Leaderboard

Popular Content

Showing content with the highest reputation on 09/20/18 in all areas

-

@Endeavor I discussed lever escapement safety action and testing a little bit here:2 points

-

Make a steel ring and shrink it over the end with the crack. It should allow you to use it until you source another.2 points

-

2 points

-

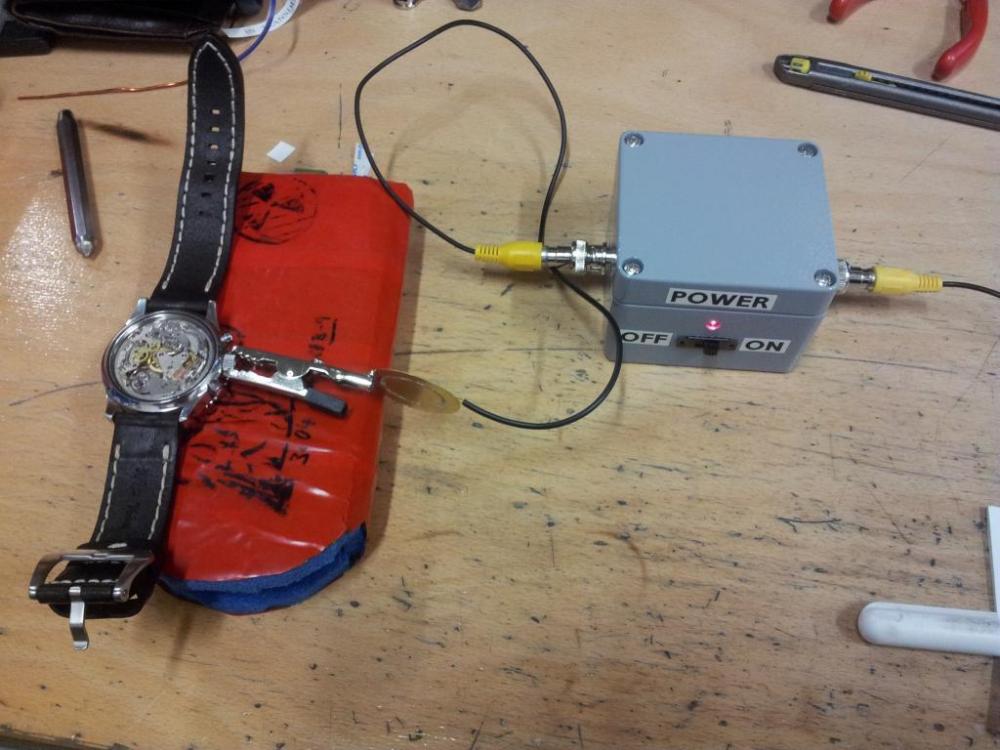

B52, by any chance can you please upload or link to an audio recording of your watch using the pre-amp + piezo? I think I will purchase one of these pre-amps for testing but I'd love to hear how it sounds.1 point

-

Hi there, Guard pin dose not function, it's job is go through the hollow in the roller so to esure the impulse jewel recieves energy at the right position," if by sudden motion of the movement" the wheel picks up speed and impulse jewel get ahead of escapement, the pallets may jump or lock. The test for the guard pin not hitting anything is to paint the impulse jewel all over( especially the tip with a magic marker) instal balance let run for some time, uninstal the balance check for any sign of the impulse jewel tip hitting the guard pin. Regards1 point

-

What a cracking thread, and all credit for sticking with it to get the thing right. No wonder you post under the name "Endeavour". The input and help you are recieving is excellent. I'm looking forward to the next instalment!1 point

-

1 point

-

Ha, yes, set up the escapement correctly! There's lots of info above, but to distill it and give you my procedure here goes. You'll want the watch assembled with power on the train, with little or no oil on the escapement. A microscope, ideally with bottom illumination really helps with the checks. With a finger, rotate the balance until you unlock one side of the escapement, keep going slowly until it drops on the other stone. It should land on the locking face, not the impulse face. At this point, with an oiler, check that there is some freedom at the fork (you're checking if the roller jewel is binding at all, so very small but perceptible freedom). Continue rotating the balance, and continue checking the for freedom to roller, the fork horns are first, contacting the roller jewel, then the guard pin to the safety roller. The guard pin clearance is normally slightly less than fork horn clearance. Do this on both stones, and if you want to do it right, on all the escape teeth. There must be freedom, AND- the freedom shouldn't be so large as to let a tooth progress onto the impulse face of a pallet stone. The fork should snap back to its banking. It's unlikely to have an issue with fork horns but bent guard pins do crop up. Now check your locks. Same as before, rotate balance, observe how much drop lock you have on each stone. It should be a bit less than a third of the width of a pallet stone as a rule of thumb, and approximately equal on both sides. Now check that you have run to the banking. This is your total lock, and there must be at least a little run to the banking. The total lock will be about a third of a jewel width. When you get used to doing the checks you'll check locks and fork horn/guard pin clearance run to the banking all sort of at the same time. But at first do them in order. A cheat for getting the pallet stones in the right position, and it depends on the horns and guard pin being correct, is this: Checking fork horn clearance, with the horn against the roller, observe how much lock you still have. Try pushing in the stone until it is as small as possible while still remaining on the locking face. Both sides. Check drop lock, if it is too small (landing on the impulse face either side), pull both stones out a tiny bit. Like 0.01mm. Very tiny. Check again. Continue until you have safe drop lock. This will be as far in as the stones can be. From your charts above it looks like something is touching, in the escapement, and my guess is the guard pin.1 point

-

Hello rogart63 !! Is all good with you? The Pouge is going like a Seiko, thanks a million for greate work... Did you manage to get the motor module to work?? I have just got on just like this one, into my workshop. So just wanted to hear what happende in the end.... Best from me... A1 point

-

First possibility one would think of, is the check spring not holding he return arm in adjust position, Possible causes , return arm not proprely engaged with check spring, broken check spring, worn out pin and.... I know of no quick fix, the dial and date must be removed to gain access to keyless mechanism and see the fault. Regards1 point

-

1 point

-

1 point

-

The problem was the bent pallet fork lever. I straightened it out and the balance wheel now turns freely in both directions. To straighten the lever, I used two sets of tweezers to gently bend it back. It surprised me how soft the metal was and how little force it took. Thanks to everyone who commented and offered advice on the issue.1 point

-

Ok, so firstly, your photos look ok, but nothing compares to having a close look with a loupe. Preferably a 10x or 12x for really close inspection. The issue is not necessarily a fault with the safety action, buit it's always worth checking, and should only take you a few seconds. Look at this image, and try to understand how the safety action works, and why it is absolutely necessary on the lever escapement: The drawing above is showing you a view looking straight down on the balance, but the hairsping, balance wheel and impulse roller have been made invisible as they sit directly above the safety roller and block our view. The safety roller acts like a gate with a rule, which is that the pallet fork is only allowed to pass when the safety roller is oriented such that the half-moon cutout is in line with the guard pin / dart (in yellow). If the pallet fork tries to move away from either banking pin (say we gave the watch a hard knock) when the cutout is not in alignment then the guard pin will simply crash into the cylindrical body of safety roller, and the pallet fork will return to the banking pin due to the feature called draw. Draw is the effect that the escape wheel has when pressing agaisnt a pallet jewel; it not only holds the pallet jewel static, but also tries to increase its depth of locking slightly and actually causes the entire watch gear train to recoil backwards slightly. To test the safety action of the guard pin and the safety roller, you must have the watch slightly wound; enough for it to run and therefore to ensure that the pallet form is drawn towards the banking pins and held there. Now we need to test the shake (play/freedom) of the pallet fork while the safety roller is not in its rest position. Very carefully arrest the balance wheel with a light oiler, or similar. Now rotate the balance wheel round to approximately 90 degrees away from rest and hold it there. You can use an oiler to do this or if it's a cheap watch then you can sometimes use the edge of your finger agaisnt the balance wheel. Next, use something delicate like an oiler to push the pallet fork away from the banking pin. There should just be the slightest amount of shake detected. You might not be able to see it visibly, but you should be able to feel it. If there is no shake, then the gurad pin/safety pin/ dart may be dragging against the roller. Repeat this test for the other side, ie. rotate the balance around the other direction. There is an additional aspect to the safety action which is the horns of ther pallet fork (the metal which surround the slot on the pallet fork where the impulse jewel enters) but this can probably wait for just now.1 point

-

I have a little light reading to understand how escapement's work and the things you're supposed to be looking for. http://raulhorology.com/2012/10/setting-up-the-escapement-eta-6498-end-shakes-divisions/ http://www.rdrop.com/~jsexton/watches/csw/les22/index.html http://www.timezone.com/2002/09/16/the-anchor-escapement/1 point