Leaderboard

Popular Content

Showing content with the highest reputation on 03/31/23 in all areas

-

I'm new to the hobby, so my collection is limited. I have two watches that I inherited from my grandfather in 1966. One is a South Bend 12s, and the other is an Elgin 18s. The South Bend is running, but the Elgin is a mess that I am currently working on resurrecting. I also have a non running but complete Elgin 12s that picked up to work on. The nicest watch I own is a Waltham 18s railroad watch. It is in excellent condition and runs like a champ.4 points

-

You can get a good printer for around $200 US. I got my son an Ender 3 NEO for Christmas and he was able to get up and printing with it pretty fast. I have an Ender 3 Pro with upgrades I added to it and it has been a good printer. The NEO comes with those upgrades already added. I get filament for around $20 US per kg spool. 3D printers are very handy to have. I've printed up all sorts of things for my garage, workshop, hobby bench, wife's craft area, and so on. That includes several things for this hobby.3 points

-

The stem is a different part number for the 4R36 and 7S26. You will need to swap the stem. The 7S26 stem is very different. In modern times, usually, but not always, Seiko uses a one piece stem. You cannot unscrew the stem from the crown. If you see threads on your stem, it is an easy swap. No threads, it is a one piece unit and cannot be separated. I guess you can find a generic crown that fits and use that. IIRC, that model is not screw down. A lot of matching of diameters and gasket sizes but it can be done. The NH36 will be significantly cheaper than a 4R36. In theory, the same movement and interchangeable. In practice, from different factories and distribution. Be careful comparing heights listed. Between generations, the height is measured from different places. It will take a deep dive into the drawings to see if there is a real difference. I believe the stem height is the same between the two if you measure from the same place. I have swapped a couple of NH36 movements into 7S26 cases and have not encountered problems. It is actually a 3.8 o'clock stem position. 4 o'clock is close but not exact. The date wheel will line up but the day wheel will be off. Seiko figured out that 3 and 3.8 line up at the same place where true 4 o'clock does not. They were able to reduce to one part for both configurations. You can buy a 3.8 Day wheel and swap it but by the time you factor in the cost of the part and your time to swap it, it is easier to buy in the configuration you need. A Day wheel change is pretty easy.2 points

-

2 points

-

1 point

-

My latest aquisition. Dial is pretty subtle but decent. Hands were off. Non running. Description on the lot did not have info on the movement. 20 to 30 minutes to remove the dial and put back on with reattached hands. Messed around with the automatic winding and fiddled with it until a very low beat on the balance for about 20 to 30 seconds. So another project to step up a level to an automatic with calendar. Will need to get the lube for the automatic gears though first.1 point

-

Our dental Pic-n-Stic is way too sticky for watchmaking work. It can stick and pickup an Adam's pliers. And it leaves a residue behind. I tried using it to pickup watch hands but leaves a smudge on gold plated hands. And don't ask me about the time I used it to pickup a cap jewel.1 point

-

just a reminder I know Americans pioneered mass-produced watches with interchangeability of parts but did you notice something? Like for instance the serial number how many places can you find the serial number stamped on that watch? Did you look at the balance wheel did you notice the serial number scribed on that? there are several reasons why everything has serial numbers but the simplistic one here is that all the parts with serial numbers should stay together. basically the parts were machine together full 100% interchangeability hasn't quite occurred yet. Then things like the escapement are usually adjusted for each watch. So you start mixing and matching escapement components like the balance wheel or the pallet fork you're going to have to make some adjustments. Oh and your serial number produces this https://pocketwatchdatabase.com/search/result/elgin/7456893 I do like your adventurous spirit of no great loss if you destroy this watch. Normally grandpa's watch might have sentimental value. typically on the group if you start with something inappropriate I might suggest it's inappropriate because of variety reasons today's reason is different. That's because did you notice how pretty this watch is? Look at the finish of the plates not just the parts of the plates that you see but notice all the finishing on the plates that no one will ever see except the watchmaker. do you not find that a bit strange why did they waste so much time finishing something that no one will ever see? Then look at the link above look how many of these they made less than 20,000 in other words they didn't make a huge quantity of this particular model of what looks like a pretty watch. as this is a full plate reassembly will be more challenging. Especially getting the pallet fork to stay in place strangely enough we recently covered that because I remember answering that question fairly recently you can do a search and see if you can find that. then it's amazing what we've covered on this discussion group like we've already covered how to put that mainspring in. But the short version goes like this anything with a special end needs to go in first and be locked in place before the rest the spring pops out or's hand wound in. If you think you're going to rotate the spring in the barrel to get it after you put it in that isn't going to happen well you might move in a little bit but typically it's really hard to move so it has to go in first a mainspring winder is preferred I prefer a vintage set versus the modern winders for these. You wind your spring almost all the way end of the winder you leave a little bit is sticking out. Then all of that is put into the barrel rotated around and get the T over the slot. Now comes the key thing you have to push it in and hold it there. Otherwise when the spring goes in for a Winder a pop back out again. Either use your largest screwdriver you have hold it down while you're popping it out or the backend your tweezers work. yes it would be really nice when people are looking at the YouTube videos of how fun and easy watch repair is if the people making YouTube videos would point out that everybody breaks parts. But the chances of breaking parts when you start out is quite a bit higher much higher. the reason why we recommend the Chinese clone is because it's cheap. To purchase a Swiss version 6497's going to cost how much more? Personally I tell everybody to start with a brand-new clean working 6497 clone. my recommendation to start with a brand-new running clone is it's running and you can see that it's running and ideally people should pay attention to what a running watch looks like but typically they do not as are eager to take it apart. Then they can taken apart put it back together again and see if it still running. Versus trying to learn to repair a broken watch when they have no idea what's wrong with a broken watch or how a watch even works or even how to put the watch back together without doing more damage. So if you start with something that's running and is not working when you put it back together it narrows down whose fault that it's. Then basically the Chinese watches are disposable it it's not a big loss. Everybody objects to the cost of everything in watch repair and starting off with the Swiss 6497 can be pricey. you will note that I added something to your comments https://pocketwatchdatabase.com/search/result/elgin/74568931 point

-

I would go through the Aliexpress refund route, if you get a free tool out of it then thread the hole and put a proper sized grub screw in. I have one of these presses and I suppose I’m lucky as it works fine. I have had to fettle Swiss made tools as well as Chinese so doesn’t bother me too much, just a bit of a pain. Tom1 point

-

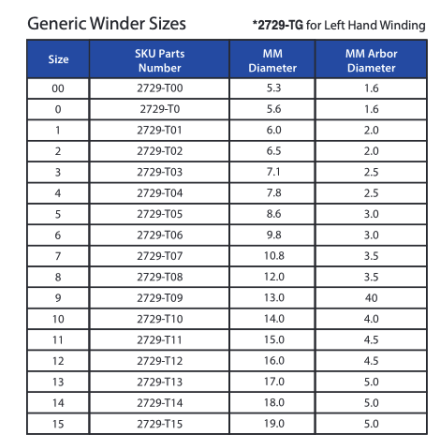

Thanks @tomh207, I sent a message to namokimods asking them what I might need for this movement to go in that case, so hopefully I will hear back from them in a day or two. I'm sure they have helped a few people through this. Right now, I am taking the 7s26c apart and I plan to clean and lubricate it. Nothing else, it will he a good movement to practice on. It was running strange anyhow, so I guess it was time. It was either this or an Orient that I have. I want to do a few practice movements before I tackle my Grandfathers Hamilton Morton from the 1950s or the Sellita mechanical that was my wife's Grandma's watch (not a very expensive watch I don't think, but a HUGE sentimental thing for her). One of the things I will need to start thinking of is a mainspring winder for this sucker. I can't afford to buy a whole set of them, so how do I figure out which size I need? I'm looking at a chart that Esslinger has and iit asks for a MM Diameter (is that the INSIDE diameter of the barrel housing (or is it the outside diameter). Arbor diameter I think I understand. OR should I just not take the mainspring apart? The watch is about 6 years old, so I think the right thing to do would be to open it up and clean and lube it.1 point

-

This is copied from an online source. Cap Jewels: Some bearings utilised cap jewels, sometimes known as end stones or ‘capstones’. This bearing structure operates similarly but has a second outer jewel, which sits at the very tip of the gear shaft. This has several effects. Firstly, a small oil reservoir is formed between the two jewel layers, ensuring continuous lubrication for the fastest-moving parts such as the balance wheel. Secondly, they allow the shaft to be constructed in a conical shape, which prevents oil from seeping down the arbor and stops the shoulders of the arbor from rubbing against the jewel, which would negatively impact accuracy. These caps also prevent the arbor from moving up and down during rotation Rgds Joe1 point

-

I've bought quite a few tools on Aliexpress, and only a couple of times I have had problems. When that happened, I directly asked in the app for a full refund, sending photos of the problem, without talking to the seller, and so far I've always get my money back without having to send the item back to China. When I buy something I always make sure that it's going to be shipped via AliExpress, not China Post or anything else, because if the item doesn't arrive or arrive damaged AliExpress would not help to solve the problem.1 point

-

That makes more sense. I couldn't understand how you could "peen" a small hole in brass. I'm used to peening as the hardening of a metal surface by hitting it with something to create surface stresses - e.g. a ball pein hammer. In the aircraft industry parts will be shot-peened to harden the surface and prevent cracks forming.1 point

-

Everything I have seen is the NH36 is a drop in replacement for the 7s26 range. Only things you will have to do is move the 7s26 day and date wheels over along with the crown as the stem is different I believe. Have a look at sites like namokimods, they are a pretty reputable modders site and I think they have articles on this type of upgrade. There are loads of Seiko modding suppliers out there, one of them will have something on this. Tom1 point

-

No, the jumper (upper part) needs to turn 180 degrees, and the lower part of the spring needs to be in contact with the side of the corrector, it's on top of it now.1 point

-

Since I couldn't get a deal on a vintage one off of eBay, I got a budget one from Esslinger. The teeth look to be brass. I did have to do a good deal of deburring to them but it was worth the effort.1 point

-

I'd be cautious about being hopeful of finding any technical documentation. If you only want part numbers, you could try checking vintage parts catalogues, maybe there's a really old Bestfit or similar. You could also look for a patent mark or date stamped on the movement, that could yield a drawing or diagram.1 point

-

1 point

-

1 point

-

An "Uno" branded 17 jewel gents dress watch. It was just a few pennies over the 404 club qualifying boundary, but I rather liked the look of it. Uno was a brand name of both " Dimier Frères & Cie." and "Fabrique d'Horlogerie Chs. Tissot & Fils", both of which are/were quality manufacturers. Probably from the 1960s (or possibly late 1950s). There were no pictures of the mechanism, so this is completely pot luck, however I found a nearly identical watch online which contains this Peseux 192A. So I'm hoping this one is the same. Time will tell.1 point

-

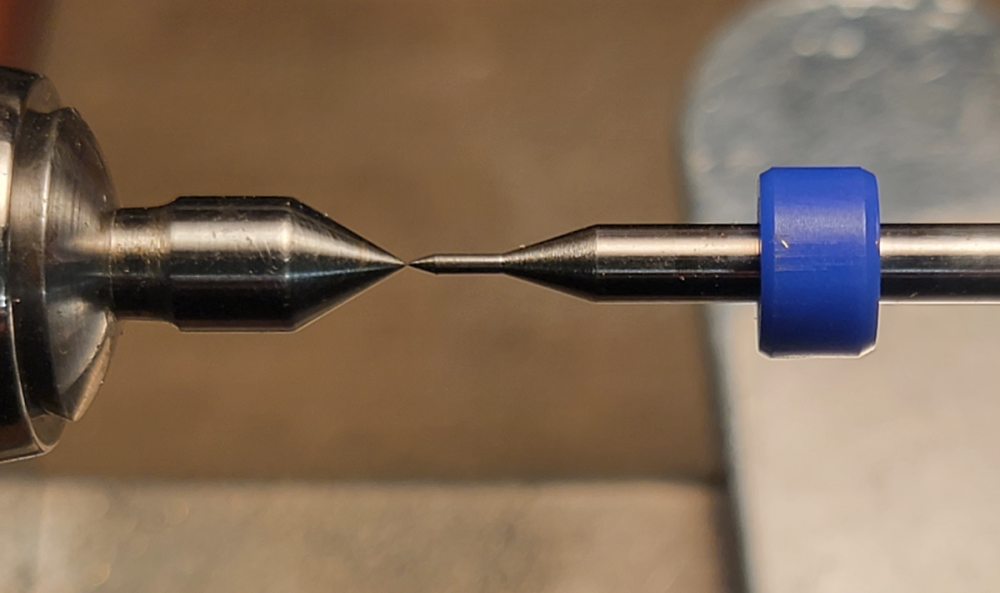

That's a mouthful! I have a collet-holding Levin tailstock lathe, but was curious if I could make a device that allows me to mount a drill bit on a conventional tailstock runner. Took me a long time to get the taper right. Turns out that the taper angle is 2 degrees. I was able to do this accurately with my cross slide. The drill bit post is pretty common. You can buy assortments of all different drill sizes with the same post (base). The bit shown was broken, so it was used to test the setup. I used brass because it was easier to turn...and quicker.1 point

-

The photos that watchweasol has posted. The center spindle is taped out this will also make the cannon pinion become loose on the shaft to be pulled off.1 point

-

Wow, what is the movement? Looks like someone oiled it with diamond paste, or the jewels are made of wax.1 point

-

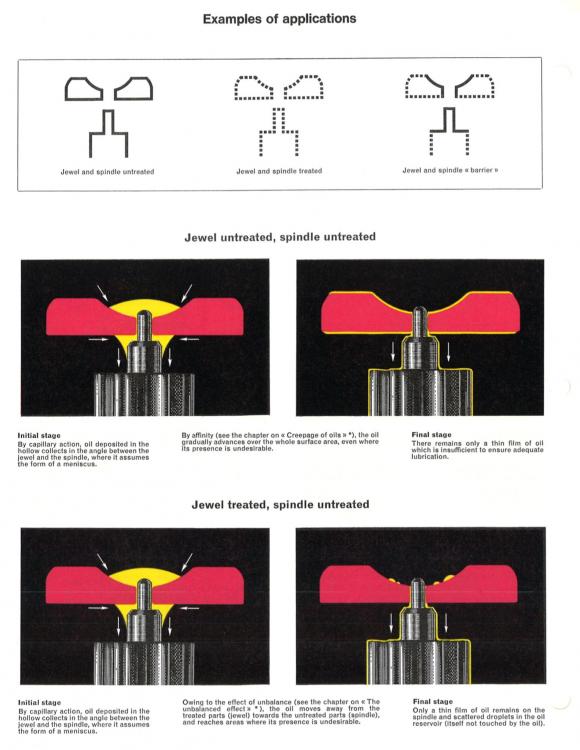

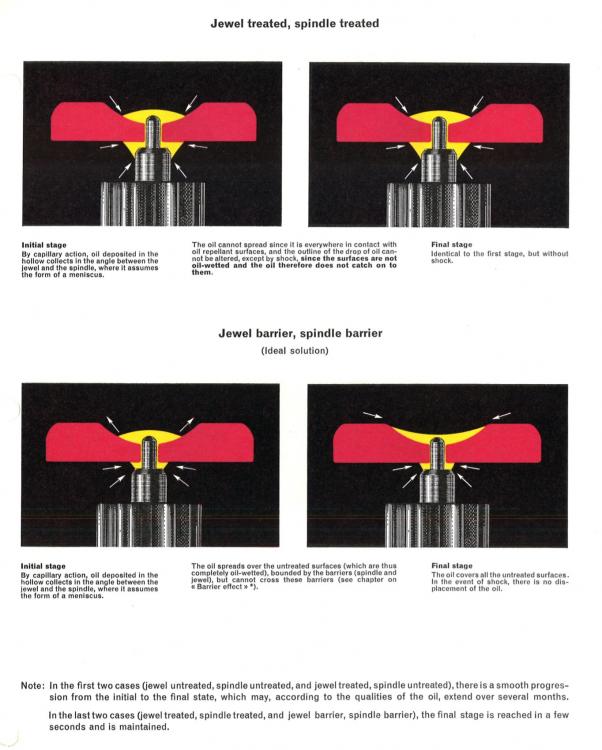

I find this a very interesting cross reference. Unless you just happen to remember which I do you could go to the website below where they still lists the names of their oils before they had nifty numbers. But classically the Synta-Visco-Lube is 9020. That's an oil my favorite oil for use in just about everything. Then the 9504 is my favorite grease which I wouldn't classify as an oil. there's several reasons not to oil the pallet fork pivots unless you're Seiko. Then depending upon the tech sheet or maybe when the tech sheet was produced because I've seen at least one caliber that was yes no yes for the pivots but classical a as long as is not Seiko you never oil the pivots at least in a watch. There is several reasons for this in that it's not considered a revolving component so it has basically nothing to wear out. It has to move really really fast and lubrication can have a dampening effect. In other words you going to lose amplitude and if you are using non-synthetic oils and with time when the oils go bad did really lose amplitude. But it makes you happy a tiny bit of 9010 isn't going to hurt it just isn't going to help either. https://www.moebius-lubricants.ch/en then at the next link you get a whole bunch of documents download all that you like but while you're here get number 40 it's for lubrication. https://www.cousinsuk.com/document/search?SearchString=working then the problem with official tech sheets are well watches can be old and tech sheets can be old. Plus the tech sheets change with time typically was Omega they appear to be going for heavier lubricants. So then there's the other little problem with the tech sheets they don't tell you everything. I can the case of Omega they will refer you to other documents like the working instructions that is a link for up above but that's only a tiny fraction of the actual working instructions. So if you have the working instructions you find out that they use things like epilam which may explain why they use insanely thin lubricants in my opinion. Unfortunately all those other working instructions are hiding behind well basically you're never going to get those. for instance they have a working instruction on timing specifications here is the page covering the relevant movements in this discussion.1 point

-

The problem with the best fit book is it only includes the watches imported into the US that means conceivably a heck of a lot of watches that you will not find. Also it's kind of time restricted depending upon which the volume of the book you have. So the current version we download is only really the 60s and the 70s and this watch is probably prior so you might need an earlier book. Then there's another way to possibly verify this if you're replacing the balance staff you can measure the old one and there's references we can look up staffs sizes and see what staff matches the size you have. The same as the stem you can measure the stem and see which watches use a similar stem size. They're not as nice as the fingerprint system at least for the stem but much better for the balance staff especially if that's what you need to get one the same size.1 point

-

1 point

-

1 point

-

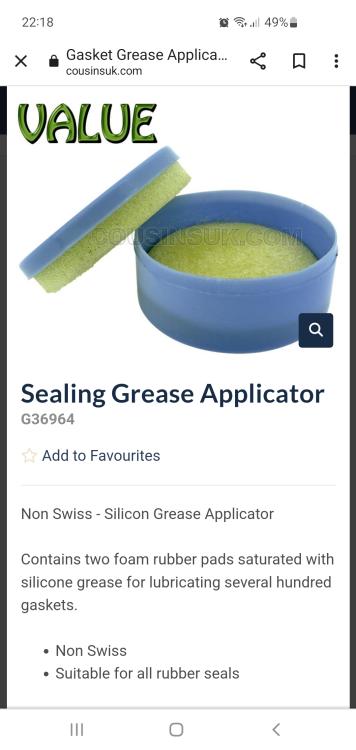

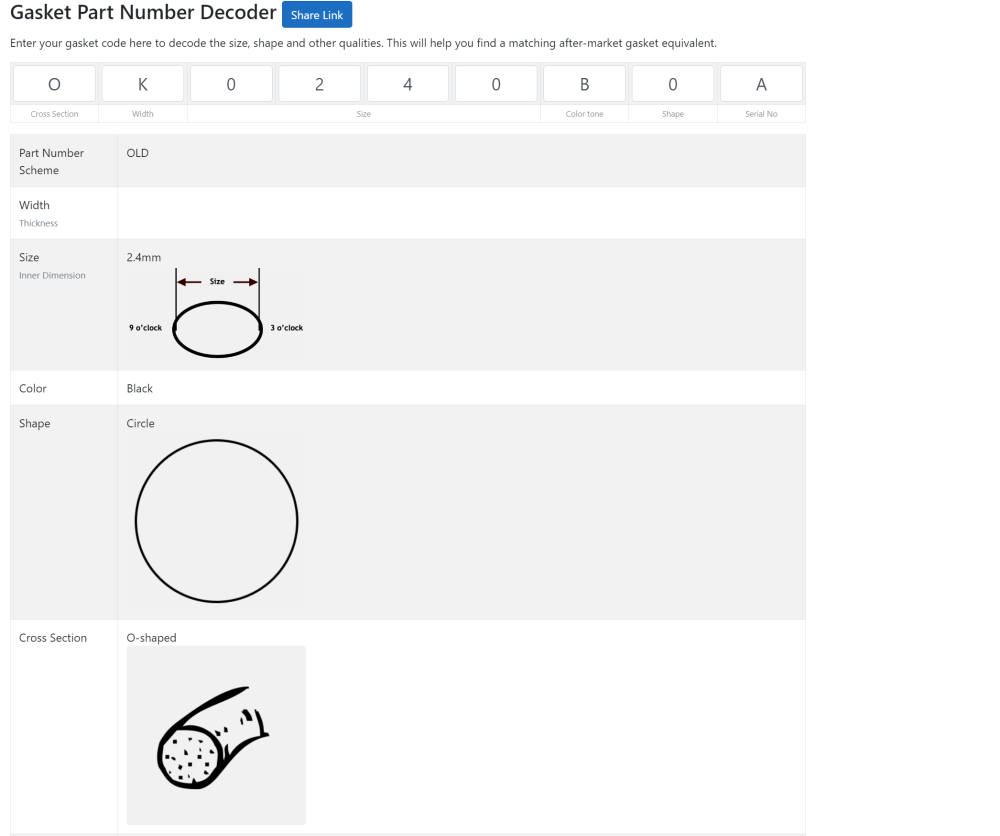

I don't have the actual dimensions on hand but you can decode a lot from the part number using the Seiko Gasket Code information. O means o-ring shape. K is the size class, should be a 1mm cross section. 0240 should mean 2.4mm inside diameter. The outside diameter of your gasket should be about 4.4mm. If these numbers are close to what you have in your hands, you should be good. Keep in mind that aftermarket crowns have been available for at least a decade that I have been playing around with the 6309 diver. No guarantee that the gasket area is correct on these aftermarket crowns.1 point

-

Unless you 3-D printer belongs to a union or something it hasn't worked hard enough to take a vacation yet. It doesn't even look like you've gone through a whole spool Of filament yet. Out of curiosity which 3-D printer do you have?1 point

-

I have branched off the Tools & Equipment sub-forum and made it a separate section on the front page with sub-forums on specific topics. I have done this because, as a sub-forum, the Tools & Equipment area was getting way too congested and it was difficult to find if a topic was already discussed. I've moved a heck of a lot of posts from the old sub-forum into relevant sub-sections but there is still about 60 more pages to go through, I will chip away at moving posts into the new categories whenever I have a spare moment, and hopefully some of the mods here can do the same, but in the meantime, please try to help by checking the new sub-forums in the "Tools & Equipment" section and post any new threads in the correct place The old, Tools & Equipment sub-forum has been retained as a "General" sub-forum to the new front page section and no posts have been lost. If you previously posted there and cannot find your post then you can either find it via your profile page or by going through the sub-forums, I have tried to be as accurate as possible so far in matching topics to the sub-forum. New section: https://www.watchrepairtalk.com/forum/55-tools-and-equipment/ Old sub-forum, now part of above new section: https://www.watchrepairtalk.com/forum/21-general-tools-equipment-discussion/ Thanks for your co-operation1 point

-

^^^ Just when you think you got it all figured out, the next curveball hits you. Thanks @nickelsilver , now I have yet another thing to keep me awake at night.1 point

-

1 point

-

Mission accomplished. The Eagle has landed! So, I’m all good to go! Just can’t thank you enough guys! I know that for you seasoned repairers this is nothing special, but me, well, I feel like I’ve successfully taken off in a rocket! For those of you finding this thread in the future here’s some additional info that I learned on the way. After having removed screw A and B the spindle C just wouldn’t move pulling it by hand. So, I tapped on it ever so lightly horizontally in the direction towards spindle F and it moved in increments. To tap I used the plastic part of the hammer in the picture. I also needed to rotate the spindles C and F slightly. I did this by grabbing on to the thick part of the left spindle C (after having tapped it out a bit) with pliers with a bit of transparent and though plastic film (zip bag) in between the pliers and the spindle. To rotate the right spindle F I simply used a small BAHCO adjustable wrench. Loosening screw K as @nickelsilver and @rogart63 point out is indeed the way to get the scale back to normal! The inner sleeve can then slide as well as rotate without affecting the thimble (the barrel with the graduations 0-99). I’m really thrilled to own this beautiful precision tool! It gives me the same feeling that I get from looking at a really fine watch movement. So again, a really big thank you to all of you!1 point

-

Hello there watch people. I just wanted to tell of caution with some cleaning solutions. I accidentally left a barrel and lid in some Elma Pro waterless ammoniated cleaner for a week while i was away. The result was some brass surfaces that i had polished after peening the arbor holes has been stripped away and left a very rough surface also some of the nickle plating had peeled.0 points