Leaderboard

Popular Content

Showing content with the highest reputation on 02/17/16 in all areas

-

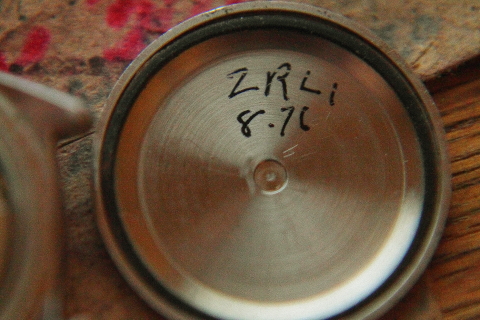

Ok. So its a Miyota OS60.Battery is an SR927W www.citizen.co.jp/miyota_mvt/download/pdf/manu_0S60_multi.pdf2 points

-

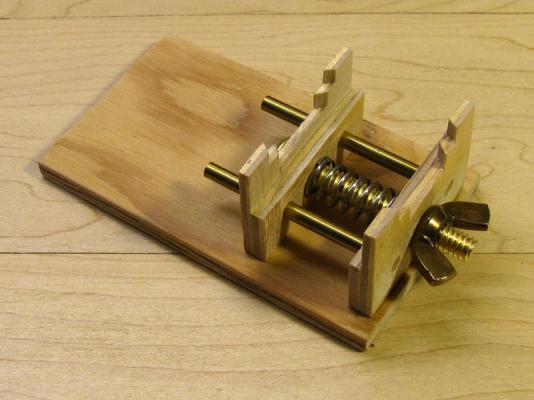

Ramrod- here's a photo, lapping a 6119 case. Sorry to hijack your 7005 thread. Steve2 points

-

I have started with lady movements :nurse: if you master ladies you can do anything. In fact size doesn't matter so much, but with ladies you must be delicate and absolutely clean.2 points

-

1 point

-

well, maybe not rare, but not an everyday movement. i got this on fleabay a couple of weeks ago. the seller took a horrible picture of the watch, but i thought that the dial might be nice. and the movement number was barely legible - 5126 with 23 jewels. i think they were only made for three years - from 1968 to 1970. this one does not run at all. but the dial is in great shape overall, slightly discolored around the date window and the center hole. it won't clean off - the paint is discolored. i'm not worried about it because it just adds to the patina. the date on this one is june 1968.1 point

-

I would try this (screw loosening fluid) in combination with the ultrasound:1 point

-

Hi Stephen, Looks like the date jumper - part 2576 You will find the parts sheet for the 2824 on Cousins website, it's not obvious, but listed under "Eta 2801,4,6,16,17,19,24,26,34" - Parts 1 & 2. Rgds S1 point

-

Obviously the dial must not be soak in cleaning solution but you can clean enamel dial in distilled water with some drops of dishwashing liquid. I suggest you read some books like "Practical Watch Repairing" (Donald de Carle), the "Chicago School of Watchmaking" or the "Bulova School of Watchmaking"1 point

-

What would help mostly would be to check it on the timegrapher. If it needs lubrication, the display will show that.1 point

-

dayum! a 70 watch lot?! that oughtta make you a master when you get through tearing down and reassembling that bunch. i'd have a heyday with them.1 point

-

out with it, jeff. we want the bloo dy details, with pictures is possible. :D1 point

-

Don't worry Steve, we'll be honored! As in my junior years in computer science, one thing I learned is that there are many right ways to do things...as they say, more than one way to skin a cat...or, incidentally, to restore a watch case?! I'm sure your way will be very educative as I said before, to many of us. If, at the same time, other people chip in, maybe, just maybe we will all benefit from the many ideas and ways provided so everyone wins! :) That's the beauty of many great minds working together! Cheers, Bob PS. I promise I'll be the first student, not having much experience in this field.1 point

-

Thank you, you are amazing! Would you also be able to help with a further enquiry? This is also to do with a Zeitner watch, but this one is the Aquasport z2000g.i need to replace the movement, which says Rondo, but there doesn't appear to be any numbers. If you could help that would brilliant Kind regards, Keith1 point

-

Actually I think you were right. Could not help myself, after snow plowing 6 driveways, my neighbours, I jumped back at it and found that there is a plate that that controls the stem position and this plate has a rail where a small knob from another pivot plate fits. Sorry for the lack of technical terms; I am sitting at coffee and do not have the breakout drawing with me. I had not hooked another keying plate onto a point on the movement and this caused the plate to lift up the part i needed to slide into the rail. FIXED. Tonight I will complete the build.From Canada1 point

-

Reposting Ramrod's photo to get this thread back on track [emoji6] Steve1 point

-

Sounds like a worn sliding pinion and also a worn setting lever? Sent from my D6603 using Tapatalk1 point

-

Thanks! Good memory, I did post this photo or a similar one before, probably on SCWF. I was doing pretty well with this lapping setup then I got busy with remodeling and work and was kept away from it for while. Lately I've been spending more time working on movements and trying to build my skills and gather the right tools, which is why I'm often on this great forum. Now I'm having brush up on some of the case finishing methods- pun intended. I've considered doing a write-up thread with photos about case lapping but I don't think I'm proficient enough yet to do that. I still have a lot to learn, and it's mostly trial and error. There is a huge body of information available to help with working on movements but very little out there about how case finishing is done by the factories and pros. The equipment isn't exactly cheap or commonplace either, most of what I use I've made myself. If it was easy, what fun would that be?1 point

-

I did refinish the case on the 7006 in the photos, it was one of my first victims with the case lapping rig. If you look at the shot with the lume you can see the top lug surface isn't quite as it should be. Unfortunately the case was so beat up I had to remove more material than I would have liked. The 6106 I'm working on is a DX. here's the current state of things with the case. I'll try to dig up a photo of the lapping process. This case was also pretty bad, looked like it fell off a train. I did the best I could bit some of the nicks were too deep. The caseback tool slippage marks are especially deep, if I remove them I'm afraid there won't be much thickness left. Tool marks were not put there by me, i should add.1 point

-

"Bonne Maman" jam pots Also used for cleaning movements in the ultrasonic, storing parts, tools.... The lids are also very convenient because they have a high lip all around, and the plastic coating inside keeps the parts from bouncing around. We eat one of those pots every week, so I have a few spares :) And I make scented candles for my other half when I run out of space for them :)1 point

-

I use the double ended pusher tool too (hand fitter?). No complaints, but it's the only kind I've ever used :)1 point

-

1 point

-

whoa! very nice! and lume too?! mine doesn't have any lume. i've been thinking about adding it to the dial. the indices are perfect for it. that's a nice watch. what is the date on yours, steve? mine is june 1969. ok.....here are some pictures of the movement.....and an edit: i removed the balance for the hell of it and reinstalled it. the watch hasn't stopped running since. but the amplitude is extremely low. barely turnining.1 point

-

Buy the best tools you can within your means. They are as much pleasure to own as your watch collection. Tony Sent from my SM-G900F using Tapatalk1 point

-

Hi Stephen, I have both and honestly, they don't see much use...maybe I need more "training" or ran out of ideas as how to use them or I don't work on the watches they were designed for often enough...who knows. I managed to break the tips of the first link/tool you posted, working on a Citizen chronometer and resorted to "hand" tools for the pushers (hammer, pliers, you name it)! In my mind, maybe we should wait for someone that has used them to advise the proper way and use...at least that would be reassuring for me! Cheers, Bob1 point

-

1 point

-

Where there's an achievement there's is a precise technique masqueraded as "dedication" to deter newcomers. What about a round of sewing thread to keep things in place.1 point

-

Train bridges should be called trestles; that's what I think. Getting all those pivots in the right place and then carefully placing the bridge without displacing them and making sure all the pivots go in the right jewel hole can be a bit trying. I guess the more you do it the better you get. I'm always amazed by Mark's patience. But my mother's former students always commented on her patience; I always wondered if they were talking about the same person. Dave1 point

-

Try some of the cheap Swiss movements, like a Baumgartner 866CLD, Brac 28 or a MAM 3467 they are all one jewel or low jewel pin lever movements, but the degree of difficulty reassembling them will really try your patience and see if you are suited to watch work. I was servicing a MAM today and the time it took to install the train bridge I could have completely reassembled a Seiko or two, some of these pin lever movements look junk but they keep going for ever. Well worth having a go at even if it isn't a working movement you will learn a lot from them.. Max1 point

-

I would have saved a lot of money if I'd gone on WRT a couple of months ago. O well....live and learn... Dave1 point

-

1 point

-

1 point

-

I started with some old russians. Slava and Poljot are available at cheap prices on Ebay. You could buy a 20 movement for next to nothing. Or why not buy a nice Vostok Komendirskie?1 point

-

Another alternative, which I don't think has been mentioned before on the forum, is to buy two or three HMT watches on eBay. It's still possible to get a barely used one for under £10, if you look carefully - and there are always several for sale. And because they're quite common, breaking for parts is not a problem. The HMT factory has now been closed by the Indian government - it hadn't been a profit-making concern for many years - but I don't think that will raise the price of the s/h stuff on eBay. Worth a look, at any rate.1 point

-

Jdm, ramrod, endeavor, Thanks for taking time to reply, all good, solid advice. Shall copy your method of training myself Endeavor. All the points you make seem sound and well thought out. Thanks again1 point

-

1 point

-

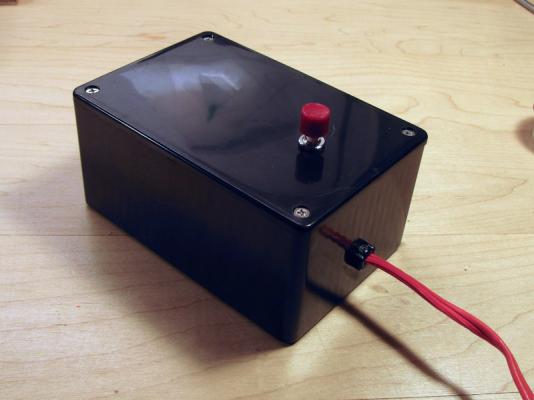

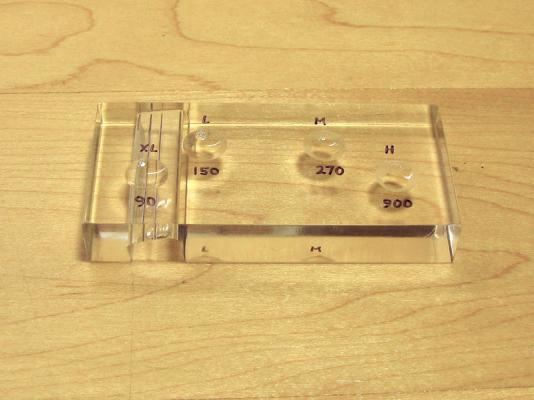

I've made a few of my own tools: Case holder: Movement holder: Oil pots and oiler (not shown): Caseback press (just some appropriately shaped blocks for use with a drill press): Crystal press (a block molded to fit a domed crystal, to use with the drill press): Demagnetizer: And of course the timing machine I'm working on. The articles on my web site show some of these tools and other in use.1 point

-

I would love one of the Jewel measuring micrometers, but the budget and wife, won't allow it. So I bought a reasonable quality 0.001mm micrometer and formed a small piece of aluminium around the shaft, which will also slide to allow normal use of the tool. It is excellent for Jewels as they sit flat on the arc of the sleeve and give as good a readout as the top of the range one.1 point

-

1 point