Leaderboard

Popular Content

Showing content with the highest reputation on 08/16/22 in all areas

-

Usually people don't try to tackle replacing balance staffs until They have worked on a few watches and grasp more aspects of how the watch works. Replacing a balance staff is considered a higher-level skills. In the wobbly balanced discussion did you ever figure out why your balance wheel is wobbly? Then perhaps the most important thing is have you identified your watch to purchase a staff because typically get a replacement staff you have to know what the watches. We can if you measure these old staff possibly figure out what it is in get a replacement.2 points

-

I just serviced a Vostok cal. 2431 in overall very good condition. I've had it since it was new (2014) and it was performing reasonably well before servicing it. It's identical to the cal 2416B but has been modified (by Vostok) to make the hour hand rotate 360 degrees only once per day (24h movement). Anyway, in the process, I carefully adjusted the end-shake to be as small as possible while carefully making sure all wheels were spinning freely. After the service, the amplitude became extremely erratic. The dial-up position jumps between 300 degrees and 240 degrees in what I perceive to be a random manner. I can't detect any particular pattern for the variations. It appears that the amount of power reaching the escapement varies randomly. Now, Vostok movements aren't exactly known for their precise tolerances. Could it be that these movements don't handle super fine end-shake as well as modern Swiss movements? Perhaps I should try to increase the end-shake? Of course, and as always, the problem could be something entirely different, but as I did adjust the end-shake to be as small as possible (0.01 - 0.02 mm) that's what I suspect could be the problem, no? I guess my question is, can end-shake and/or side-shake be too small even when all wheels are perfectly free (Libre Sans Jeu)?1 point

-

Hi Charette, balance staff replacement is not an easy job for a beginner. Assuming you have a staking set to rivet the new staff in place. Quite an expensive tool investment. And as John has mentioned you will need to identify the movement first or be in a position to very accurately measure the staff's various dimensions . If the pivots of the staff are broken you will be guessing the staff's length. So an id. Of the movement is probably your only option. Look all over the movement once it is stripped down sometimes the train bridge sometimes stamps, logos or initials on the mainplate. If nothing then matching up the keyless works to a known brand and calibre is your next step.1 point

-

I finally got round to tidying up this rather beaten up Allwyn 21 jewel Automatic from the early to mid 1980s. I picked this up a couple of years back, and it was in pretty bad shape, with damaged hands, the remains of a smashed crystal, which had been superglued (badly) into the case, and a large collection of dirt and battle scars. It looks a whole lot better now, but there is still some evidence of the hard life it has lived. Allwyn were a competitor to the arguably better known HMT, and Titan Indian watch brands, producing licensed Seiko movement watches in Hydrabad. This is actually a licensed Seiko 6319A movement, and I believe the parts are interchangeable. One neat feature that makes it unique from the Japanese version is that the the day disk is in English and Hindi (Devanagari) script.1 point

-

The regulator has three components the boot, the pin and the frame. to release the spring you need to turn the boot portion 90 deg to the frame away (there is a slot in the boot to enable you to turn it). from the pin , this will enable you to lift off the balance cock free from the wheel or vice versa.1 point

-

Hi The tool does indeed look like the base of the Platax tool with out the upper portion or the plate. To remove the balance from the cock you need to turn the boot portion of the regulator to release the balance spring then press out the stud to free the wheel from the cock. remove roller first noting the position of the impulse jewel and then the spring after marking the rim at the position where the stud rests. Take plenty of pictures of the above positions this will enable you to reassemble the balance once the new staff is fitted. all the best1 point

-

I have a bunch of NOS springs with the 180 degree bend, ready for the inserted hook. They're blue steel, old. If the bend is tight, and the hook well formed (not too long and curved to match barrel wall) it's an excellent system- theoretically even better than standard springs with the hook rivetted/welded on. But they're b!tchy to get in the barrel, and if not well done eat up real estate in the barrel. They tend to be found in cheap watches. But the concept is good.1 point

-

It technically can go straight in without the thicker piece of metal that acts as the hook, although the end that is left is not a hook as it hasn't been flattened or rivetted or spot welded to make the hook strong enough to use, so it would more than likely snap when near full wind. The heavier piece of metal that does actually hook on the barrel wall puts force on the end of the mainspring in a different way. The force is directly on the bend on the end of the spring which can handle that force. In this way the bend on the end of the spring isn't trying to open up, as if it were fitted directly into the barrel1 point

-

Both balance jewles appear to be pressed in from the same direction. The jewel in the balance cock looks to be set in place by that flower pattern around it. The opposite jewel would not need as much retention because there is nothing that can push it out except for it's own inertia. Proced cautiously, looks can be deceiving. The other jewles all look to be rubbed in place. Not sure about your second question. I have assembled movements in the same orientation as in your photos. Best of luck. Shane1 point

-

Why not finish it the way you like? I like playing with different finishes on cheap watches to up my polishing/brushing skills and get an idea for what works and what doesn't. I've even done glass bead blasting and Cerakote on some pieces to make them unique. If it was one of the popular Seiko divers, speedtimers or a Pogue that might be a different story, but practice on something cheap so you have some skills in your arsenal for when you do get a popular piece I buy 7S26 movements in quantity from SpeedTimerKollektion. I forget now what they go for but it was pretty cheap. Awesome source of parts and many can be rebuilt to proper working condition as well. Great for practice too.1 point

-

We need to see the jewels first before comment some are pushed in some are rubbed in.1 point

-

That is correct. Also known as the Geneve stop work.1 point

-

I thought I would compared to Rolex so I snipped out some other specifications. When you're looking at the chart you do need to find a watch comparable in diameter size as others have pointed out that will change things. You'll notice that your beating out there specifications you're much tighter than you really should be especially with a watch of that quality. When I'm reading this it's reminding me of clock repair typically by a watchmaker but not necessarily. But usually when a watchmaker looks at the clock things seem really sloppy and there's an obsession to put bushings in. Typically only need a bushing if the hole is no longer is round. No matter how sloppy it is if it's still round that's the way it was made. So then obsession with bushings you can end up with clocks that will not run on the weight there designed for because it's just too darn tight. So yes if you get carried away with getting your tolerances super super tight you're going to have a running issue in the watch. Especially if the watch was manufactured with more liberal tolerances that requires greater spacings possibly bigger hole diameters for pivots.1 point

-

Hi there are as many designs as there are clocks some are plain and simple others ornate and reflect the design of the top, others are plain flat tops with an ornate moulding. as you can appreciate from the examples its difficult to pin down any one design. But looking at your clock I would assume it was something like a moulding reflecting the design of the top.1 point

-

other than looking similar there are many difference Since I have only seen the tip of what must be an extensive iceberg of information you have on Timex watches, I would surely take your word on this. Not having the parts lists of the M25 and M105 to compare, I was only speaking to what I had previously read. The internet, can't trust any of it. Shane1 point

-

Nice CAD work. VWatchie, also remember that Nickelsilver probably also modeled those parts in theoretical perfection. All dimensions spot on, lines that should be parallel are, all angles are accurate without internal filleting or external rounding, concentricity or T.I.R. zero. Which is all easy to draw, very (impossible) to obtain. Watch parts (even "cheaper" mass produced watch parts) are probably closer than most but will (on average) deviate from print. That's called acceptable tolerance. If you don't want to hand fit every part in every assembly, you assemble using fixtures adjusted for parts assuming the widest possible "acceptable" deviations. And as Nickelsilver said, while under torque is not the same thing as when it is free wheeling. Shane1 point

-

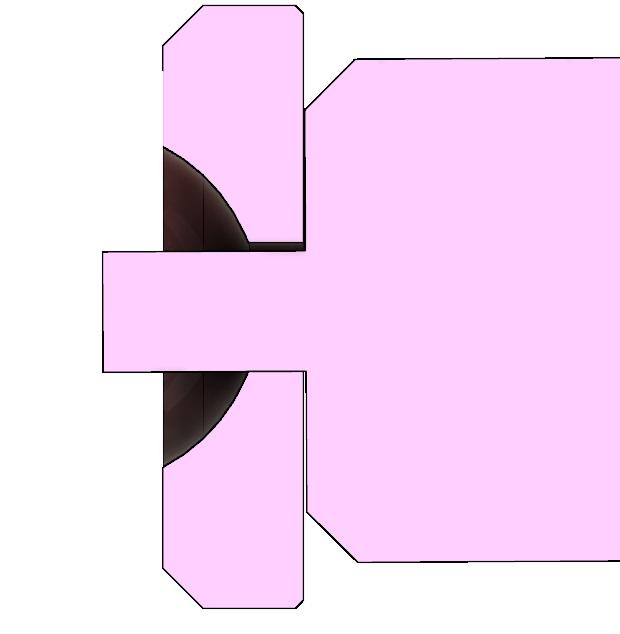

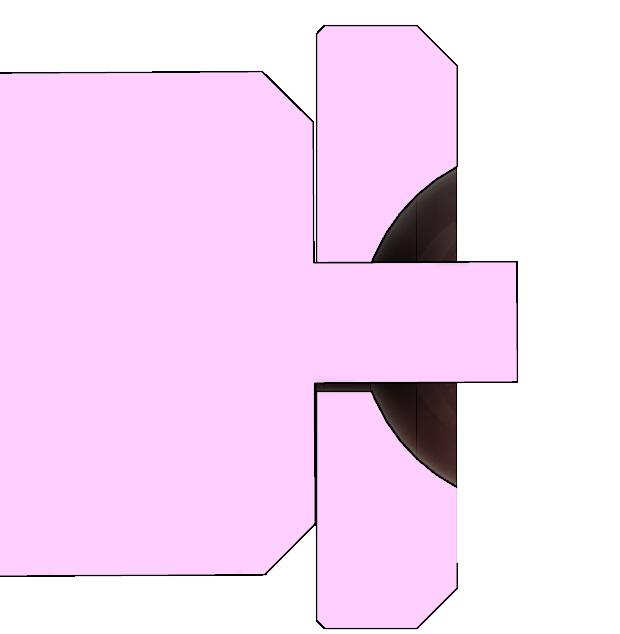

Here's a cutaway with close ups of the two ends. The sideshake is 0.01, which is about right for a 0.15 pivot (this size). If the arbor is under tension, it will generally want to tilt- like when you try to wind the watch with the wheel train in but haven't put the bridge yet- everything tilts . With a very small but existant endshake, the shoulders of the arbor can touch both flat surfaces of the two jewels at the same time. With a little more endshake, as the tilt is restricted by the pivots, it will become possible for one shoulder to touch one jewel (and is almost certainly the case 99.999999% of the time), but both shoulders can't contact both jewels at the same time.1 point

-

Just a PSA for archival purposes. Bought the Esslinger cheapo chinese version of the bergeon #2 presto https://www.esslinger.com/watch-cannon-pinion-and-watch-hand-remover-tool/ It's a high quality tool that needed a bit of shaping of the jaws as the gap was too big for a seiko cannon pinion but it works great and it's about 1/5th the cost of the bergeon version.1 point

-

Depending on the sideshake and diameter of the arbor at the pivot, you can have a situation where the shoulders at both ends are making contact with both hole jewels at the same time if the endshake is very small. It can be exacerbated by very short arbors too, particularly the pallet fork*. 0.01mm is hard to visualize, I made a sketch of an arbor with jewels and exactly that much endshake to illustrate. *Troubleshooting a new-build tourbillon a few years back I had a situation where the fork was ultra free, with "feelable" endshake, but the watch was having amplitude issues- ended up adding 0.01mm endshake fixed it.1 point

-

.01 - .02 mm / .0004 - .0008 in, is quite small. Some mechanical assemblies require a higher degree of clearance do to a wider acceptable tolerance within all the components making up that assembly. Once you pick a design philosophy, you need to keep with it all the way through the assembly (assembly is being used as both a noun and a verb). Dimensional and angular deviations abound, total indicated runout of the shafting and the pinions and pivots machined into them, as well as the ID in relation to the OD of the gears those shafts are pressed into, the engagement between the involuted gear pairs, times how many pairs within that gear train. Not to mention, if the pivots are at the end of a tapered shaft, you have also restrained them all radially as well. It's hard to say what the problem or problems might now be but if it was running better before you tightened it up, is it really perfectly free now? It sounds like you will need to loosen it back up. Let us know how you make out. Good luck. Shane1 point

-

Frank ( @praezis), please excuse my poor math skills So, just making sure I'm doing this right, 23 e5 is 23 to the fifth power. deg = 5.5 X 274 X 18,000 / 23.e+5 12 = 27,126,000 / 23.e+5 23.e+5 = 27,126,000 / 12 2. e+5 = 2,260,500 You must have rounded 27,126,500 / 2,300,000 = 11.79413 degrees. Woot! Thanks!1 point

-

A tiny update, in case anybody looks at this later with a similar question: I ended up masking the pendant tube and giving the pusher bodies in the case a little bath in WD40. One cup of coffee later, they unscrewed without objection using some needle nosed pliers. I'm not sure why this operation scared me more than disassembling the chronograph, but there you are. Now I'm hoping the replacements I've ordered are the correct size.1 point

-

Hello, I would like to know why and how the convention appeared to make the minutes hand the longer one. The second hand was typically small and on its own, if present at all. One might think that the more the hand moves, the smaller it should probably be from the energy efficiency perspective. The hour hand moves the least, so it can be the largest, and it is more important to know, if it is 3 or 4 in thers of hours, instead of 15 or 20 minutes past. Any insights will be much appreaciated. There is an argument that it might have been carried over from the clock days, where time was set by moving the minute hand, as making the minute hand shorter would make the pushing of the hand much more difficult, but I am not buying it since the invenntion of the setting mechanism could have addressed it. Thank you.1 point

-

I would have to agree with Graziano. Knowing it's before the hour or past the hour is all the hour hand really needs to tell you. How much before or past is significantly more important (if not everything happens on the hour). The second hand is typically much thiner (I assume) because if you are bothering to have one it would be easier to see which one of the five, six or how many beets between the seconds it has, you were looking at. Shane If efficiency was the main goal the hands would (as you suggested) probably look much different (thinner, shorter and probably counter balanced) but these changes would interfere with your ability to quickly, accurately and reliably interpret the time.1 point

-

Hi there Dmitry ,minutes must be more precisely indicated to give an accurate time reading; simply pointing somewhere between numbers won't work. Therefore, the minute hand extends farther than its counterpart usually to the markers on the edge of the dial so as to provide an exact accounting of the time .With the minute hand being longer, you smoothly travel over the hour hand without it getting in the way.The fact that the minute hand is always longer, and often thinner, than the hour hand, serves a very specific purpose, though. The hour hand doesn't have to point specifically at the hour number it relates to for a person to know what time it is. For example, if the hour hand is pointing anywhere between two and three, anyone capable of telling time will take this to mean it's two o'clock. Probably carried over from early cock days when you pushed the minute hand to set the time so that you would get past the hour hand without touching it . Cheers ,Graziano1 point

-

The line on the timing machine looks good, and the position of the fork at rest looks good, and the position of the escape tooth on the pallet at rest looks great, so yes, you are in beat! I don't know if there's a gain adjustment on that model, but likely playing around with it, or squeezing the microphone tighter on the movement, or slipping a piece of paper between the movement and the pickup prong of the holder (or something) will clean up the signal so the displayed beat error matches the line.1 point

-

You must have missed the web site link above https://violatweezers.com/1 point

-

1 point