Leaderboard

Popular Content

Showing content with the highest reputation on 11/12/22 in all areas

-

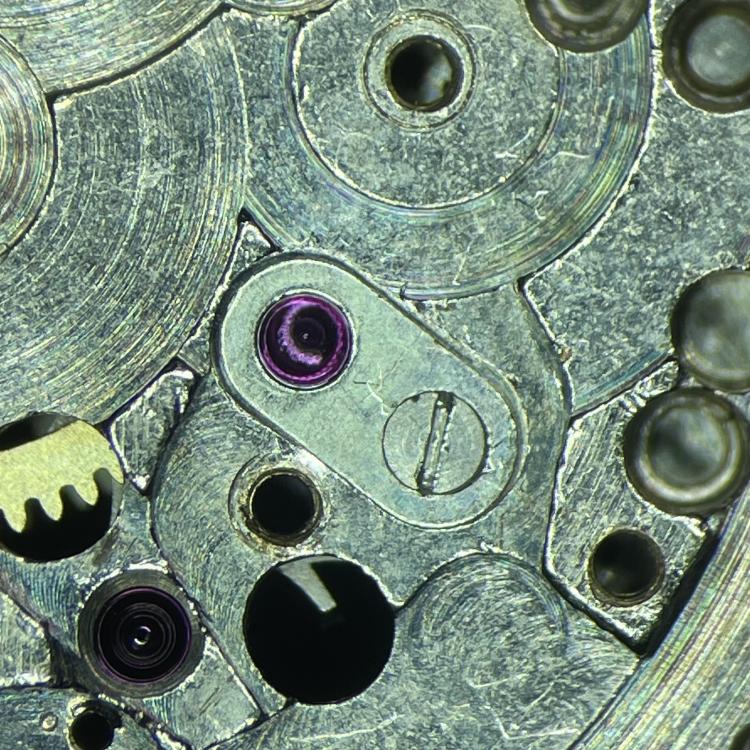

Looks like a nice tool. The three shafts are the runners, the short one is specially made for working on long 4th wheel pivots. The slotted ends are the beds, and the markings on the beds should correspond to pivot sizes; as I understand it there were some tools made where the numbers are arbitrary, but generally not. Depending on the tool the number might be the actual pivot size you will make when the burnisher stops contacting the pivot, or it might make the pivot slightly smaller to fit a jewel of the marked size. These are intended for use with steel or carbide burnishers. Neither will appreciably wear the tool beds even with frequent use- but- often in the past they may have been used with stones or other abrasive tools (like sapphire tools). You should be able to discern grinding marks on the beds that are "factory", in which case you can pretty much rest assured the tool wasn't abused. Using abrasives on this tool is a big no-no. The discs are called lanterns, and are used when working on the pivot ends. A chip here or there isn't the end of the world, as you just need a hole that will pass the pivot through enough to access it with the burnisher. Yours should be fine. These tools were made as matched sets, and will almost always have a number on the frame and then numbers on the runners that correspond. In some cases the runners might just have the last digit or last two from the frame number. You will need a burnisher and a means to drive the pulley, I highly recommend the Bergeon carbide burnisher model 2933G. G is for gauche, or left in French, but it is actually for right hand use on a Jacot tool. They aren't cheap, so if you look for a secondhand one beware that some older ones have a rather large radius for conical pivots and might only be useful for large pocket watch staffs. The current ones (and ones made in the last 20-30 years for sure) have a 0.2mm radius which is small enough for even tiny staffs and still works well on larger pivots. To drive it, traditionally you would use a bow. I use a bow, with light fishing line. Another fine way to drive it is with a piece of elastic, with fishing line attached, and a ring at the end of that. Attach the elastic back on the bench behind the tool (which will be in a vice), wrap the line around the pulley, and pull on the ring to drive it.3 points

-

Can you post a pic of the dial side? Your escape wheel has a conical pivot on the lower side, which means it should work with a cap jewel. If the cap jewel is missing, or if the wheel was replaced with one needing one, it would cause exactly the issue you are seeing.2 points

-

It's hard to put a value on it. I have several, all Steiner (Horia now), and paid as low as 70 bucks for a basic set, which was a terrific deal, to several hundred for a larger set, which I also considered a good deal. A friend of mine recently got a large set Steiner for about 350 and was happy with that price. Steiner do go for a premium; I would say a set like yours, without a box, really should be under 100 and closer to 50. Getting over 100 I recommend trying to wait out for a deal on a Steiner. Yes, if you will be holding the burnisher in the left hand you will want the "D" model (droit). The reason for the confusion, as far as I can tell, is the naming came about with the idea that the tool would be used on the underside of a pivot being spun in a lathe, which reverses things. The difference is the location of the radius and the slant on the non-radius side, which is slanted so that a true square shoulder can be made. You might get lucky and find a Favorite burnisher. These have a carbide rectangle with 3 different radii and one flat edge, and can be flipped end for end in the handle for right or left hand use.2 points

-

casually from memory I remember there are two different designs for ruby cylinders so there were probably other makers. But no matter what making the cylinder is an interesting thing to do and they tended to be fragile. I knew somebody that once needed a replacement cylinder the problem was on their particular style of the entire end was missing that wasn't just making a new Ruby cylinder it was figuring out what the entire rest of it was. So other than getting to look at it that's as far as the project went. then in Daniel's book he actually tells how to make the cylinder. For those people have a little extra time on their hands and need an extra project.2 points

-

I totally agree with you, and really appreciate the support. Thanks Nickelsilver. I do understand the economics involved, although as a consumer it can be hard to swallow. Ive had a couple of businesses and really do understand just how expensive they are to keep going, and how the cost is passed onto the customer. When I had the car workshop which I consider to be a very small business, it cost me many thousands each week just to open the doors. Customers sometimes struggled to understand why an hourly rate could possibly be so high, but it was very carefully calculated so we could keep the doors open. What I don't like is the disingenuous nature of some of these brands. Trying to tell you, you are getting something special when you aren't. The aforementioned brand made a big deal of their special stamped brass dials! it felt like they were taking advantage of their chosen market. I really can't stand that. Wow. Im not sure what to say! Thank you Claypipe. Im not sure I can take the credit for this. This is a very special forum that brings out the best in people from my point of view. But I am very pleased you like the watches, and would love to see your work. Welcome to the forum. Today is my 45th birthday and I’m very happy to have completed the watch I will be wearing for the rest of the year. I’ve finally got the brushing on the chapter ring exactly where I want it, the bleached silver just the right shade of white, and an even blue on the hands. Definitely making progress.2 points

-

Well spotted, the escape wheel did have a cap jewel which I had removed for cleaning and promptly forgot all about. I didn't know about conical pivots and that they are supposed to ride on the cap jewel! Of course, replacing the cap jewel solved the issue and the end shake is now much more reasonable. No more binding! I feel like a fool now, but at least I learned something new I owe you a beer @nickelsilver! I'll update this thread if I manage to get this running again. Still not sure why it wasn't running before, though my bet now is simply because it was very dirty.1 point

-

a lot of people use a Seitz tool especially if you're going to put in a modern jewel you would have to open up the hole and the tool usually comes with the reamers. Or simplistically if you doing all of this right you need both of them. sometimes I hate dictation software just the little line up above three separate things had to be changed otherwise it wouldn't have made any sense at all. On the other hand without it I wouldn't even be here.1 point

-

this is my amusement on the collectors discussions. They like to complain about the high cost of watch repair. The greedy watchmakers and brag about how they have a watch running perfectly and I haven't had its serviced in a very very long time. Then of course at some point time they're upset with the greedy watchmaker because their watch has a problem. that's where you start finding all the issues of things worn out broken destroyed. Plus on authorized Rolex service they automatically replace a lot of components that we can't even get. So even Rolex knows a time limit between servicing where things have to be replaced The other aspect of this that would also cause your problem is the gaskets will all disintegrate at some point in time and if you can get moisture into the case you can end up with a little rusty even surface rust which is actually a really nice grinding compound. It's one of the sad realities of synthetic lubricants rather than becoming sticky and stopping the watch like in the old days and saving the watch synthetic lubricants just disappear everything is dry and then the watch grinds itself to death. this becomes very common on early automatic watches that don't have jeweled bearings for the automatic mechanism. genuine versus other has changed with time. I was once working on a Rolex that I had and it was at a time when the material houses still could sell Rolex parts. Seattle used to have anything at one time we had for material houses you could walk into and do business which was really nice. My favorite one run by Dan attempted to convince me to buy a best fit rotor rather than Rolex because it was $25 versus 75. But all the rest the parts I had purchased were genuine in the original packages. I was unhappy but. All the years I done business with that particular material house and than he had never steered me wrong and everything that he said was good was definitely good so we ordered it. It looked identical I could not tell at all. Years later I get an answer to that question. Somebody going to school in Switzerland visited the best fit factory. At that time when Rolex would sell parts to us common folk they also sold parts to bestfit soda Omega. So when he was there they were packaging up Omega parts in the morning in the original mega packaging. But in the afternoon bestfit parts the same part but just under the bestfit number. So sometimes at least the past generic wasn't generic.1 point

-

Sorry John, I know you use dictation software but I just had to repeat it: In a year laying spinach I will find a way to work that into my normal pub conversation, somehow.1 point

-

1 point

-

I don't see the bow which is used to power the tool.1 point

-

Thanks watchweasol. I have no idea about the service history on this watch or if the escape wheel is original. Maybe I will be able to fix this one day, but that day is not today...1 point

-

is a little bit cryptic in the service manual because it's exactly in the middle of the page where half the paragraphs on one side and half is on the other.. It indicates that by alternating the contacts on the motor the same as you would any other stepping motor it's supposed to step. The problem with these sealed motors are there not really meant to be serviced.. It's a design not unique to Bulova I know there were some other companies that had sealed motors that looks similar. They just didn't anticipate that we would be wanting the watch to run all these years later they were met the last forever. Like for instance if you look at the bearings white color I'm not even sure that's a sapphire I think it may be nylon. Or maybe Teflon. 992369810_Bulova242.pdf1 point

-

Hi the main criteria is to take your time and not to rush, Lay the bridge on top of the wheels pop in the screws loosely just to hold the plate in position with no pressure and gently adjust the wheels untill the pivots drop in to the jewels (make yourself some tools for this). Apply no pressure when you think they are all in check the end shake ( do they lift and drop) easily aaaaa0 then tighten down the screws slowley checking the wheels as you go. best of luck.1 point

-

That pivot is very worn, it should have nice polished parallel sides. You could refinish it, but then the jewel would be too large, so change the jewel, now things aren't original... I would go with the generic wheel you posted from Cousins. Pivots get like this from being run past the service life of the lubricants. Not all, and not always, but some movements will keep running seemingly happy with every dry and dirty, and only come in when something breaks or the watch just stops. I did a Rolex for a friend last year; he had it serviced the last time in '98 or so, haha. Luckily he doesn't wear it often- and it did run pretty darn well! But dry as a bone. In his case there was no wear, but I have seen pivots in Rolexes and ETA movements that had worn so thin it was amazing they still worked.1 point

-

Eyup matey. Not something i have seen on any swiss movement i have repaired. Maybe john or another pro could answer if this is specfic to this rolex model. Could you improve the focus on the picture, any wear pattern visible would be obvious compared to something manufactued that way. A cheap phone tripod will help with the focus..1 point

-

I picked up one of these Bergeon knock off crystal removing pumps for less than $10 delivered from Aliexpress. It worked on the one case I tried it on, but it took a number of tries. I got it to work by pushing the plunger very fast. Using a moderate and slow force didn't work, it had to be a fast with a lot of force. In its favor, I tried using just a large medical syringe with the same plastic bag I used in the video and had no luck.1 point

-

Maybe it's too early in the morning.... but if you measure and cut it according to the photo above, it'll end up too short. It should be measured from the end of the case tube to the bottom of the crown.1 point

-

This piece has been floating in and out of my job queue since summer but it's finally all done. I had a second specimen and after chatting with someone I sold a different Timex to, it turns out he was in search of this exact model. I then found a third with an unsalvageable crystal but perfect dial to swap for my own bad dial. So between mine and the one for the other guy I've got 2 in great condition now. I put mine on a blue faux crocodile strap.1 point

-

Hi Bear that is one hell of a watch, I love it, the simplicity, clean lines. the blue hands just set it off Be proud of your self be proud of your work and be most proud of your ethics and Honesty. That is quality with a big Q cheers mate.1 point

-

If it's spring loaded, it's just a "normal fitting" ? What I'd do, is make sure the crown is screwed on fully, and the stem pushed in. Then using callipers, measure the distance shown - you don't need the number, just leave the callipers at that setting. Then holding the stem in a pin vice, remove the crown and measure, from the end of the stem, the amount to remove using the callipers. Mark with a felt pen, then cut and file (to slightly longer at first), and try the fit. When happy with the fit, Loctite the crown. SEE CORRECTION BELOW1 point

-

Yes! Pictures please! In so far as a cylinder made of ruby, only one name leaps to mind: A. L. Breguet. There possibly could have been others, but making the cylinder in a cylinder-escapement out of ruby was his idea. I have worked on a few cylinder escapement watches, and would love to see pictures of this one. John and I could possibly help identify it. But as John says - they are rare as rare gets. I would not envy the man assigned to search for parts for it.1 point

-

Hi you have just fired up Johns enthusiasm as the resident Vintage man. Please post him some pictures and make him a happy chappie.1 point

-

no pictures we love pictures especially a picture of something like this. Probably a better question to ask is not how rare is it on a pocket watch but just how rare is a Ruby cylinder? I do have to ask the question though how do you know it's a Ruby cylinder versus a standard cylinder? Then Ruby cylinder is tended be rare because they're hard to make making the Ruby cylinder part is difficult. Then they have a habit of breaking meaning that finding a running one is going to be even more rare. So basically a Ruby cylinder is going to be rare whatever it is in. It be nice to have a picture1 point

-

1 point

-

1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

Hello and welcome to the forum, the Seiko 7009A is a long time sacraficial time piee plenty of parts to be had. I have attached the service sheet for the Seiko and a couple of others which may be handy. 277_Seiko7009A (6).pdf 1612608791_ToolsfortheHobbyist (2) (1).pdf TZIllustratedGlossary.pdf1 point

-

Problem solved in a rather unusual way. Since the old crystal is in good shape and fit the movement perfectly, I did this. Took a piece of aluminum foil and covered the crystal and over the module (capsule). Then I pressed that into the bezel. Using a surgeons scalpel I cut away the foil. It is a very tight fit and you cannot see the foil. The foil, incidentally, is 20 microns thick. That is all it took. My method is easily reversible (i.e., I can press the movement out without harm).1 point

-

The reverser wheels should be epilamed and must nut be oiled at all (the pivots only).1 point