Leaderboard

Popular Content

Showing content with the highest reputation on 02/07/23 in all areas

-

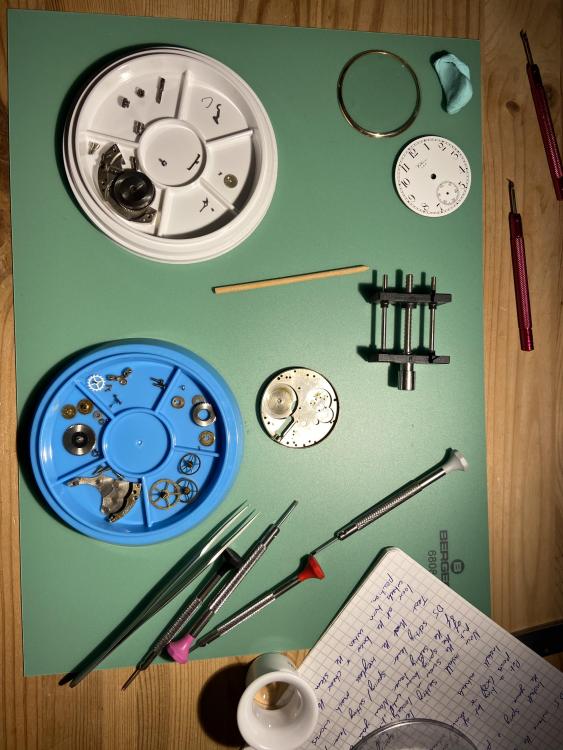

This is my first time trying to restore and fix up a mystery watch from ebay. If anybody who's worked on these old 70's seikos wants to follow this thread your wisdom would be appreciated! Picked up this guy for a song on ebay specifically because it's one of the nicest condition ones i've seen with an original dial. THe hands are a little patina'd but the dial seems perfect other than two missing lume pips. I love this dial. THere's no real deep scratches or gouges in the case just a MESS of desk dive scratches that should polish out real easy. It's non running, the date and day roll over with the hands but the day does not roll over if you use the second crown position. The crystal would polish up nicely but there is sadly a small crack at 12 oclock so that will have to be replaced. Opening it up the movement looks pretty good. The balance will move with some pretty strong blows from the bellows but things seemed pretty gummed up and there is what looks like either really old solidified grease or oil or maybe glue under the reduction/ratchet wheel screw. Not sure what is up with that. I'm unsure what is going on with the hairspring as i dont' know what a good one in this movement should look like but it looks a little strange inbetween the stud and the regulator arm. I hope it's not shot but if it is i got a parts movement that does barely run so if i have to scavenge one then hopefully that one works well. The movement looks pretty clean other than some light powder rust. Guess i'll pick up some evaporust unless other people have a better method for de-rusting. Under the caseback is what looks like the signature of a watchmaker and v-9-24-87 Amazing to think this thing hasn't been serviced in almost 40 years. Here's hoping that's all it needs now! I'll be diving into this next weekend probably. Real excited to give this boy some new life as i just love this funky 70's design on it.2 points

-

So, with a little more data, I will be convinced that it is genuine. I will give it back to the guy I made the trade with. At the time, I thought it was a copy and so did he. He was kinda clueless, so whatever he thought about the watch is not a data point.2 points

-

The problem with the typical lists are they only really represent the modern watches they don't represent the vintage pocket watches. So is always best to just figure out what it actually is rather than guessing. Although amusingly on this group somebody did find a pocket watch list on another group and referenced it which I did find amusing because that was my list that I posted on another group of pocket watches.. But I just now checked I don't have any of the Omega pocket watches that I've done listed probably because I just wasn't worried about it.. Then if you like PDF lists here's one attached.. Lift angle Scope Schlagzahlen def 2-3.pdf2 points

-

If you’re like me, taking apart you first ETA calibre 2472 and feeling somewhat intimidated after having removed the case back lid looking down on the automatic works, then you will likely appreciate this post. By the way, except for the oscillating weight itself, the automatic winding device is identical for the following calibres: ETA 2450, ETA 2451, ETA 2452, ETA 2453, ETA 2454, ETA 2472, and ETA 2474. My only other experience of ETA’s automatic winding devices comes from calibre 2824-2. So, looking down on the oscillating weight of the ETA 2472 and not seeing a screw holding it attached to the automatic device framework, made me think the parts had somehow been riveted together and probably were inseparable. Having removed and looked at the back of the automatic device framework I could see that the oscillating weight was indeed attached with a screw or at least something that reminded me of a screw. Its slot was very thin, and it sat in a large jewel! No way I was going to try to remove it without knowing for sure it could be done and how it should be done, especially as this watch wasn’t mine but my brother’s who’d trusted it to me for an overhaul. My first thought then was to try to remove all wheels without touching the oscillating weight. After having looked at the device for a good long while, I realized I wouldn’t be able to remove a single wheel before separating the oscillating weight from the framework. So, I decided to be patient (hardest part of watch repairing), put the parts away for now and research the Internet. I Googled “eta 2472 how to remove oscillating weight”. The first hit was “Untitled - OM-Mechanics”, a PDF document. Well, I wasn’t feeling very optimistic but lo and behold, there it was, in full detail! Anyway, the PDF is pretty poorly scanned, and it isn’t all that easy to read the part numbers, so I decided to make my own picture guide for disassembling the automatic device of this ETA calibre 2472, and that’s what follows next: (Eventually, I’ll publish a complete ETA calibre 2472 service picture walkthrough. If interested, you’ll find a link to it in a future post in this thread.)1 point

-

I'll repeat the advice to ask for a modification on price, especially if condition isn't like the photos..but I handle the dunked it in oil guys a bit differently. If they send on time and it looks like the photo they get positive feedback with a 'Not only did this seller deliver the watch on time as a bonus I received a free quart of oil...right in the watch!' Perhaps you've seen one of my positive reviews?1 point

-

That looks terrible. Ask for compensation. The only time I bought a "Serviced" watch, it looked like it had been dunked in oil. I sell watches on ebay I advertise as Serviced. I provide timegrapher pics, a pic of the disassembled movement, and ask them to contact me if they want details of the work.1 point

-

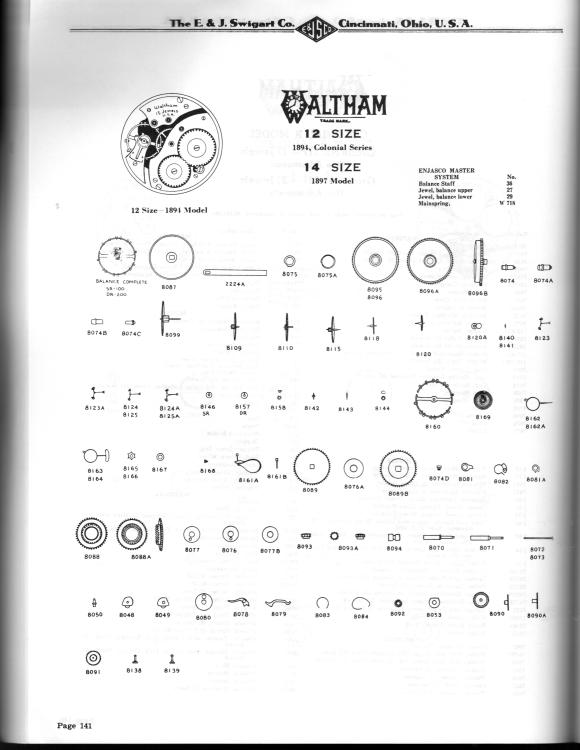

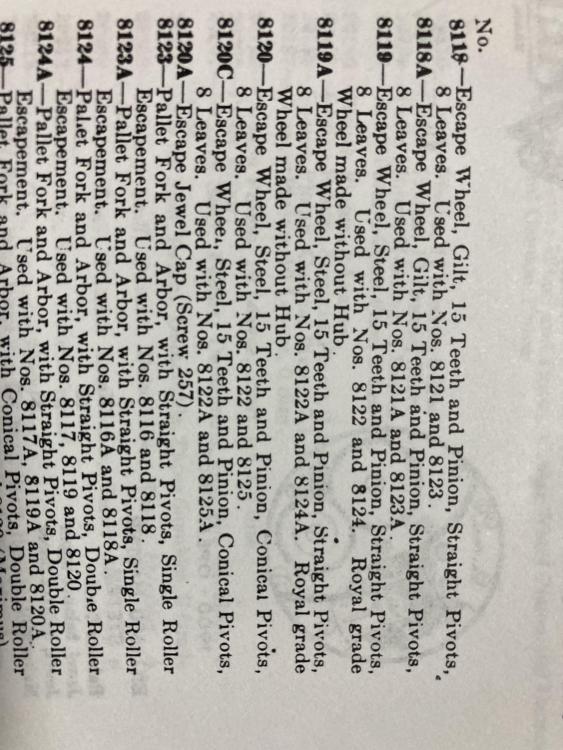

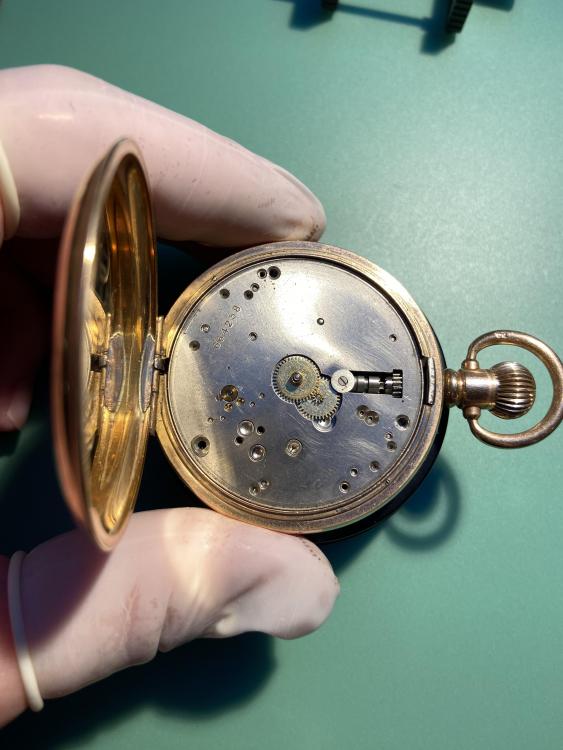

Waltham and Elgins were made by the thousands in the early 20th century. They represent the beginnings of American "mass production". The problem is that while a given watch movement may have 250,000 pieces made over time they really are not identical. You can't assume that just because you have an example produced in 1910 and another of the same model produced in 1925 that you can swap parts. That said usually the easiest way to get parts is to purchase an entire second movement. Pocket watches make good first watch candidates because they're relatively large. Scans from one of my books... ...based on data from the next page, that model used 11 different escape wheels over the course of its production: some gilted/some steel, some with 13T others with 15T, some with straight pivots others with conical pivots. So, even with a relatively informative book you still will have detective work.1 point

-

Listen to the heart. A low grade ETA balance complete can be fitted into a Chrono grade Tudor, but the Tudor then runs only as good as a $400 west end watch. The tg print out you posted is a poor listener and analyzer, yet I believe you have a genuine Tudor.1 point

-

1 point

-

I've always wondered about the watches on eBay that claim they've been serviced. Often times a picture of the timing machine results and well they usually don't look good for a serviced watch. It's my understanding sometimes the definition of servicing means that they dumped the whole thing In lighter fluid and swish it around a little bit That's a servicing at least by some of them. Then I agree with everyone the description isn't quite accurate See if you can get a price reduction. Then I don't suppose you have a timing machine? Wind it up and send pictures the seller that it looks pathetic Usually if you have a legitimate complaint sellers are happy to give a refund or a discount or something.1 point

-

I'll grab my calipers in a sec and check the ID of the mainspring barrel for a 7xxx series, they're all the same I believe. Looks to be 10.6mm, so I'd say any left handed winder with an OD of around 9.5mm - 10.5mm would be ideal. Of course the crank diamater on the winder handle can't be too large or too small either....1 point

-

I'd start by contacting the seller to see if I could get a reduction in the price since the item was clearly misrepresented / misdescribed, keeping the negative feedback option open.1 point

-

I got my set for $70 AUD, which is just ridiculous for a set of 10 winders. https://www.aliexpress.com/item/1005004895035484.html?spm=a2g0o.order_list.order_list_main.149.21ef1802i3V3W7 They have steel arbors so shouldn't wear too badly. Honestly, for what I do, they seem to work just fine. I've had trouble with the bridle on seiko automatic mainsprings, getting them into the winder is difficult and I've broken a few. But that's not the winders fault. Maybe keep a few mainsprings spare just in case.1 point

-

1 point

-

Looks like a great pick up. I also have a sieko with the same movement that I plan to service but the case on mine has some deep gouges. I really picked it up as a practice piece but will be following the thread to see your progress. Good luck1 point

-

I use a bench micrometre; JKA Feintaster. Although, they are going for silly money these days. Five years ago, you could pick them up for less then £100. Now they are triple that! A jewel gauge is useful too, as someone has already said, it's handy to check the pivots 'feels' free in the jewel.1 point

-

You should never fit a mainspring that is to strong or long. Firstly to strong will cause excessive wear and affect the regulation, to long and you will only be using part of the spring.1 point

-

I searched my library for mainspring rules. None of the celebreties mentioned in this thread invented those rules themselves. They were taught it and passed that knowledge in their books. In fact some old books mention such 1/3 rule while the exact dimensioning of mainsprings was already known and published for a long time. Seems it was a rule of thumb among craftsmen who were more busy with file and lathe than with books. The rule for a maximum of barrel revolutions that determines the optimal length of a mainspring was published by Rozé in 19th century. Claudius Saunier mentions this in his comprehensive textbook (paragraphs 1211-1216) from 1861. I also found this rule in books from 1902 and 1923. So Mr. de Carle could have known better. Nevertheless a watch or clock with a too long mainspring will run its 24 hours and so supporters of the 1/3 rule were contented. Frank1 point

-

It appears he's using standard silvering powder, and the link looks like standard silvering powder. The silvering powder is a combination of silver nitrate, salt, (or silver chloride, which is what you get when mixing silver nitrate and salt), with cream of tartar and sometimes a little alum. There are many recipes. Having mixed up quite a few, I will say it's far less trouble and with more consistent results to buy the ready made mix like in your link. The finishing powder they list is just cream of tartar. You do have to lacquer the surface or it will tarnish.1 point

-

You might already know this and there's another issue, but this chrono does both stop and zero with the zero or flyback lever. Start with operating lever, stop with flyback, then you can start again with operating lever or zero by pushing the flyback again. The function of that lever is a little tricky to adjust if needed; when stopping, it pushes the operating lever down, which moves the cam/hammers toward the center- the end of the flyback also acts as a stop, keeping the cam/hammer from going all the way to zero. When the flyback is then released, is should return to its neutral position. If it is restricted from doing so, some careful filing is necessary where it's contacting the cam/hammer to allow it. Not too much, as the contact with the cam to zero is very small. Before filing anything, check that the cam jumper is fully seating in the notch for the wanted position first. If it's not, find out why and fix it. Which brings us to: These movements can be very particular about lubrication. Everything that moves, slides, pivots, needs to be greased in the chrono. There are numerous shouldered screws holding things down and acting as pivot points, these need to be greased. Also check them for freedom with their part; there are several that are the same (the ones just holding things down), but they may have been adjusted for a particular location and switching them might mean binding of a part. If a component was replaced, the associated screw may need adjusting by undercutting the head or the shoulder with chrono screw cutters or in the lathe.1 point

-

1 point

-

Hi As its a front loader it more than likely has a split stem, there are two schools of thought on their removal. Some advocate a straight parallel pull using a presto type tool for the purpose and others by removing the bezel and crystal turning the watch face down and turning the stem untill the joint is vertical allowing the movement to drop out ( if the joint is slack enough). Most I think use the straight pull to release the stem but always be aware that it could break the female end of the stem on removal requiring a new stem if available. Others will also have their pet ways of doing it, so likely more posts will be offering you advise. cheers1 point

-

Well, I got a reply. Here was how the conversation went: Me: This was was advertised as "just serviced" as well as "flawless" and "super clean". This watch hasn't been serviced in DECADES. It is filthy with rusted parts and smells like an ashtray. The photos show a jewel that hasn't been oiled in decades with caked on dried oil. All of the jewels are like this. Running the watch in this condition will destroy it. The case clamps are completely rusted on which means you could not have removed the movement from the case and therefore did not service it. Part of the money that I paid for the watch was for the service you claimed had been done. Now I am going to have to pay for a real service, not to mention the cost of any other rusted parts that need to be replaced. I would like a discount to help cover the cost of a proper service or I will return the watch for not being as described. Him: "you will not receive any discount , you me return the watch for a refund. demanding that things be done your way is reall not the way to go. the watch was serviced and is in excellent running condition. please open a claim for return of the watch. any questions please feel free to be nice jim" Me: You did not have this watch serviced. Period. No one has serviced this watch in decades. You lied in your description and the feedback I leave will let others know that you are not to be trusted. Him: again you threatening me to obtain a discount means nothing. please just send the watch back. with the email you sent threatening to leave a bad feedback is enough to get ebay to remove it. do what you like i have offered a solution to you. your choice from here. jim and again {in your opinion} the watch was not serviced... thats just not the case. it was serviced, just not overhauled like you are depicting, please learn the difference jim Me: I'm not threatening you. You said you didn't want to give me a discount on the price to cover a proper service. That's fine. I'm simply letting you know that you lied in your description of the item, I showed you the proof of the lie and you still continue to lie and I will mention that in my feedback. I will be reporting you to ebay for this as well. Servicing a watch means you clean and oil it. That is industry standard. This watch wasn't cleaned as show by the rust and caked on oil. It wasn't oiled as all of the pivots are dry. As I said, running the watch in this condition will destroy it. I guess you think "service" means running a cloth over the crystal?0 points