Leaderboard

Popular Content

Showing content with the highest reputation on 02/16/16 in all areas

-

Thanks Geo! They will only get better and I'm hoping my skills will follow suit;) I do this as a hobby 7 days a week, every single night so there's plenty more to come:D2 points

-

2 points

-

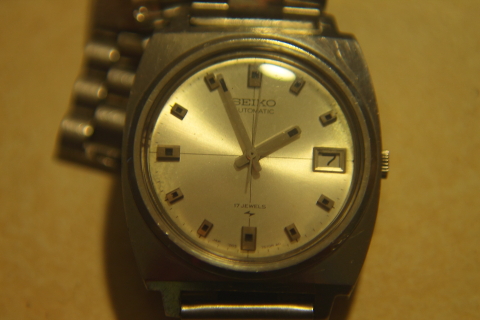

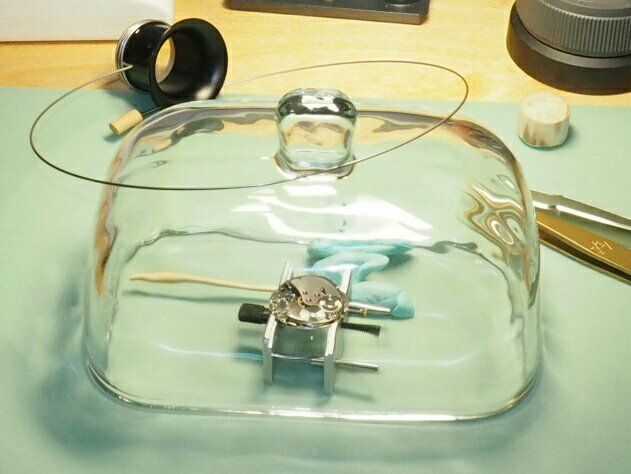

First off, I apologize for the lack of pics here. I didn't realize members are doing walkthroughs on this forum until recently so I neglected to take "progress pics" for you all. I am a beginner watchmaker in my 7th month. I've broken quite a few movements so now it's time to get serious now that I am BEYOND experienced in breaking them:( Yes, I have restored about a dozen but have also broken several dozen movements trying to understand everything. After reading and breaking (then repeating over and over), I'm proud to introduce a real "beater watch" that I could save from the scrap pile/junkyard. Again, I apologize for the lack of before and after pictures but I can tell you that this thing was nasty on the inside and out let alone not working at all. Now, she not only looks decent but is ticking away happily with a BE of 0.8 (I know, not great) and amplitude is back up to 271! It is truly exciting to be on a forum where we can share these types of things, I'm hoping to learn a lot from you guys and will also help as much as I can too:D Thanks for reading! The first two pictures below were "reference" points during disassembly just in case I needed to figure out how to get it back together, lol. (didn't need them after all) The last picture is the final product:) There is supposed to be a second hand but A) it was totaled to begin with (snapped in half when I bought it) and B: I like this particular watch better without one;)1 point

-

Sometimes, the old tools are the best tools, such as old watch screw drivers and tweezers, there's something about the quality of the steel that makes them stronger than the modern versions, even of the most expensive ones. These are some other tools I bought from the markets, and I've gotten a huge amount of use out of them. (Oh and my rubber watch ball opener, I couldn't live without that.) There are only two tools I use as much as these, which is my timing machine, and a pair of digital calipers.1 point

-

Buy the best tools you can within your means. They are as much pleasure to own as your watch collection. Tony Sent from my SM-G900F using Tapatalk1 point

-

That's the trouble Bob, Dave. I've always bought the best tools that I could afford (without going mad) throughout my working career as a truck mechanic. They got some real abuse but lasted well. I once spent quite a bit of money on what I thought was a great piece of kit from Snap On, thought it would save me loads of time on certain jobs. It's still lying in the top drawer of my toolbox 30 years later and I doubt I used it more than twice. :biggrin: But I still love nice tools, that's the problem.1 point

-

My lights are just some cheap LED clip on's from Ikea. They cast shadows but worked ok for the pictures. For the photos I set a custom white balance in camera. You photograph a piece of plain white card or paper under the light you will be using for your pictures and the camera compensates for the different colour temperature of the light. Or you can adjust the white balance until you get the look you want using Lightroom or other photo editing software.1 point

-

Thanks bobm12! This movement was surprisingly fun and easy to work on as the gear train layout was quite nice in terms of gear placement:) Everything just settled into place right away so the project only took 4.5 hours total! Tonight, I will be attempting to service a Cornavin from the 70's with a 17 jewel movement that I've never seen before. (certainly not an ETA) This should be interesting to say the least;P1 point

-

It's great to have to participating Jeff, complete with good quality photos!1 point

-

Another I got that can happen is if the old oil has turned to hard varnish, the new oil will eventually soak into it and make it swell. When this happens, the expanding varnish grips the pivots and stops the watch, this may take a week or two to manifest. This happened to me in my early days of watch servicing, all the parts had been through the ultrasonic cleaner, but there was still residue in the jewels that I had not seen. I won't make that mistake again1 point

-

Also if the watch is clean, and ready for lubrication, you have 3 drops too many for the whole watch!1 point

-

it takes so long to download them, the computer times out. i have already adjusted the size of them so they are as small as they should be. i dont know why this started doing that. i never had a problem before. i'm going to make triple sure that they're downsized and try again. ta daaa! i fixed it. apparently i was trying to download unprocessed pics from the raw file.1 point

-

I understand this link wasn't intended for me but thank you for sharing this, I'm hoping to find some much needed parts now!!!!1 point

-

I would use the oil as a hand moisturizer :-) Putting oil in a dirty watch will produce an abrasive sludge that will accelerate wear on the movement. I suppose you could *cover* the movement in oil to prevent rust, but in that case you shouldn't let it run!1 point

-

1 point

-

1 point

-

1 point

-

Hello Budsy; I'm also new to watch repair and was advised to get some cheap training watches. My goal was to learn as fast as possible on Swizz mechanical movements, so I went after (in my eyes) difficult training material and bought two ETA2540 New Old Stock (N.O.S.) 17.5mm ladies watches. Why? 1) Well, on this forum is a very good "walkthrough" which takes you by the hand and guide you through how to dismantle, clean and assemble them. 2) I went for N.O.S. because they are new and running, so you check your work after you are done. Secondly, the idea is that you repair a watch without leaving scratches behind.....a "ghost repair" so to speak. Since these watches are new, you are the first one to dismantle them, so any scratch, and you know it's yours. 3) I bought two in case I ruined one, so I had "back-up" spare parts. At first attempt to open for oiling, I ruined one leg of a Incabloc spring and during my third assembling (I did multiple "rounds"), I broke a pivot from the pallet. Both valuable lessons of how not to. 4) Since these movements are so tiny, they reveal and expose straight away (and you can practice on) your tool handling skills, quality of your tools, parts handling skills and what you need for doing the job. There is a very good Dutch Seller "Vacheron_nl" on eBay who has these ETA2540 for £7.60 or $11 each, including hour-wheel. To save on postage, you can ask for combined postage. http://www.ebay.co.uk/itm/Tressa-ETA-caliber-2540-N-O-S-Swiss-watch-movement-running-/361474036132?hash=item54298811a4:g:8CQAAOSwFqJWogo- If you rather start gentle with bigger movements and depending on your goal; for the movement of your choice, first find clear information like exploded views, PDF-files or clear walkthrough's. By this you avoid getting stuck at first attempt. Buy running watches and preferable N.O.S. for the reasons given above. These are my "Two cents".........;-)1 point

-

1 point

-

Someone is interested in purchasing the watch, so I had to do something. kept movement in case removed upper jewel assembly, balance, winding weight, auto bridge and 2nd reduction wheel. let power down removed pallet bridge and pallet fork oiled pallet jewel faces and balance staff lower pivot reistalled parts oiled upper jewel end stone. winded fully, let rune few minutes, on timegrapher for regulation.1 point

-

That erratic pattern is very indicative of poor lubrication. Clean, lubricate, demagnetise - retest. :) Sent from my iPhone using Tapatalk1 point

-

I agree with CB, demagnetising is always a good idea. Before taking things apart or making adjustments, I would also be curious to see what change, if any, you get by oiling the pallets.1 point

-

Welcome to the forum. There are lots of guys here to advise. A starting point is some good quality screwdrivers & you will need a movement holder/s. As Geo suggests your first watch should be a watch that does not matter, perhaps a cheap watch for repair off eBay. Enjoy1 point

-

Welcome to the wacky world of watches! As Micky said above, search the forum and you will find lots of info on the subject. Have a look at Mark Lovick's repair videos and start on something that you are prepared to destroy first.1 point

-

Welcome to the forum and enjoy the advice and all the support that is offered. Have a look at this topic Question For The Watchmakers. All sorts of advice there including mine. I have around 30 years asa watch/clockmaker but now retired.1 point