Leaderboard

Popular Content

Showing content with the highest reputation on 02/04/23 in all areas

-

Should not be a problem. If It's the same design as a Slava 2428/2427, as long as you have released the tension, removing the screw will allow the click to be lifted. The spring should say in place.2 points

-

2 points

-

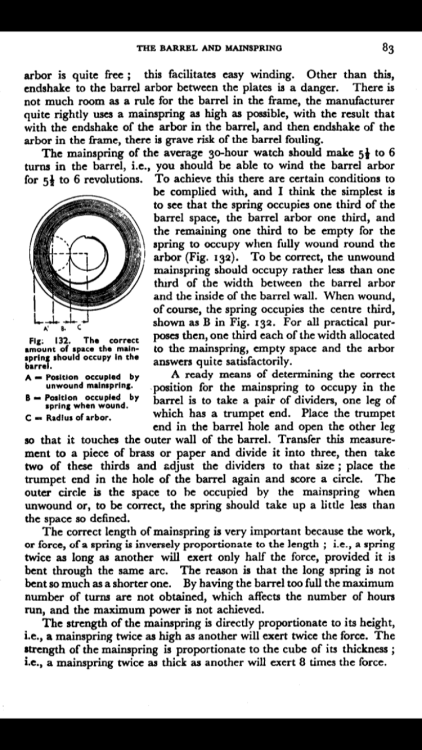

As @praezis an Laurie Pennman calculated correctly the rule of thumb should be 1/4 instead of 1/32 points

-

That means if you play by there strict rules then in many cases you might never fit the correct mainspring. These days as you know there is a limit on springs available, so you have to go for the nearest that is available.2 points

-

I did spend a few minutes searching it but came up empty-handed. I (and I'm sure you as well) did find a comprehensive list of Omega lift angels but no luck. Perhaps someone could make a qualified guess based on a similar Omega calibre?2 points

-

Thanks everyone for your input, this is exactly what I was hoping to get here. I can't believe I missed that NOS circuit board. Great find! Also, that is a very good suggestion to try a new battery myself. Plus, it certainly wouldn't hurt to have a look inside to see how it looks and if there is battery leakage. My father thinks it had been about 6 months since it stopped working before he took it to have the battery replaced. The place didn't say there was leakage which he should have if there was. So this could be a good sign. Of course, I really should see for myself. Thanks for the service manual, that is EXCELLENT! Any excuse to buy more test equipment is a good excuse as far as I'm concerned. I'll have to do a little research to see what I'll need in order to test the circuit board, I imagine it is more than a DMM. This is good advice. I don't know if I want to jump in head first with this watch. At the very least, I would really like to be able to determine the state of things myself and test the coil, circuit and cmos. I don't want to be at the mercy of an unknown repair person who says I need a new movement or circuit board when in reality the problem may be much simpler. Do you know if the circuit board has to be removed in order to test these components or can it be tested in the movement? I completely agree, dealing with the dial isn't something I would want to do on this watch unless I had done it a LOT on other watches. The potential for error there looks very high. One other question. I have seen listings for various 959.001 movements and many of them indicate that they are for a particular brand, like Longines for example. Are there different 959.001 movements made for different makers or all they all generally the same? I understand there might be brand engravings but in terms of dimensions and functionality etc. are they actually different movements? Thanks again for your very helpful responses!2 points

-

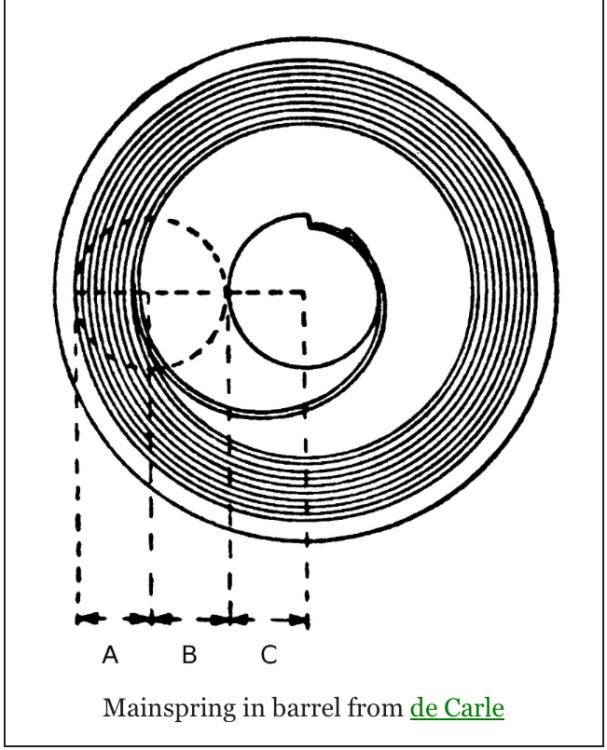

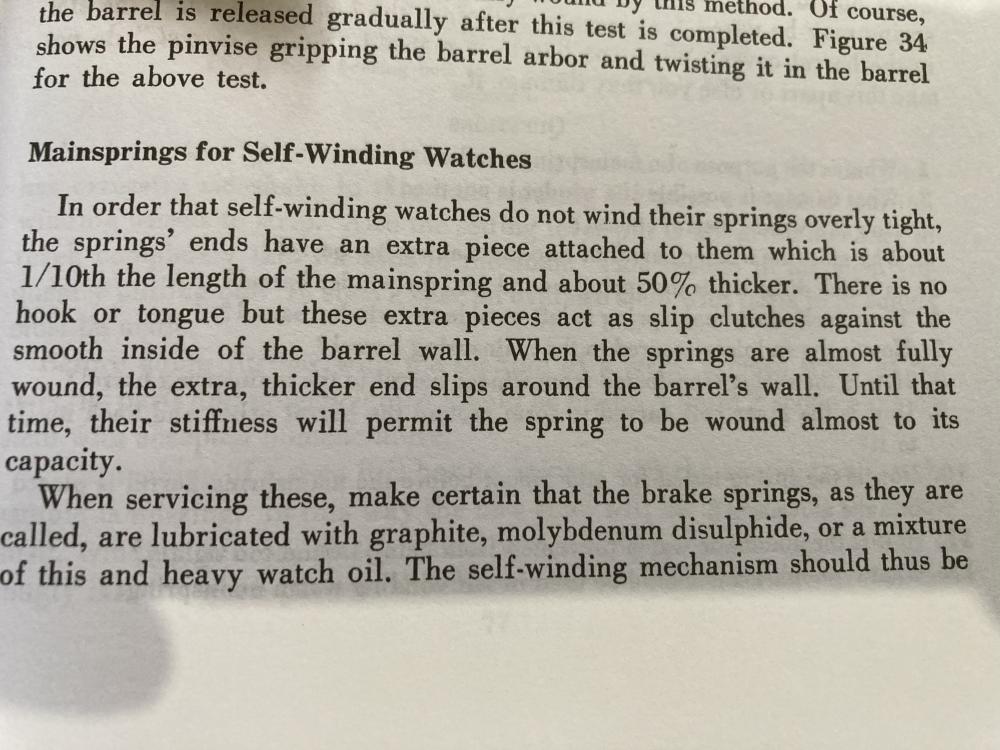

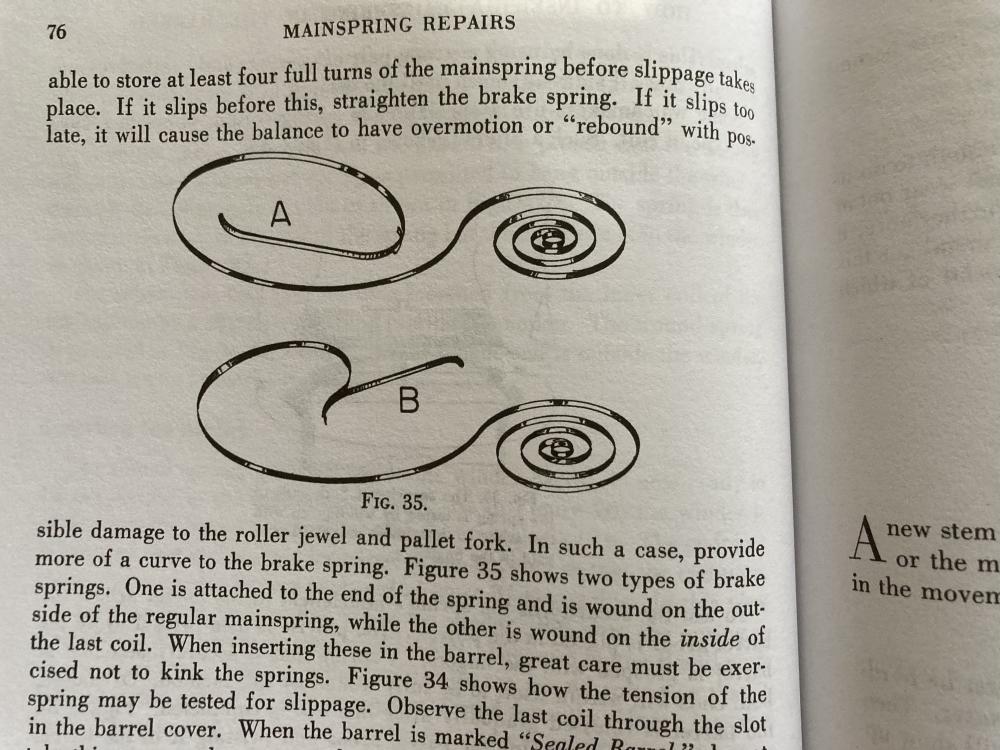

Hi Guys find attached pages from Laurie Pennman (Master clockmaker) and his calculations for the mainspring acommodation as regards to the barrel fitting. This man is spoken of in the same terms as Brian Loomes also a master clock maker. Not having done Geometery scince leaving school in the 50s I would not attempt to dispute Frank's figures but as a rule of thumb its a fair guide, not as proven the hard fact. We are unable to determine in what context De Carle used the diagrams without him telling us which is impossible. So best probably to put this one to bed.2 points

-

2 points

-

Hello all you watchmaking peeps, i trust you are happy and in good health. Well I'm back, missed me ? Please don't all sigh at once. Work commitments has kept me busy and my watch repair interest had to take a temporary back seat. But its now time to return to it with a vengeance. Starting with my latest acquisition of vintage tools. Nothing spectacular but some food for thought for beginners on a budget and maybe some interest and a question or two for the more advanced and pros if they would indulge me. So lets start with a source and a figure of cost. My favourite buying site Ebay, this can be a waiting game for the right tool at the right price. Which can payoff if you are like me, I'm never in a rush to buy anything in particular. But always keep an eye out for something i like and might use for when my skill set improves. I never get into a bidding war, i decide what i want to pay long before the auction ends and submit that figure around 6 seconds before the auction ends ( known as sniping, unethical ? As has been discussed before, you have to play the game same as everone else). These are actually two ebay purchases, one at 6 quid and one at 14 quid so including postage came to around 24 as they were the same seller and he combined the postage for me. The majority of the two buys are cutting broaches and files. A lot of large sized broaches probably for clocks and some smaller ones for watches. Some nice part making files, names include stubbs, favourite and one the oldtimers may know Gantoine Glardon. A graver and a few homemade gravers from square files handles i think . Something of particular interest to me is a pivot burnisher with the name David Borlo A. Vallorbe. Also in the bundle is a solid ss one piece case knive, love this as it has a cracking Marvin logo on it. An unusual staking block with v slots at each end. Three agate oil cups that i am keen to replace the plastic ones i have been using, since reading some discussion regarding some plastic components can leach into the oils placed in them. And lastly the quiz tool that has 3 accessories slid onto the handle shaft. Happy reading and any input would be welcomed and appreciated thank you.1 point

-

Why not to glue a M10-Nut with Cyanoacrylat (Superglue..) to the back, afterwards it should be possible to unglue with Acetone, this was the Solution for some Cases as reported in this Forum. Or else buy a 5537-Clone Set from China...... regards, Ernst1 point

-

I have played with a lot of Russian watches over the years and as far as I can remember they all share the same click layout, namely a spigot around which a roughly circular click with a tooth pivots, and about which an almost circular wire spring sits with one end bent up to engage the click and the other end bent down to engage a hole in the barrel bridge, and a central screw to hold it all in place. With this design so long as the ratchet wheel is removed there is no tension on the click or its spring which means no motive force to propel anything anywhere. So with the power let down you simply remove the ratchet wheel, undo the click screw, and lift out the click and the spring, first noting (or better still photographing) the orientation of each part. If at this point a part goes flying it is likely to be more to do with tweezer technique than movement design, so, ensure that your tweezers are well dressed. The rule of thumb here is that the tips should be such that you can pick up a hair from a piece of glass. Then practice your technique. You only need to squeeze the tweezers enough to pick the part up, and no more. The harder you grip with the tweezers the more motive force you impart to the part when it inevitably makes a break for it, and the further it will fly.1 point

-

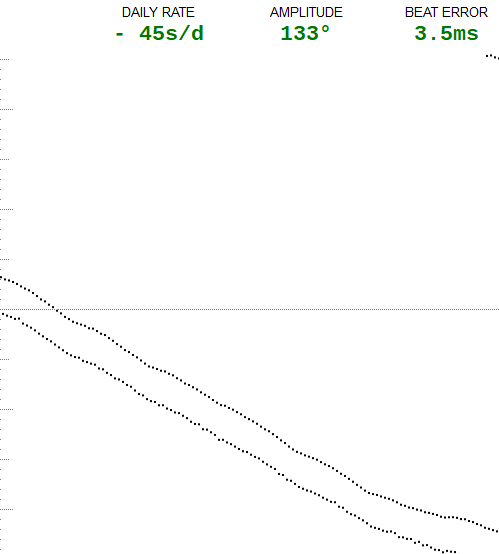

Lets see TG print outs and the max delta in various positions. Having bought so many fakes, I can claim expertship now.1 point

-

These of course are Chinese clones of Swiss watches. This means that getting anything resembling any sort of information is impossible because the Chinese don't do information at all. But if you looking for the difference between 6497 a 6498 that's easy. Oh then there's the other difference the original of these came in 18,000 beats per hour then they put it – two for second-generation and that's 21,600. I have a link below for each one of them so you can look at the dial side and see with a little secondhand goes. So the 97 the crown is at the 12 o'clock position in the secondhand is at the 6 o'clock position. Basically what I would call your standard pocket watch. Then the 6498 and it's even noted on the link below is the hunter style case. This is the watch you pull out of your pocket that has a lid the crown is found at 3 o'clock position versus the 12 o'clock position and the secondhand would still be at the 6 o'clock position Then either watch will work fine for the class. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&ETA_6497_1 http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&ETA_6498_11 point

-

Always nice to have a picture just so were on the same page. Anything it's a vintage you're not going to build a look up a case number and get anything resembling casing parts. At one time the crystals came in diameter sizes and thicknesses and how tall the door but today he will be lucky to get almost anything. The hunting crystals are usually superthin fortunately today there plastic so the outbreak. I remembered going the material house once I'm lucky in a city where it used to have a lot of physical material houses when I purchased the glass hunting crystal the person said it be better if it was set by him because are a lot stronger when they're in the bezel. Sure enough even though it was in a tin can with tissue paper the glass broke by the time I got home. So had to go back with the bezel and then it was fine as I said plastic is much more tolerant the things. So you just need a really thin plastic crystal that will probably say that it's for hunting cases and then you just need at the right diameter to pop into the bezel. Then the reason I'm not to be helpful for diameter size is we still have a physical material house that will fit a crystal stuff I need something like this the case just gets sent down town and she fits the crystal for me.1 point

-

The only time documentation exists for us is if we need the documentation. Documentation for amplitude is only needed if the timing machines exist. Timing machines in the hands of everybody to measure amplitude is a relatively new thing. Yes Omega does have a timing sheet of all of their calibers but how far back do they go? To give you a clue almost none of the watches in the timing sheet or 18,000 beats per hour don't know if their watches are actually numbered in order but it looks like 100 a is the lowest number in the old caliber section.Then looking at the revision section the see if I can figure out when the oldest version of this documentation came into existence it looks like 2006. Then but don't worry vintage is included in the timing sheets this will give you a clue because it lists the watches by size. The clue here is I don't see any pocket watches.1 point

-

Ah I missed that you wrote that! So often folks seem to want to avoid looking at the amplitude... When I was in school it was a transition time for timing machines, we had about half and half old paper tape machines with no indication of amplitude, and more modern Witschi with amplitude. So we were forced to learn to see it, and as mentioned above, you learn that the official lift angle isn't always right!1 point

-

@nickelsilver Thank you for further explanation Exactly this is what I meant with the "180 degrees amplitude timegrapher trick". Perhaps it was just my illusion that Omega, everything they ever produced, was well documented by them; guess not An illusion less, an experience wiser Everybody, thank you for your time & help1 point

-

It looks a little long and from the angel of the barrel looks as if it could be a little higher. From what I can recall the springs in these movement are very strong so a little less strength should be fine. Don't have it to high you do not want it rubbing the inside of the barrel cap.1 point

-

You are correct Old Hippy. You are limited as to what’s available in the market place. And the closest you can get for the clock/watch you are working on as you say you may never fit the exact spring as it was made with.1 point

-

Hi. As a rule of thumb Iwould say so as the spring needs space to operate. But the actual data for springs in barrels is calculated as Lauri Pennmans formula in his book for exactness and confirmed by Prazeis (Frank) who also came to the same conclusion with his calculations. So in conclusion Pennman/Prazeis are correct and De Charles theory is just a guide.1 point

-

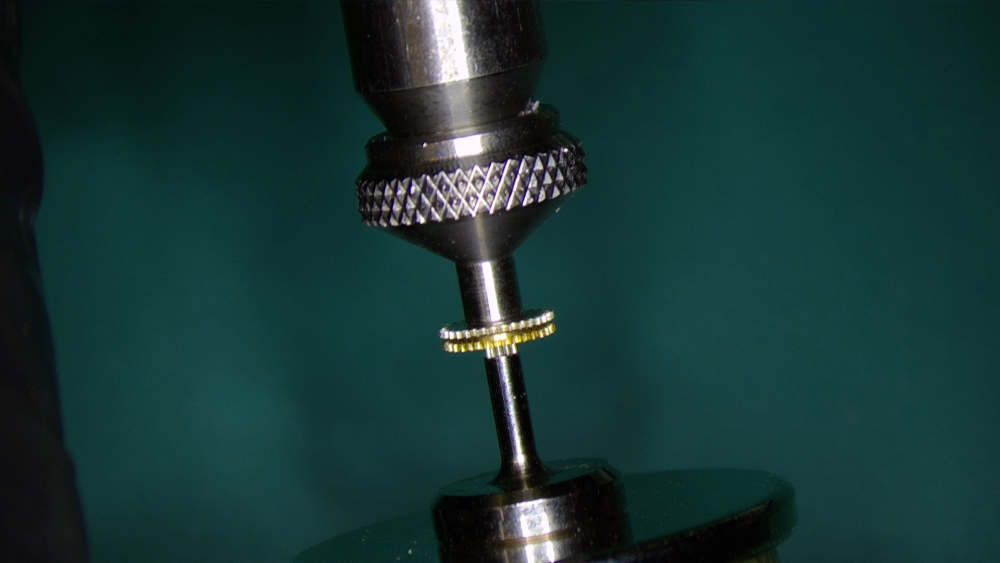

My guess was right. Slipping in that part was the cause. I could see a small gap between the wheels under a microscope so I figured out I might be able to push in a retaining ring you can see on top. I didn't dare use enough force in the jeweling tool so I eventually tapped it down in staking tool. Now the hour jumps and watch keeps somewhat decent time considering it's a pin lever escapement (Amida model something). At least the wheel train is pretty nice quality with small tolerances. 17 jewels.1 point

-

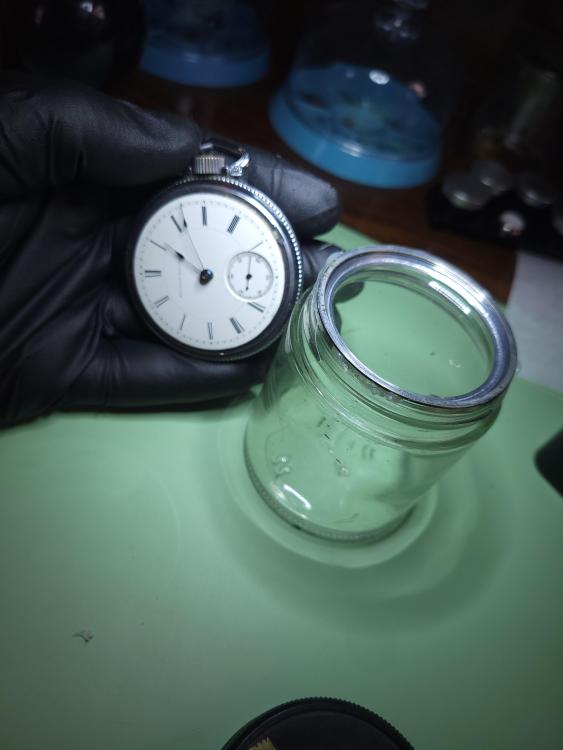

I was afraid this would be the answer. I will try a drop of oil, and also may try a method I saw where you hot glue an appropriately sized jar lid to the bezel and use that to turn it. I feel like it would be better than the ball in this case since I won't have to apply downward pressure on the threads to generate friction, like with the ball. A drop of P'Blaster and the hot glue got it done. Really interesting that you need to take the bezel off to set the watch and pull out this little lever. To add a little historical info: I own a brewery, and one of my customers brought this in for me to look at. It was his grandfather's, and no one knows the last time it was used. I wound it up and it sprung right to life. Not only that, but it looks better than a lot of more modern watches I've had on the timegrapher. Not bad for 140 years old! Here's a little video of it merrily tick-tocking away.1 point

-

1 point

-

Looks like he's using OneOf Accuracy2, it's an app that works with their sensor (275 pounds at Cousins). https://h2i.ch/products/accuracy2-watch-acoustic-measurement/ https://www.cousinsuk.com/product/oneof-accuracy-2 It's a simple sensor, no positioning (probably why he's using the Chinese machine later), but good software. Praezis (Frank) here on the forum can also supply excellent software, with a simple sensor (or it can work with old positionable mics from Vibrograf and similar machines) for a better price. I have it and it's really good. I use it with a Vibrograf mic plugged into my computer. You can pic up the mics for 50 bucks or so on Ebay. The only difference I can see between it and my 7500 buck Witschi is the Witschi has an automatic mic and printer (you can easily print the results with Frank's gear, and fill in caliber and other info for future reference- and also store it as a file). Something it does the Witschi doesn't do is tell you where the heavy spot is on the balance when doing dynamic poising!1 point

-

He's a great guy and has a brilliant sense of humour. He goes into quite deep detail as well. Hehe, he even gave me a shout out in one of his videos1 point

-

You can purchase Incabloc spring from Cousins (UK) by size. https://www.cousinsuk.com/product/inca-shock-springs1 point

.thumb.png.e3cf5d1a05171a4b3614c974857c9058.png)

.thumb.png.e079e7d9ffe7d2d6e599b837f69d6d2c.png)