Leaderboard

Popular Content

Showing content with the highest reputation on 06/27/15 in all areas

-

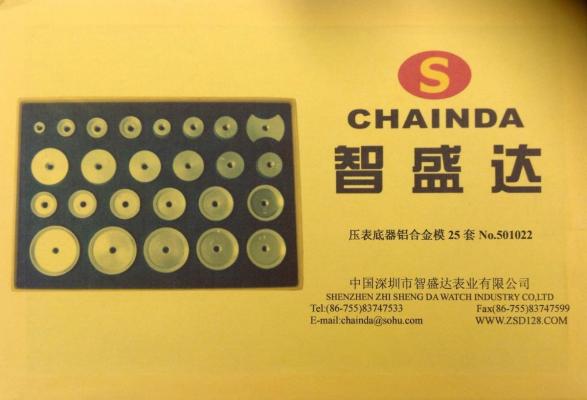

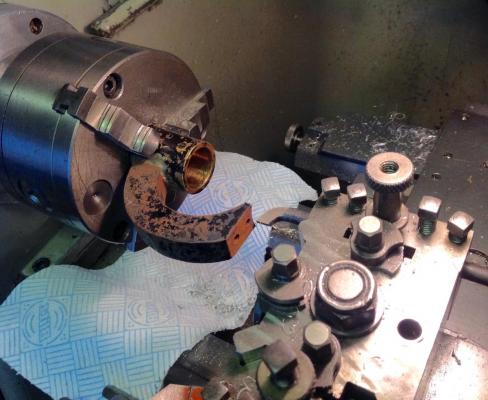

I purchased a cheap Chinese crystal press when I took up watch repairing/refurbishing a few years ago, this was one of the lever operated type with nylon dies. This has served me very well, but there are some jobs that a screw type of press is far better for because of the more sensitive control. Being a canny Scot, I kept an eye on eBay for a second hand Robur or Horotec and stumbled across this antique home made press for £14 delivered. The engineer in me immediately saw the potential, all it needed was stripped down, modified to take new dies and repainted. The other thing that was required was a set of new aluminium dies, so after a search on AliExpress I purchased these for £26 delivered from China. Right, down to business. (1) Modify the lower die holder to accept the 6mm threaded alloy dies. (2) Make an adaptor to fit the bottom of the ram with a 6mm thread to take the dies. (3) Machine the lower end of the pillar to give clearance for the largest die. (4) Accurise the dies to ensure that the faces are parallel. Many were slightly out of truth. (5) Remove paint and rust from press, paint and polish. (6) Reassemble. Total cost of complete set £40.................well pleased!3 points

-

Hi Bob, It's probably for the best. That wide rear tire will make turning difficult and the seat looks like the two of you would be crowded. These would make learning difficult, although from her appearance I'm sure she'd be a very caring and patient instructor. My list of bikes, best I can remember; 1975 Kawasaki S3 400cc twostroke triple 1988-90 1981 Suz Gs1000 1990-92 1992 Suz DR650 1994-96 1991 Honda CR250 1997-2001 1989 Kaw ZX-10 1997-2003 1989 Yam WR250 1998-99 2004 HD 1200 Sportster 2004-07 2001 Honda CR250 2007-2012 1973 Honda Z50 2009-present 1971 Honda Z50ak2 cafe build 2008 1972 Honda CB175SS 2007-present 2001 Yamaha FZ1000S 2006-present I'm sure I missed a few.2 points

-

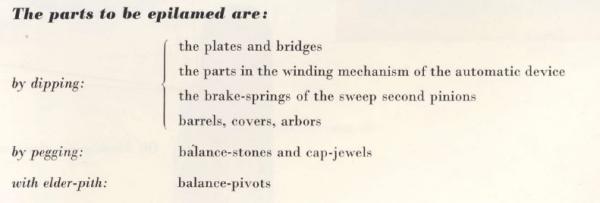

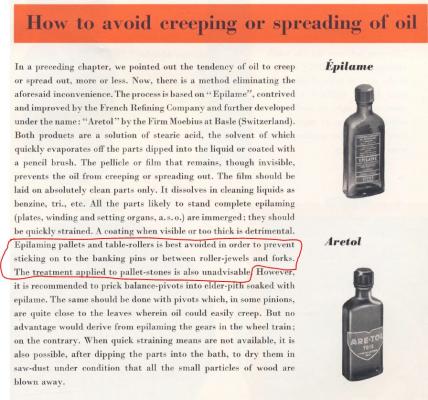

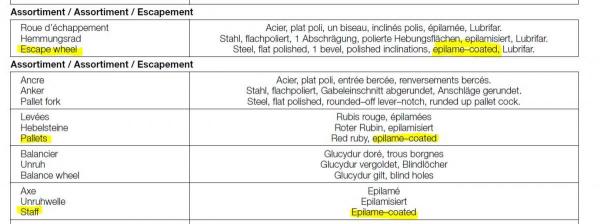

Somewhat hijacking your question I find this an interesting subject in that it's not always that visible on the normal service tech sheets. The reason I'm pointing this out is we usually try to follow whatever the manufacturer recommends but if we are unaware that the parts have been surface treated to prevent the spread of oil and we use the oil they recommend without the surface treating the oil is much more likely to spread. So I'm attaching some images two of them are from an Omega 1957 guide on lubricating their watches. Even though it's a lubrication guide is spends quite a few pages on cleaning the watch because that is a requirement before lubricating. So in the fifth jar of their cleaning machine they have the epilame. Then I've attached some images from that guide telling you what they would use it on and the write up. On the write up I've circled what they're not using it on. Then you'll notice there's a discrepancy between modern surface treating which is the surface treat the pallet stones and their recommendation to not. Then ETA used to publish manufacturing guides for their watches in addition to their tech sheets. Manufacturing guides are really interesting in that they tell all sorts of technical specifications. So I've attached the interesting part for us and highlighted where surface treating is being used. What I find interesting is the balance staff is treated. Then some links one explaining about the various substances. Another explaining of the cautions. The problem with the solvent is when it evaporates the parts get cold there is a possibility of condensation which conceivably could lead to rust. http://watchmakingblog.com/2011/07/29/one-hazard-of-epilame/ http://hiro.alliancehorlogere.com/en/Under_the_Loupe/Epilame Then on page 7 of this document the special bottle that you're supposed to have aMicrophone off microphone offnd how to use it. http://www.bhi.co.uk/Documents/certificate/Tech/PractLub.pdf Than as Eta surface treated the balance staff to prevent the spread of oil incabloc Uses it on their jewels and they talk about it at the link below. http://www.incabloc.ch/en/huilage.php2 points

-

Thought the strap could do with a decent buckle to finish it off. The watch has exceeded expectations. Time keeping is good and all it needs is a few shakes in the morning and put it on my wrist and it is set for the day. Many thanks to George who introduced me to these gems. Trouble is that when I service and fix the other one, I may not be able to let it go. My son and his wife have had a few days in Rome / Paris and are back on Monday for a week before returning to LA. I must set to with all my projects and keep my mind off the Bay - there is however this tasty little Gerard Perregaux movement I have my eyes on that has some parts I need for another project. Oh dear ! Cheers, Vic2 points

-

2 points

-

This video shows how to repair the luminous compound on a watch where the old is dis-coloured or broken away. It's a relatively simple job to do if it is done right.Repairing the luminous compound on watch hands is not a very difficult job, but it does require patience and a steady hand. It is important not to apply the new compound too thickly otherwise the hands will catch on each other once the watch is re-assembled. There are two kinds of luminous compound available (and several different colours). Pre-Mixed Provided pre-mixed in a bottle ready for application. Powdered Provided in powdered form. Mix with a binding agent. Which should you use? Well, the pre-mixed compound is quite convenient and allows you to get on with the job faster with less preparation. This can be advantageous should you be in a hurry to get the job complete for a client. However, there is very little flexibility with pre-mixed compound and it can dry in the bottle with time thus going to waste. The powdered compound (which is what I use and recommend) takes a bit more to prepare but it does allow you to create a compound mixture in the consistency (or thickness) you desire. For example - I like to apply the compound very thin and so I usually mix it down accordingly. This makes the compound much easier to apply. Applying the mixture Once you have prepared the hands, as shown in the video, then you can apply the compound with a fine watch oiler or needle. Simply dip the oiler into the mixture. This draws a quantity of compound onto the oiler tip. Now you can apply the compound to the watch hands in a spreading motion and the compound should end up suspended within the gap in the hands. It can take a bit of practice to get this right so when you first start the process you should mix slightly more than you need in case you have to attempt the job more than once. Drying Time Once the compound is applied, you will want to let the hands sit under a dust cover. Depending on the mix, the drying time will vary. I would recommend you should leave them drying overnight to be fully sure. They should not be touched or disturbed whilst they are drying. Re-Assembly When re-assembling the hands onto the watch - make sure there is the normal amount of clearance between the hour, minute and hour hands and that they will not touch each other as they turn. Potential Pitfalls If the hands are seated correctly and the compound is too thick, then this can either rub on the dial (hour hand) or a sub dial's hand may catch the hour hand (on a chronograph for example). Likewise, if the compound on the minute hand is too thick then it will catch on the hour hand. What if I did apply too thick? So it is very important to make sure you do not apply the compound too heavy, but if it is too heavy then I do not recommend trying to scrape it thinner as you could end up with dark and light spots. The best practice would be to start over. Yes - that would be annoying, but you will be much more satisfied knowing you have spent the extra time to make sure the job was done correctly. http://youtu.be/aQUN2A4iHok In summary Three words: Patience, Patience and Patience! You cannot really rush a job like this, but the more you get used to doing it, the more confident you will be. It is not a particularly difficult job, but it can make such a difference to the look of a watch. Enjoy the videos.1 point

-

Turn the crown slightly in the winding direction to allow you to hold the flat click spring back with back with a piece of pegwood. Now let the crown spin under control between your fingers to let the spring unwind.1 point

-

1 point

-

1 point

-

1 point

-

Geo that's an amazing shop! I have no words and enjoying the view tremendously! Cheers, Bob1 point

-

I don't know steve, those were exactly the features I liked about this bike...I'm not bothered by slow turns much,...oh! and the rear tire, amazingly wide! :D1 point

-

1 point

-

Looks like some sort of bodge with glue (could be epoxy) to get the hairspring to attach to the end stud instead of using a pin. You will probably have to do likewise because removing the old glue from the hairspring could be risky.1 point

-

1 point

-

Wow, nice job mate. Some well developed skills evident there. And I'm very envious of your Colchester.1 point

-

Yes, it did. Thank you very much for the response. It turned out that the problem wasn't the barrel but the sliding pinion and winding pinion were faulty (when you tried to wind the watch it slipped). I changed them for the ones in 2840 (they fit). Thank you! Bogdan1 point

-

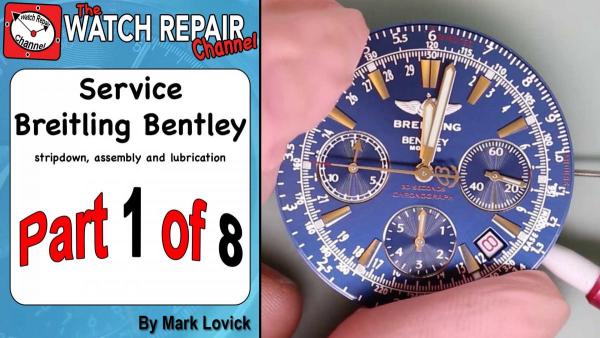

I have finally finished editing the Breitling Bentley chronograph video. Featuring a stripdown, assembly and lubrication of this ETA2892-A2 movement with the dubois depraz module. The first part will be published today on Youtube at 12pm GMT You will be able to see it on the watch repair channel at Youtube or http://www.watchrepairtalk.com/page/watch_repair_videos.html/_/watch-movement-servicing-stripdowns/part-1-breitling-bentley-service-eta-2892-a2-dubois-depraz-watch-repair-tutorial-r351 point

-

Absolutely tremendous job Geo!! The press looks fantastic.1 point

-

In case you did not know - part 2 is up.1 point

-

Vic: "I would be happy to be erected". I'll bet you would - but don't ask me to do it! :D1 point

-

I have watched the uncut version............. and I have to say it is ................. "Tantamount to Horological Porn" ....... :)1 point

-

It looks like some sort of glue. I think cleaning of the old to start with, be very careful not to bend the hairspring. Position the hair spring in the correct place and a little glue should do the trick. You right in saying its not shellac that always had a brownish colour.1 point

-

I always cleaned the balance with Ronsonol lighter fluid. I found it better than any watch cleaner. I even tried what was on the market in my time as balance cleaner it came in a small jar, that stuff was useless. Nice post on cleaning a small ladies Tissot. Surprising even with a dustproof button the fibers from clothing still get in. I hope all you watch repairers/makers spend time in cleaning the cases and bracelets.1 point

-

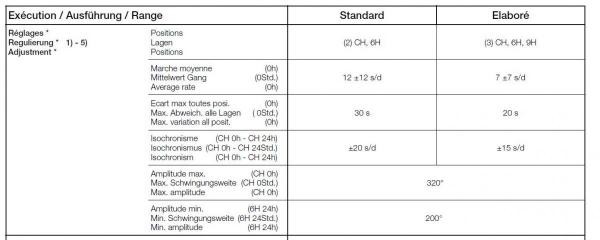

I don't quite understand the question why are you concerned about timekeeping of your Rolex at 150°? Then when exactly is the watch running at 150°? So to help you understand timing specifications I'm attaching timing information for a eta 2824-2 watch. So you'll notice that the end of 24 hours running the minimum amplitude is 200°. Then the timing specifications are based on a 24 running time even though the watch has a power reserved 42 hours timing is based on 24 hours. So here's a link explaining about COSC certification you'll notice specifies that every 24 hours the watch is wound. http://people.timezone.com/library/wbore/wbore631733384647656250 So what's the problem with going below 200°? As you found out timekeeping gets really bad. The escapement that supplying power to the watch also screws up timekeeping and the effect becomes much greater as the amplitude decreases. Then you're probably timing the watch either dial-up or dial down try putting the watch in one of the crown positions and see what happens especially when you're at 150°. There's always a drop in amplitude between dial-up and dial down and one of the crown positions as there's more friction on the staff typically on its side. The other problem with low amplitude is positional errors become much greater.1 point

-

1 point

-

Your a canny lad Geo make me one PLEASE. Great job done. PS didn't know you had a lathe. Wish I had room for one1 point

-

Fantastic restoration Geo. What paint did you use?1 point

-

1 point

-

1 point

-

According to a quick Google your watch has a 784-2 movement. If that is correct then this is what the underside of your rotor looks like.1 point

-

1 point