Leaderboard

Popular Content

Showing content with the highest reputation on 05/07/23 in all areas

-

Eyup watch peeps. Thought a thread about random ideas and tips we have might be of interest. If i can kick one off with something i thought of last night while wrestling with a hairspring. At 1 oclock in the morning trying to figure out a ridiculously low amplitude on a cheap swiss movement was testing my patience. Power was good with a nice escape wheel back spin, pivots on the lever looked good and the lever flicked nicely over once installed. A well shaped hairspring was put back on the marked up balance fitted to the cock and installed back into the movement. Looking inside it looked pretty naff, all bent up at one side and rubbing on the bal cock, so a slight twist at stud should pull it into place. Needing to be right up to the stud was proving arkward to get to even with the smallest tweezers i have as i wanted to be directly above the spring to twist. Checking out the dial side i noticed a very conveniently largish hole directly below where i wanted to be. Largish hole but not quite large enough to get the tweezers in and be able to twist. Being a rough arsed joiner i love my days of tearing stuff apart on houses and first fixing, its all big hammers and crowbars and makes me very happy . I have a few specific bars and one in particular that is fork shaped is great for twisting joists over to straighten them out when nailing in noggins. moment, some kind of thin fork shaped metal twisty thingy. Looking around the watchroom at all the random shite i have I'm not seeing what i need, " i need to make something " . Then i clap eyes on a pack of needles, golden idea me thinks. Taking the smallest needle and honing off the eye gave me the smallest forked prybar known to man. Who said joiners are thick ? Nah we just pretend to be then we get the easy jobs4 points

-

I'm about to try to match the lume colour on the hands of a "Montine" 17 jewel dress watch. I'm not going to touch the lume on the dial, 'cos I don't want to ruin the dial, so I'm doing a few experiments with "dollar store" acrylic paints, my selection of cheap Chinese lumes and my date expired Westfalia lumes to see if I can get a close match with what is currently on the dial. I could just mix up some shiny new lume, but it would probably look way too clean. As a result of all of my messing about, the bench currently looks like Holywood's idea of what a nuclear spill would look like. I'm getting some pretty interesting effects. The experiment consists of mixing up PVA wood glue with acrylic paints and various spooky looking powdered pigments. I'm sure there are more important things I *should* be doing, but none of them appeal quite as much as messing around like a small kid with things that glow in the dark.3 points

-

3 points

-

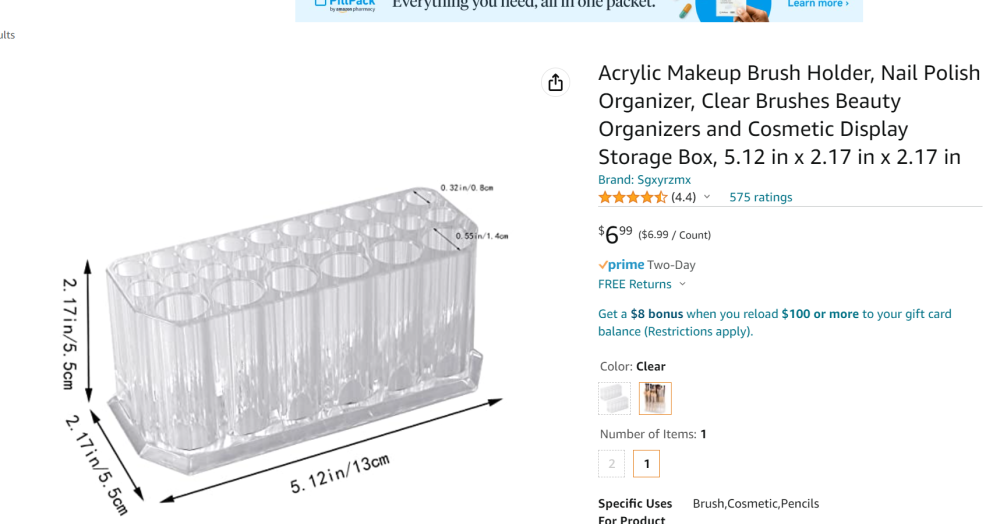

https://www.youtube.com/watch?v=Eh4mCLbkVPQ All you need is piece of plastic with holes for differnet sizes barrels? Ingenious or what?2 points

-

You could use a barrel arbor holder($$) or collet holding pinvise ($$ plus collets $$). Though some cheap pinvises have fairly soft jaws, might not mess up the bearing surfaces.2 points

-

HectorLooi, I know all about these movements the reason I need to see it is KarlvonKoln has said parts are missing so I need to see which parts. The movement in the video is probably the same but the pendulum is very different2 points

-

And, he has some really nice tools in great condition, and I'm a sucker for nice tools! Also, clean, orderly and structured. I like that a lot! Well, not skilled like an experienced pro, but his way of learning is skilful! I especially enjoyed the following video:1 point

-

Watched one of Leo's videos late last night while fixing. I enjoy listening to his accent , the way he talks to himself and dry sense of humor it all ties in quite nicely with his repairing. I cant comment on his skill as not seen enough yet, I'm also rather critical1 point

-

Here's another channel I'd like to promote: Leo Vidal Watches This guy reminds me of my own approach to servicing/repairing. Not to say I'm as good or skilled as him, but I really like his approach and his pedagogic skills are fantastic (video and narrative).1 point

-

Wow not cheap a full complement of all 8 sizes of Bergeon arbor holders runs to £500 at best. I guess some luck and a good gauge of how much to tighten your pinvice helps. An unnoticed damaged arbor will surly chew up the barrel or lid's arbor bearing in time. This might be a good alternative it was a tenner. The jaws are wide, thick and made of brass and when fastened down give good coverage of whatever they are gripping. The only issue is the size 1.8mm to 3mm so well out of the range of most arbors. Or this steel pin vice - square off the jaw tips and smooth broach out the jaws. I think that one was only about four quid.1 point

-

Rude As my well fitting t-shirt rightly states #Thats what i do - I fix stuff and I know things # ( sometimes )1 point

-

1 point

-

Who else noticed the four mangled springs in the corner of the room . Tbf not a bad idea with a bit of tweeking. Not so sure about the barrel arbor in the pin vice though, under magnification thats going to show up some scuffing of a polished arbor shaft.1 point

-

This is brilliant! I do tailoring and alterations, and because I find that needle shaft can always be used for other things, I've saved any that broke. I think I will look through my small stock of broken needles and make myself a tool.1 point

-

Hello, Thank you for welcoming me in your community, I am passionate about watches and this forum is a gold mine for me! I'm here to sharpen my knowledge on the movements and I think that here we are well surrounded! Thanks to you for making your knowledge available to us1 point

-

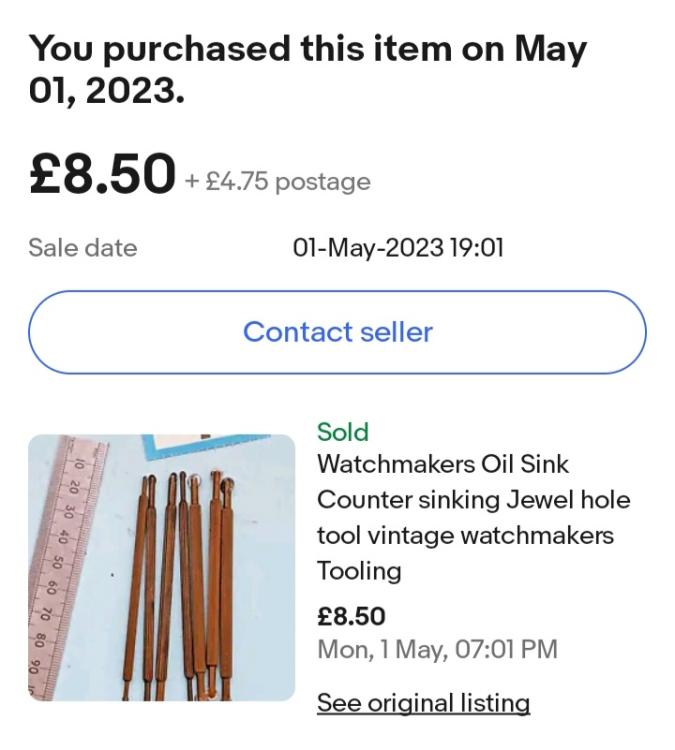

It's always crazy to see old used, sometimes broken stuff on Ebay for more than new price. Full set is just of 60 pounds at Cousins, 20 something individually. I have a couple of old steel sets that have seen a lot of use; recently got some tungsten carbide ones from Slick, quite a bit more at 260 CHF, but worth it for me. The steel ones do do a good job.1 point

-

I noticed the bergeon ones at the same time these came up and another set of four went for 30 quid. If i see any more Steve i will give you a nod. Yes matey i usually do well when I'm buying, patience and being a tight arse works for me I actually used these in a pin vice while i was looking for the sinks.1 point

-

1 point

-

Absolutely, i didn't say but it worked a treat, 2 twists and it was fixed the second was to correct the first overtwist. Tbf i did have a very good vantage point from underneath, and I'm sure thats why the hole was there. After honing the eye you may need to bring the fork together. Twists with tweezers can be tricky, when using 2 pair, one is to hold and the other doesn't grip and twist but is open moved to a position and then closed to twist the hairspring. Less hand action1 point

-

I have two of rubbing Breguets that need help. Searching here and everywhere else the technique to correct the overcoil in the flat is..elusive. Hovering tweezers midair whilst twisting is not in my physical repertoire. I may have to give this a try.1 point

-

perhaps one lubrication can do it all except that's not the right one. It's the right company is just isn't the right lubrication they make something better. The only problem is getting it. TS5500EN elgin oil.pdf1 point

-

I believe this is a similar movement except the pendulum is longer and teeth count might be different.1 point

-

1 point

-

Could you take the movement out of its case and take clear photos of the works, a photo of the complete back plate, remove the dial and a photo of the front plate. As you live in America it will not be difficult to get replacement parts.1 point

-

1 point

-

We've been through that. I applied down to microscopic amounts and still got less amplitude. Of course it's never the (heaven forbid a Moebius!) oil, it's always the operator to blame. Doesn't that excuse sound familiar with things which don't fulfill their promise and you bring it back to a shop? "Surely, you must be doing something wrong ....." or "You are the very first ...." Let me put it this way; Moebius 9415 doesn't work for me, Dr.Tillwich 1-3 does1 point

-

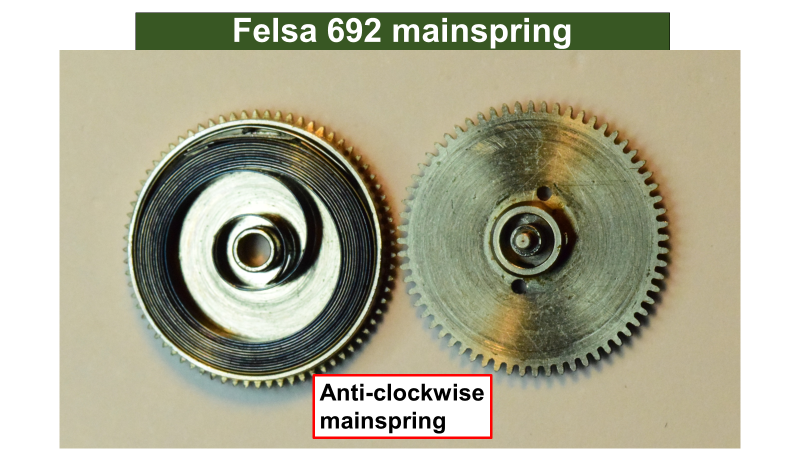

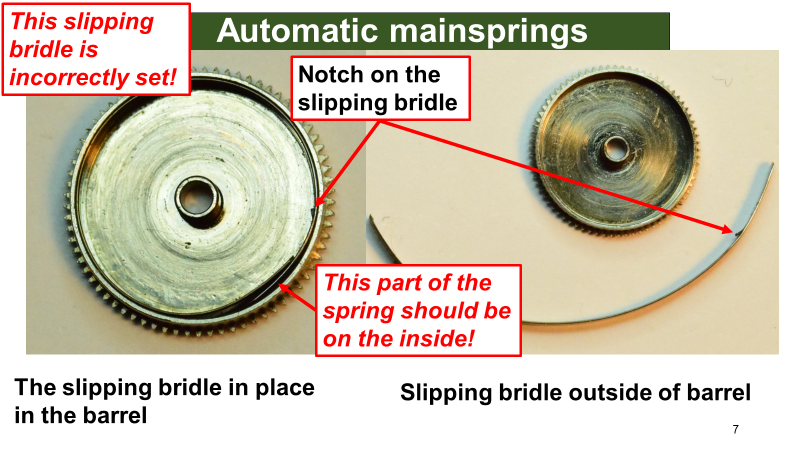

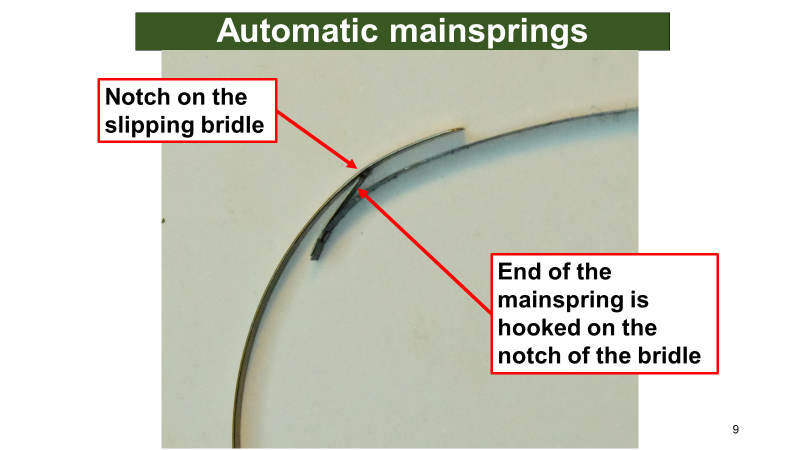

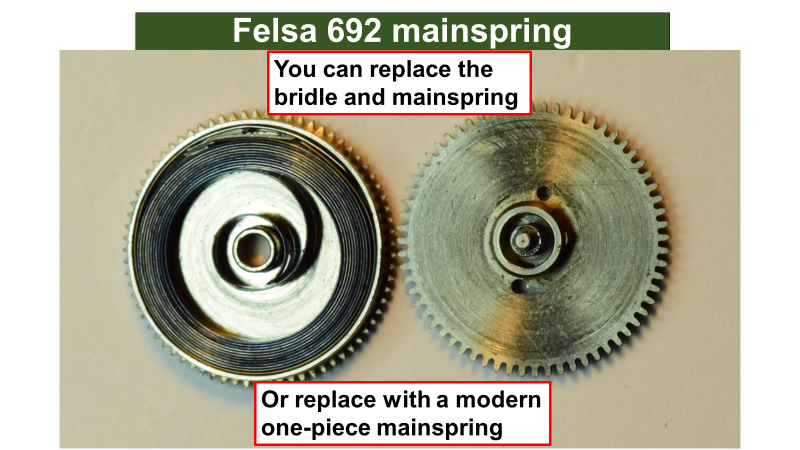

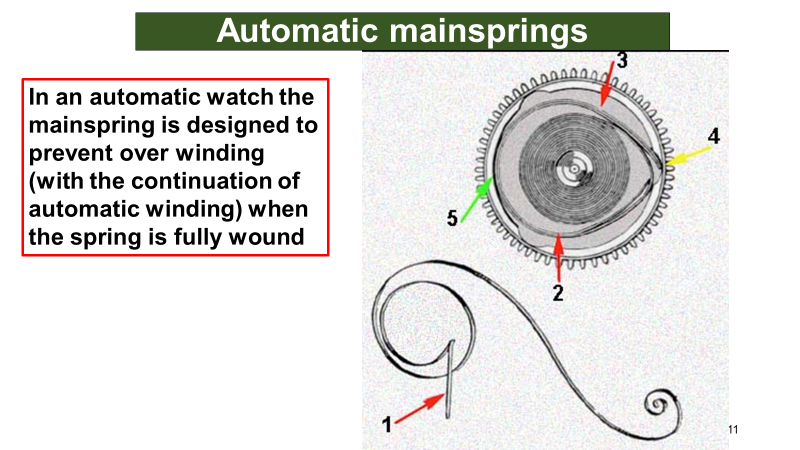

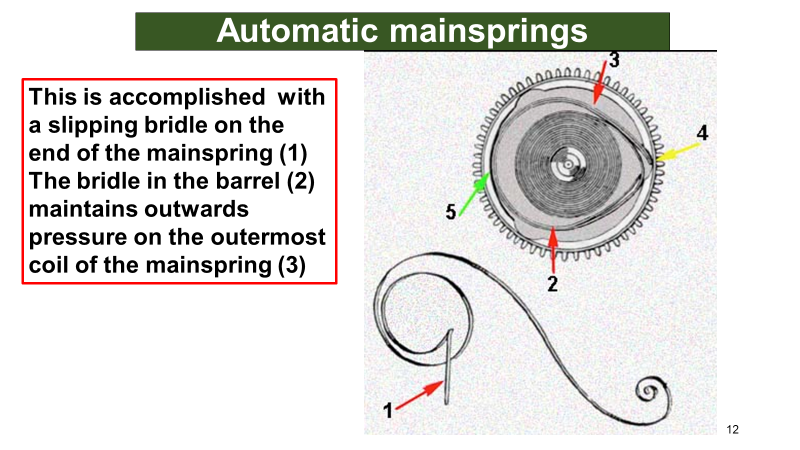

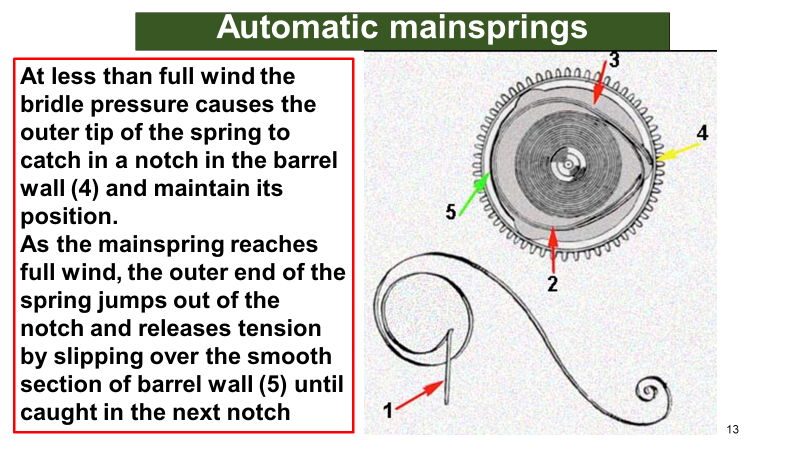

somewhere lurking in this discussion group somebody actually had mainspring winders specifically designed to put the bridle in. Fortunately today the mainsprings are all supposed to be assembled and not require that tool.1 point

-

Hi there, welcome indeed. Certain niceness gushes out in your intro. I have seen some digital intros, like, " I AM HERE BECAUSE MOM GAVE ME LATE GRANDPA'S WATCH WHICH AIN'T WORK. He died this mornin you know.1 point

-

if you look at a Swiss package of a watch parts about the size of a postage stamp. Not a lot of room to write paragraphs of data so this is probably why at some point in time they adopted number schemes for naming components. But that often leads to confusions for people who are excited when they see their part number for whatever parts are looking for not realizing it's really a two-part system. You need a number that tell you like balance complete and then you need the actual number of the watch or some other equivalent number. so for instance in the beginning of the bestfit book they list all the part numbers several pages of them I just sniffed out the first image so you can see. what becomes interesting is if you look at Swiss watches a lot of models could come with several different balance wheels from standard to chronometer so there would be a difference in the balance wheel I assume someone is probably a difference in the number. In the case of Seiko their numbers would be very specific if it was a chronometer grade balance wheel. I was tend to think of that as the best fit number. because that is how they do things usually. so for instance I take that number at I go to bestfit online and ask for the cross reference I get the image which I have attached. Seeing as how the balance wheel doesn't cross reference to every single Seiko balance wheel existence it probably suggests that maybe it's a little different or special possibly higher grade.1 point

-

I thought maybe it was a specific escapement lubrication. just in case you don't have it I do have the PDF specification. TK2213EN Type 1-3 oil.pdf1 point

-

interesting observation. The lift angles can be found at the link below and sure enough the Omega section starting at 240 going up to 250 does increment by one. Which is a interesting observation maybe my Omega specifications are wrong but we should tell Omega they made a mistake because they're listing them all as 52°. Then I don't seem to have a 250 on the Omega document? I suspect the 250 on the chart at the link below is wrong it doesn't exist. The reason is they cents 58° in doing a search of the Omega document there's only one watch with 58° and that's not the right number. 2600A + B 21600 58° that's the only watch they have with 58°. I wonder if anyone ever complains that maybe the numbers are wrong? One of the likely was copied off one of the other lists most of the lift angle lists all look the same because they all came basically from the exact same source. https://watchguy.co.uk/cgi-bin/lift_angles?&redir_count=11 point

-

Congrats on your incoming Seiko. Those 6138's & 6139's are great to work on.1 point

-

Here's a link to the type that I have: Dr. Tillwich Uhrenöl Sorte 1-3 TK2213 für Steinlager Metalllager 3,5ml1 point

-

I've used the Dr.Tillwich pallet-jewel oil on several occasions with excellent results! The only time I go for 9415 is when doing high-beat ETA movements (28800 BPH), but I wouldn't be surprised if I would get excellent results with the Dr.Tillwich oil too.1 point

-

1 point

-

Oh I forgot to mention--for anyone trying to get a detached bridle back into the barrel. I turned my mainspring winder upside down and carefully fed the bridle in through the slot on the side. I was able to gently slide it in by pushing with tweezers and pegwood while making sure it didn't pop out the top with a gloved finger. It was surprisingly easy. The hardest part was all the time I spent making sure I got the hook orientation right, as well as which end would overlap the other. Make sure your disassembly photos are better than mine! And don't forget to make sure the winder you choose for the mainspring is small enough to fit *inside* the bridle you just installed.1 point

-

Well of course, Mark has his courses (which cost) here: https://www.watchfix.com/ This web site has an amazing amount of animated information: https://ciechanow.ski/mechanical-watch/ Alex's tutorials are also pretty good if you follow them in sequence: https://www.youtube.com/@watchrepairtutorials1 point

-

I made another set of pallets and have the movement working at the moment. But I have a few questions. If I set the pallets according to classic Brocot escapement theory, i.e. with the flat surface in line with the centre of the escape wheel, I can't get the escapement to unlock. But if I turn the pallets a little off, the escapement seems to work fine. Is this an acceptable practice? When the movement is level, it is definitely out of beat. It doesn't appear to have a slip clutch, how do I correct the beat? I'm currently using a pocket watch as the pendulum. I only have the movement, without a case, hands and pendulum. I have no idea what length pendulum to use. Do I have to count the teeth in the gear train to determine the rate and then calculate the length of the pendulum based on the period?1 point

-

Hi All, Just thought I would post a few pics of my restoration project of a Seiko 6119-8083 I picked up off ebay. It was pretty scuffed up but the dial looked ok and the seller had decent pictures of the movement. Once I opened it up the dial was indeed in near perfect condition and the lume was still going strong despite its age! I wanted to get this looking as "new" as possible so gave the case a bit of attention and popped in a new crystal. I only noticed after it had all gone together that the day-disc is offset; it does not feel loose so I suspect it was taken from another watch with a different crown position. Overall, Im really happy with it.1 point

-

It's a shame no enterprising engineer is making new 5 jaw collets to update the Cheap (never thought I would ever say that) Bergeon Clock Cannon Pinion tool with its 4 jaw collet Someone would make a killing if they did. Any of you enterprising dengineers up to the challenge1 point

-

Typical wristwatch escape wheel pivot is around 0.1mm, similar or smaller for pallet fork. Definitely too small for a needle and thread, and too small for machine sharpened peg wood. I use a standard snap-off cutter, but use the extra sharp NT Black blades- really makes a difference on peg wood. Also, different pieces of peg wood even from the same batch sharpen up differently. I have old stock peg wood and new stuff from Horotec, some pieces are great, some so-so, no real difference between the 30yo stuff or new.1 point

-

Based on this website I found, http://mirius.co.uk/CalibreIndex.htm?All,MST It looks like an MST 48 cylinder movement Good luck finding parts, however this and the MST 59 may (may) have interchangeable train wheels, so you may (may) have more chances. Hope you can fix it!1 point

-

Hey all, I inherited this 1959 deep sea alarm. I’m very excited about having it restored. Ideally I would love to find someone in Florida who would allow me to be apart of the process as this is something I’m not ready to tackle. I told my mom I’m getting into watches and asked her to keep an eye out as she thrifts and yardsales. She said I have a couple of cheap ones of your grandfather’s. I was shocked when I looked up LeCoultre. It’s in rough shape and I want to get her ticking correctly again. I know it needs a full service and am not sure if the alarm works but the watch runs a bit. I have purchased a k815 caliber of eBay as a donor in the event I need parts. I am waiting on some jlc crowns and nos stems(found the service bulletin for the k815 on here.) I’m looking for guidance on finding the right watch maker to do it. I have emailed with Zaf of classic watches.com but mailing this thing scares the hell out me.1 point

-

1 point