Leaderboard

Popular Content

Showing content with the highest reputation on 05/03/23 in all areas

-

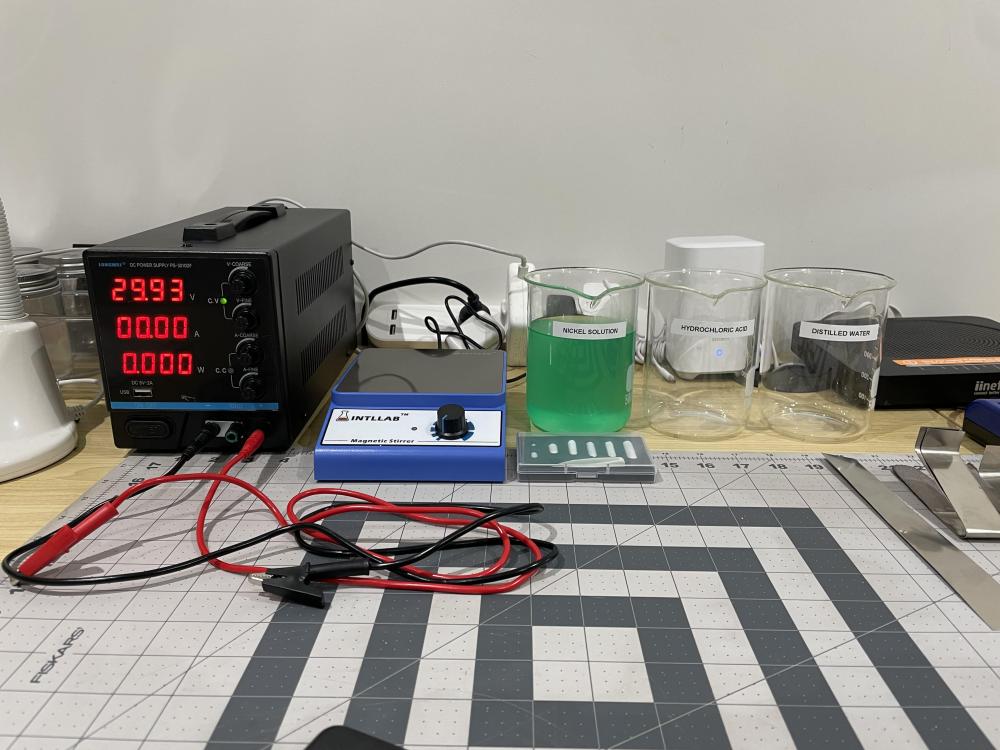

I thought I would post a few pics of how my setup has grown in 4 months. I started with the basics and I am graduallly acumulating more of the essentials. Today I mad emy first Nickel solution (liquid nickel sulphate). The carpet is a nightmare when droping screws and small parts but my neodyium magnet is awesome for rounding them up - parts will jump from 6 - 8 inches away! Anyway - enjoying the journey. Just thought I would share.4 points

-

There is the whole spectrum of YT channels, some are very good down to what I think are complete idiots. If you don't like what you see, move on to an other channel. From nearly every channel you may pick up some interesting information or techniques which do work good for you. There are many ways to skin a cat. There are currently methods and techniques which are touted as "the only holy way", only to find them obsolete in a few years time. The past is littered with those. Also there is no point in worrying about beginners, they have to learn to differentiate between what's good and what's less good, just as we had too. Beginners have to, just like we had to, take their own responsibilities. I'm pretty sure that my all techniques are total crap. The way I skin the cat is a combination of techniques I've learned through the years, picked up from many different sources and guess what; all my watches I've done are still working fine. Who on this planet has the total wisdom anyway ? If I see an interesting channel, I watch, learn, thank them for their efforts and move on once I'm done. To me there is no point in winding myself up about those whom I perceive as well meaning "idiots". Besides, if these people weren't there, how can you compare?3 points

-

Oh my... now you are playing with fire , I never noticed his oiling technique, but I guess I won't be able to not notice it now I am aware of it. Maybe the best strategy is to take the best bits from each youtuber to develop your own style/skills.3 points

-

Yes, probably best to stop digging, and I'll disregard your "data point". Of course, it's worth emphasising, and he may also be spot-on with the 80% recommendation, too. I suppose I was hoping that someone with knowledge of the current training at WOSTEP or wherever would chip in and clarify. Just being lazy! I will have to find out for myself. I was also trying to say that it's not reasonable to expect perfection every time from any YouTuber, and it's right to be sceptical and gather information from different sources. Even if Dimitri were dead wrong on this one specific point, I'd still find his videos very useful and I'll continue to watch them. Thanks for the tip!2 points

-

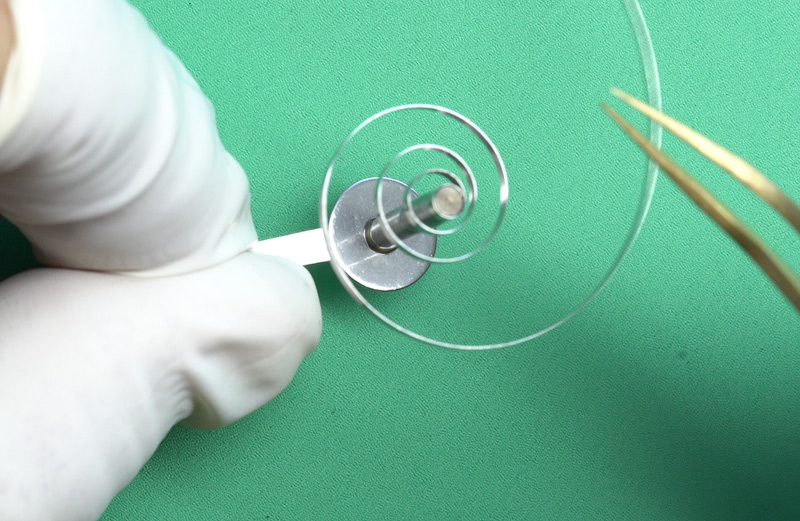

Here is how I think about it. I look at the mainspring in the barrel and look which way the spring runs, from the hole end to the bridle end. In the 11DP as you showed it goes counter clockwise (CCW) if you follow it from the hole end to the bridle. That requires a left hand winder. If it were to run clockwise it requires a right hand winder. So: CW = right hand winder CCW = left hand winder Then when you want to wind it into the winder, place the spring on your bench so that it is in the same orientation as it was in the barrel (CCW). Now lift the spring up, keeping it in the CCW orientation and slide the winding arbor into the spring from UNDERNEATH. It doesn't matter if it's a right handed or left handed, if you put your spring on your bench in the same orientation it is in the barrel and then slip the arbor into the spring from underneath you will always be OK. Here it is illustrated on a CCW mainspring like in the 11DP. The spring was laid on the bench in the CCW orientation and then I slid the winder in from beneath. I just looked at an 11DP and it takes a left hand size 6 winder.2 points

-

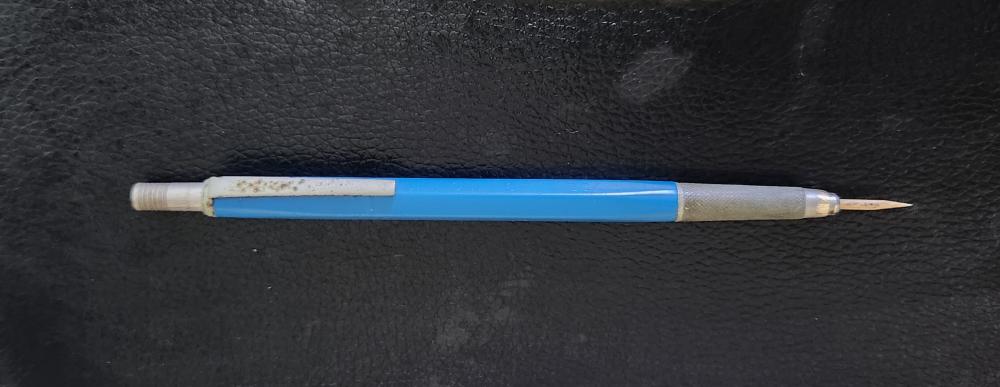

I have never enjoyed sharpening pegwood. I get wood chips all over the bench, floor, clothes and places you never even imagined. I recently found a mechanical pencil from my secondary school days. These dinosaurs use 2.0mm leads, which set me thinking.... Can I put a toothpick into it and stick it into my pencil sharpener to sharpen it? This is what I got. I just discovered that AliExpress still sells these antiques. I ordered a 3.0mm version for my pegwood.1 point

-

Way back in 2018, I picked up the Newmark shown in the post above. I've been keeping an eye out for a suitable "404 club" style donor with a balance for it. One recently showed up on ebay, so persistence paid off, eventually. That of course is where the problems started. The donor arrived and I harvested the balance, and it sort of ran, slightly. So I stripped down the donor, cleaned it all and fitted the balance. It ran a little better, but the donor had no sub-seconds wheel, so I then stripped down the original movement and cleaned it too. It still didn't run well. The issue was traced to a loose shaft on the balance fork, so the balance fork was also harvested from the donor. It ran a lot better, but the hairspring was now causing problems, as it was sticky. I eventually resorted to degreasing it with acetone, as my usual trick of dipping these crude balances in lighter fluid didn't work. Now it runs pretty well, if somewhat fast, so I'm going to leave it going to see if it makes it through the next 24hrs without any issues. If so, I'll regulate it and see if I can correct the beat error at the same time without wrecking the hairspring. I'm also tempted to swap in the plate from the other movement as rather oddly it has something resembling Geneva stripes on it, Croydon stripes perhaps. I'm now a bit of an expert on these somewhat agricultural movements. I can't say I'm impressed with the build quality, but they are quite easy to strip down and re-assemble. The balance is a little bit finicky to fit, and the hairspring is somewhat delicate. The least little disturbance tends to pull it out of alignment. A new crystal was fitted, and a new navy blue Nato band is on its way for it, and then it can finally join the 404 club after an almost five year wait.1 point

-

I think you misunderstood my question. yup. I think I commented on this and agreed saying, those little glass vials are expensive. If it doesn't have a science project growing in it, I'm using it. forget expiration dates and spending $$$ on multiples. let's look at what I was responding to. We have littlemachineshop commenting about the quantities of oil supposedly required. He's not discussing the properties he's just only discussing quantities. Then your comment is about the expense. My question is alternatives? Were not discussing properties of the lubrication and other words horological lubrication is only expensive if we can compare it to another horological lubrication. Because if you look at everything used in watch repair it seems expensive. So I'm just ask if you have a cheaper horological lubrication other than the standard recommended? Because if there is not something to measure the cost of lubrication against then it's not really expensive unless of course you want to compare it to automobile oil but that's not the same kind of oil. Just like a cleaning machine used in watch repair seems expensive compared to make a dishwasher in the kitchen but they're not relevant. So do you have a relevant oil used in horology that's cheaper than the current recommendation that's all I was asking otherwise the cost of the current oil may seem expensive compared to vegetable oil in the kitchen but it's not relevant the size is little tiny bottles last forever almost at least that's the way I like to think about it I'm never going to upgrade my oil again because I perceive it last forever at least at home and the network I don't care about it that's not my problem. Although I think several of our bottles may have expired by now I wonder why that is? So my basic question is in order for something to be more expensive you have to have a comparison and it has to be a relevant comparison.1 point

-

Probably nickel plated. Spot welded battery contact strips tend to be nickel plated, either steel, brass or copper, so with that in mind, I would say nickel plating is most likely, but silver, and possibly tin are maybe an option. I suspect tin might oxidise or maybe even evaporate at the temperatures involved, since it would form a relatively thin layer on a very rapidly heated substrate. Tin's evaporation point (2602 °C) is a little lower than nickel (2730°C), but tin is more inclined to oxidise than nickel, and tin oxide might not bond well. Of course tin plated steel is pretty common too, since that is what most steel "tin cans" are made of, and some of those are indeed welded.1 point

-

I've never used one, but what I can say is that in theory at lease, since it can spot weld steel, it should be able to spot weld copper, since steel has a higher (but broadly similar) melting point. Cooper melts around 1,084 C and carbon steels, somewhere in the range of 1,371-1,593 C. Stainless and other steels are a little higher. Also worth considering is that dials tend to be brass (except perhaps the really cheap ones, which are steel), so if it spot welds steel to brass, then spot welding copper to brass sounds possible. You would probably need less current, or a shorter time to do copper vs steel feet to avoid over cooking them, thus possibly turning them into weld splatter. That having been said, you would need to try it to be certain.1 point

-

Very bad he floods the oil sinks and oil is even out of the sinks when he has finished.1 point

-

Providing the pallets are the correct dimension for the escapement to work the rest can be bigger for a tight fit. I'd forgotten about loctite. Yes it can be difficult, I remember I spent a complete afternoon restoring the same type as you have. So good luck in your quest I'll keep my fingers crossed for you.1 point

-

I think each mfg. has different profiles. This may not be a GS crystal. I suggest you buy several styles and pick the one you like. I prolly have some PK crystals...will post a picture later if I do.1 point

-

Hi Kd8tzc. Who is the vender that you purchased the winders from? I have just one more winder to get for a full set of Bergeon left blue and right red arbors to get. The one I need is left 3 blue. All of these were purchased from Cousins. I started with an empty Bergeon box and itshas taken me 2 years to fill it, buying winder when needed and money would allow. Now Jon has got me nervous and I will have to check all my arbors to ensure that I have no right /left crosses.1 point

-

I tried some filming while servicing an old Zenith pocket watch from 1915. I bought it from an auction and it was not a runner. I'm not showing cleaning, assembly or lubricating so it's not a walkthrough or tutorial or anything, just me learning some filming and simple editing. Most notable thing is I changed the 3rd wheel upper jewel. Old one was rubbed in and I reamed the bushing hole a bit and put a friction jewel in. Of course I forgot to clean the rough edges with a countersink tool. I also changed the mainspring. It's in Finnish and no subtitles but the narration isn't too helpful anyway1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. Watching videos on watch repairing they make it look easy I can tell you it isn't. I wish you every success.1 point

-

You need to have the new ones you have made nice and tight for there respective holes so tight you have to tap them in so they can hardly move, Rodico might help. If they are nice and tight smooth jaw pliers are all you need for adjustment.1 point

-

But I guess you get his drift ......? Indeed, I agree; well trained, well equipped, good techniques and excellent recording, editing and video quality.1 point

-

1 point

-

I guess I should have written "I came to realize that the channel does not exist as a result of a passion for repairing watches". So, you're absolutely right, not an opinion that you have to agree with or is expected by me to agree with. I guess bad choice of words on my part. No worries! I believe there's consensus about covering about 50 to 70 (or 80?) per cent of the cap jewel surface with thin oil like is shown in the video. As I remember it this is also what Mark recommends in his courses. Anyway, I'm not a professional and I'm always interested in differing opinions (the best way to learn!)1 point

-

dial cleaning is always a bit problematic. Basically they really weren't meant to be cleaned and cleaning them can be extremely risky. Some dials are its even meant to be touched at all. Very shiny dials trying to get the fingerprints back off is basically impossible. Frosty dials if you touch them the frosting finished changes and then you're really in trouble. watches are always confusing when you're starting out in that the name on the watch probably didn't actually make the movement. So in other words there are basically an OEM company who makes movements. They'll sell them to a company that would case them up and a lot of times they will put their name on the dial sometimes up with the name on the plates. If they're big enough company they might actually buy the movements with other company and only have their name on them and then modify and change them a little bit than getting parts can be quite interesting depending upon the degree of modification. So basically unless it's a name you recognize like Seiko the movement will probably be made by somebody else. or in the case of some companies that are moments will be made by lots of companies so there's no guarantee of what's going to be in the case until you open the case. Oh and then there's another mystery here did you notice the letters on the balance bridge? Those are US import codes. When watches were imported into the US for tax purposes they were marked with a import code indicating who imported the watch the import codes can be found here. But as you can see for identification of parts it's not always helpful because that's not necessarily who manufactured the movement SON Defender Watch Co. http://www.ranfft.de/uhr/info-uscode-e.html that's interesting because the dial claims to be 17 jewel and the watch looks like a jeweled movement. Usually the pin pallet movements have limited quantity of jewels basically almost none because are usually very inexpensive. looking at their other movements that they make this one is definitely an upgrade by quite a bit as the other ones are definitely low cost snipped out some images from the bestfit book. You see the difference is the main plate size basically all the parts should be identical except the main plate it would depend upon which case they put it into. Then if you're not familiar with the bestfit book it also has a fingerprint system to help you identify movements which is why there's a page number and what's interesting is they referred this as a pin lever watch but typically as I said I think I said pin lever watches typically don't have a lot of jewels. Conceivably they may have zero jewels which makes this one weirded 17 jewels?1 point

-

it would be really helpful if others using the same cleaning fluid could report back. The reason I got excited about the blue coloring is traditionally when you're using the solvent-based if you leave it too long in their something interesting happens but interesting isn't necessarily good. The cleaning fluids that have ammonia the ammonia is what makes the plates bright and shiny. But if you leave it for too long in the solution or EL of the temperature which speeds things up the solution can turn various shades of blue and/or green and that's the copper in your plates being etched out. In other words you can actually frost plates. Worst-case example is if you go on vacation makes some professional watchmaker once did it was asking in another group if anyone would have a replacement movement because it had largely dissolved. But that would take an entire week or so in the cleaning fluid not likely normally happen. Then the water base I know what I cleaned my first clock with the clock water-based solution I don't recall the solution turning blue but I do recall the plates frosted. My guess was good as the water was warm so keep an eye on things you might want to cut your cleaning time back down to closer to the five minutes. Anytime I'm using the cleaning fluid at home five would be the maximum I would do it more like four minutes to avoid this sort of thing. The rinsing solutions of course are no problem typically it's only the cleaning fluid can get a little aggressive but maybe this is normal for your water base solution.1 point

-

It's an Amida, either a 530 or a 535, the base plate is common to both as I believe that one is a variation of the other. I don't know what the differences are between the two.1 point

-

Other than Doing it by hand , no tools. You could use a hand broaching tool to hold the hand securely whilst you stroke the hand into shape. Avoid any bending as it will crack off, tease it back gently.1 point

-

I have encountered those kind of mounts before. At the time, I used my older (non-digital) vernier caliper, as an ersatz wrench. It worked. I'm thinking of making a purpose-made wrench from heavy brass though. But I haven't worked on another automatic like that in a while now, so I haven't made it a priority.1 point

-

As an electronics engineer using low melt solder to desolder things because it melts at a low temp would be my way to go here as it sets like regular solder given enough time but melts at 138 deg. Thus with the metal of the dial acting as a heat sink you do not have to apply the iron for very long to melt it into place. As a conductor Tin/Bismuth is crap, but we arent bothered about electrical connection here just attachment...1 point

-

So I feel your pain re: while I got the watch back together and running, I noticed it wasn’t auto-winding very well (leading to only running about 12 hours at a time). So I took it completely apart, recleaned everything, and took my time applying lubricants. One thing I did different this time is fully disassemble the magic fingers mechanism (wheel, etc), and more thoughtfully clean it and lub it. So now it appears to auto-wind more freely, but I can’t get the amplitude above 180 dial up or down. not sure I like these seikos…..0 points

.thumb.jpg.f1a29a0f2bbf72f94295583bed5078e9.jpg)