Leaderboard

Popular Content

Showing content with the highest reputation on 06/10/23 in all areas

-

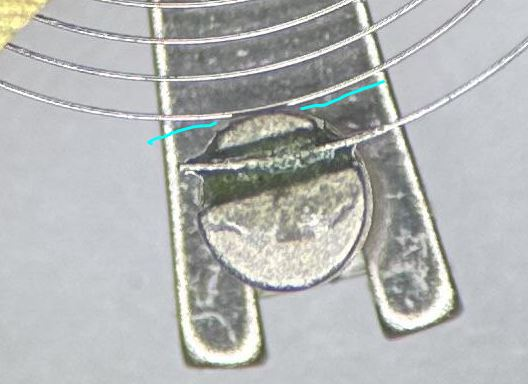

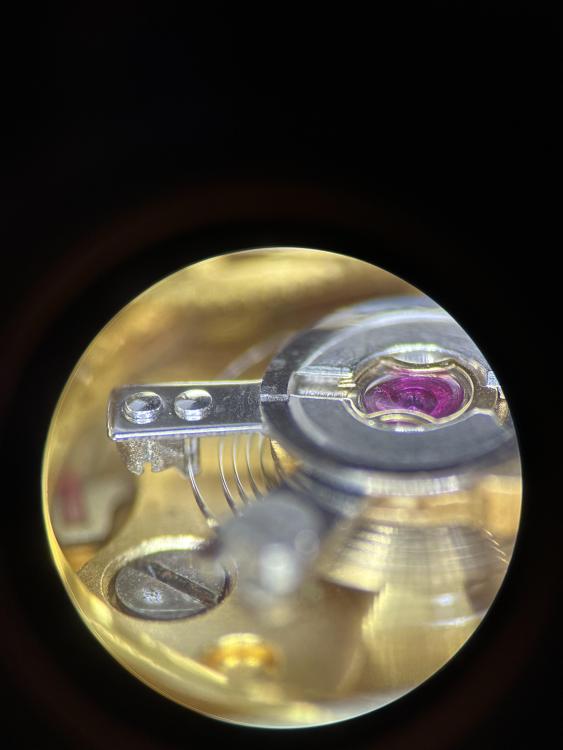

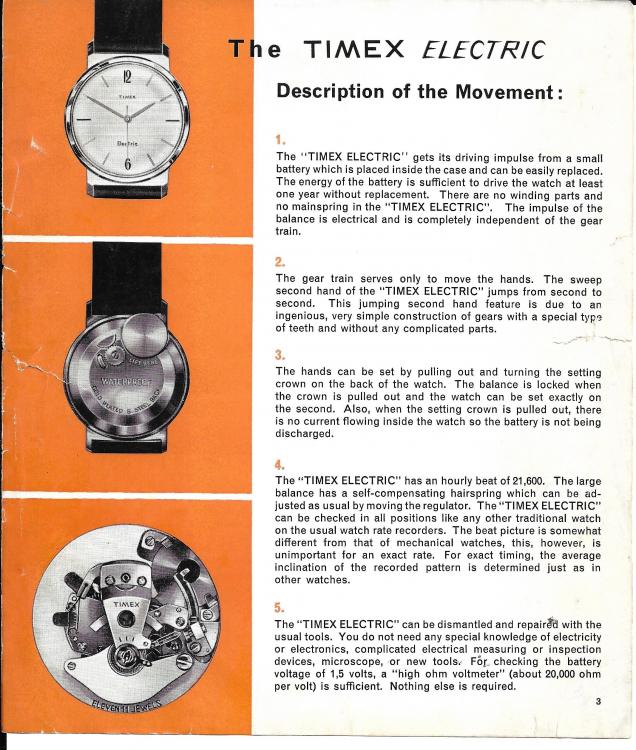

As nice as your picture isn't it does show something that's a problem it would be nice to have a picture of the balance wheel in the watch looking straight down so we can see if they hairspring looks like it's centered. Because right now it does not look like it's centered but that could be because the balance wheel is leaning as it's out of the watch. In a case here is an image from your image and notice a problem it looks like they hairspring is touching the stud? So when you put it back in the watch look carefully is the hairspring actually touching or not and when the watches running even if it's not touching when it stopped it may be close enough that when the hairspring opens up it will touch the stud. Then this is where it's nice to have pictures of your watch so we can give you helpful suggestions fortunately I found another picture online. I notice your stud has a screw on top I assume when you loosen the screw the stud will rotate? With no power on the watch providing they hairspring actually is touching the backside of the stud you can loosen the stud and see if you bump they hairspring back into being centered in other words you have to move the hairspring away from the backside of the stud like in the picture where you notice the outer terminal curve is much greater than what you have as a guess caused by your stud not being quite in the right place I suspect when you loosen the screw up with no power of probably just align itself where it's supposed to be. Then yes the words to describe this totally sucks versus if you could just see somebody do it. That's why I'm giving an image that's more of what you should see versus what we see with yours as soon as you get us a picture in the watch of the balance wheel then the definition a centered is if you look at your image you look at the coil spacing near the stud and look at the coil spacing on the other side of notice on the other side they are much closer together. I think once all the spacing is even you should be away from the stud the watch should be fine.3 points

-

When I clean a watch I put the balance on, without the pallet, to see how freely it swings. I give it a strong blast with a puffer, and I want to see the balance still swinging after 30s. How long does it swing ? If not, you have a problem with the pivots/jewel or hairspring. As your hairspring isn't flat, it could be catching on the balance arms, cock, or centre wheel.2 points

-

Hairspring coil is not concentric " pushed to side" , hairspring needs a bit of manipulation near the stud to center the coil. Turn the stud with a reglare screw driver to center the coil, thats all it needs.2 points

-

https://www.instructables.com/Mechanical-Apple-Watch-From-Real-E-Waste-Apple-Wat/ You might enjoy this.2 points

-

I think we need to go over what you do oil and what you're not Oil in your watch.. Then I consider this a discussion group of people learning which means I authorize you by the way I have no power to authorize anybody but I now authorize you to Oil your escapement with any lubrication that you have for horology without the epilam. After all in the old days used to oil it without epilam and I don't even use epilam at work and yes epilam opens up another can of worms I really curious about how you lubricate your balance pivots and which you use on them..1 point

-

Yes oil it's needed on the lever escapement otherwise amplitude sufferers timing machine results suffer and yes you really need some oil there.. Whatever oil use on the balance pivots put some on the fork or the escape wheel teeth I prefer to put it on the fork. In other words the oil the impulse plane the pool drop in the move the fork back and forth until one third of the teeth go by the you put another drop another third and another third and then you let it run a little bit and put it back on the timing machine sometimes it didn't transfer all the way around you might have to just touch of the loyal on the other side of the fork. But for right now in your learning it's not critical you don't have to order anything special but you do have to oil it..1 point

-

Yes hairspeing almost in mid point in the regulator slot, good enough I wouldn't touch it. Am I understanding right, you have not lubricated the pallets yet, or you might lube the escape teeth instead, in case you haven't you will see considerable amplitude gain when you do. Swiss lever escapement lives on oil. Rgds1 point

-

It's a brazed carbide turning tool ground to bore very small holes. I think that one will do less than 0.80mm bores. In the hole is a plug gage showing the hole size. I use diamond grinding wheels. In my early days (like slightly pre-2000s) used a roughing wheel in a crappy WW lathe, then honed on a copper disc with 3 micron diamond paste. More recently, a proper grinding machine, with diamond wheels, rough and finish. All freehand, and for tiny things like this, finish the functional faces on another (lathe object) with a really fine, D7, diamond wheel.1 point

-

The pallet fork pivots are never lubricated. But the pallet stones are definitely lubricated. One of the clues I have of lack of lubrication is look at your timing machine line notice how it's not smooth. Then lubricating the escapement usually bumps up the amplitude by quite a bit..1 point

-

1 point

-

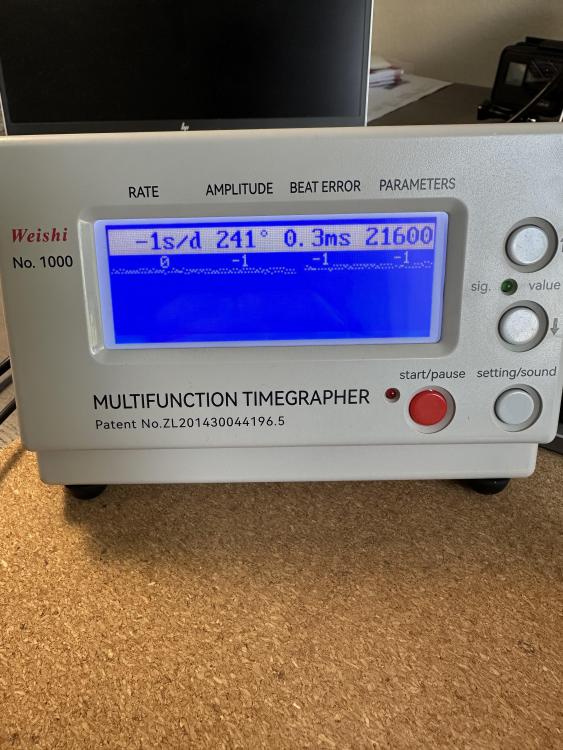

Oil changed. "hairspring exactly centred" - probably, bot honestly do not want to touch it anymore =). other then that will wear it and see, bout honestly even before the fix, I was wearing it and all seemed fine =)) Thnx for the advices. Please check the picture, looks to me that its in the right place. "Demagnetized" - not yet, waiting for the device to come. "how do you lubricate" - I don't. Neither the pellets not the fork. Read somewhere that people do that, but correct me if I'm wrong. "isn't touching what it's not supposed to be touching" - ha Update 20min later after saying I would not touch the spring: OK, OK ... I turned a bit more the stud screw, now the Amp is 260... Guys this is it, I will not touch it anymore, don't even ask! But jokes aside, I guess I would live it like this and see after a while?1 point

-

This is something i always check seperately before assembly, i also do the same with the lever. I Install the lever with nothing else, check the end and side shake and a final check to see if the lever will fall from side to side under gravity while tilting the movement. That feels like a good indication of free movement with no restriction and no interference from anything else. It is so much easier doing this first without the barrel and train installed, especially if a problem is found. The train restricts visibilty and you also have the ease of removing and installing the balance and pallet without working around the train.1 point

-

Even with the escapement in if you rotate the balance wheel manually 300° or you given a puff of air it should oscillate for more than 5 to 7 seconds.. Yes it's amazing how much loss of amplitude occurs with the hairspring not where it's supposed to be. Then for the balance jewels issues with those like the end stone's are they facing the right direction? One of the ways to tell if you're having a balance jewel issue sometimes is the loosen the screw the bridge a little bit and see if that helps.. I don't need to see the lock if you look at it and it looks fine In other words when you push on the fork with power does it snap from one side to the other? If you look at the lock of both stones is it looked the same? Then did you remember to lubricate the escapement again?1 point

-

1 point

-

Have you demagnetized The watch? Then how do you lubricate the escapement.. Then isn't it amazing what happens if the hairspring isn't touching what it's not supposed to be touching.1 point

-

So hairspring no longer hits the stud, it also( the hairspring) should pass through the regulator slot ( boot-pin) mid point. Looks to me a micro, mini, little bitty adjustment can be made the same way you centered the spring.1 point

-

That looks a lot better. With the difference in amplitudes, it might be worth recleaning and oiling the cap jewel which is on the bottom when the amplitude is lowest. Depends on what you want out of the watch. It looks like it will keep good time. See what the amplitude is after 24h (if it's above, say 180°, it should be OK). Wear it for a few days and see how accurate it is. You may not have the hairspring exactly centred, which could be losing you some amplitude.1 point

-

Hi Moe, you've come to the right place for help with your project, so please, listen to the advice you have been given, and practice on some less valuable pieces first. It's not that the Longines is tricky to work on, but as a beginner you will deface, damage and break things. Even the most talented do, in the beginning. Good watch repair is mostly about knowledge of the correct techniques and tools, plus a lot of hands-on practice. Even with the considerable support you will get from the membership here, you are almost certain to make some very expensive mistakes if you start work on your Longines now. Check out the threads on beginners tools and what movements are the best to practice on. A lovely-looking watch, by the way!1 point

-

Update on the results. So, the hairspring was really touching the stud. I moved it a bit away from the stud with the mentioned screw. The centricity now looks much better. Amplitude is looking a bit better now (imho). Left it running after the adjustments for a bit. Picture attached. Also turning the watch 180deg, does not make much of a difference comparing to how it was before. Amplitude gets even better on the other side, around 254. Should I leave it like this?1 point

-

Seeing how the stud is mounted which I couldn't really see before it's kinda like the etachron system in that you can rotate the stud in its clip. In other words when you look at it he just gently rotated and see if that solves your problem you shouldn't have to be bending the hairspring at all. Also look to make sure that they hairspring is centered between the regulator pins as it probably currently is not. Then as I have 50% chance of getting it right I think you rotate the studs group counterclockwise just a hair see what happens but that's a 50% chance and write it has to do with the way the terminal curve looks.1 point

-

I did something better yet, I updated my report and included a link to this thread!1 point

-

Haha, i used to do that when i spotted fake rolexes partly hidden in the corners of joblot watches. I guess the seller would hope some poor soul would think he had discovered a hidden gem and bid up. I suggested i was part of rolex's elite fraud squad and would be visiting the address listed by the end of the day, the listing promptly disappeared1 point

-

1 point

-

I suspect intermittent sticking of hairspring. Can you show few minutes vid of hairpsring coil when the watch is running? The vid can be posted on you tube and give us the link to it.1 point

-

This is where it's always nice to give pictures of the watch so I have a link. One of the problems are having is the beat is adjustable separate from the rate but they're stacked on top of each other which means when you move one you can move both of them. So this is why when you're moving to beat your also moving the regulator when she get the beat adjusted you have to move the regulator.. Water damage you will elaborate as to what damage and where and how did you fix the problem? Then when you have your watch and a timing machine turn it hundred and 80° so the crown is out it often helps give better timing results. Also since watch is having issues should be best of it wasn't in the case altogether.. Then in addition to the requested hairspring picture basically a picture looking straight down at the balance wheel assembly where the regulating arms etc. are.. Also where timing the watch it be nice if we could see a picture of the results of dial-up, dial down and one crown position minimum of which would be crown down all three would be nice and I would be curious 24 hours later how is the watch running? Then yes that beat is so close you don't need to worry about that but the amplitude does look a little low which is why I'm curious as to how it's running 24 hours from now. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Tissot_24811 point

-

Don't worry about the beat error, 0.4ms is fine. The amplitude isn't great for a newly serviced watch. Can you provide a close up pic of the hairspring ?1 point

-

Hi check that the balance spring is not bound on the regulator and beating between the pins freely. I take it you received it “ serviced” which is not always the case. Pictures on the movement will help members in their diagnosis If you serviced it you self look for balance spring issues like not flat catching the cock. Was the mainspring changed,if so was it the correct one, as you can see there can be many causes to the problem Oh don’t forget to demagnetise the watch as dirt and magnetism both cause sticking coils speeding up the watch1 point

-

Thats exactly how i see it. I meant the hole is increasing in size but not symmetrical, growing gradually as the cutter makes its way around the circumference of the hole. I think everything has been covered now haha1 point

-

Perhaps we are talking the same? In my virtual brain picture the asymmetrically doesn't increase, it is constant but shifting its position during the rotation, provided you ream with the same downwards pressure, i.e. the thickness of the shaving stays constant. In fact, the asymmetrically decrease towards the cylindrical part of the reamer, where the reamer tapers off. The "problem" with this type of reamer is that the back-side of the reamer (the non-cutting) leans against the borehole whereas the cutting side digs in, enlarging the hole. One could see it a bit as following an increasing spiral predominantly in the horizontal plane. Correct. I do agree that there are nicer, perhaps better ways to enlarge a hole. Reaming with a one sided cutting action reamer seems crude, but, in the end of the day, if it works, it works. I drool over Nickelsilvers machines, but those I may get in my next life For now, and to me having solved the initial question, I can ream with these Seitz-reamers, when following the correct procedure, and be confident that I'll end up with a nice, in center and cylindrical hole. Crude, cheap but effective. I thank you all for your input ....... I think this was a thoroughly enjoyable and interesting discussion1 point

-

Neither made from gold, nor baked bean cans, it showed up today and is a very attractive, high quality, very well made, Peseux 320 based stainless steel cased little watch. As the "least expensive Catorex on the web", it was certainly worth the gamble. I would guess it is from the sixties or early seventies, as it has a fixed stud, rather than the later moveable one. I'll post pictured once I have it cleaned and serviced. Here are a couple of teasers just in case I forget to post the finished result.1 point

-

And so would I, but sadly that's not an option. If it can be done with those Seitz reamers, that would for me be infinitive easier and cheaper. I think in one of your previous post you hinted to that person. I found and contacted him, but never got a reply...... So far, the Omega movement is in parts, awaiting for a save and solid solution. One of those "time will bring the answer(s)" and don't hurry watches1 point

-

I know a fellow who does a lot of Omega work, and does top notch work, and he regularly opens the barrel hole in the bridge for a bushing, just using the Seitz reamers. He says he's had no problems with the hole wandering off center. I think if you're very careful and let the part move with the reamer it should be ok... but I personally would still do it in the lathe. I'm not sure where he gets his bushings or what sizes are available (I make all my bushings), but if you open it to the smallest OD possible for a bushing, and find that the barrel now sits tilted, the hole can still be rectified in the lathe and a slightly larger bushing fitted.1 point

-

Very useful Jon thanks. i think you've posted the use of a mainspring to remove the drive wheel before, handy tip. I had made some miniature levers for removing collets a while ago which made a good job of lifting it. The cs pinion sits really low on mine, i think its been previously forced down the arbor by someone installing the second hand. The wobbly drive wheel was skipping it's mesh with the pinion because of. Your diagram illustrates perfectly how the positioning heights should be, mine is way off that.1 point

-

1 point