Leaderboard

Popular Content

Showing content with the highest reputation on 09/09/22 in Posts

-

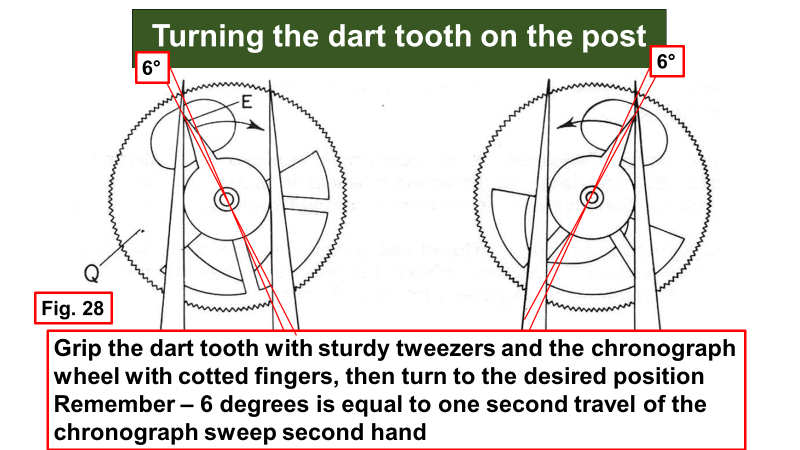

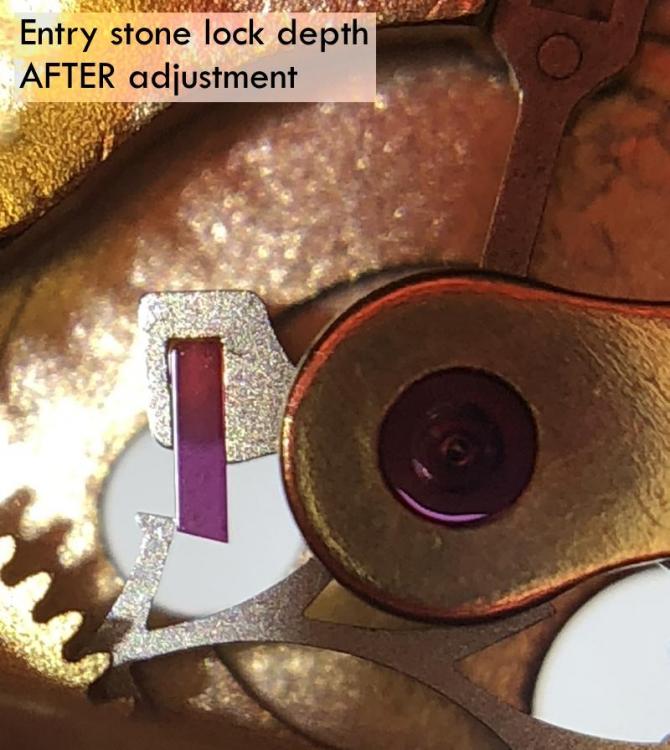

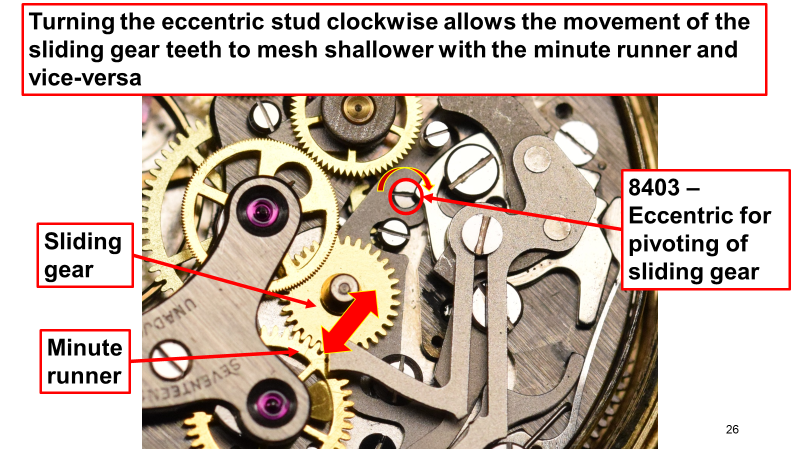

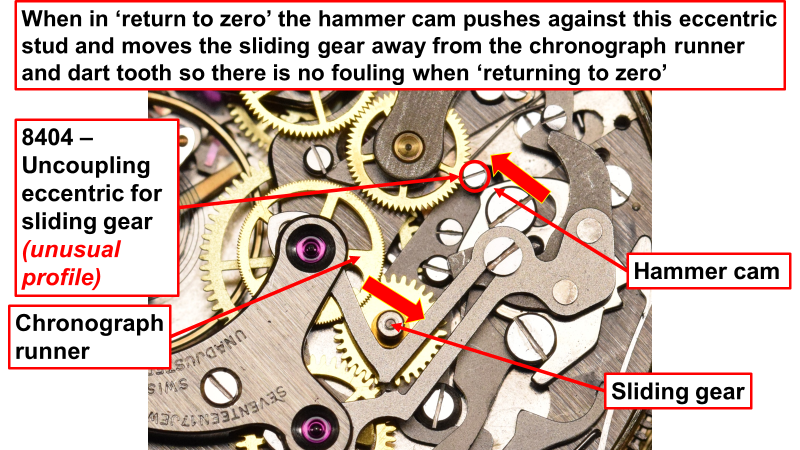

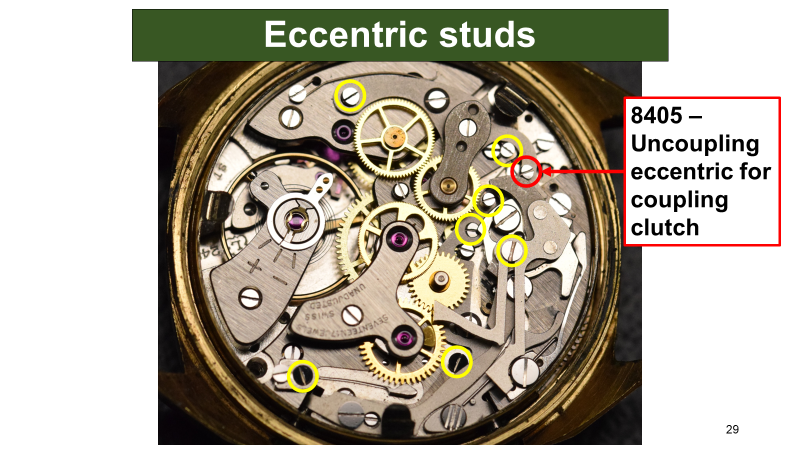

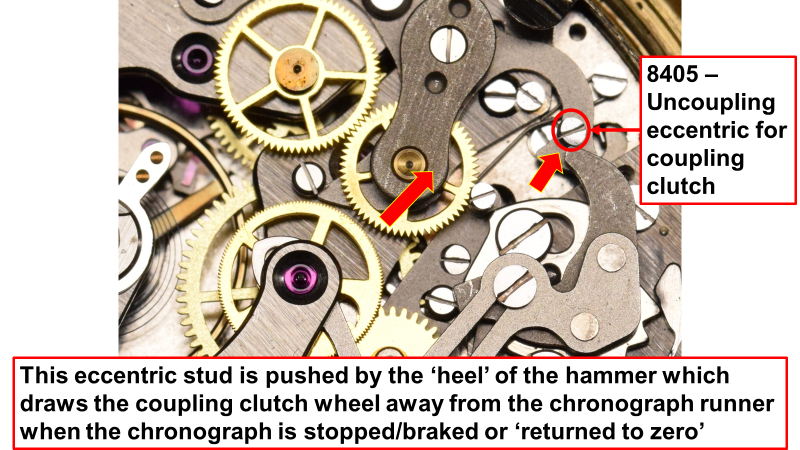

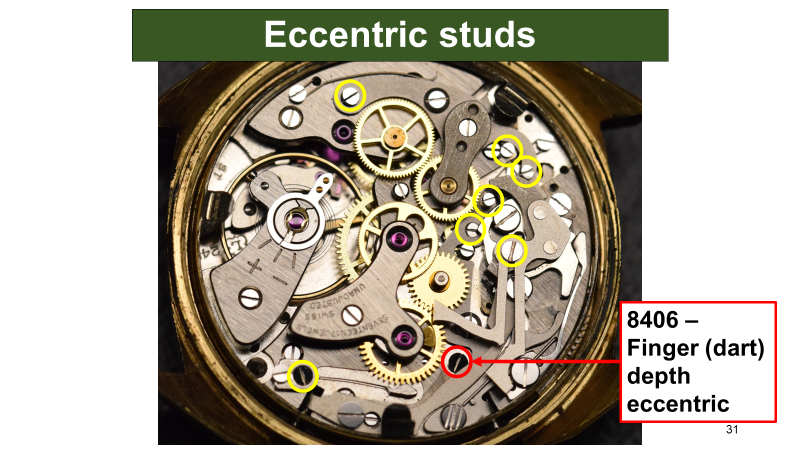

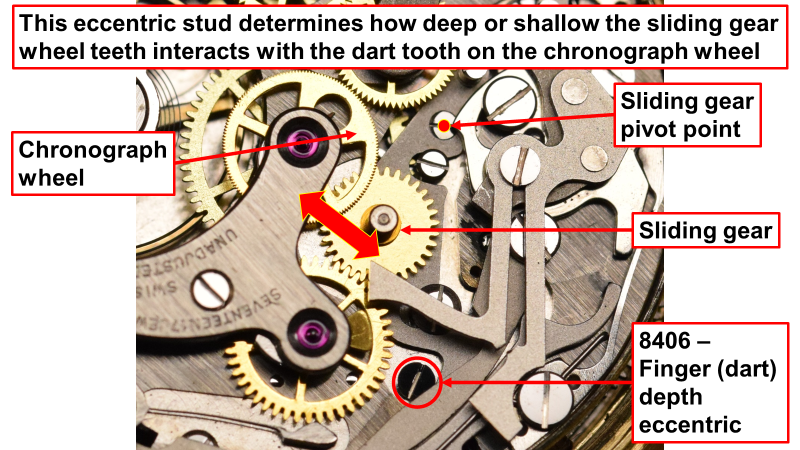

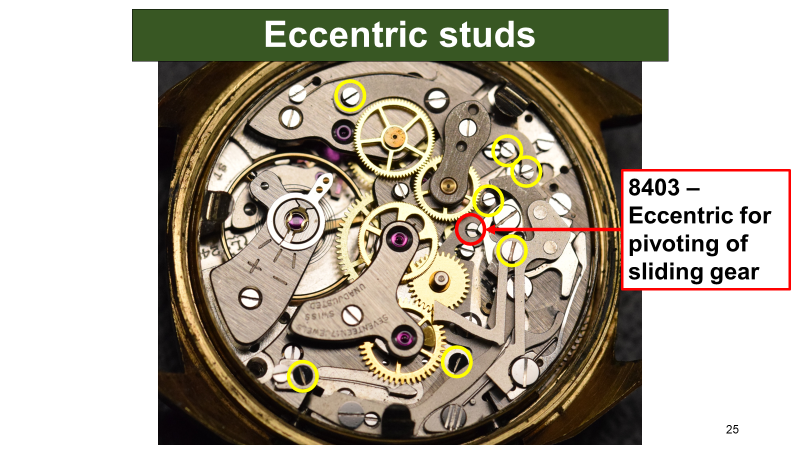

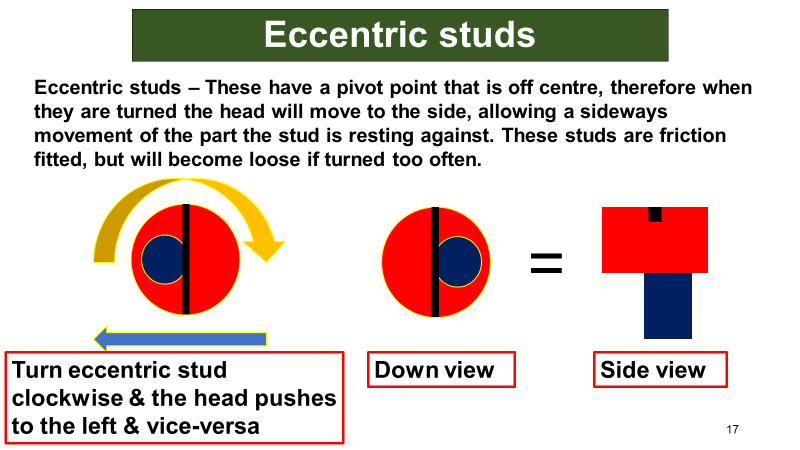

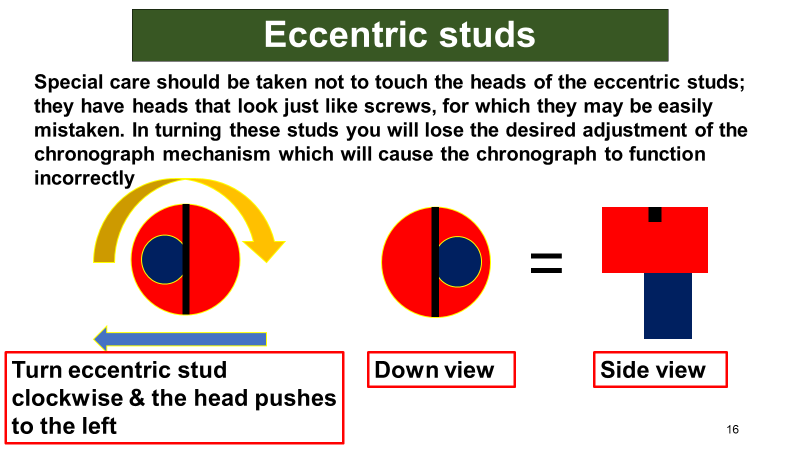

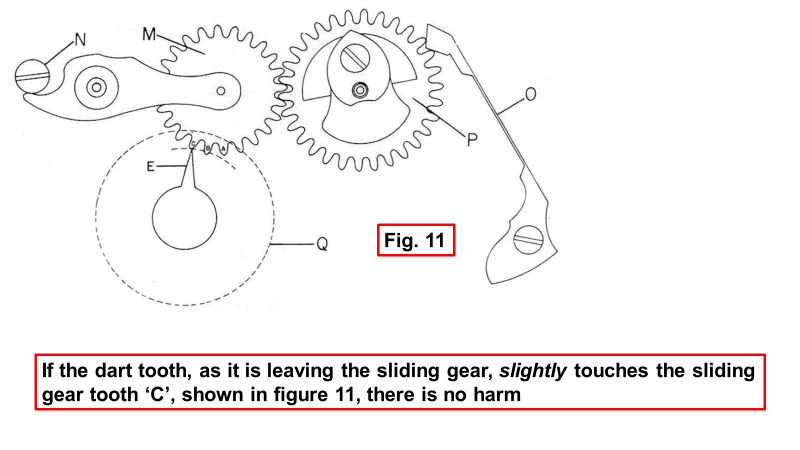

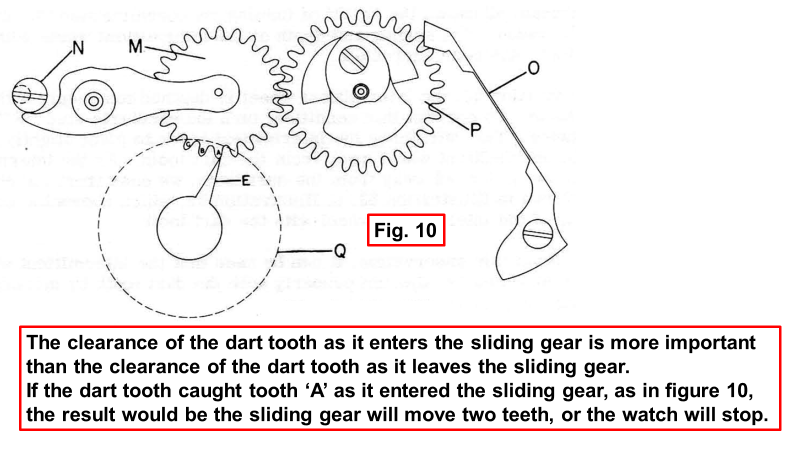

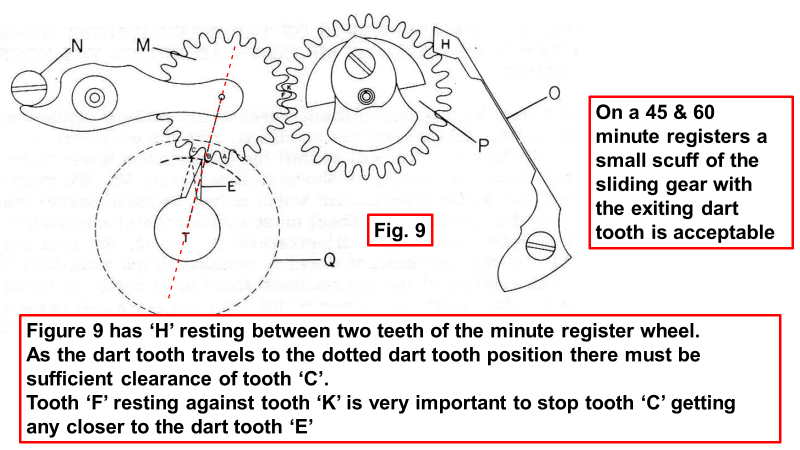

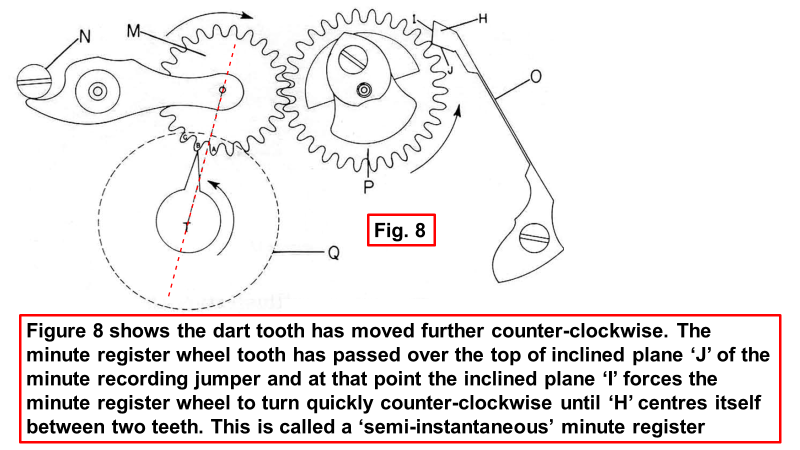

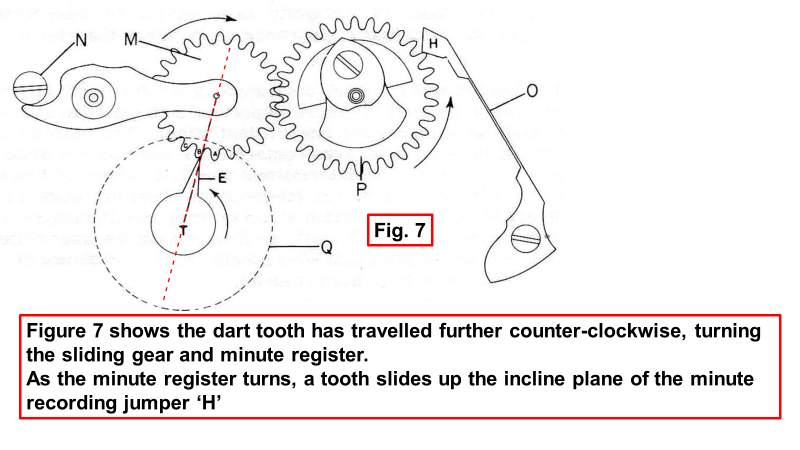

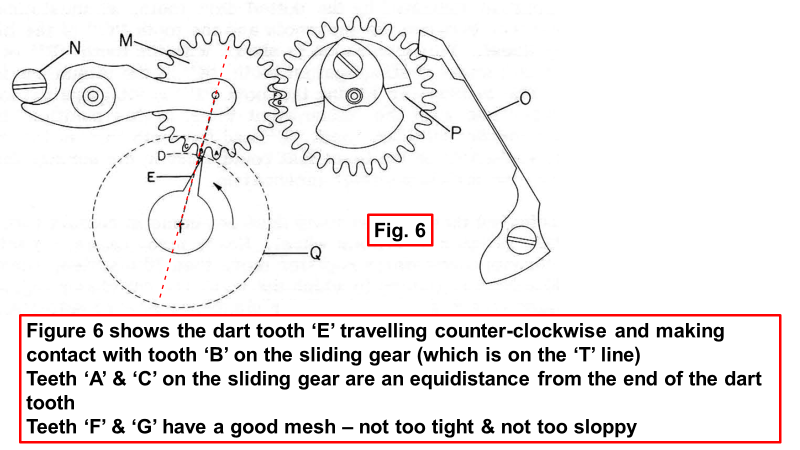

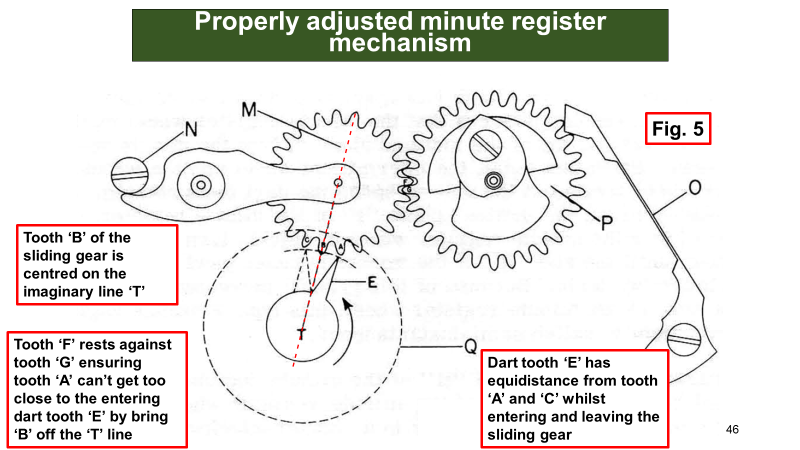

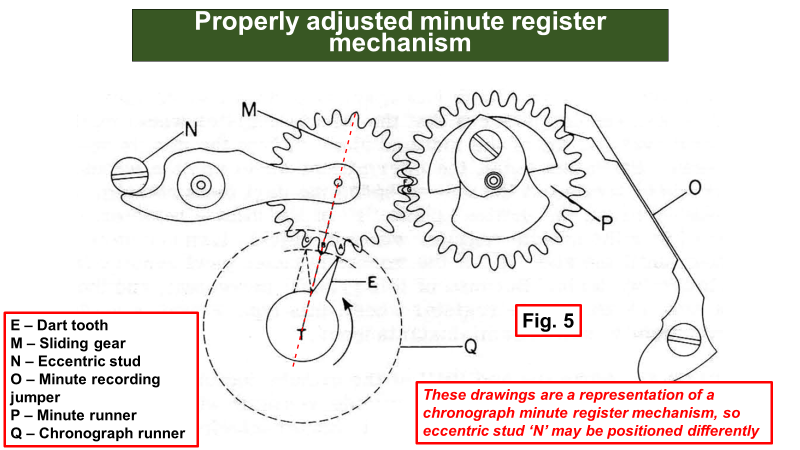

This is slightly different from the Landeron 51, as this is a Landeron 248, so the eccentric studs might be different, but the principles are the same. Before thinking about moving the dart finger, I would ensure the minute register mechanism is set up properly. The slides will help understand the theory as well as the practical application. You have to understand how this works before adjusting anything, as turning an eccentric stud and not knowing what the result will be is asking for problems! These are just a few slides from one of the lessons. There are many other ways to adjust the chronograph work that aren't in these few I have posted, as there are over 300 slides in the Landeron 248 lessons I wrote with the aid of the Ensemble-o-graf drawings. They are a great aid to understand chronographs. The position of the dart finger is incorrect in the photo you posted. It needs to be on the other side of that tooth of the sliding gear. Here's a picture of how the dart tooth should be almost touching the sliding gear tooth, so it travels almost 360 degrees before turning the sliding gear and minute register. If you set the minute register mechanism properly, it may change the position of the teeth on the sliding gear so the dart finger is on the correct side when starting the chronograph, or you may find that you need to turn the dart tooth, as @praezissuggested.4 points

-

3 points

-

Those extra tiny shock settings are the subject of a recent thread. The moral of the story is it's probably best to leave them in place and oil from the other side. It can be done, and I've done it myself, but it's way more trouble than it's worth is the consensus. Auto oiler is the answer.3 points

-

3 points

-

My condolences to all of you in England. Being American, I am confused as to how I should feel about the Queen's death, and unsure if I have the right to mourn her. That, and I never really knew her, let alone personally. But being monarch since before I was born, she was the only British queen that I, and so many others, ever knew. So, with her passing, part of what I knew of England has become a memory. And she will certainly be remembered for some time. I imagine all eyes will now be upon King Charles III. He is no Elizabeth, to be sure, but perhaps his example will be well received.3 points

-

Not a problem. Thanks to everyone for identifying the mystery object. I’ve been looking at all the parts both with the naked eye and microscope while referring to the 7s26 technical guide. No post seems dislodged from the plate and all wheels are intact. That pin/dial foot was jammed tight between the center wheel arm and mainplate, preventing the wheel from rotating. Will clean and reassemble the movement. Curious to see if it runs. I don’t yet have a timegrapher so will use the watchtuner app for measurements (assuming it starts). I’ve been practicing on some Incabloc settings from Otto Frei (mounted in Rodico) so should hopefully be able to handle the bridge shock jewels. Will attempt some balance spring manipulation also.3 points

-

The number one thing when doing positional rating is that the watch be in perfect running condition. That means running at good amplitude vert/horizontal, escapement checks out, amplitude at 24h ok. If you have replaced a staff, whether made or bought, it's good to check on the static poising tool. If it's close, leave it. If it's way out, correct a bit. Then, you can look at dynamic poise. You can get a good watch to almost perfect posistional rate like this. A lesser watch, close. The quality of the hairspring* and general proportions play a lot here. A 5x7 ligne watch will never perform like a 13"' watch. The proportions are off. A watch with the lever and escape wheel proportionally oversize to the balance will never perform well. There may be exceptions, but that's what they are, exceptions. I worked on overrun vintage work for a major manufacturer of many years. The largest movements were typically 10 ligne. Smallest, down to LeCoultre 101. A weird thing with the really small stuff, and I and my colleague who is amazing at timing never figured out, is sometimes the dynamic poise theory gets reversed. We knew exactly the amplitude we had, but on something like a LeCoultre 101 or 104 (basically the same watch) you have to reverse the normal procedure. Funny thing, I had another colleague who needed a staff for a 104, I made it for him. He had like 300s vertical delta. He asked me (with Belgian beer as a motivator) to poise it. I STATICALLY poised it, and he was within 20s. A-fing OK for that watch (LeCoultre times them visually, is the minute hand where it needs to be?, haha). But the above is an odd case. If I restaff, I check poise casually statically. If it's close, off we go., I correct with dynamic. You can have cases where a balance is perfectly statically poised, and then you have to remove (or add, if lucky) weight to get it right on. Or you can have a LeCoultre 104 that should be a mofo to get timed within 100s in 6 positions and a simple static poise gets it better than the average Seiko. But bottom line is: before doing precision timing, the watch must be running at the utmost optimum level. Perfect escapement, perfect hairsrpring, nice recoil on the escape wheeel, etc. You might do some tweek and get a poorly running watch to give good results on the wrist (it can happen, a crap running watch that keeps good time), but that's like dialing in a sniper rifle with a bent barrel to hit a target at 100m. It will be a mile off off at distance. *The quality of the hairspring is a surprisingly important thing. I read about Mercer abandoning a hairspring after weeks of timing didn't bring the desired results. A friend of mine who worked at Hamilton toward the end of WW2 told me about a prototyper who put a pin lever escapement in a Hamilton 21 marine chronometer and it rated almost the same as before, and well within the requirements for marine chronometers. Hamilton had their Hamilton Elinvar Extra hairspring material, coupled with their stainless rim Invar arm balance, and it was amazing. He proved it was so good with the pin lever escapement, but gov regs wouldn't allow simpler movements (the model 22 deck watch also performed as well, with lever escapement).3 points

-

You don't really need a hairspring to make the balance spin. You only need it if you want the balance to stop at some point and spin back the other way.3 points

-

when I first came to the shop where I'm working now there were three other watchmakers. I learned from them they wouldn't even touch a watch unless they had the replacement mainspring in their hand. When I inquired I was told it was a liability reason. You'll find in most modern shops if not all modern shops they will always replace the mainspring is just what they do. But is it really necessary? If it's a modern white mainspring and it still looks like it's in decent condition. And in the watch if 24 hours later you have 200° or whatever degrees of amplitude you're supposed to have in other words it seems to be doing the job it's fine. I do find it rather amusing that Omega has a working instruction on recycling a mainspring parol. They explain how to disassemble the barrel everything is supposed to look at which is not just a mainspring. Everything has to look perfect basically. Mainspring is wiped off with a lint free cloth. Then the whole thing is reassembled. But as we have a Swatch group service center in town the watchmakers I talked to they always replace the entire mainspring and barrel obviously this memo and never made it to the service center as I'm typically working on vintage watches incoming before I service I like to pre-time. Iin order to pre-time I just need to get the watch running somewhat and I don't worry about whether the mainspring is set or not. A set mainspring will initially run the watch it just will not run the watch for 24 hours. So you have to be careful in assuming her mainspring is good when you finish servicing because unless you run the watch for 24 hours in not necessarily going to know whether the mainspring is good or not. then do I reuse mainsprings yes. As the mainsprings in pocket watches are getting harder to get if the mainspring in the watch was white it appears to be in good shape all reuse it. In other words if it does the job it stays with the watch. Then the use of blued steel Springs? For variety reasons I will use blued steel Springs like if it's a small Waltham sometimes the only way to get the hook into the barrel is you have to have original spring too much work to make anything else fit. We take blued steel Springs out of the package some of them actually look more beautiful than a moderate white spring they have a beautiful back curve they been sitting in a package for the last I don't how many years and they look better than a modern spring. Others have rusted and come out in pieces some other times they look set but if they look good there isn't any reason why you can't use them. Oh and some modern white Springs that, the package I've seen them looking set they just don't open up for a big. Is unfortunately no guarantee that your mainspring was properly manufactured in the first place even if it's white and new. then I'm not good as a hobbyist if the person doing the servicing is the owner of the watch and you're objecting to the high cost of the mainspring. It's a modern way colored mainspring and it looks fine I would just use it again. Only if it's going to be your every day watch that you really need to know what time it is and it's not making it 24 hours and you suspect the mainspring then you get stuck changing it otherwise I wouldn't worry about.2 points

-

Every now and then you'll come across a ratchet screw that is a left handed thread. I'm not saying that is the case here, but it is worth noting2 points

-

You're right. They would never be cleaned properly left in situ. No matter what anyone will tell you, a movement has to be completely disassembled to be able to clean it properly, otherwise you may have a big drop in amplitude and wonder what is causing it, when a glaringly obvious problem of dirty cap jewels and contaminated lubricant was the cause. It's the same with replacing a mainspring, which should be standard practice. Putting the old spring back is a bad idea, as a big drop in amplitude is probably due to the old spring, but if not, you will never be sure, as you didn't rule out the mainspring by replacing it with a new one. You'll end up chasing your tail if the obvious possible causes of problems aren't addressed. I think it boils down servicing a movement properly, or easily. The easy way isn't always the proper way.2 points

-

Hi. Just asking that you have checked for a reverse thread. Post up some pictures please2 points

-

I dont understand how the top of the jewel and the cap jewel can be cleaned properly if it is left in place. Apart from the jewel hole this area is encapsulated, surely dirt could become trapped inside. Or at the very least a residue left behind from the cleaner and any dirt present to then contaminate the new lubricant. From an enthusiasts point of view using a basic cleaning machine.2 points

-

I agree they are fiddly, but I wouldn't leave them in place to clean, as they aren't going to be cleaned properly, then lubricant is added to a dirty cap jewel. Learning how to remove and replace these springs isn't that hard with the correct tool. I also use a honed down oiler to push the oil through the oil sink.2 points

-

@JohnFrumI hadn't intended to be correcting your numbers by such an insignificant amount. @Neverenoughwatches asked for the measurements in metric on page one of this thread and I didn't notice that there was a page two or that you had already converted them. It's just that I did not round off my numbers and it looks as if you did. I can see how that may have made me look. I assure you all it was just unfortunately timed. Shane2 points

-

1 point

-

John, I would never say that you are wrong, it's just that you and others have different goals. I have quite a few watches within my personal collection. I like to wear a different one every day or so as I randomly rotate through them all. If one of my watches runs a bit fast or slow due to something outside of my control, current desire or budget to fix, I'm not going to lose any sleep over it. The odds are it will need to be reset by the next time it's worn anyway. I certainly can't afford to purchase a new mainspring for every watch I own just for the principle. I have worked on watches for other people and if it was not obviously (in my opinion) needed, they were given the option with a full understanding of the situation. After all, it was their money and they are only paying for the parts used (no labor). Some have opted for and others against but everyone has been happy with their results. That being said, I try to do the best work that I can within my limitations. I have repaired watches that have run on the wrist for weeks without a perceptible loss or gain of time and that is good enough for me. Every one of us must work within our own limits or within the limits of our "customers". Good luck with everything you try. Shane1 point

-

Unfortunately, it is rare for me to be able to get a mainspring for less than $20 when shipping and taxes are considered. Most of the time it's much more. Many of the watches I work on, I'd never get my money back. They just aren't that valuable. If I'm working on a watch for a customer, then it's their choice if they want to put the money into the watch. As often as not it's a no. I have a large stash of "vintage", mostly blue steel, mainsprings and I can often find a usable one. Again, if it's for a customer I'll let them know that the spring is just to get the watch running, it is not likely to last, and that they should not expect the watch to be suitable for daily wear. I have many watches like this in my own collection. Every once in a while I wind one up and wear it, and it's fine. I'd love to be in a position where I can routinely replace a mainspring, but until I have clients that are willing to spend $300+ for a service, can't be done. And there just aren't that many people out there who are willing to spend that much money on a watch service. Maybe someday.1 point

-

I agree entirely. They are VERY fiddly to put back. Clean them in place and oil through the hole. You don't need to buy an auto oiler. I use an old oiler sharpened to a point, which I put through the jewel hole resting on the cap jewel. I then use a fine oiler to put some oil at the jewel hole. Capillary action will draw the oil through to the cap jewel.1 point

-

Shame looked a good set and a Boley too . $260 very good price. In the early days I had to change balance staffs without a staking tool using a set of punches and a stake. If done very carefully it can be done. At that time I couldn't afford a set but had more successes than failures. Main problem is rim distortion but applying the pricipals of the platax tool and holding the rim and arms flat whilst removing the staff it worked. good luck. cheers1 point

-

I originally moved here about 5 years ago because I started a business with a guy who lives in this city and we did quite well till covid came along and the business basically went under as a huge chunk of the country lost their jobs and people stopped buying our products. I had really been just looking for a reason to get out of California though which I love but it's WAY too expensive. I make my living as a freelance artist and doing the art things that I want to do while paying 45k a year to rent a tiny apartment is not really tenable. Pity you're not closer, i'm always down to go on a hike. The forest right near here has 100 miles of wild wilderness forest trail you can camp on and I've only explored about 1/5th of it because finding anybody to keep me company is almost impossible. Also my late father is from texas and connecting with some of that side of my family has been nice.1 point

-

Swapping parts from "donor" seems to be quite popular. But there will be no progress with your watchmaking skills if you swap (and make inoperative another watch) instead of chasing the cause of the fault... Frank1 point

-

King Charles certainly will be succeeding a most prominent figure. I had the utmost respect for her. I hope Charles to be her equal.1 point

-

It's an almost complete set (Boley). Bidding is at 140 USD now. Ends soon. I will send some pictures after. Bidding ended on 260 dollars. I bid 250 but was overbid the last second. 260 dollars is a really good price! It worked wonders! I did lose a couple degrees of amplitude but nothing really significant. Huge thanks for the tip! You solved the problem(:1 point

-

That's really strange. I have just rebuilt an AS 984 (without Incabloc), and the bottom pivot was too short like yours - not broken, just shorter than the top. I fitted a new balance staff (they're cheap) but then, when adjusting the hairspring, it broke I ended up buying a donor movement and using the complete balance. There's plenty around, so it might be an easier option.1 point

-

1 point

-

Correct. Unfortunately we read terrible advice from time to time here, and isn't possible to always catch and flag it. Sometimes it even comes from experienced members, making it even more dangerous because author's post count. Parts should be dryed from water based solutions only with a small blower, and provided that are either held securely, or kept inside a mesh thimble. And when the last rinse is, as it should be, isopropyl alcohol, there is no need to dry at all, because it will have absorbed all water, and evaporates very quickly. There is no surprise in what has happened to you. It is, in fact, very common for beginners to damage hairsprings one way or another, sometimes without even realizing. That is the reason why when someone shows up here declaring belligerant intentions against his expensive, unreplaceable or just nice watch the best advice that can be given is to leave it alone. And the problem with Seiko hairsprings is even more acute, because these a bit thinner than others, in order to improve overall efficiency. They won't resist not just abuse but any mistreatment, like the use of the torture tool called balance tack. Despite shock protection, it's perfectly possible to distort a Seiko hairspring with a proper shock to the complete watch, something that surprises even some professional. After a Seiko hairspring has been even slightly deformed, the result will be, as a minimum, reduced amplitude, something that when reported here invariably produces page long topics of theorizing and inconclusive discussion, with surprising suggestions going from set the angle in timegrapher, to clean it better, to what about the mainspring. Sorry about the long tirade, I occasionally repeat myself with the hope that someone will perhaps read this and be informed before digging himself down the rats hole.1 point

-

Thats fine G. As long as cookies are on the menu it doesn't matter who bakes them1 point

-

Correct. A shaped metal tool grabs good, "too much" on delicate metal, making much easier to break the spring, especially in the hands of a beginner, compared to a soft one. The latter will slip when excess turning force is applied.1 point

-

1 point

-

It's obviously the pin missing from the hacking stop arm to my Ball watch. I'll be needing that back please.1 point

-

I happen to have so completely borked a few Seiko hairsprings that I happen to know they're anchored from the factory in a slug with shellac, and that slug is anchored to the cock with a screw. Are those sand people shooting at Luke's landspeeder? And Tarzan the Presenter.1 point

-

I have not needed to use those yet. But after the performance i had with a tiny oris kif spring fitting into a 3 slotted setting i wanted a back up plan.1 point

-

Yep, we are recent arrivals to the Duluth area. The plan is to stay here, we're renting while we get more familiar with the area. It really is an awesome place. @MechanicMikeis by the cities too. We might come down to see a Twins game this month, if we do maybe we can meet up. I'm also going to try and make it to the November 19th Chapter 20 NAWCC meeting, if I'm coming I'll let you know! Cheers!1 point

-

My man, when you have a bit of free cash you should really, REALLY do @Mark course. He specifically addresses this very issue in one of the classes. The advice @Nucejoe gave is considered standard practice. You have to remember that in cases where there's a post and a screw, lifting the cock one end at a time may lift the cock at an angle vs the mating plate and with the post/cock hole interface there's very little clearance, so easy for it to jam - especially on 7 series Seiko movements. You then put a little extra effort into getting the cock off and pew, you have an RUD (Rapid Unexpected Disassembly). That very thing almost happened to me on the last FHF 66 movement I've done because I got complacent - thank goodness I got lucky. That's the issue with watching most YT videos (mine included) as many of these little things are glossed over in the interests of keeping the pace of the video up. Go do Mark's course, it's not that expensive vs the amount of money you may lose when things go wrong. At the very least you'll learn what is accepted practice and technique. He also addresses pretty much all the questions you've been posting over the last few months. You clearly have an interest in this hobby outside of just working on the odd watch. Training is a better investment than fancy tools... That's a brilliant illustration - it's obvious you're an artist! Thanks for that hehe1 point

-

Did Waltham make wristwatch movements, or did they just use Swiss movements? Roughly what age do you think it is ? Pics of the movement would be useful. Are there any letters/numbers/symbols under the balance ?1 point

-

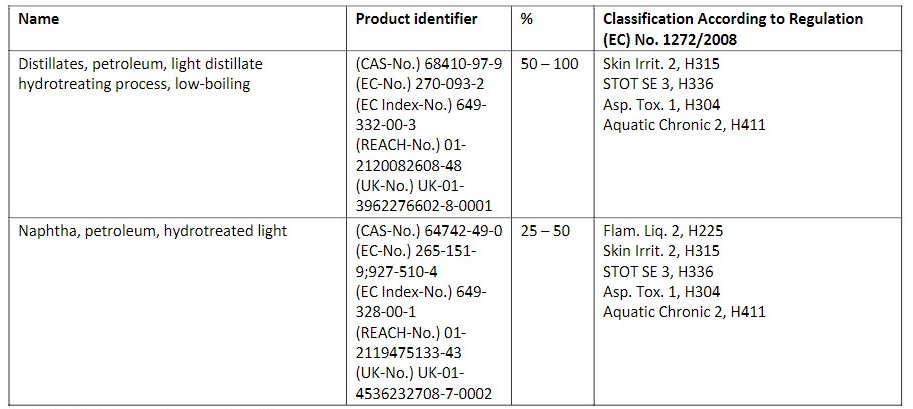

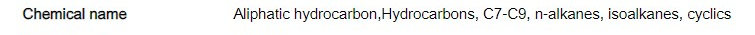

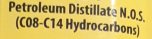

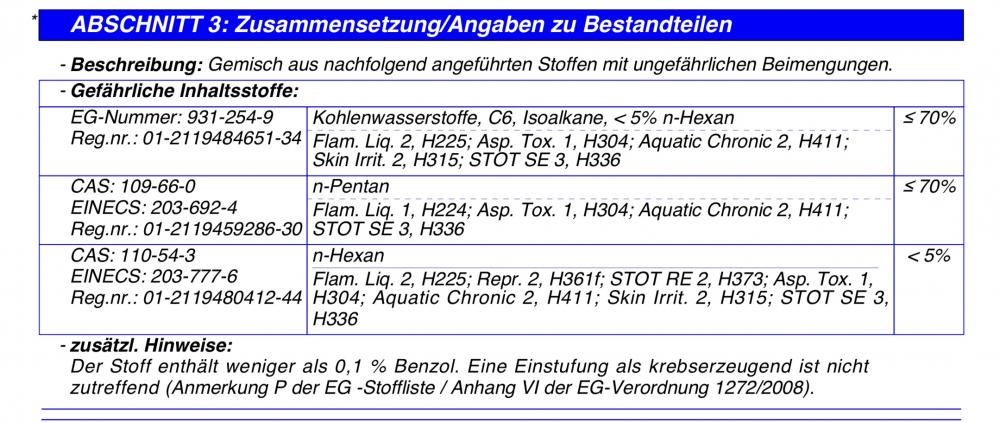

Hello @nickelsilver, I think you're right. A lot of people (including me) use the "trade names" that were created as a convenience and shorthand within a sector or industry ("Kleenex") or even the marketing department of a single leading company ("ESSO Premium Gas") to refer to things as if they were either canonical or categorical. When it comes to petrochemicals, both of the above appear to be happening. As you mention in your posting, gasoline may not be the best option for cleaning watch parts. What we call "Gas" is actually a recipe sold out of pumps at fueling stations that represents the removal (and addition) of tons of things from the feedstock crude oil that in and of itself is a highly complicated organic chemistry stew that resulted from millions of years of the "fermentation" of ancient variegated vegetable matter. There are no fixed points to start from, and then we humans made it even more complicated by adding stuff. My (guess) is one of the biggest problems with using gasoline these days is all the additives, some of which may not evaporate, leaving a deposit or film behind. This may be by design. If I remember right, it was an engineer working under Charles Kettering (of General Motors fame) who first proposed the addition of lead to fuel to eliminate an undesired characteristic of that fuel, that is to say engine knock, or premature detonation. This was in 1921 and a little history of that can be found here: https://bit.ly/3Rdctyw A very interesting general timeline of gasoline additives and their phasing-out (usually due to health or environmental concerns) can be found at: https://bit.ly/3dMfxTA The CAS System The Chemical Abstracts Service (CAS) system, which you rightly point out as a candidate fixed starting point, tracks molecules by their chemical composition. It may be our best option as a lookup because (A) It attempts to segregate things down at the molecular level; and (B) The CAS number is something that seems to be printed on the side of things due to regulatory requirements. At least that number is being divulged. The CAS number(s) listed for ZIPPO liquid lighter fuel as of 2021 are: Source: https://bit.ly/3wxLVzQ The CAS number(s) listed for RONSONOL liquid lighter fluid as of 2015 are: So ZIPPO and RONSONOL do share an ingredient (64742-49-0) and that ingredient is identified in the ZIPPO documentation as the one that is desired ("Naphtha"). But in other places on the Internet it is baldly stated that "ZIPPO removed Naphtha from RONSONOL after the takeover": This, along with a potential recipe change for RONSONOL, is leading to a LOT of confusion. Hydrocarbon Families The next thing we might want to address is the fact that the RONSONOL recipe may vary according to the target jurisdiction. In other words, your RONSONOL may not be my RONSONOL. In the 2015 RONSONOL datasheet, the following hydrocarbon group (C7-C9) is listed in the ingredients: Source: https://bit.ly/3Km4cWx But my RONSONOL the following hydrocarbon group (C8-C14) is listed in the ingredients: So the same branded product does not appear to have the same formulation worldwide! This may be due to regulatory restrictions, economics or some other factor(s) that I am unaware of. It may also be the case that C7-C9 and C8-C14 share enough characteristics to be substitutes for each other and both classes fall under the same generic trade name(s). This is beyond my (current) understanding and knowledge. Questions: - Do you have a can of RONSONOL on hand? - Does your can list C7-C9 or C8-C14? - Can you post a photo of your RONSONOL hydrocarbon labeling? NAPHTHA For those still seeking "Naphtha" as a cleaning agent...good luck. It's actually a family of compounds with a bunch of different trade names and a bunch of different CAS numbers, and therefore a really hard target to hit in terms of procurement. It is also a highly toxic and flammable substance that is subject to very tight regulation everywhere. Perhaps even worse, "Naptha" has many, many aliases: Trade Names Naphtha Hi-flash naphtha Benzin Petroleum benzin Petroleum naphtha Benzin B 70 Amsco H-SB Super VMP Amsco H-J Solvents, naphthas Kwick Dry Naphtesol M Exxon Naphtha 5 Naphtha 5 HI-SOPL Exxsol D 3135 Naphtha 200 Paragon 100E+ Paragon 100E Plus Naphtha HT Shellsol D 25 Terlitol D 60 Texsolve V Shellsol D 40 Sanstar-sol 600D Aromina 150 CAS Numbers Even at the molecular level, the substance we call "Naphtha" is a bit of a moving target. While everything does seem to have a unique CAS number according to the Common Registry of the American Chemical Society, that may not prove to be ultimately true in the sense of a 1:1 mapping between a CAS Number and a Trade Name or even a CAS name. If you search the ACS CAS registry with the phrase "Naphta", you are presented with a single result that has been assigned the CAS number: 8030-30-6. But in that result, the following CAS numbers are either associated or deprecated with respect to the name "Naphtha": 8030-31-7 50813-73-5 54847-97-1 116010-52-7 121448-83-7 345960-90-9 1217187-52-4 Source: https://bit.ly/3TaLkOi But the ZIPPO lighter fluid MDS lists the CAS number for its "Naphtha, petroleum, hydrotreated light" as: 64742-49-0. Unfortunately, this number does not seem to appear in the ACS CAS datasheet for "Naphtha" at 8030-30-6. But when you use the ACS CAS lookup service to look up the number ("4742-49-0") and not the name ("Naphtha"), you do indeed get navigated to a datasheet titled "Naphtha (petroleum), hydrotreated light", which is located at: https://bit.ly/3wvTF5z The ACS owns the CAS system and assigns the numbers. If anyone knows what "Naphtha" is, the ACS should. CONCLUSION Depending on where you look (and when) RONSONOL is either 0% or 100% "Naphtha". "Naphtha" (to me) seems like a bit of a rabbit hole. Lots of fun to explore - if you have the time - but maybe not a path to clear results or a clear way forward in the immediate term to address the original question posed. While the confusion is being worked out we need to get out of this "analysis paralysis". It might turn out that the RONSONOL you use where you are contains "Naphtha" whereas the RONSONOL I use where I am does not contain "Naphtha"...but both fluids may work equally well to clean watch parts. What I plan to do now is an evaporation test with my RONSONOL liquid lighter fluid to see if anything is left behind. I have already identified, characterized and documented the substance to be tested. What remains is to test it. My test protocol will be to A) Fill three clean glass containers with approximately 1ml of RONSONOL Lighter Fluid (directly tipped from the canister). B) Allow the fluid to evaporate under covered but well-ventilated circumstances C) Shine a light through the bottom of the containers D) Attempt to detect if any residue remains Until I get my digital microscope, the best I can do in terms of magnification is 2X or 4X. I'll post my results soon. g. ----1 point

-

1 point

-

Always use finger cots when using it. It absorbs oil from your bare fingers very quickly.1 point

-

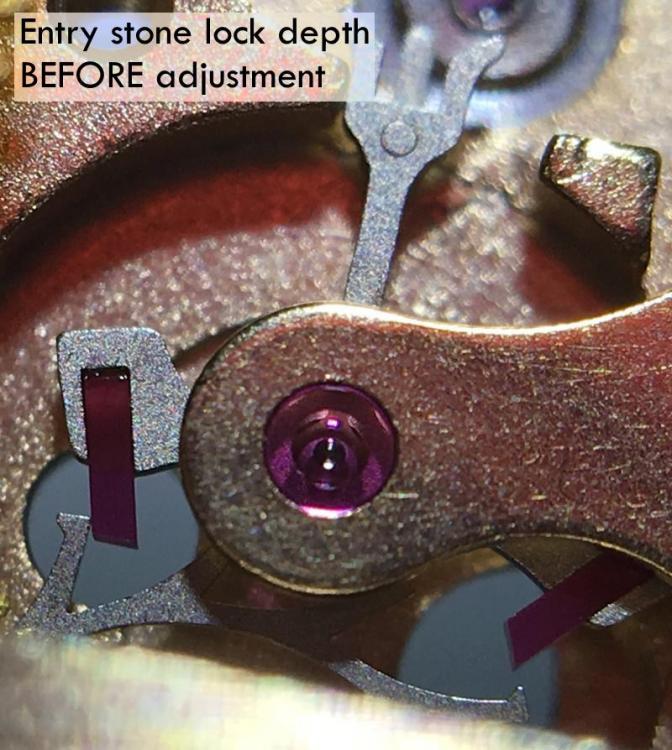

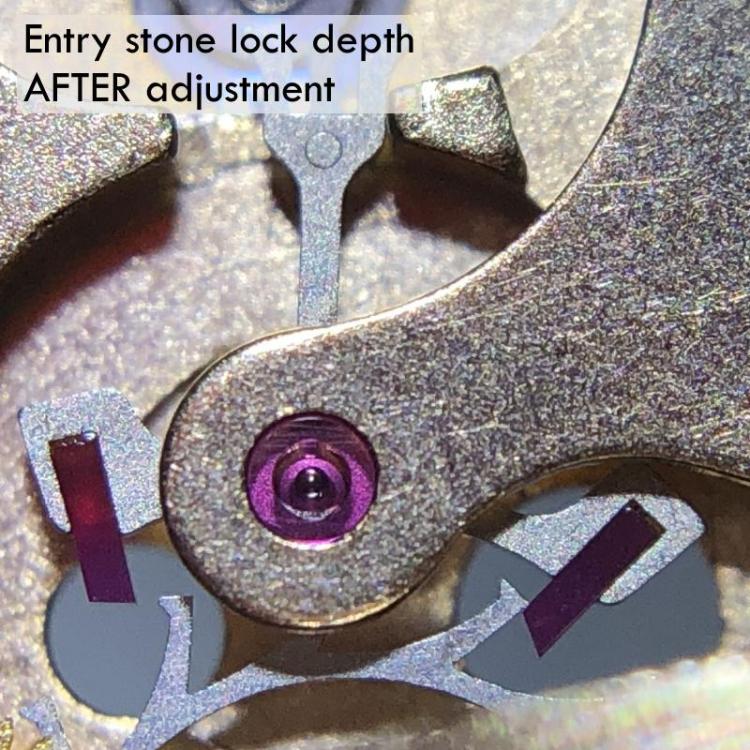

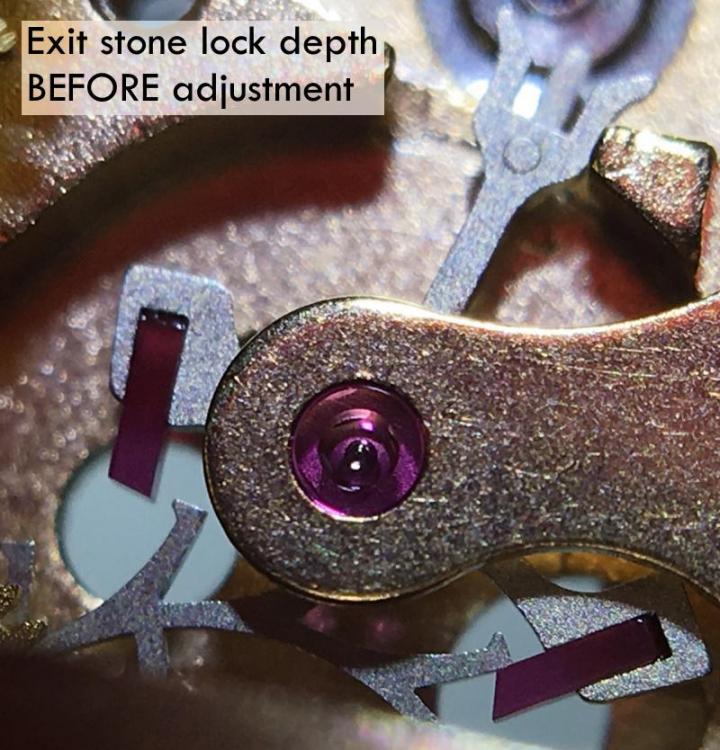

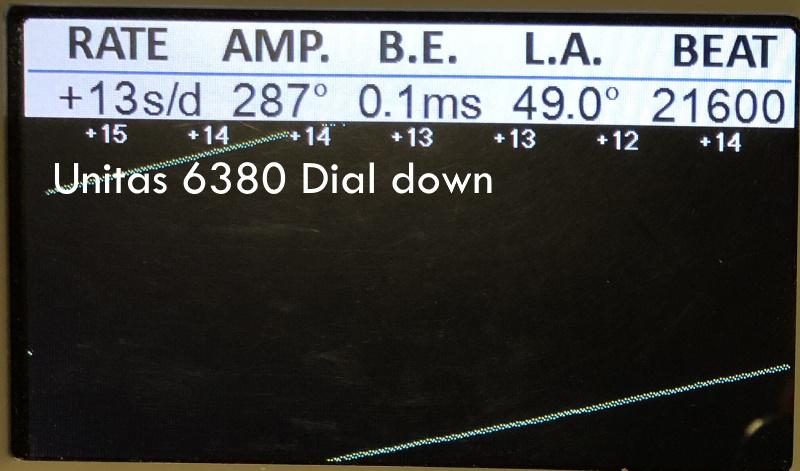

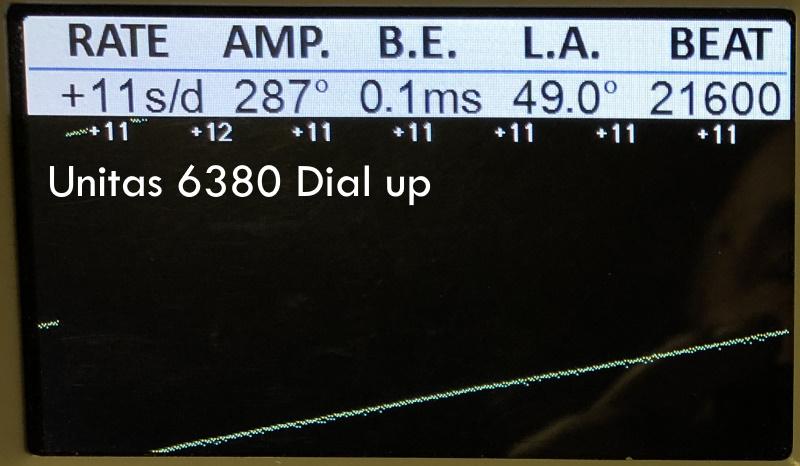

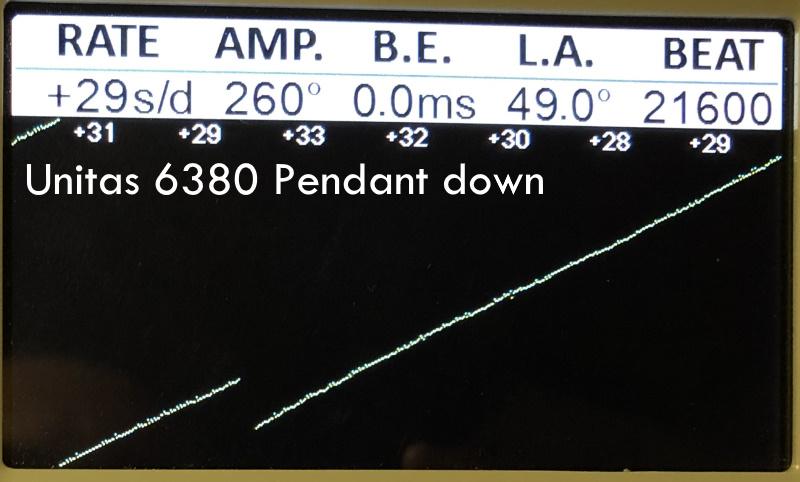

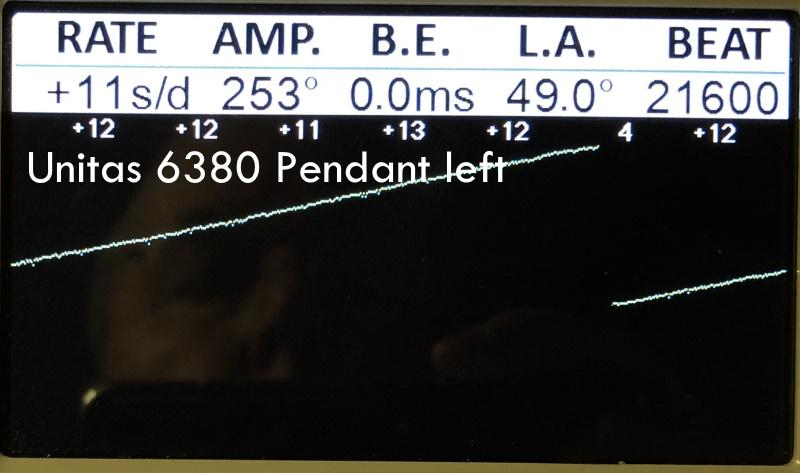

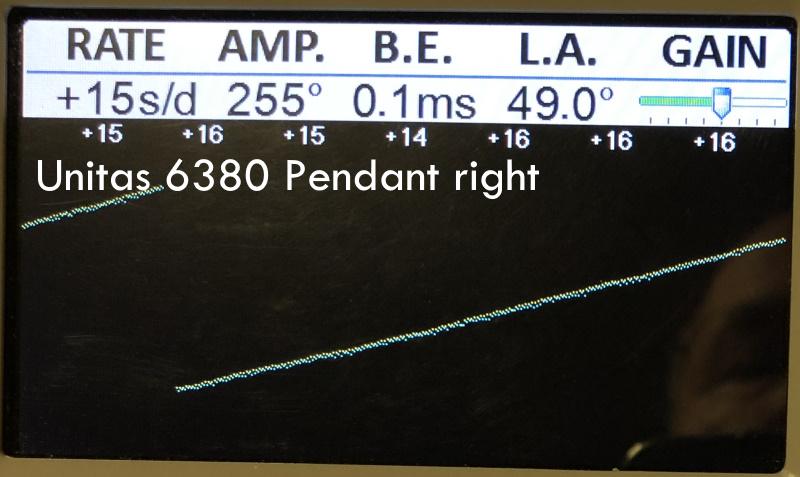

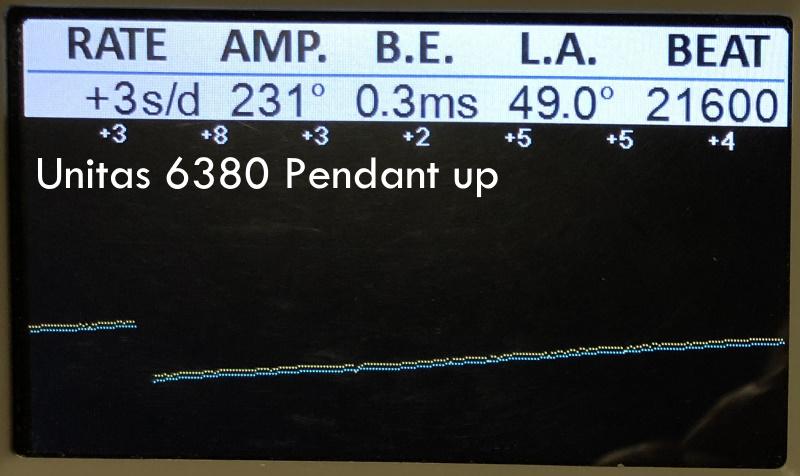

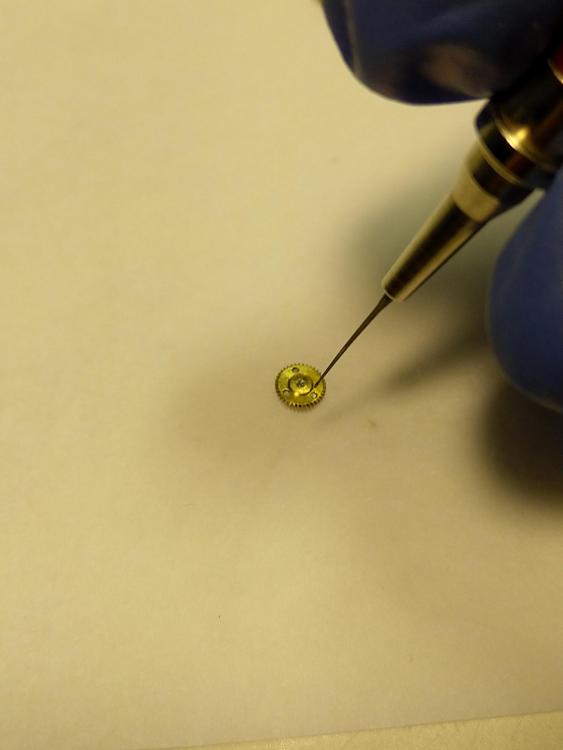

So, I finally got the time to return to my low amplitude Unitas 6380. You were right about that John. There was plenty of room to push both pallet stones back. I didn't just warm them but re-shellac:ed them. The reason for doing that was twofold. Firstly, I wanted to try my newly bought shellac flakes (from CousinsUK). Secondly, it was easier, or at least appeared to be easier, to adjust the lock depth before applying the shellac. The shellac flakes is the best shellac I've tried so far. It's very hard, but not as brittle as the shellac from my clear stick of shellac. To the question of how far I should push the pallet stones back, I tried to follow Henry B. Fried's advice in the book "The Watch Repairer's Manual" where he writes: "In a well-adjusted escapement, the lock should approximate 1/3 the thickness of the pallet jewel." This is a 15 teeth escape wheel 21600 BPH calibre and Fried's example was a 18000 BPH calibre. I believe I read somewhere that the lock depth should be shallower for a high-beat, 20 teeth escape wheel 28800 BPH movement, so I was somewhat ambivalent, but I believe/hope I made the correct decision? I thought about that a lot, and decided, as I was already at it, to re-clean and oil the cap jewels. I also re-cleaned the entire balance and polished the staff pivots with a bit of Dialux green rouge applied to an oil-drenched piece of peg wood. I should really have done this cleaning before adjusting the lock depth of the pallets in order to be able to tell what had the most effect, but hopefully there'll be plenty of new opportunities to test this in the future. Anyway, thanks for reminding me of how very critical this is. With parts being so very small it's easy to underestimate how very critical cleanliness is. Cleaning the cap jewels I made me a new peg wood tool which I was pretty happy about and that I demonstrate in the following video: Anyway, here's the end result of these two activities (cleaning the cap jewels/staff pivots and adjusting the pallets): The pendant up position isn't all that impressive, but I've decided not to dig any deeper at this time but instead reassemble the rest of the watch and wear it for a while to see how it fares. After a bit of regulating I wouldn't be surprised if it turns out to be a pretty decent timekeeper, or at least that's what I'm hoping. Anyway, always being curious, any ideas of why the pendant up position loses about 20 degrees or so?1 point

-

Guess there is a short way to do this too, since I have some reversers lying around I could share how I do this, the chemicals are not nice but what a heck. Here we go Nucejoe all in a PDF for you to keep and cherish . Reverser.pdf And no I don't use V105 or V106 in as lubricant in the reverser.....1 point

-

Today I received an Elgin grade 409 that I ordered because the grade 409 that I have has a balance that doesn't spin (and the seller specifically commented that the balance on the one I ordered spins). That's because THERE'S NO HAIRSPRING!!!0 points

.png.f6ae2040631614914c4a2b30c83ab193.png)