Leaderboard

Popular Content

Showing content with the highest reputation on 04/16/23 in all areas

-

I can "ditto" what John said. I have a friend who brought me a Rolex to service. He's owned it since the 90s, and it's never been serviced; I was expecting to find a worn rotor axle at least, among other wear. But it looked decent on the Witschi prior to service, a bit low on amplitude and rate a bit slow. And there was no wear. Turns out, like John, he wears it from time to time, not daily. So it survived just fine. I told him it's good for 5 years now of daily wear, 10 if he just puts it on occasionally. Had it been a customer, I would have told them it needs a service if it's to be worn, or it can remain unserviced if it was to go back in the safe, but would be specific that if it was used in its non-serviced state it would risk harming numerous components, plus the unknown water resistance John mentioned- which could spell total destruction.4 points

-

3 points

-

we probably need a clarification here. Does the owner of the watch intend on wearing it daily now or was the owner of the watch just concerned that the watch should be serviced even though there's no intention on using the watch? if the watch was going to go in the daily use then it should have been serviced. The gaskets more than likely after that amount of time will go bad and because it's perceived that this is a Rolex is waterproof more likely it's going to get damp and damp with bad gaskets is bad. As far as the oils or lubrication's evaporating I'm not sure if I've ever really seen that. Not saying it can't happen it just isn't what I've seen perhaps. Then I had a Rolex that I had serviced and basically never worn almost. I would occasionally where it for special events just to show people look I have Rolex and the rest the time it was someplace safe. Then I purchased my witschi timing machine I decided to service the Rolex because now I could do a proper before and after timing and I can see the amplitude. No cheap Chinese did not exist back then for timing machines. When I service the watch I had remembered how I had previously lubricated it the PML stem grease on the keyless looked well if I wasn't paying attention I might've thought I was reassembling the watch it looked perfect. Then the rest the watch the thing is that I remember was the 9020 on the gear train was visibly still there. The 9010 on the balance pivots as usual for anything I've serviced over time where I know that there was 9010 there there was none. I'm still not sure I 9010 I'm assuming that it spreads and does not evaporate. This is because all the literature I've ever seen anywhere where you use 9010 you also have epilam to keep it from spreading. But it also could evaporate in any case it was no longer there. It's a shame the owner of the watch couldn't get a guarantee. Like everything is perfect and you will guarantee that it will stay perfect for X number of years so I can go and where my watch every single day and not have to fear that the gaskets are bad or the lubrication is bad and that someday down the road the watch repair won't cost twice as much because disintegrated because it really should've been serviced. The problem is even with a timing machine it just tells you the balance pivots are good but it doesn't tell you the functionality the lubrication especially on things like the automatic. Very common with the first automatics with a lot of metal on metal bearings and synthetic oils of the oils we just disappear and the bearings would disintegrate. One of the advantages of organic oils are they just typically get sticky the watch stops it safely immobilized until it's cleaned versus no lubrication at all and it's free to disintegrate. so probably the answer is of the watch was going back into the safe and it wasn't going to be run it's probably fine. But if anyone was going to wear it then it should be serviced even if it looks fine. It's actually better service a watch when it looks fine than waiting until it looks bad then typically it's going to be really bad.3 points

-

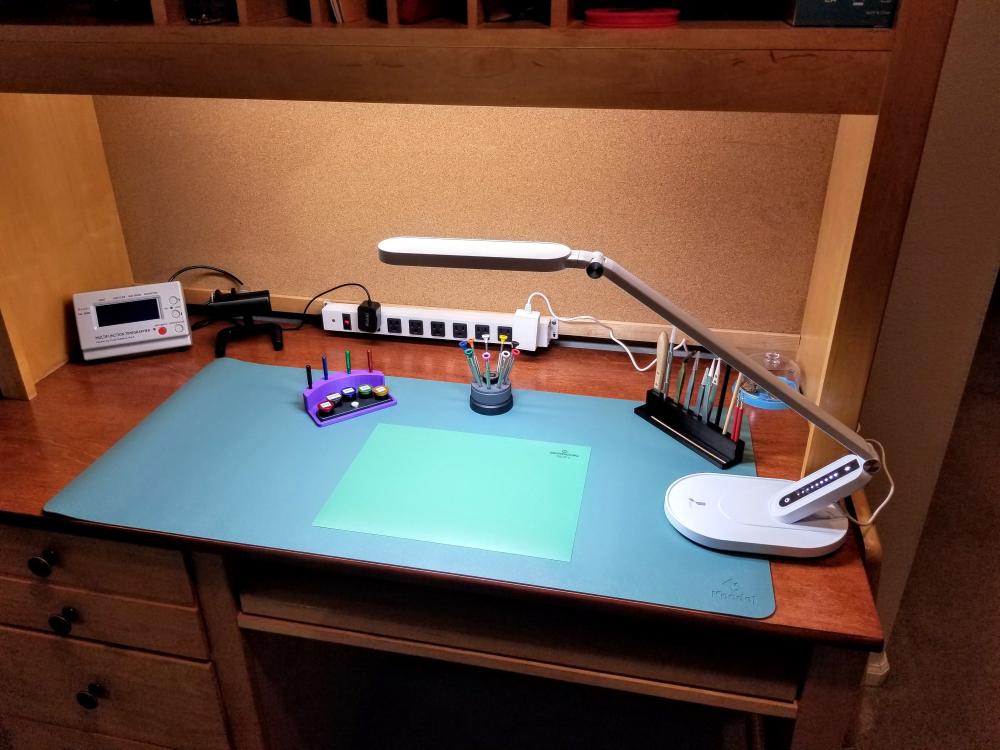

I've been working on getting myself a workbench put together. The kitchen island was not going to cut it for the long term. Seeing as I wanted to save as much money for tools as I could, I wanted to do save some bucks on the watch bench. I took a 2nd hand desk that I got for cheap, refinished the desk top, installed a LED light bar, added a power strip, and created some storage in the otherwise useless keyboard tray pullout. The hutch is good to store some tools and accessories. I've got a couple of drawers to store parts, supplies, and project watches. I put a chair pad down over the carpet, to hopefully keep some flying parts out of the carpet. Hadn't used this much yet, but so far it seems like it will work. Eventually, I would like to add a binocular microscope to the mix.2 points

-

Someone on the Swedish watch forum klocksnack.se told the following interesting and puzzling story. In 1991, a Rolex TT DJ36 was purchased. It was used daily for about a year and then sat in a chest of drawers for over 25 years. Since it had been unused for so long, the owner took the watch to one of Sweden's most reputable watchmakers (Nymans ur) and asked them to assess the need for a service, and was then told that the watch was running so well that there was no need for service. Nyman's ur said: "We'd be happy to serve it, but if you don't have a problem....Your money, Your choice." I think this sounds like a very strange answer because the oils should have evaporated after so many decades. Or could it be that the oils are preserved if the watch is not used? Personally, I would never have taken a chance with such an expensive watch, but at the same time I can understand that you hesitate to carry out a service when the "experts" say that it is not necessary. It would be very interesting to hear your thoughts and views on this, especially from one of our professionals such as @JohnR725 and or @nickelsilver.2 points

-

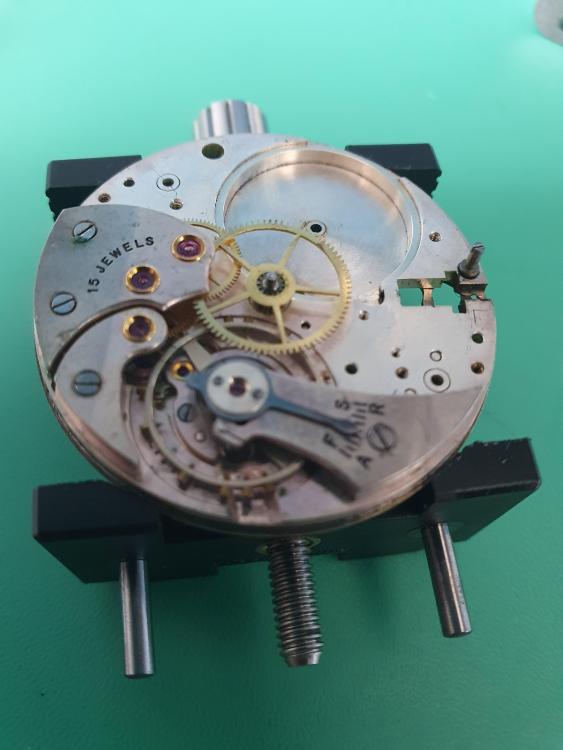

Okay some success here. Resetting the jewel more like DeCarle's diagram has worked and the movement is now ticking. It won't run dial-up though, and that appears to be due to excessive end shake. I'll have to see if I can correct that - it is also possible I fitted the wrong staff since the ebay seller was a little ambiguous. This was meant to be a practice watch anyway so I'll keep practicing. I had thought the roller table was just not a tight fit on the staff as it wanted to rotate a little too easily, but ultimately discovered I didn't have a good enough rivet on the staff (and that my staking set is missing the exact rounded stake I needed). I did get the rivet set in more solidly and assembled the thing, got the roller aligned between the banking pins, and am pleased that it is at least kind of running since this started out with 2 broken staff pivots.2 points

-

Lubricants (oils) are made from standard base-stocks of given viscosity. This applies to both natural mineral oils and synthetic (POA) oils, (not chemicals) These base stocks are then blended to get to the required viscosity. Normally a thinner oil is added to a thicker oil to get a lower viscosity than the thicker oil. All oils have a range of molecules and the lesser/greater sizes are referred to as light ends or heavy ends. To 'evaporate' an oil would require temps well in excess of normal temps (even tropical areas). However some evaporation can occur with the very light ends and the heavy ends will tend to oxidise more, particularly at higher ambient temps. Both these effects will tend to thicken the oil. The more blended an oil the greater the effect would be, but still miniscule in the realm of things. This is why the sticky residues are found in bearings etc in old watches and non-serviced watches. Synthetic oils (PAO and not 'chemicals') have much better control of the molecule size and therefore have much fewer light and heavy ends. They therefore tend to degrade less noticeably (ie oil thickening). Some oils (both types) have 'addtives' incorporated to control other factors (extreme pressure EP, ant-iwear, metal pacification etc). These additives will do their job whether the oil is active or not and some will be 'consumed' doing that job, so a further age related degradation occurs. If the oil has stayed in place, then it will probably still lubricate ok. If it has spread, then the part it should be lubricating will be starved of oil and will therefore wear more rapidly. Obviously the comments above re servicing make sense if the watch is to be worn regularly again2 points

-

That's very interesting, thanks, and reminds me very much of the Russian approach (Vostok, Raketa, Poljot, etc.) where you'll most often find one or two shims under the balance cock. I would have thought thin foil (I assume you mean aluminium foil!?) to be too tick, but perhaps it's an ideal material. Got so curious I'll measure a bit of aluminium foil right now. Back in a minute... This is the aluminium foil I found in my kitchen drawer and it's 1/100 mm. So, pretty ideal I'd say. One or two shims would in most cases, I believe, be enough to make the necessary adjustment. I'm afraid I have no idea. Or, perhaps, oil the pallet fork jewels with a bit of thick oil (HP-1300)?!2 points

-

I think all of us start with a nice and neat bench. Then things have a tendency to creep out of the drawers and scatter themselves all over the table. Perhaps it's the gnomes and elves hiding under the table that are responsible. So, having more legroom means more room for elves and gnomes to hide.2 points

-

The split rings pull away revealing a hole or gap where you can drip oil. Not as convenient as when there are larger dedicated reservoirs, but many lathes are this configuration. In some cases you can rotate the dust covers to reveal a cutout to allow oiling.2 points

-

Hi all. Ive got into restoring old watches as a hobby. Inspired by Wrist watch revival on YouTube. Using My Retro Watches as a video tutorial.1 point

-

1 point

-

I could be wrong but all of the Seiko bracelets that I've encountered that had removable links have had an arrow stamped in the underside of the removable links to indicate both which links could be removed and the direction in which the pin or insert should be removed, and they were always fairly easy to push out. I don't see any arrows in your photos which suggests to me that either your bracelet doesn't have removable links, or that if it did have once, they have all since been removed. Which may explain why you are having such difficulty.1 point

-

There are a few factors that need to be considered. the type of lubrication that Rolex use. Temperature where the watch was kept. What type of place did the owner of the watch live or work in. Watches should be serviced between 5 to 7 years with normal use but then what do you call normal. I expect Nymans ur know what they are talking about.1 point

-

1 point

-

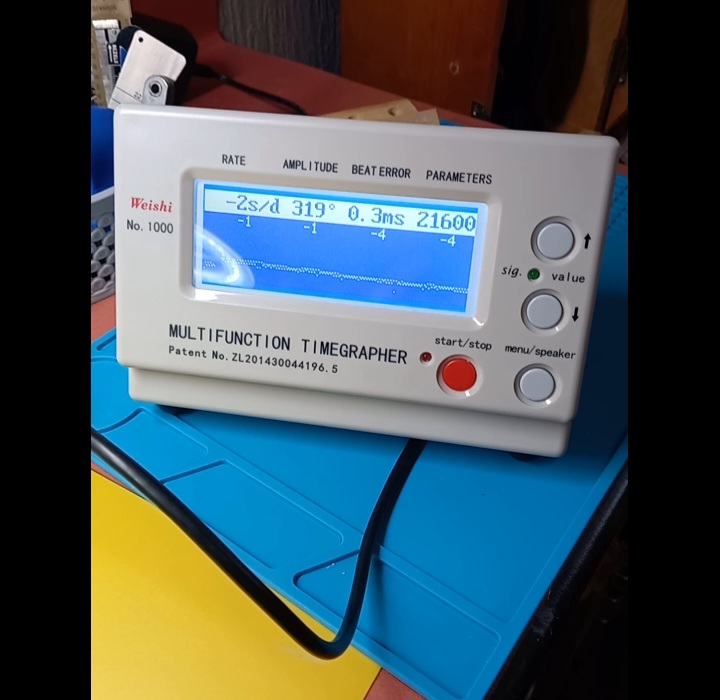

Hi watchie I mentioned the same thing to John yesterday about my sister's 45 year old watch that had never been serviced. It had a beat error of 8.8, she said she always had to shake it to start it. It had been in a draw for 40 years or so. Once correction of the beat error it ran perfectly. The oil was still in the jewels even the balance. This is the tg readings i got after the beat error was almost removed.1 point

-

The bezel remover does work for some types of bezels, but others are just a sod to get off. For some you need to remove the bezel insert then remove the retaining spring, others, like the Squale I've been working on, need 3 hands and the patience of the pope. The bezel remover would not work on either of these bezels.1 point

-

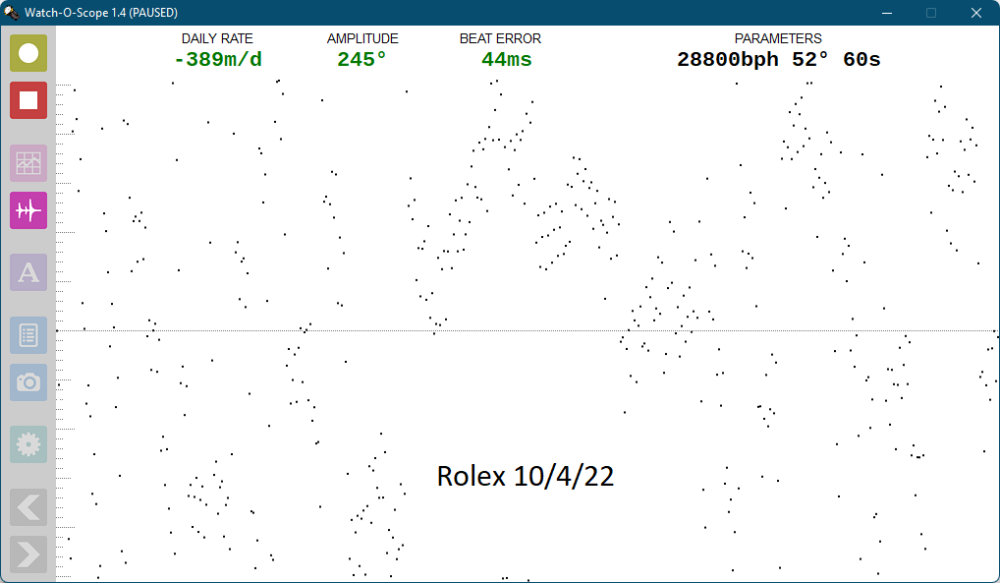

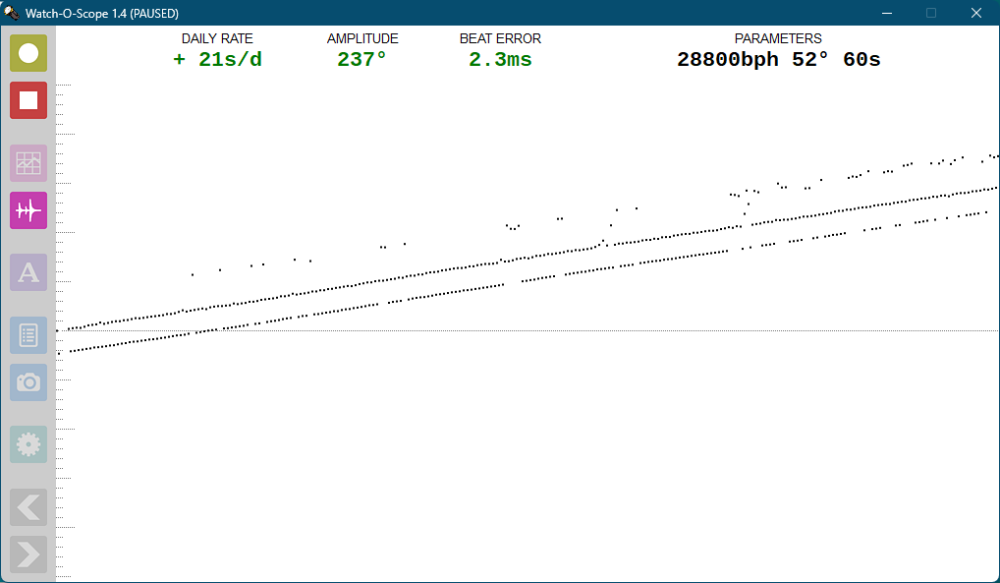

somewhere in the group recently we had a discussion about that and basically you cannot rely on the graphics display of this program if you're running the PC version because basically it looks like crap. then there are alternatives that you work with your microphone. The first program runs in the full mode for a certain number of days and it reverts to the free version. So if you like the enhanced features it doesn't cost that much to purchase the program. The second program the link is for the free version but if you read through the literature you'll see what the enhancements are of the enhanced version. http://www.watchoscope.com/ https://c.web.de/@337134913998293880/YuEh_TobSjaCfyBDix_1gg then you should have a demagnetizer anyway because you never know where the watches going to get magnetized.1 point

-

Very much new to this, but I am dedicated. Have spent some money on tooling to include grabbing up vintage tools when I can. Have a vintage K&D staking set, two vintage screw polishers, and an older undercutter. Other tools are new to include mixing in Bergeon and Horotec as well as generic when it makes sense. I have a fairly good size collection of around 50 (cased and straped) watches so far, and somewhere around 30 movements in various states (cased, no case, working, few not working). I have been practicing some acrylic polishing as well as cleaning case parts in an ultrasonic. My test run on working a scratched acrylic on a Benrus that is running very very well attached. A few deeper scratches to attach but considering I did this in about 20 minutes running from 800 to 10,000 grit pads (hand) not bad. The 3L Vevo ultrasonic came in today along with the L&R ultrasonic cleaning solution, so I put in a gross case and stem from a Bradley watch (EB 8800). I am using the jar method, where I put distilled water in the tank and the cleaning solutions in jars with the parts. That way I don't have to dump out the solution constantly; I can seal up the jar and wait for the next run and of course do concurrent clean/rinse if I get staggered. The L&R rinsing solution is a day or two out still, so I just rinsed with water for now - this was a test run on a watch I will service and then flip. I will catalog my journey here, get tips and tricks from you experts. I have the oils, oilers, tools and gumption to start taking down some movements, so game on!1 point

-

1 point

-

I did add an inexpensive desk light, from Amazon, to give some targeted lighting. The color temp and brightness can be adjusted. This is definitely better than just the hutch light and room lighting. I wasn't liking the silicone pad that I started with. It was a bit grippy so it wasn't easy to clean off. The new desk pad is faux leather and easier to clean. I'll see how these go.1 point

-

Good evening, friends. Finally found a free minute to get back to work on this. Last time I left you I'd ordered a new great wheel. The next time I picked up the work again, I noticed that the 3rd wheel also had a bad pivot, so I ordered a replacement. And here we are with the before and after: Not complete perfection, but I'm going to let it run in for a day or two before touching anything else. I should get the motion and calendar works together first, but since nothing can go smoothly, I managed to shear the head off the brass setting lever screw. It looks like there's still a nub I can grab--maybe I'll get lucky and not have to disassemble the whole keyless works again. It's been a long road! My heart was beating faster than the balance when I put it back on, but it started to beat the moment it touched down, and I was elated. Edit: this is the screw. Re-edit: found it on eBay for $15. Whew!1 point

-

1 point

-

I do not believe there is one answer for this, a lot depends on what you work on. I have come to believe, possibly, that modern watches use m-fine screws. However if you are doing vintage it can be all over the place, between manufacturers and even within ranges they had their own specific threads. I have seen a post by @nickelsilverthat he knows a clockmaker with 500+ different screw making plates. i think this maybe why you are not getting answers on this topic. Tom1 point

-

The something more drastic is me being clumsy . Anyway I'll try to make a pin with a little bend at the end and see if I can push it out. The pivot is not visible through the hole. I really don't want to push from the front because I'm scared I'll mangle it.1 point

-

1 point

-

There are three aspects to making a microscope-camera connection. The first is the one that is basically a plumbing problem where you need to fit up the proper diameter and threads with one or more adapters to make a physical connection. The other is the magnification factor, which is generally noted on the adapter. The final piece to the puzzle is the resulting focal length of whatever lenses ended up being in the light path, and whether or not they can be adjusted to focus properly on the camera sensor array. It's possible to solve one or two of these problems but still end up with the third being unacceptable if the choices aren't compatible. Some connectors have no integral optics, so it's just the lenses in the microscope and trinocular mount that are sending light through to the camera sensor. Others may have their own internal lenses, like the 0.35X connector mentioned above, which will establish a new focal length/image plane. Finally, some adapters don't have integral lenses but are meant to fit over an eyepiece lens and then it is the magnification and focal length of the eyepiece that will have to be matched by the camera placement. The top diagram in the drawing appears to be an example of an eyepiece adapter, so it will have a much longer physical dimension than the direct coupling adapters. There are a lot of variables, so the easiest path is to match a particular camera/scope/adapter combination that has been documented to work together to avoid reinventing the wheel. Also - this might have a more noticeable effect on a high-mag microscope than it would on a dissecting-type scope, but adjustable eyepieces can play a role in getting the camera parfocal. If only one of your eyepiece lenses is adjustable, then you can really only use it to match one eye to the other. However, if both are adjustable, then in combination they both can be adjusted in tandem to one end of their adjustment or the other, which can help you get to that final sweet spot where everything is in focus. Worth playing around with in any case.1 point

-

1 point

-

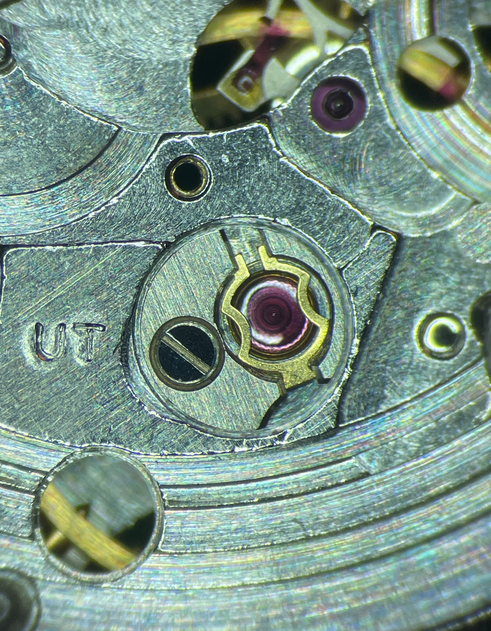

Oh no, that would be way outside my comfort zone! I simply unscrewed the disk that holds the cap jewel assembly and shimmed it with a couple pieces of thin foil. Shimming the balance cock would probably have worked as well, but I believe it would have been more difficult due to its geometry. Side-note: Do you know why the lower assembly is held in place by a disk such as this? The leading theory is that the balance was replaced at some point, and that the new balance staff was slightly longer than the original one, but it's hard to be sure. Anyway the movement runs with ridiculous amplitude now - well in excess of 330 degrees DU/DD, and it does knock a bit at full wind when I move my arm too much. Maybe someone replaced its spring with a slightly stronger one to combat the binding balance? I should inspect the mainspring again... one day! There are too many projects on my bench.1 point

-

Those aren't difficult either with the proper technique. Put the back-side of the spring in first with the aid of a small piece of Rodico and keep it in place (pull the back of the spring firm into its seat) with a sharp pointed peg-wood and while holding, close the legs, one-by-one with fine-pointed tweezers. Sometimes these spring do already have a slight curve and if they do, make sure that the curve is at the bottom, that helps with closing the legs. Bit hard to explain, but I do hope that you understand1 point

-

If you are going to work on vintage watches you probably quite fast will realize some parts is just not available any more, and one probably will turn a balance staff faster than waiting for one in the mail with some training. I noticed you said your problems would be over when getting the setup fixed, I would say your problems are just beginning when you get the lathe running, it sometimes just can be so addictive your better half have to pull your away from it at 2 am. So, they might just begin ?1 point