Leaderboard

Popular Content

Showing content with the highest reputation on 05/14/23 in all areas

-

My wife took these pictures today. Not sure if there is a message that I am supposed to get The first bench is the one from my Dad. The second is the one I bought from Maine. The third I bought from someone in Wyoming. The last watch bench came from Dallas. The other bench is just a converted office desk. The last picture captures a portion of the room. This was not staged...and I am a little embarrassed about how it looks. That's me and Cromwell.3 points

-

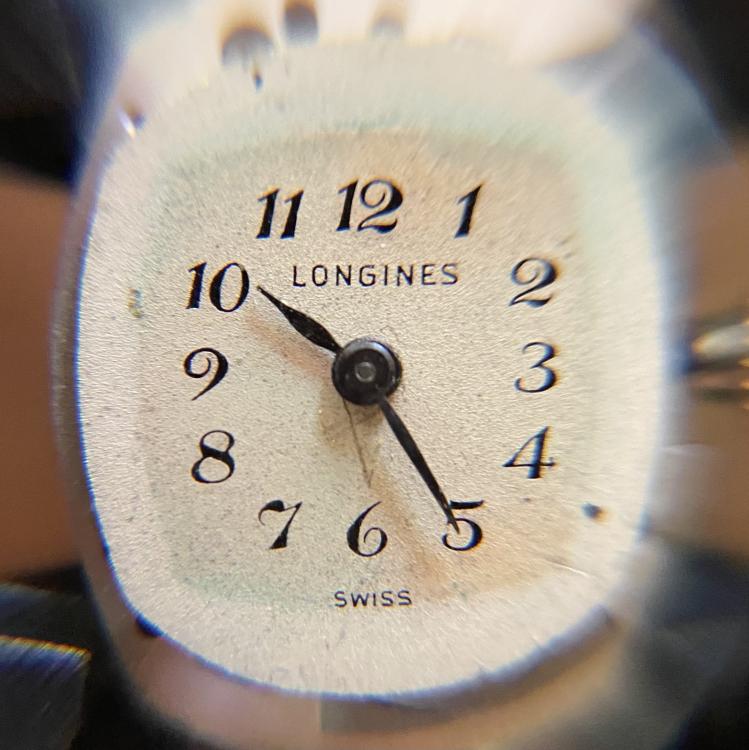

It's quite possible that the problem is that your crystal isn't acrylic at all, but rather celluloid. Celluloid was the early "unbreakable" alternative to glass for watch crystals long before we had acrylic and one of the problems that you get with celluloid is that it discolours with age, typically yellowing. You can't polish it out either as it is all the way through. I suspect that there is something in the Polywatch that dissolves celluloid, it ought to be absolutely fine with acrylic since that is specifically what it is made for polishing. One of the other undesirable qualities of celluloid is that it degasses, the products of which can accelerate rusting of steel.3 points

-

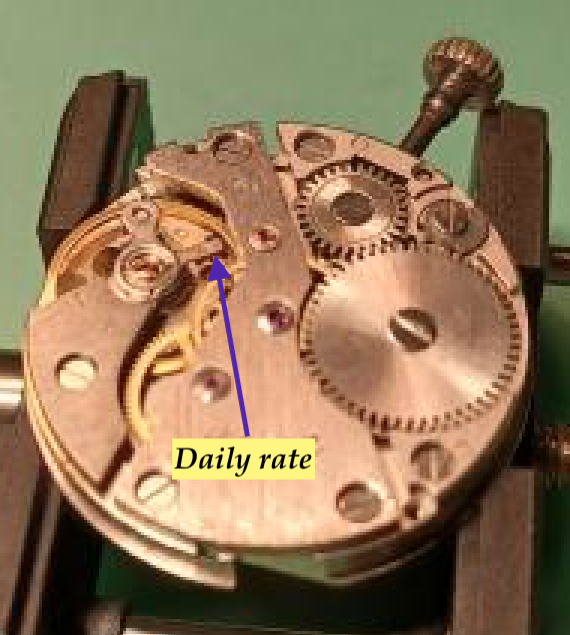

Searching eBay, I found a gas spring Atumtek ATMS032 monitor arm, opened box but new, for €47.50 including shipping from Poland. Studying the downloadable installation instructions, the head (Vesa-plate) can rotate (360˚), swivel (180˚) and tilt (-85˚ to +90˚). The head can be moved 35cm up/down and the arm-height is adjustable on the cylindrical post (table stand) Can be mounted on the side of a disk or on the desk. The one I bought has a single monitor arm and the height of the post is 30cm. The gas spring can be adjusted to suite the weight I think that I can adopt the (square) Visa plate for mounting the microscope head + bracket. Definitely worth a try3 points

-

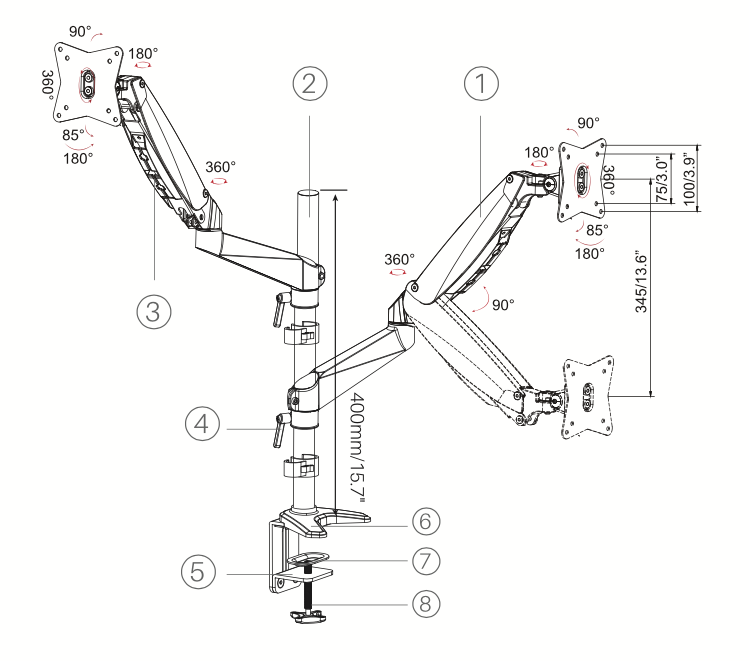

In a previous thread ( https://www.watchrepairtalk.com/topic/25971-2x-barlow-lens-yesno/#comment-214658) we've been discussing the 2x and 0.5x Barlow lens. Turned out that most people are using a 0.5x Barlow lens, often in combination with the 7x-45x magnification scopes. I tried a 0.5x Barlow lens, but discovered that due to the height of my microscope base (5cm) that the eye-lenses were sitting just too high for comfortable working. What I figured out already is that I can swing the microscope 180 degrees around its stand. To keep the stand from tipping over, placing my staking-set as dead-weight on the base works fine. Still the microscope looks straight down and is close to the edge of the table. Looking at flexible arms for microscopes, which can also tilt, don't seem to come cheap. Last night the question came to me; "What has happened to all these billions of swing arms used in the 1990's and early 2000's for lifting/supporting computer-monitors?" Sure enough, looking on local 2nd-hand stuff websites, these arms can be picked up for between €20 - €100. With some adaptation, can't these be used? In my case the microscope head can be mounted on anything with a 32mm cylindrical post. The weight of my microscope head + bracket is 2.7kg, less than a flat-screen, never mind those 1/2 ton monitors of the 90's. They are for sure sturdy enough and come in all kinds of shapes, forms, lengths and various mountings. I need 6V for my ring-light and often these arms come with hidden cable trays. For example this one for €95, new: Or here a used one for €25; Anybody some thoughts, idea's, adaptation idea's, suggestions?3 points

-

One of the more "interesting" properties of some older clear plastic objects (and this includes old film stock, and some old watch crystals) is that they are made from nitrocellulose. Of course this makes them interesting in a similar way to the way that radium dials are interesting. They have a certain level of mild peril associated with them. Nitrocellulose is the main component of old fashioned "gun cotton" explosive. Nitrocellulose film stock for this reason is notorious for spontaneous combustion, and furthermore for being almost impossible to extinguish, since it contains its own oxidizer. The reason more recent types of film stock are called 'safety film' is because they don't have this rather inconvenient property. With this in mind, and if you are up for a small and mildly hazardous experiment, you might want to replace the yellowed crystal with a modern alternative, and then try burning the old one. If it burns rapidly and rather alarmingly, then it is made from nitrocellulose. If it melts and burns rather poorly, then it is a more modern acetate based crystal. The usual caveats apply, you obviously do this entirely at your own risk. Don't forget to film the results. Burning down your entire neighbourhood may well net you a viral video. You can thank me afterwards.2 points

-

the reason I pointed this out or asked was I've seen typically on YouTube where watches are disassembled in a specific order and reassembled sort of in that same order. so based on YouTube balance wheel comes out. Entire watch is disassembled with the very last thing being the pallet fork and its bridge. This means that when reassembly occurs that's the very first part you put in that's why I asked. As correctly quoted above the pallet fork bridge and pallet fork can come out right after the balance wheel. This way if you forgot to take the power off you can be surprised with no major destruction hopefully but it also allows you to look at the gear train see how it spins before you disassemble it. When you reassembling the pallet fork is one of the last things to go in its a lot easier to put the train together without the pallet fork their. plus how can you check for backspin if the pallet fork is the first thing to go in?2 points

-

The pallet bridge should be removed before the main plate. Sometimes there can be some residual power left or we may forget to let down power from the mainspring, there would be less damage to the train wheels doing it in this sequence. Yes, ladies movements are painfully small. The main bridge screws are the size of pallet bridge screws. And anyone who has wound a ladies watch mainspring by hand can tell you how painful that is. My mentor made me work on ladies movements to make me comfortable working with small parts. Great training.2 points

-

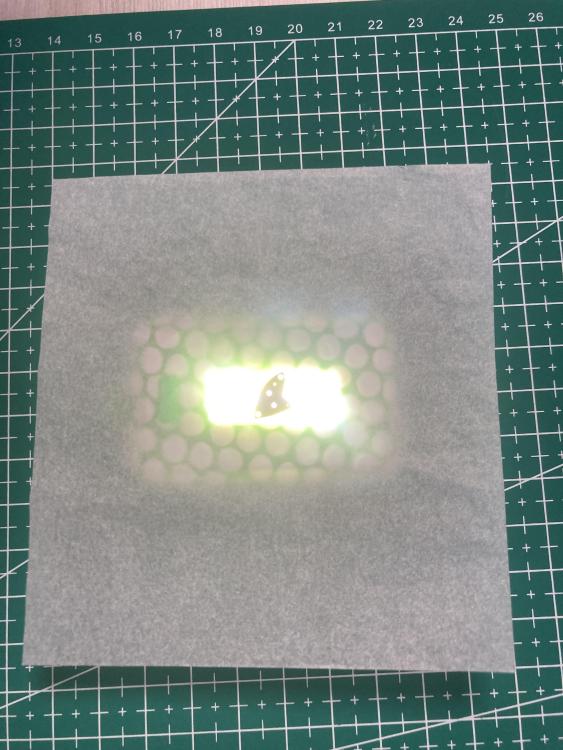

So, I haven’t used film in over a decade. But when I did, I proofed my negatives on a light table. I have a battery powered portable one I have re-purposed for inspecting rubies and their bores. Any crack or spec of dirt is easily seen when back lit. Lighting from the top only, can hide cracks. Lighting through the stones makes any flaw easily apparent. No idea if these are still available but probably. It runs on batteries and has an A/C adapter. l1 point

-

I've got to concur with @MarcIt is more than likely a cellulose compound the crystal is made from. If it had a yellow sheen to it and had some serious age to it, then it's very probable. There is nothing you can do to resurrect this one, I'm afraid. Always best to replace one, as you can't even see through some of the really bad ones , unless it isn't too bad then you might want to keep the originality of the timepiece. Some will have their views on patina of dials and hands, etc. Personally, I like to see some history that has been etched into the watch case; not necessarily the acrylic though. I do like to give an original acrylic a polish to remove the major scratches by starting off with some 1200 grit wet and dry, or powder charged on a cotton bud, then go through various grit counts to end up using something like cerium oxide as a finish. I find original acrylic crystals, say from the 60's or 70's have a nicer smoother rounder profile than the modern day ones which are a bit blocky in my opinion.1 point

-

In days gone by they used a rolled up piece of bread to mop up anything, Blutack is in effect Rodico, except Rodico has less oil in it so it is able to mop it up better. I think the idea of using blutack until you have some Rodico was a really good idea. If I find something works for me, sod what anyone else thinks about it!1 point

-

What did you use to polish it Steve Before acrylic crystals, cellulose was used. Aged cellulose is likely to be more reactive than acrylic.1 point

-

Now that is what I like to see a lovely mess. Providing you know where every thing is. My work bench was always in a mess, my master would always tell me to clean it. When I had my own workshop it always looked as if a bomb had hit it. Funny really as I like to keep my home very tidy I do not like things out of place.1 point

-

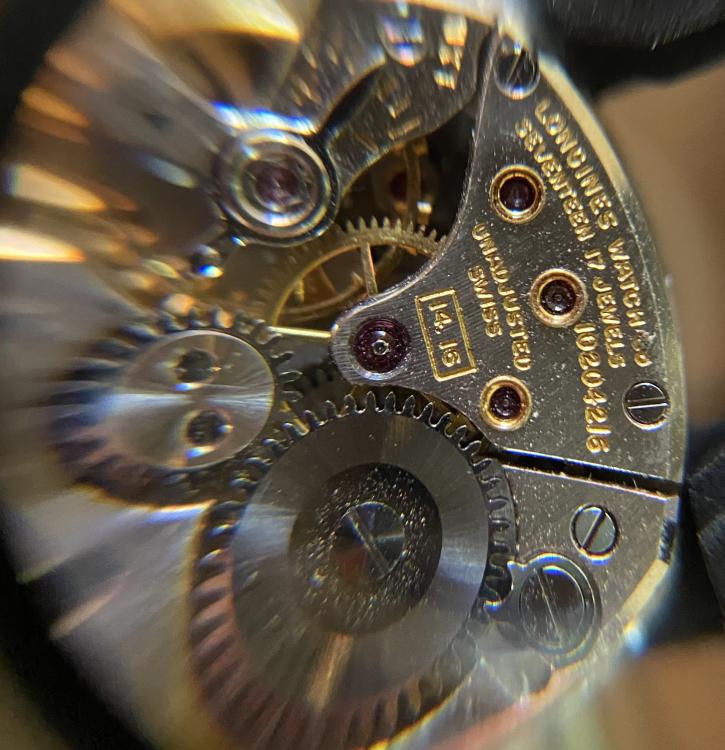

I'd say this is a very early pin-set, maybe mid-to-late 1860s. Looking at the pendant tube, it is still round like it would be on a key-wind case. But I do not think this was a converted case, because they also would have needed to drill for the setting pin, and the cuvette has no key holes. The style being reminiscent of key-winds makes me think this may be from that early transitional period. And the movement looks right for that time. But being unmarked, likely a generic ebauche (maybe A. Schild or FHF or such like) that is as much as I can guess about it.1 point

-

1 point

-

1 point

-

I got the full cousins setup, camera, ring light, scope, Barlow lens and arm. It’s fine, pretty solid. Not got the camera working yet, the manual that came with it is not for the same camera. So will need to spend some time figuring it out to connect properly to pc and extra monitor. The whole setup is a generic white box Chinese manufactured piece. There is a short video on the cousinsuk YouTube channel. Tom1 point

-

okay that was the information I needed. What has looking in the bestfit book it was vintage but then you have the Lord and as being confused looks like we get a bestfit staff number. okay it looks like the balanced staff of 43 interchanges with a 41. then I suppose a good bad news link now that we have a bestfit number we can look and it does exist well it did exist it's out of stock. But the fact that it did exist means that it probably exists somewhere in the planet. As opposed to we can't find it at all which means it probably doesn't exist at all http://www.julesborel.com/s.nl/it.A/id.150145/.f1 point

-

I wasn't paying attention that makes me nervous now that you told me. now is that the name of who made the watch? Because you have the number with some initials up above. Which I can find that description but other places have nothing on the outer wall. Did find a reference to the Lord somewhere but not that number. Then I've seen staffs like this before basically a creatively made staff for a pin lever watch.1 point

-

Ok. All the Swiss trained watchmakers will be up in arms. But I have been using a mixture of Rodico and Faber Castell brand "blu tack". I learnt that from my mentor and he learnt it from his Swiss master. And instead of using a huge blob of it in your fingers, we wind a small piece on the tip of a peg wood, just like a Q-tip.1 point

-

not many references to that movement number first link hints the parts may be available the second his staff number 99https://www.watchsparesparts.com/watch-parts-branded/ahs-calibre-movement-and-spare-parts/ahs-43/ https://boley.de/en/caliber/watchmovements/ahs/13768.431 point

-

yes the picture makes them look really really big I wonder if they made tower clocks with cylinders? then they do come in a variety of sizes to correspond to the size the cylinder you have. so yes the cylinder watches could be from pocket-size all the way down to possibly a ladies wristwatch and I'm not sure that people made cylinder staking punches understood that. We had one punch in the staking set it was too big we managed to find a vintage set of bergeon ones and they were all too big and this is a pocket watch. So maybe they were designed for carriage clocks or something much bigger.1 point

-

is not so much the lift angle that can be measured by just the classic method of 180° and possibly adjust the machine to now say 180° but it's the waveform. I don't know on our oscilloscope what the waveform looks like and whether the timing machine will understand and display the correct numbers. So I wouldn't worry about the amplitude. The beat should be right and the graphical display is interesting is it is but being a pin lever anything that looks like well anything that looks like it goes down the screen and running straight is probably fine. This is where we need a nice running a pin lever watch to try experiments with to see how they look on the timing machine maybe it look great ideas don't know1 point

-

1 point

-

1 point

-

The movement side of the split stem is the part that is caliber specific, so what you need is a generic compatible male segment. That's an ETA movement, so the stem should fit with the common style of coupling that can be either slid together/apart from the side (preferable when possible) or pulled/pushed straight on (seems brutal but they are designed to work that way). You DON'T want the Mido-style coupling which is more bulky and incompatible with cases requiring push/pull. You should determine the thread size of your stem to be sure what you buy will fit the case tube (and it must also fit the crown you want to use) and then you are looking for a part like this: https://www.leosics.co.uk/male-pivot-shank-l12-tap-090.html1 point

-

1 point

-

Another 404 watch bought in a lot of 20 (see below) so a cost of £2.85 each, Its a SIRO Cal. 296. This one fought me all the way, I needed to make a shim to lift the train of wheels bridge to allow the second wheel to rotate freely. The watch had no jewels in the main plate and bridges, so this is the only way I knew how to do it, ie on a jewelled watch I could re-position jewels, but this one just had holes in the main plate (anyone know a better way for next time??) Also the watch came with the wrong winder which I only realised after hours of trying to make the setting lever work, then another 2 hours searching through my collection of spare stems before I found one that would work. Finally I had to remove the damaged loom from the hands and re-lume them - I was left with a spot/clump of lume on the hour hand, but decided to leave it as it looked quirky and I kind of liked it ... and I was too lazy to do it again New crystal and strap (changed to a black one) and polished the case with Flitz (amazing stuff!). So here are the before and after shots: Before front: Before back: Movement: And here is the finished watch: Not bad for £2.85!1 point

-

I found this info for you. It is a swiss movement. The term Ancre Ligne Droite had a specific meaning. The Swiss styel lever was emerging as a standard form in the 1860-1880 time frame. It mean that the three pivots, escape wheel pallet lever and balance were in a straight line. The English style had the three pivots in a triangular lay out.1 point

-

1 point

-

Indeed. I can confirm that. No gain setting on the 1000. Within my short watchmaking journey, I've not yet needed it; but I trust your experience.1 point

-

As for jumpy springs; Has happened to us all in the beginning. Experience and better techniques will reduce the frequency. As a starter, if you suspect a jumpy spring you can put the movement inside a transparent plastic bag. If or when it jumps, it should be inside the bag, but check your hands and sleeves when you pull them out! For me, best is to hold them down with a chisel-shaped pegwood and be "light" on the tweezers when handling. But there are many other ways to prevent them from flying ..... nonetheless, still some will do the escape-trick. I guess, in the beginning I spent more time underneath my desk, searching, than above When a spring jumps, and you don't hear it landing, don't move and check your hair, eyebrows, hands, sleeves, your lap, desk, chair, trousers, socks, shoes etc. When you get up and move, check your shoe soles, the chair again, etc. Try to find it before you move too much around or leave the scene. Magnet is a good idea, in the night a very strong narrow beam flash-light scanning close over the floor (looking for a reflection) or an empty bag in your vacuum cleaner may also help. Clean the floor before you start, good for your hobby and your wife will be happy too These should be in every watch-repairers kit: Suc61 point

-

When you say dial left do you mean vertical? If so your amplitudes are not just normal but excellent. If you mean dial down then the amplitudes should be the same within a few degrees. In the first case amplitude drops because you are going from the balance resting on the tip of a pivot on a flat jewel to both pivots resting on two jewels. So more friction, less amplitude. In the second case, you could have a pivot end that is too flat, a cap jewel that is worn, or just some foreign matter in the jewel.1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)