairer. The Gleave catalogue has quite a bit of technical data which is useful. Sorry if you already know all this2 points

-

yes the magical amplitude as I call it should have zero positional errors showing up on the timing machine or the running of the watch. Of course the problem is keeping your watch running at 220°. Then running in all of the pendant/crown positions at exactly 220° is an issue. I'm guessing the problem when Mark does a video is time this means things have to be simplified. It's really hard to tell if you have a positional error if you only test in two positions that would show that. Ideally at least four pendant positions eight would be even better. then for the rest of your question mark skipped over a lot of things in his video. Then if you're dealing with a modern watch you can probably skip static poising other than it doesn't cost you anything. Like for this discussion it made for a really good discussion. Because you cannot dynamic poise unless the watch is perfect and it was clear this watch was not perfect so wasting time dynamic poising would've been very bad. I have two links below which might shed some light on things. The second one is a Greiner timing machine manual. What was really nice about their early manuals is they made the assumption that the watchmaker had no idea how their timing machine worked or anything related to precision timekeeping. This then gives us some really good manual on using your timing machine and how your watch works. On PDF page 23 it discusses dynamic poising. Greiner gets credit because it's in their manual and basically without a timing machine you can't dynamically poise. the first link talks about timekeeping of course. Written by an obsessed former students of a Swiss school. I'm point this out because you'll see the influence of the school and an occasional reference to the American butcher watchmakers although I may be a bit harsh on my interpretation. I've seen his writing is in other discussion groups and he definitely does not favor American watch repair authors at all. The influence of the Swiss training. Then he does comment that vintage like American pocket watches have gone through a lot of hands. This is why static poising in my view is a good way to start to see just how bad things are. If they were perfect from the factory you could conceivably go straight to dynamic poising. Kind of like Mark's doing in his video because on a modern watch it hasn't suffered at the hands of poor watch repair. plus typically is a screwless balance not bimetallic there's way less bad things that will happen to it. Or basically it's more likely to be cracked in the first place. At least up to a point remember Seiko does not typically make Rolex timekeeping watches and less were discussing the grand Seiko. Which means you can dynamically poise a Seiko and get it better up to a point. https://www.historictimekeepers.com/documents/Watch Adjustment.pdf http://www.historictimekeepers.com/documents/Micromat.pdf1 point

-

Hi Steve. A burnisher will allow you to remove small amounts like you describe. You can make a very sharp burnisher using a tungsten carbide D-bit and “make” the coarse flat surface by drawing it across a diamond stone. Another alternative is to make one from an old needle file - remembering to create a safe -edge with a slight back slope.1 point

-

Hi Markr will this do find attached cheers 3564_Citizen 0200, 0201, 0271, 0272.pdf1 point

-

1 point

-

Hello everyone, I keep finding this 70s ladies pocket watch in my junk heap so to stop it appearing everytime I have a dig I thought I would get it going. A new mainspring and balance staff and clean, and a lot of love and a little bit of oil, and bingo. I haven't timed it yet I just wanted to get it out of my junk heap. Now it's sitting in collection. What do you think? VID_20201118_162745.mp41 point

-

1 point

-

1 point

-

Here are my thoughts on the UK suppliers: I have used Gleave on odd occasions and they used to only deal with trade but maybe their policy has changed. When I have purchased from them it is on a NO return basis. A.G. Thomas I had a problem with them cloning my card. They denied there was a problem but using tracing I proved they had, they did it twice. I have never used them since (5 years ago) maybe they have better security now. Meadows are very good but pricey. Cousins are the best on price and service. eBay can be very good or very bad. Depending on the purchase I always check the sellers ratings There is accompany who trade on eBay “Red Rooster” who are very good on price selling nothing high end but never the less useful for watch crystals in bulk etc.1 point

-

Graziano, Thank you. Yes, it's a different thing using these tiny screwdrivers. And the tweezers; yoke spring flying everywhere, ugh. And the spring is $25 alone, omg. I'm hoping I can just purchase an hour wheel and new hands and have a complete watch to wear after learning everything about it.1 point

-

Hello Richard1963, my suggestion to you would be to use this movement and learn the basics and practise all other aspects such as disassembly and assembly and oiling and using your tools such as tweezers and screw drivers. The hands and hour wheel are not a great worry. Once your happy start getting some vintage watches and pull them down and you will learn how to take the dial, hands and hour wheel off. Slow and steady is the way. Hope this helps.1 point

-

Welcome. It looks like the hour hand and the hour wheel are both missing. Complain to the seller.1 point

-

1 point

-

1 point

-

1 point

-

I still say Omega makes the most beautiful (mass produced) movements. Nice walk through!1 point

-

1 point

-

That’s cool but a blue seconds hand would be over the top on that one!1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Yes, but better than lot forever... If you can't tell the parts from the flies, simply heat. The popping items will be insects...1 point

-

1 point

-

1 point

-

1 point

-

This is coming along nicely! i’ve been following this and finally I can contribute. If you want to get a “black” polish on the index ring, you need a large, lose and flappy wheel with very fine rouge. A small Dremel wheel is going to produce swirl marks that’ll drive you insane. Even on the sides of a watch case, I use a 6” wheel, not a 1” wheel.1 point

-

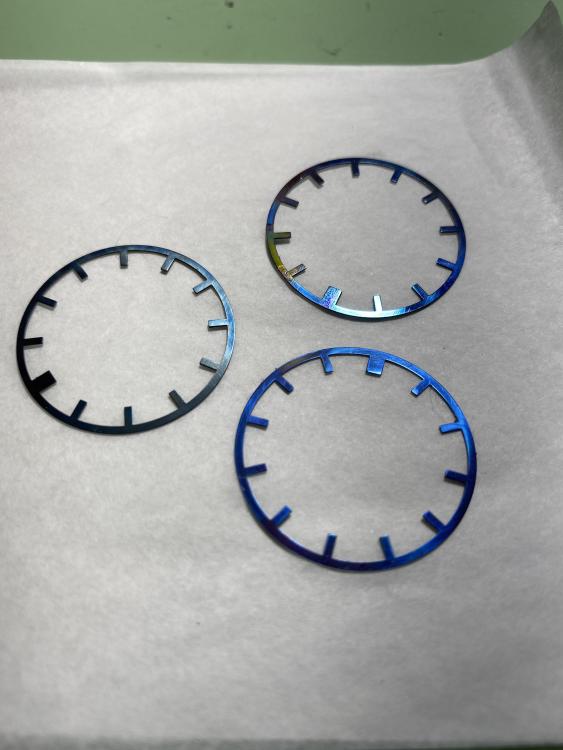

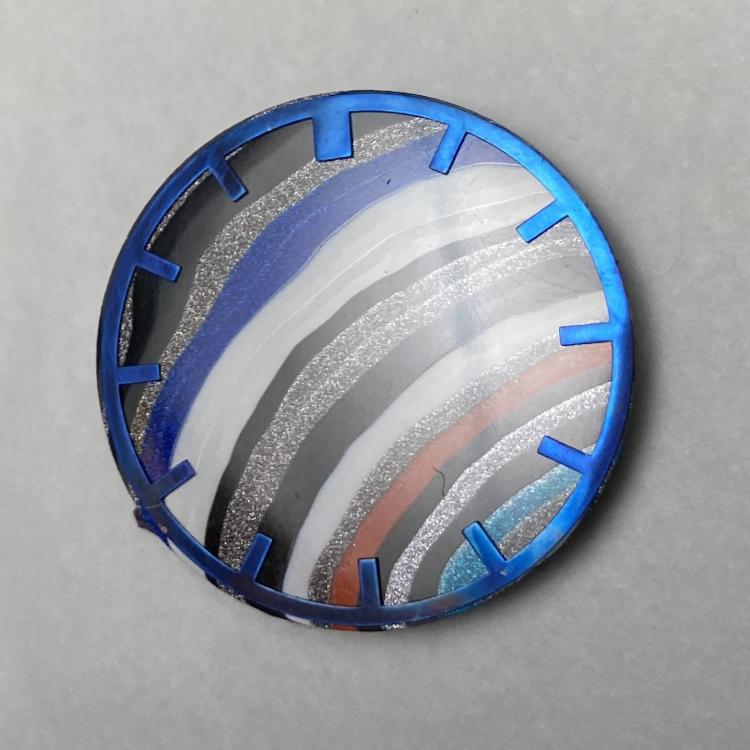

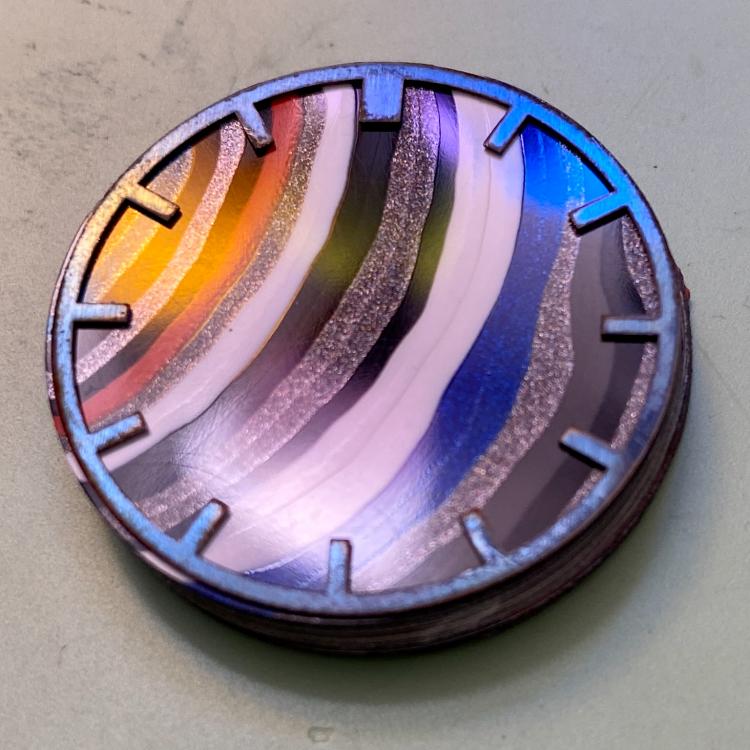

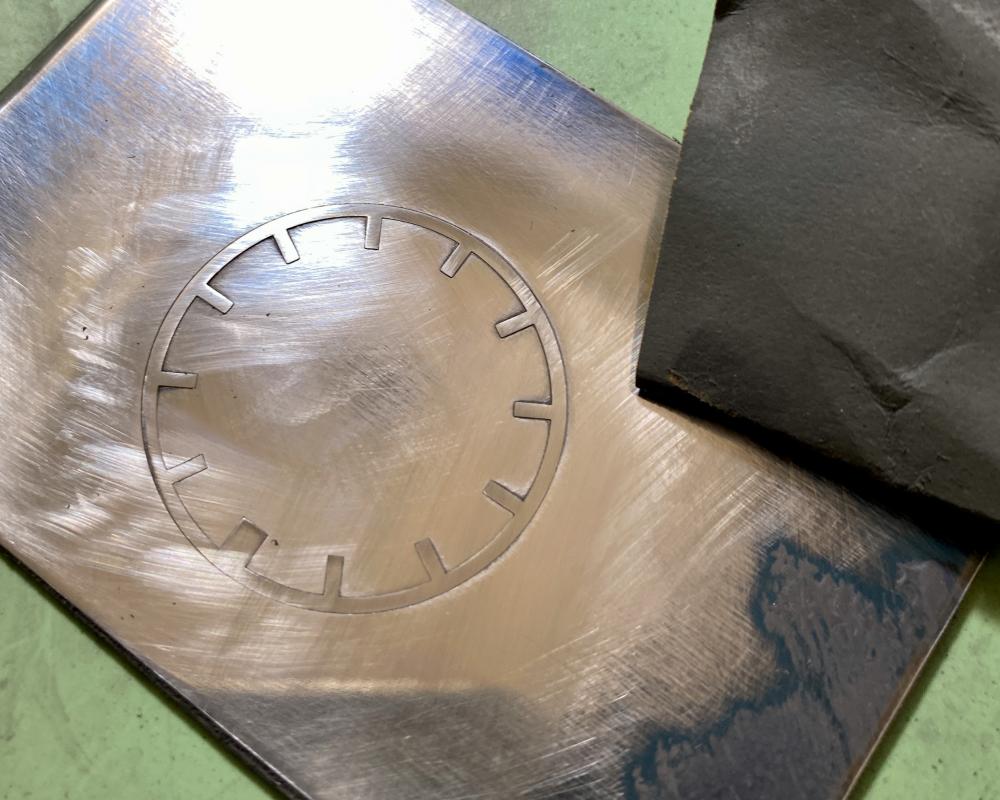

Couple of brief updates: 1. I have a "for parts and repair" Buehler IsoMet 1000 on the way. The new tool sells for $8,900. Even if repairs are pretty expensive, I'll likely be saving a ton of money. I hope. 2. My chapter rings came back from the laser cutter. I had them cut a little die for holding the rings during polishing, and it works quite well. I'm waiting on some jewelry-polishing dremel attachments to arrive, so that I can give these a great polish. I'm also waiting on the precision hot plate I ordered to arrive, so that I can blue these. Here's the die I had cut to facilitate polishing. I can get a nice finish by hand, but it's not good enough to sell (working from 400 grit sandpaper to 3000 grit). Hence the expensive Dremel jewelry-polishing attachments I've ordered. Here's a quick hand polish on a fordite core, so y'all can see what the final dial will look like. I'm likely going to offer the chapter rings as an add-on in polished, polished+blued, and maybe polished + gold plated. Here's an unpolished, straight-from-the-laser-cutter example. I'm just sharing this to get an idea of what a blued ring is going to look like.1 point

.thumb.jpg.91aeb08765b4f2b7f0fc10182999bcc2.jpg)