Leaderboard

Popular Content

Showing content with the highest reputation on 04/03/23 in all areas

-

2 points

-

2 points

-

2 points

-

yeah! I'm excited! I really hardly know what most people even use them for other than they're used constantly for all sorts of things. Kinda makes me want to look over some of my junk movements and see if there's any worn out arbor holes that could be tightened up with a little staking. All i need to do now is hurry up and get into swiss stuff cuz i don't think any of the seiko stuff i work with now has any part of the balance disassemble-able or replacable. But when the time comes, the parts for the balance staff remover are all present with this set which is good to know.2 points

-

I would suggest chekcing out some of the newer stuff. They really are so easy and a joy to work on. This one, probably cuz it's old and beat up has really become a never ending project. And yeah as for the flotsam. I try real hard to maintain a clean workplace but texas is a dustbowl i swear. I rent an apt and the ducts probably really need a cleaning too.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

No not exactly what I was trying to say, Practice on scraps to gain the confidence and dexterity to do it right do it once. You wouldn't know the condition of end stones and hole jewels before removing and inspecting them. Best to detach the balance from the cock, you then can remove the shock spring to check/ clean / peg end stone and hole jewel and give them a bath in ultrasonic, so you can be sure things are Ok in the setting, so to have one less fault to wonder about in case timegrapher shows low amplitude. Good luck1 point

-

1 point

-

unfortunately for watches like any mechanical device they need to be serviced from time to time. The lubrication can go bad with time and in the case of battery watches people keep popping the back to the change the batteries and stuff can get in there. Or the batteries themselves can leak out and that's particles of stuff that shouldn't be in the watch. or the biggest thing of all is the gaskets will disintegrate with time and that let moisture and that's very bad. in other words quartz watches are very intolerant the things in the with them like dust rust or bad lubrication then yes there's things like this you put the watch on it can spin the entire gear train knocking off the offending stuff possibly freeing thing is up but it's not necessarily a permanent fix. then one of the interesting things in watch repair is typically the movements are made by somebody else not always but in the case of Gucci they don't make movements they do is put their name on them so for instance the movement is really this ETA 978.002.1 point

-

1 point

-

See video from the 14:30 min. mark where he explains about the floating table. You can also watch both his video's to see how he reduces hole sizes .....1 point

-

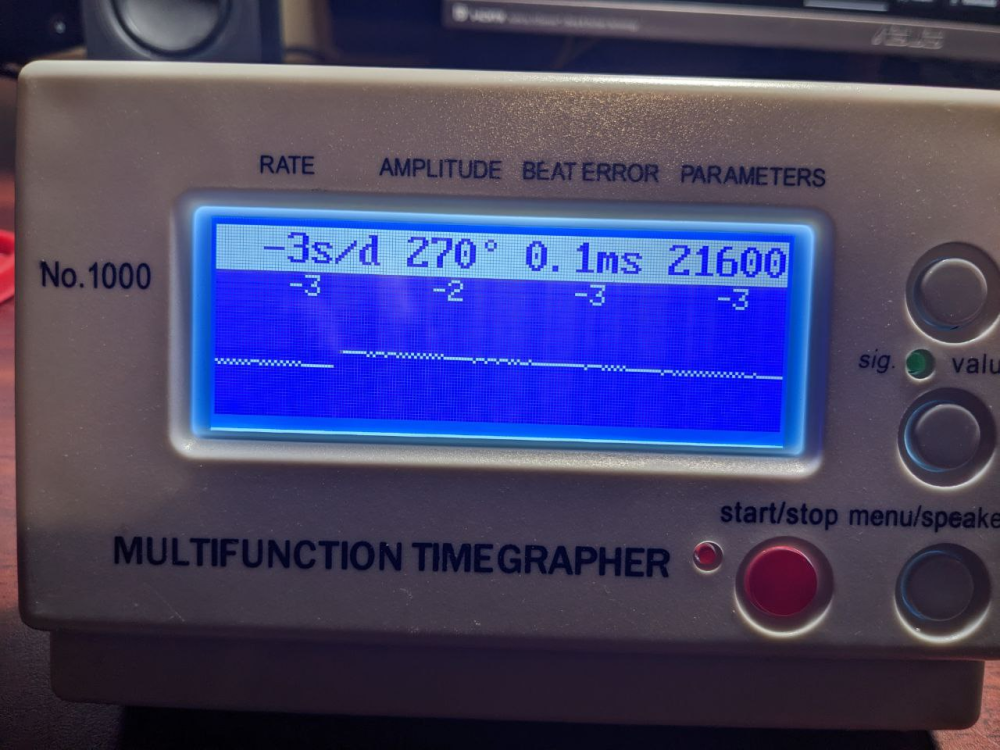

Was super busy and had to take a break from this. I opened the thing up, found a long carpet fiber wrapped around the seconds wheel, found like 2 or 3 more in the escapement. Also added a tad bit more oil to the two pivots on the mainplate for the 4th wheel and the other one that needs oil from that side and things are looking much better. That was dial down right after i got it all put back together Amplitude dropped a bit dial up, about 15 degrees which i'm hoping evens out as it settles in overnight. I'm so confident in my oiling at this point if it doesn't i'm pretty damn sure it's just cuz the movement is beat up and might have a bit of excessive endshake here and there. If dial up and dial down are at least 255 and 270 and the delta is ok i'm gonna get it back on the wrist and call it done.1 point

-

As Nickelsilver and Endeavor said...your staking tool will operate as designed. You are ready to replace a staff!!!1 point

-

Well, you got the center-shaft out; that's good news Not only that, but all seems as it should. As Nickelsilver mentioned already, my Boley has also a "floating"-table and the selected hole has to be lined up with a center-punch, before tightening the big-knob. There should be a centering-punch one among your punchers, which is there for this specific reason. Now you can clean the set up and make it smooth to operate. Your eBay purchase may become a success after al Congrats !1 point

-

Some staking tools are set up so the table holes are precisely on a circle concentric with the center hole, and the clamp shaft is a snug fit. The top of the tool that holds the punches has an insert with an eccentric hole for the punches; this is turned until the hole is on center with the table holes and locked in place. When centering a hole in the plate there is just one adjustment, turning the plate until the desired hole lines up with the centering punch. Other tools have a hole for the punches that is not adjustable. Here typically the table can "float", so that the desired table hole can be aligned with the centering punch. Both types are made that way to account for manufacturing tolerances that can stack up ending with a table that simply doesn't align with the punch guide. So yours is normal, the seemingly excess freedom is normal. If you find there's no adjustment for the clamp interaction with the cam lever, you can put thin shim stock under the head of the clamp where it comes down on the table. A little goes a long way.1 point

-

Thank you for your concern, but you don't have to be sorry because I have a method (mentioned in my previous post) that I feel is more efficient and precise! I've tried with a 1ml syringe and it could be that it is a bit small, but I don't think it has any decisive significance. Any bigger and I believe the risk of flooding the pallets increases even more. Or, it could be the reason the epilame evaporates too quickly for me!? I've seen the video previously and I think it somewhat strengthens my argument. When the first pallet stone is treated the epilame spreads all the way to the pallet fork staff, and then the video is cut, so it could be that it actually also spread to the pivots (although it doesn't look like it). When the other pallet stone is treated it looks perfect, but compared to my own experience, that is only with a bit of luck. It's very difficult to get the right size drop of epilame. Anyway, I've come to learn that what works for one repairer may not work for another. Probably because there are too many parameters at play (some far from obvious). Good thing there's more than one way to skin a cat.1 point

-

That is an interesting suggestion. I'll see if I can find a bag that will allow the necessary visibility of the spring.. But I definitely spend too much time on the floor, looking for those bloody springs. So far, my best method was to hold the spring with Rodico and use tweezers to direct (not to hold) into it's slot. The risk of it flying is much reduced1 point

-

Hi Dvanbrunt, welcome to the forum, you are asking a few question's about a clock that nobody can see, you need to post photos of the clock you have found for anybody to help you, photo's of the clock case the movement front and back etc. And you need to start your own topic. You are actually in Hectorlooi topic and if you are refering to a clock like what he has posted then you still need to post photos. That clock has a couple of names anniversary clock being one.1 point

-

1 point

-

It sounds like a good idea on paper but unfortunately, my experience is that it doesn't work very well in practice. The epilame tends to evaporate so quickly from the tip of the syringe that you are tempted to try to squirt out a little more with the result that you drown the pivots or even the entire fork.1 point

-

1 point

-

So how do you do that when it is the upper pivot for the balance wheel? Just move the balance wheel and spring out of the way?1 point

-

1 point

-

After some trial and error I did the forward reverse mod an my pearl. Big thanks to jimzzilla for his assistance.1 point

-

The Wittnauer 11ABC is actually an AS1395, try looking for documentation for that.1 point

-

I use the same fuel for the initial clean and then fresh fuel. Then repeat the process.1 point

-

Change it each time for a different movement. It certainly needs to be fresh for the balance.1 point

-

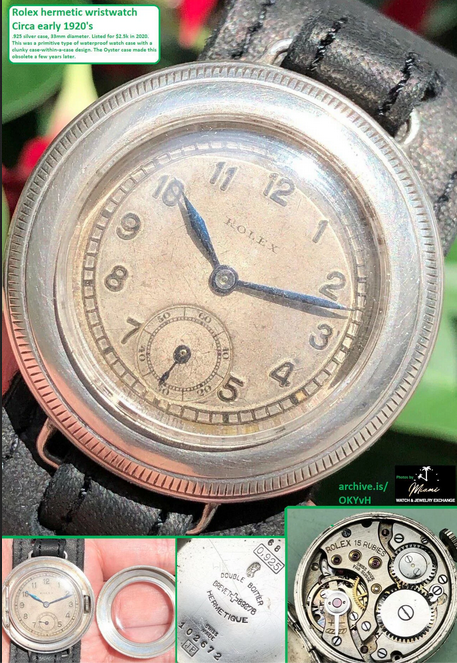

Well i really wanted to get some good shots of it in the sun to really see the depth of the incredibly gorgeous blue sunburst of the dial but texas had other plans for the sun this week haha. End result is about 255 amplitude 2 hours from full wind which is i think fine and probably hte most i can get with the tools i have. I'm pretty sure the barrel/arbor hole in the mainplate is worn causing too much sideshake and that's dragging down amplitude a bit. My first attattempt at hairspring shaping is probably also a factor haha. Currently to keep the rate at -3 crown up i have to have the rate arm almost entirely in the + position haha. Not ideal but i'm proud i shaped the hairspring on it and it runs and keeps time at all so i'm gonna call this one a success. Either way i'm so happy with how this came out. I think it's gorgeous and it's keeping great time. The patina on the dial and hands is pretty attractive imo.1 point

-

If you don't want to laquer the movement, you could always French chalk brush it that will preserve the shine.1 point

-

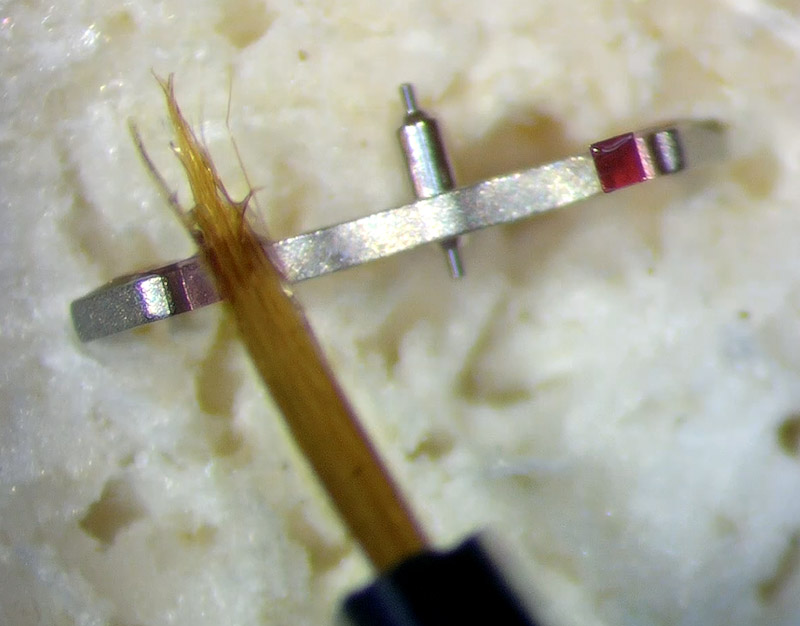

Found!!! I've downloaded a new video editor program, and I was playing a bit to get used to it. Then I saw someting below the balance that shouldn't be there...1 point

.thumb.jpg.e1737221d1bb91b37331a627546ff250.jpg)

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)