Leaderboard

Popular Content

Showing content with the highest reputation on 09/07/22 in all areas

-

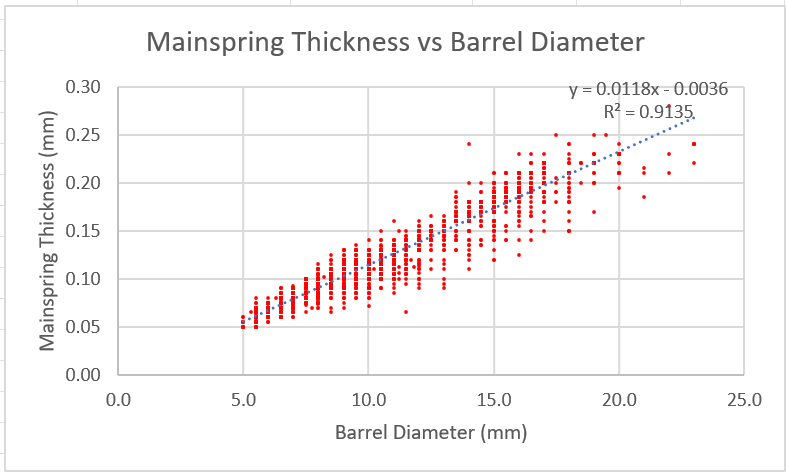

Just throwing this out there to see your opinions. Typically I trust that the mainspring that I find in a watch is the correct one. However, I recently opened a watch and found that it was definitely not the correct mainspring. Someone hacked a T-end mainspring into a normal manual bridle. I could not find any information about the movement online, so I endeavored to find out what the proper mainspring might have been. Assuming that mainsprings are designed to follow the 1/3 area rule (that the unwound mainspring in the barrel should occupy 1/3 of the barrel width), then thickness and length must scale with the barrel diameter. I took every available mainspring being sold on Cousins, and plotted the thickness of the mainspring vs the barrel diameter, and I found an extremely statistically significant relationship between the two (see picture). From the results, we find that the thickness of the mainspring is equal to 1.18% of the barrel diameter, minus 0.0036 mm (this tiny subtraction can probably be ignored). Alternatively, you can take the average of all the thickness/diameter ratios, and you get 1.14%. If you have a low-grade non-jeweled watch, you can add one standard deviation, which will bring you to 1.26%. If you have a very high grade 21 jewel watch, you can subtract a standard deviation, which will bring you to 1.02%. When reading this page about estimating thicknesses (https://www.vintagewatchstraps.com/mainsprings.php), the author says that deCarle and Daniels have suggested anywhere between barrel diameter/100, up to barrel diameter/84. These figures suggest anywhere between 1% and 1.19%, so I don't think my method is too far from reality.7 points

-

Done it!!! Thank you I took out the balance and palate fork. Wheels ok. Inserted everything again. Same problem. Backs to train. Took off Mainspring winder and saw that the click was not in correctly. It was not actually pressured against the click spring. Reset and connected everything. Woohoo!6 points

-

Really interesting work there! One thing I noticed is spring thickness equals ligne size of the movement in most cases. For higher beat watches add 10% or so. This is just an odd coincidence, but I've even dug through the Generale Ressorts book comparing and it really holds true. The formula for length is: Length = π(Rb² - Ra²) / 2x thickness Rb is barrel radius, Ra is arbor radius To the result add about 20%3 points

-

Its looking good Andy, does the misses know that you can use an Iron? could be dangerous.2 points

-

If this is your first autumn on Lake Superior, you are in for some really special weather. One more tool to add to my ebay saved searches.2 points

-

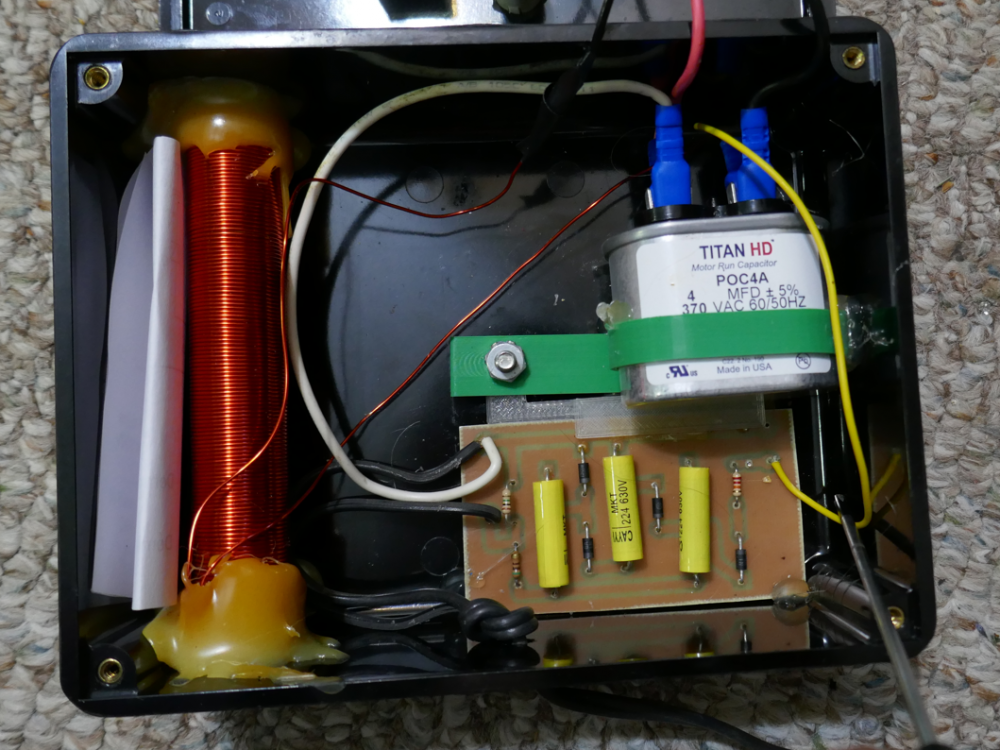

Indeed, and that is one of the design flaws in the older Vigor (have not opened up the modern one). The multiplier is running constantly putting maximum stress on the electrolytic. After replacing the cap in my vintage one (and actually re-designing the circuit layout), I used the simplest solution--an inline power switch!!2 points

-

Here's the complete mystery dial line up from the horizon line of Elgin. Left to Right 7620 - Lord Elgin Futura Black Variant 7625 - Lord Elgin Briarwood 7620 - Lord Elgin Futura 7510 - Lord Elgin Cranston 7516 - Lord Elgin Stratford 3 years of serious hunting in one picture.1 point

-

Sadly she found that out years ago. Its even more dangerous than you might imagine, since she likes to make patchwork quilts, which involves a lot of ironing or all of the pieces all the way throughout the process. I do get roped in to that from time to time. I might add, that I am currently wearing a crumpled tee shirt and a pair of equally crumpled trousers. I may know how to iron, but that doesn't mean I feel compelled to do so.1 point

-

what I'm getting at is you have to be careful to understand what the problem you're trying to fix. suppose you thought you had a poise issue or more typically replacing a balance staff. Then you would check the static poise. If it's an existing balance staff you do want to make sure the pivots are absolute perfect. imperfections on the side of the pivot which is what's touching the poising tool will cause or can cause what looks like a poising issue it's really just a pivot issue. The same as the staff has to be perfectly clean no oil on either the pivots or even the poising tool. Dynamic poising requires everything to be perfect. you have to get the right amount of power through the gear train you can't be having power issues or un-even power issues. Balance pivots have to be perfect to jewels have to be perfect. Hairspring S3 centered it has to be in the center of the regulator pins. Regulator pin spacing has to be correct for the type of hairspring. Flat hairspring a little bit a spacing very little over a coil as tight as possible but still allow the hairspring the slide. In other words if it's not perfect whatever that imperfection is may show up as a poising problem Inow I think this was the same point I was trying to make. if you're not replacing a balance staff. Dealing with an existing watch you do want to make sure that you don't have some other problem. It's amazing the influence that they hairspring regulator pins can do to timekeeping. So basically like anything else in watch repair you need to understand what the problem is you're trying to fix.1 point

-

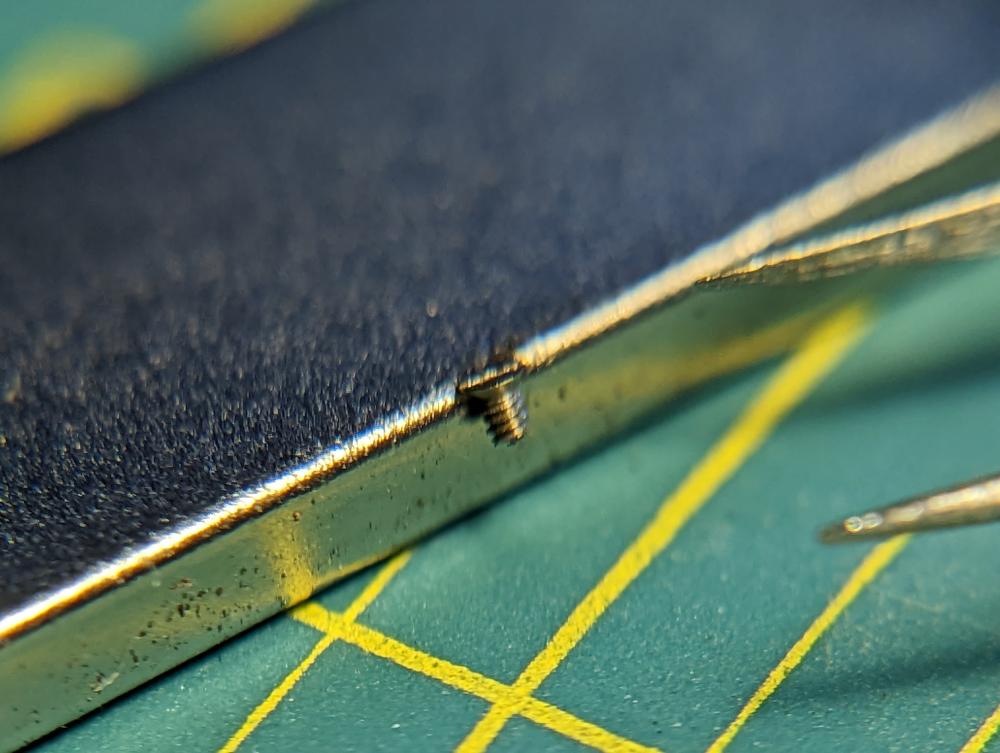

I spent a couple of hours this evening sorting out the worst of the battle scars on the "new to me" watch desk. I would guess it was made in the 1970s or possibly 1980s, with the majority of it being made of real hard woods. The drawers are lined with hardwood too. There are four fiberboard blocks on the top of each drawer plinth to align them with the top section, suggesting it is relatively recent, but the lack of low quality fittings or hardboard drawer liners make me think '70s or '80s. The leather top does appear to be genuine leather, but not as high quality as something from say fifty years earlier. There were a couple of rather nasty "cup marks" on the leather, and lots of light coloured chips to the finish of the wood, on the front and sides. The leather had a few nicks and dings, requiring some careful stippling with the coloured pens. In keeping with the 404 club theme, the damaged areas were fixed with acrylic paints, alcohol pens, and a few wax crayons from Poundland. You can of course purchase specialist materials for this sort of fix, and I do have some, but the Poundland stuff coupled with a little artistic jiggery pokery finished the job quite nicely. The alcohol markers were mainly used on the leather, and the acrylic paints were mixed to a suitable set of colours and applied thinly on to the damaged areas of the wood to blend the damage with the surrounding colour. There are a couple of loose drawer fronts which I will glue up tomorrow, and I will probably also apply a little shellac or floor varnish to some of the more obvious chips in the finish. All in all I'm quite pleased with the results. Well worth the not very much I paid for it. The white "cup marks" on the leather came out with the careful application of the heat of the nose of the iron, through a couple of layers of kitchen towel, and a fairly liberal application of neetsfoot oil. I knew this technique worked with cup marks on wood finishes, but I was not sure it was going to do the trick on leather, but apparently it works like a charm. Just be careful with the heat though. Work slowly, and don't burn the surface. Apparently, according to my wife "It looks like new", but I still think there are a few more dings to take care of before I am happy. After that I think I'll pop a cut to size acrylic sheet over the top of it to save the finish from further damage. That way I don't ruin all my hard work by spilling lighter fluid or some such on the thing.1 point

-

Imbalance weight in the wheel has exact same effect on the rate in FU & FD positions ( horizontal positions) and is constant for a given imbalancne weight, however as you add or remove weight you be looking at a new constant، such new constants may or may not converge with variations you create in vertical positions, as you add/ remove weight . Thats what I think johnR meams when cautions us to be carful and make sure we know what we are doing. Regds Joe1 point

-

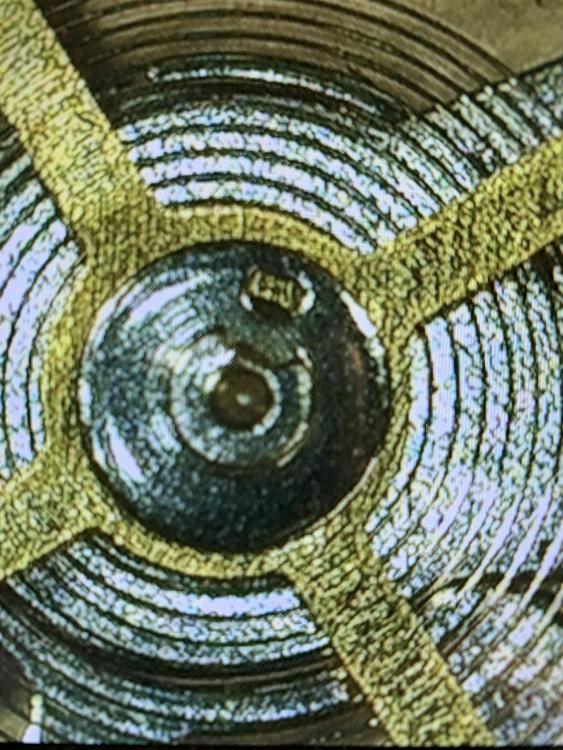

I had a similar problem with a 2789. First you have to make sure the "Day Indicator Guard" (the brass wheel in the pic) is properly seated. Then sit the day wheel on, and using something thin (fine screwdriver), slip it under the day wheel to push the day jumper lever (where I've highlighted). This then allows space for the day wheel to sit flat.1 point

-

The point I was making was not to put the cart before the horse and think that either static or dynamic poising will solve a problem when the endcurve is way out. I realise the difference between the two methods, but it's pointless statically poising before the basics are sorted out on the hairspring and regulator pins gap and how the hairspring breathes within that gap1 point

-

When I purchase a mainspring, I try to get the largest size that is smaller than the actual barrel diameter. So if the true ID is 10 mm, I'll try to buy a 9.5 mm so that it can easily slot in. As long as the retaining ring and the barrel ID are close, then the 1/3 relationship should still hold true, so the model I built should still apply.1 point

-

1 point

-

Well done Ross, a methodical approach pays of, eliminating small areas at a time make the whole process far easier. again well done.1 point

-

Yey. Well done Ross. How good is that you ask ? . ffing bloody fantastic matey, ( haha sorry my dialogue goes a bit wayward from excitement when things turn out well ). So many things it could have been,# lack of power # and many causes of that . Brilliant mate well spotted and well thought out. Keep churning em out matey you are doing fantastically1 point

-

1 point

-

Funny coincidence! But your observation reveals: you are dealing with the finer sort of watches! Frank1 point

-

Well done. You just have to be methodical and work back from the balance, through the gear train to the barrel. I guess that the mainspring wasn't winding? It's good to learn what it feels like when winding a properly working mainspring - through the crown, and via a screwdriver on the ratchet wheel screw.1 point

-

Wow, what a diligent work! You confirmed by your method (maybe for the 1st time, I never read of similar work before), what not only deCarle and Daniels have suggested, but can be found in any horological textbook: average thickness recommended is D / 85. Fine, full jewelled watches D/90, rather coarse watches D/80. From that range you have to choose first, then length can be found from the known dimensions. Figures for clock springs are different, however. How did you find the barrel diameters? Diameter given with springs is that of its retaining ring usually. Thank you for this interesting post, Frank1 point

-

1 point

-

Good point G, this is very common. Points of contact can low on cheap movement holders even on bergeon 4040 depending on the shape and layout of the movement. The cheap ones do not have enough depth on the jaws where the size increased are. I prefer the ones that have a wooden grip on each corner. Here are a couple of pocket watch and larger watch size holders and also a jewelers vice with a little hack to create the same idea. Also a circular full grip holder, here the curved jaws are undercut to help grip over a movement lip, also has a nice stable base that doesnt decrease when mounting smaller movements like the bergeon 4040 does. I mostly use my adapted one as it gives me a nice table to put small parts on when working and the base is permanently sized and stable also. It has a good weight to it unlike other holders that knock about easily, you know its there so to speak. And then the fixed ones that seem far too light for me.1 point

-

Specifically, I was attempting to refurb some VU meters. They are spring loaded with what looks like a hairspring and they have a jeweled bearing on the top and bottom of the pivot the meter moves on. To be clear, my attempt was not successful...but I also didn't make it worse!! I also have a hobby addiction that is related to a tool addiction...so a few months of playing with receivers resulted in a new oscilloscope, a transistor tester, and a 100watt static load!! The solder rework station and the Fluke meter...those I have had for years. The most difficult thing so far was rewiring the tonearm in my Dual automatic record player...those things can make a crazy hum with old wires. As difficult as that was to refurb, watches are still more challenging. I have picked up another Elgin that looks like this one and a Robot that seems cut from the same thread! The round watch movement is not as jeweled and does not work...probably the mainspring...seems like they are all broken. The spare movement I bought for this project also had a broken mainspring. I also messed with a Chinese 2650, a friends son had purchased a inexpensive pocket watch that stopped ticking. It meant alot to him so I took a look. The impulse jewel fell out!! It was just gone, just a hole left...so I grabbed a balance off an $11 movement and got it ticking again. He also had an Citizen Eco-Drive that the hands fell off of, easy fix there, and the band was falling apart. I do try to stay busy.1 point

-

Yep, we are recent arrivals to the Duluth area. The plan is to stay here, we're renting while we get more familiar with the area. It really is an awesome place. @MechanicMikeis by the cities too. We might come down to see a Twins game this month, if we do maybe we can meet up. I'm also going to try and make it to the November 19th Chapter 20 NAWCC meeting, if I'm coming I'll let you know! Cheers!1 point

-

I use a vintage Vigor. It is the one my Dad passed on to me. I have since bought another on ebay for about $75. Here is a modern one, but I imagine it is the same design. I suggest you watch ebay on a daily basis. There is a fundamental flaw in the design that causes them to die, but they are EASY to fix. If you manage to get one that is not working, I can help you bring it back to life. I think they are awesome units...but I am biased.1 point

-

Ah, he was five years younger. Even my old man wasn't mean enough to kick him out1 point

-

My Dad handled me this way - "David, we're selling the house. I'm going to rent an apartment, there will be room for you brother but not for you. "1 point

-

Back in business! I've gotta say, magnetism is pretty great; I'm a fan. I'd happily send a royalty payment to whoever had the idea to point ferrous atoms all in a line. Yes I'll demagnetize those tweezers. Now that it's come up, do you all recommend I take these tiny screws to the demagnetizer? They're >1mm and dial-side but I don't know how small of a field can affect the hairspring. I only lost one HMT click spring that never yet reappeared. But if it ever does, I can put it right back into it's donor movement.1 point

-

@NeverenoughwatchesVer? Not familiar with the term. Ross, in your video, it possibly looks as if the beat is off. Does the watch self start or do you need to set it into motion? Where does the balance sit without any power in the mainspring? BTW, it's disappointing to hear about your local windfarm. Shane1 point

-

Give it time, I'm still in the honeymoon phase. Wait till I have everything unpacked and easily accessible once more. I can't guarantee it will be anything like as tidy. Here are a couple of extra pictures just to keep the nosey buggers happy. .. and now.. drum roll... just because I now can't get the tune out of my head.1 point

-

The scruffy folding table that has ben doing service as a work bench for the last couple of years in my little cubby hole of an office got an upgrade today. We were round at Remake, the recycling workshop and retail shop out in Crieff (worth a visit if you are in the area) and my wife spotted a desk that she thought was more suitable for the task, so here it is. My next task is to organise the tools and such like that currently are stashed in some plastic storage boxes, into those drawers, and arrange some better lighting. During the move I found a missing part from an EB8800 which had somehow pinged into the tray of the printer. I have no idea how that works. I'm sure there is some strange quantum tunnelling effect going on when these tiny parts are imparted with just the right amount of energy from a click spring or a pair of tweezers. Now if someone could invent some gadget to shrinkify that printer, I would really appreciate it.1 point

-

I wouldn't opt for the cheap Chinese mainspring winders and the Swiss set is too expensive. Depending on what watch you may be working on, you may just be able to buy a new mainspring that you can just pop into the barrel from the card it will be wound into when you buy it. $200 will buy you a Moebius Lubricants Starter Kit and you'll be set for life...1 point

-

One thing that you need to watch while placing the movement into the holder is what the holder is going to clamp on. In your very first photo it looks like you'd need to rotate the movement so the points where it engages are located on portions of the circumference where there is a solid section (rather than at a point where there is a cut out. The 4040 has several ways that a movement can be placed and you have to ensure that you have the movement flat and lined up on both sides. You can also flip the 4040 over and use the different configuration on the bottom (or top).1 point

-

1 point

-

1 point

-

I had accumulated a few pocket watch movements for pocket money prices recently, so over the last couple of evenings I've been sorting out the good from the bad and the ugly. Four runners, plus one in need of a mainspring, and one with a broken balance, which donated its spring to the needy one. There are a couple more that I'll perhaps look at later in the week.1 point

-

Start a trend Spectre. Grap a piece of spare land cheap, preferably a field. The field owners charge around £10 here per seller's car, more for a van and buyers pay around a quid each. Yard sales are just one person's gear. Carboots can have hundreds of sellers all wanting to have a clear out at home.1 point