Leaderboard

Popular Content

Showing content with the highest reputation on 05/17/22 in all areas

-

4 points

-

3 points

-

2 points

-

Glue a nut on with super glue. Glue can be dissolved later with acetone.2 points

-

This is a very old movement, with no visibility of the escapement (or much else for that matter); there are so many things that could possibly be robbing amplitude. If you are accustomed to refinishing pivots, bushing holes, replacing jewels, making staffs (I wouldn't be surprised at all if the staff is in poor shape even if somewhat functional), and setting up escapements then you might get it to run OK. But these sorts of movements can take hours and hours for an expert, don't get discouraged if you can't get it to run decently.2 points

-

1 point

-

If magnetized hairspring might be sticking so you do get low amplitude and the watch runs fast. There is a free app to download on your device called WATCH ACCURACY METER, gives you the rate and beat error, not bad it will do until you decide to buy a tg. Using it you can see the rate which if crazy fast would indicate hairspring issue such as sticking.1 point

-

1 point

-

If you can make sure the cannon pinion is thoughly clean inside and out. And the hour wheel also inside, maybe a gentle clean inside with a smoothing broach might dislodge some old oil that maybe in there. If after that then i think we can only assume that either the cannon pinion or the hour wheel is not from this watch.1 point

-

My current repair has a beautiful, original seconds hand which has lost its fitting tube. The hand was sat on the pinion when the watch arrived, but it was slipping and fouled the minute hand. I'd prefer to re-use the hand rather than replace it, if possible. I have a donor seconds hand with a tube that fits the pinion. I was thinking about applying a very fine dot of epoxy with an oiler and fixing the donor tube to the old hand. Any thoughts about that, techniques or alternative fixes? Shots of the crime scene (side-on and underside) attached.1 point

-

1 point

-

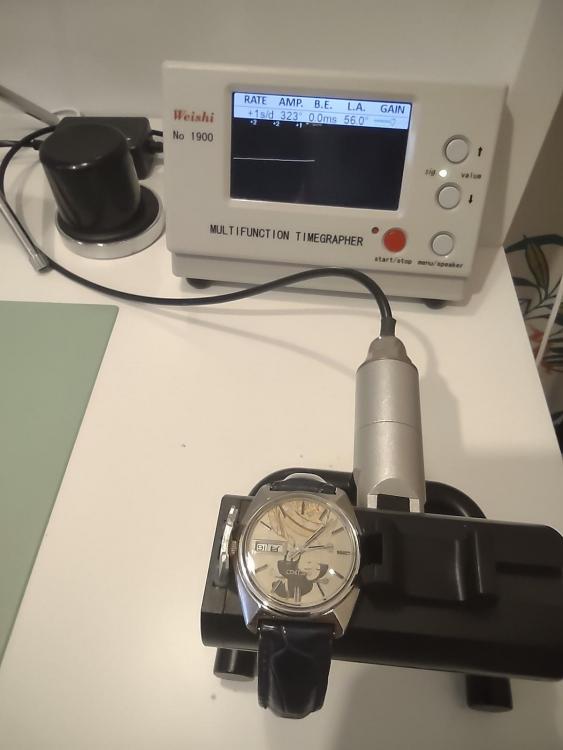

One of the things that is bad with vintage is it would've been nice if you could put it on the timing machine in the first place and evaluates the condition and how far you want to go at this time to fix the problems. But often times when the watch is not running at all you end up having to go so far into it only to find out that now you're going to require a whole bunch of well basically the timing machine gives you unhappy news. That fixing all the seemingly mechanical issues as only been half the journey and yes that can definitely be an issue.1 point

-

1 point

-

I just apply it to barrel wall (don't over do it, you just need a small amount). I usually coat mainspring with a thin film of Moebius 8200.1 point

-

This a picture of the back plate of a longcased clock movement I'm working on, just to show the lengths that the bad repairer will use to botch a job up. I've had to replace a good few of the bushes, realign the pallets, as they weren't even in line with the escape wheel. They had used a piece of Mainspring to reface the pallets , forgetting that that they are supposed to be at the same angle as the originals otherwise they really aren't a lot of good. That's just for starters. It's just one of those jobs I really wish I hadn't taken on.1 point

-

I think if you analyze this discussion you discover that several people fail to grasp what a timing machine / timegrapher is all about. Yes it is used for regulation of a watch but it's also used for troubleshooting purposes for which I find it far more useful. Nothing wrong with the timing machine for the most part they work really well. The timing machine is showing you exactly what's going on the problem is a user interpretation of what exactly watch repair is especially with vintage watches like American pocket watches. A lot of times I will relate learning watch repairs similar to learning to become a doctor. It requires a lot of study and a lot of practicing. All of us on this group are currently practicing. You never going to meet an expert watch repair as there's always something new to learn always something to become better at doing. As you start off in watch repair you face the challenge of successfully disassembling the watch cleaning reassembling lubricating possibly changing a mainspring not destroying anything. Then if something accidentally gets destroyed you can just replace it typically and if you're lucky you have a running watch. Always aside a beauty when the watch starts often runs. Then you get the bright idea let's do vintage what would be the problems? Vintage American pocket watches as serial numbers because the plates were made in batches. Usually the escapement's were all adjusted by hand. This is where you start swapping escapement components you'll have problems. Those problems typically don't come up in modern watches. So you typically can't swap your way out of a problem like you can with a modern watch you going to have to fix stuff. In order to fix an American pocket watch you need understand how everything works how everything runs and you need to know what everything is supposed to look like. Is a certain degree of one thing with fact another thing which is why can't give you a step-by-step of how to fix in a vintage American pocket watch. The timing machine though can point you in directions but not entirely an exact science unfortunately For instance I have a PDF this came from a day of timing machines that were just paper tape paper tape came out you looked at the graphical display you can look at the timing chart he didn't have all those nifty numbers you didn't have to get obsessed with my amplitude isn't high enough oh dear the world, come to an end he didn't have any of that nonsense is had graphical display. Does the lines looked close enough together is fine you don't worry about the beat is you don't have a number again to look. Numbers unfortunately can be distressing especially with a vintage watch. So basically nothing wrong with the timing machine it's telling you you have a problem. Then you have to decide whether you want to try to fix the problem or if you're happy with the watch running don't worry about it. Or perhaps set the watches side with a note that when you get more proficient at things didn't go back to the watch and fix the problems that you perceive that it had that you're just not ready to fix. Because unfortunately the start fixing some vintage stuff you need some tools conceivably a lot of jewels depending upon how far you want to go with this. Timing-Machine-Charts.PDF1 point

-

If it's the one you have in the picture you need to understand how to use it somewhere on the website we describe how to use this. Usually the generic is you put whatever is magnetized in the middle you push and hold the button and slowly pull it out to a distance of I don't remember how far away you have to go. Then I can't remember when you do in the watch movement whether you want to do it in two separate positions or multiple positions. But the key is you have to put it in the middle and then slowly pull it out as opposed to just putting it in pushing the button which conceivably will magnetize the item.1 point

-

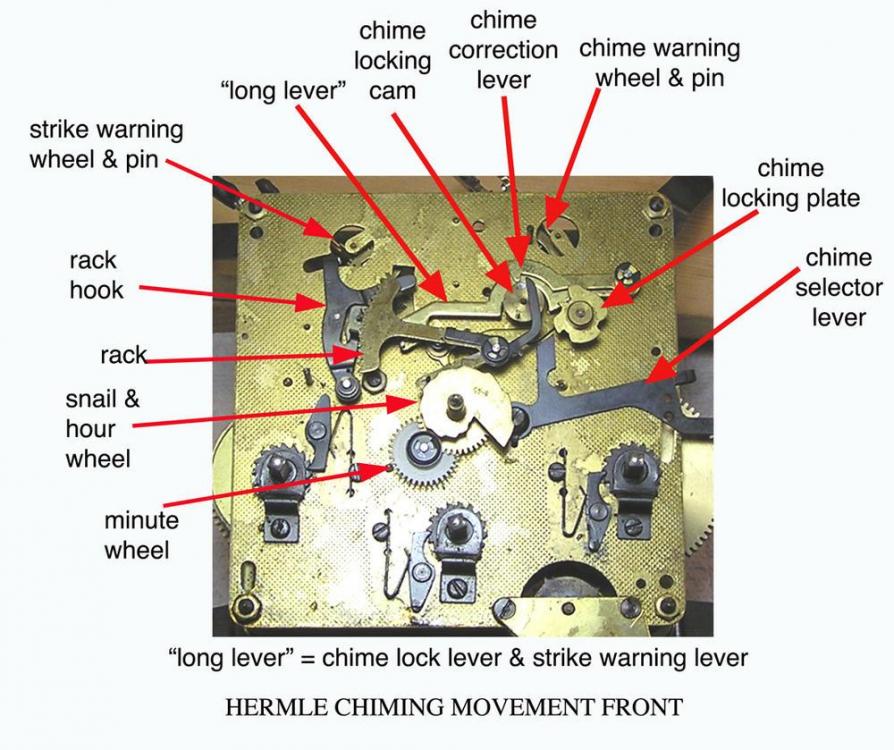

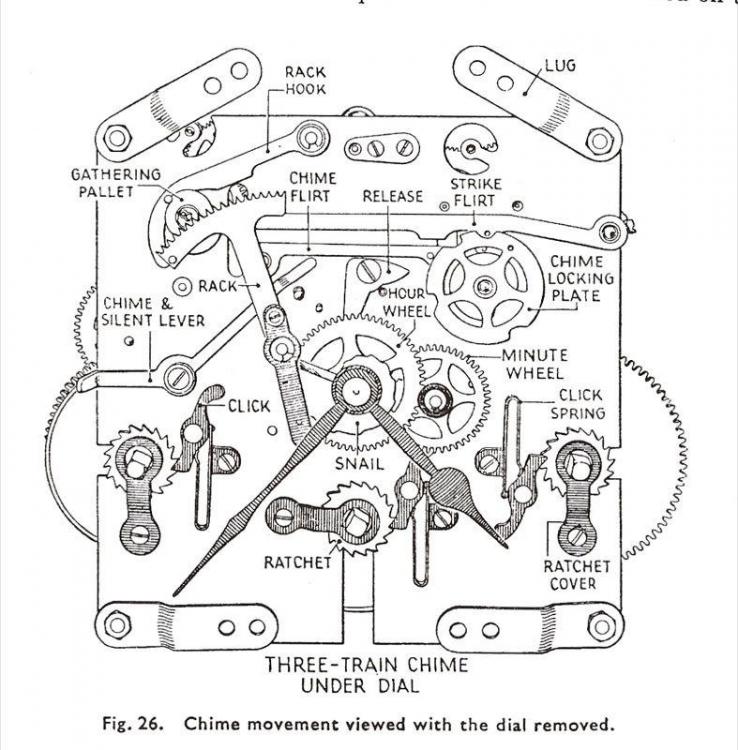

One can anly concur with the advise given, startwith a strike only before moving on to the westminster as there are many complications, the auro correction , the timing of th warnings, and the cams and levers. You need to do a bit of research and reading before attempting the westminster. Hi There is a site by Barrie Smith (no relation) on siths clocks you might find usefull reading. Attached a couple of picks explainging the fromt plate levers. They differ from clock to clock but do the same job. De Carles book on clock repairing and Mike Watters book worth a read also Laurie Pennman and Brian Loomes.1 point

-

These are the unevitable setbacks and frustrating moments on the long way to mastery. I learned that especially in watchmaking you cann‘t imagine what can go wrong before it has gone wrong. I would wait with the Omega…1 point

-

Have you shown all the pieces? according to Dr ranfft there ought to be more.1 point

-

1 point

-

1 point

-

@PostwarO27 If you are anything as terrible with dynamic poising as I am, then we can't tell a Chronograde oscilator apart from a regular one anyway. I go ahead and fix the watch with what you got, it'll run accurate. I mean you don't plan to send the piece in for COSC approval do you? Oh just noticed you scavanged the whole balance complete from the donor, its just adjusting for various positions then.1 point

-

Yes that's definitely a set mainspring. Then it looks like a standard tongue end. The critical dimensions are the width you don't want to go to wide or you won't feel the close the lid and it won't work at all. Then the thickness and the length can vary a little bit because you may not actually Billy get an exact spring.1 point

-

Classically in any watch under power the pallet fork has to snap. This is what supplies the energy to the balance wheel and if it can't supply energy way out your amplitude is going to suck then I assume from the picture you put something together upside down? Because the pallet fork has to go into the cylindrical opening to engage the balance wheel it does present a problem. This means people either assemble it upside down which I find a pain or they do it the other way but then you have to hold the pallet fork in place with a clip and bring bridge and the fork down and then of course make sure everything aligns otherwise things get broken or damaged. The definition a broken damaged are broken pallet fork pivots quite common. Pallet jewels knocked out of alignment because they end up on top of the escape wheel. Or sometimes escape wheel whole jewels will break and/or pivots because it's really hard to see what you're doing when you're pallet fork and escape wheel are hidden between the plates. Oh and other little things this is a seven jewel watch seed you want to make sure you lubricate it properly convinced I have a lot of power loss and did you lubricate the escape wheel in other words escapement lubrication which is hard to do because you can only see the edge of the escape wheel so that means you only put the lubrication on the teeth itself and hope that it spreads around.1 point

-

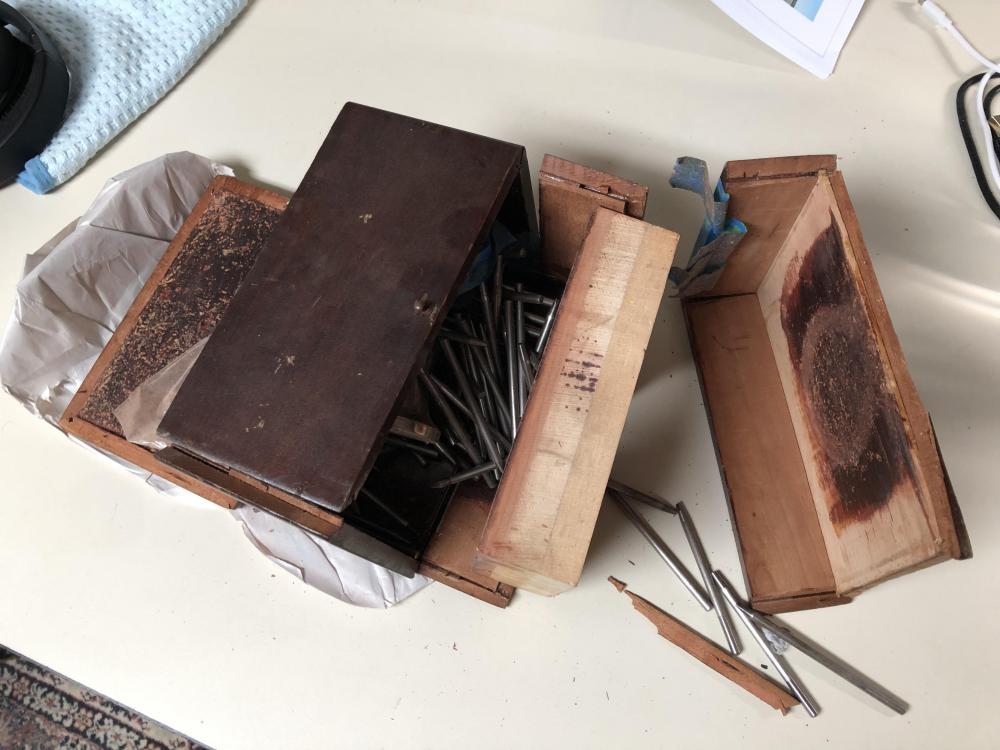

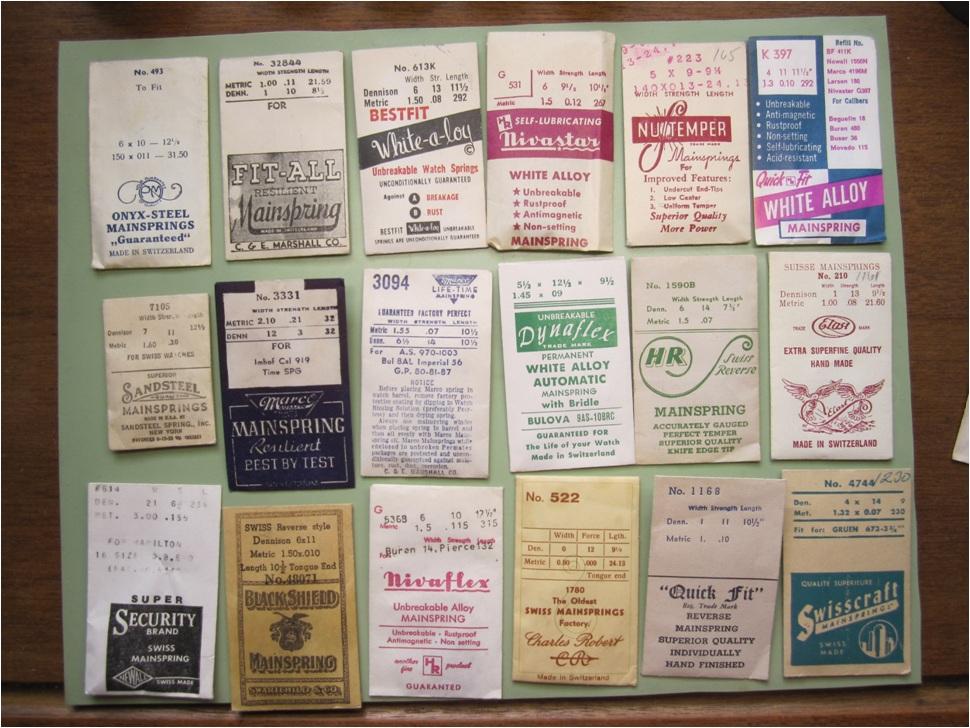

Barrel diameter size is only specified for modern mainsprings. Typically on older mainsprings it's never mentioned at all unless? Unless it's made for a specific watch in other words the only time you care about barrel diameter is if you're going to shove the spring in from the holder it's in. Otherwise with holder packaging especially when it's the older blued steel Springs a lot of times they would be in holding rings much much larger than the barrel. Then I have a image here for you here's a sampling of a whole variety of mainspring packages how many of them have the barrel diameter? Then I also have a picture of what the mainspring ring looks like if you're not familiar with it springlike that it billed to just push it right into the modern barrel which is why a lot of hobbyist watchmakers never end up with mainspring winders because they typically buy brand-new Springs and just shove in Microphone off lights in them lot of how to live in by the spring strangely enough it is a spring but it will line of not being used to set spring take them out of the barrel much bigger circular route there's nothing that Mister them back Then the third image mainspring is when their brand-new the top one that some modern white spring you'll notice the back curve it has. Some modern Springs website which back curve they have more back curve the front curve it just depends on who manufactured which watch was manufactured for etc. the spring below strangely enough is a good spring but in my mind borderline on not being good least it opened up. Usually when you take out blued steel Springs their circular they have zero resemblance of the taken aback curve and there's not much bigger than the barrel. They will work they will run the watch but not for very long because it just no energy left is no spring left in the spring.1 point

-

Let us know when you you have it i stalled so we discuss the outcome.1 point

-

It begs the question when a new movement can be had for the princely sum of £2.30 plus vat and shipping....1 point

-

The spings ability to unwind itself is where its power lies. A worn spring would tend to be more coiled up when relaxed out of the barrel. The fact that it is not a tight feed onto the arbor would point to someone over prising it to fit it onto the arbor or possibly the incorrect spring. Generally a barrel diameter is also required as well as the height, thickness and length of the spring.1 point

-

I really don't think you want that mainspring as you're going to have to modify it. Then did you actually measure 2.55 mm for the width of the spring? Brings up the problem of you want to go up in size or down in size the words maybe 2.50 mm? I snipped out an image from the mainspring catalog and I mark the one that you like but notice those initials I wonder what they mean? DBH anything we should worry about? Then the rest the dimensions? Any time you're dealing with a vintage watch your lucky to find a mainspring at all. Things you want to worry about art making sure it's not too wide because otherwise you won't builder close the lid and if you look at the existing barrel does it look like the barrels all scratched up because maybe the spring was too wide? Then there's the strength that's the thickness but that can vary a little bit because modern springs tend to be stronger than the blued steel Springs. Length not much you can do about unless you want to modify the end which you really don't want to do. Oh those initials again what the heck did they mean? You want to get a spring that doesn't have those initials after it as that's a specific type of end that you don't have. Let me see if I can find a picture from the beginning of the book? From your picture it looks like normal type end which looks bigger than usual because it looks like somebody made a homemade end. The DBH Is commonly used in Elgin pocket watches and you don't have an Elgin pocket watch. So it wouldn't really be your best choice1 point

-

Ok. What is letting you think there is not much tension in the spring ? Is it quite coiled when relaxed ? I would still be curious to see what sort of performance you have with this spring. Ok just a question to ask how much inspection have you made regarding the rest of the movement ? Visually to the naked eye it may look ok but under close inspection with a loupe or scope may very well tell a different story. If the mainspring is fatigued and this may not be the original as you say. So could be two mainsprings worn out then the rest of the mvt may well have a lot of wear, logically.1 point

-

Hi kiwi. One of my favourite fruits by the way, considered as something of a super food by some. Oh yeah watch forum. What are you wanting to know matey ? Just about the model you have ? Its value ? Some googling may give you a few answers. Or about the watch company's history. Certina has been a good make since its beginnings. Founded by the kurth brothers around the end of the 19th century in Switzerland at the base of the jura mountains where a lot of swiss brands originated from. They followed a path of a good marketing strategy, sending their watches to the depths of the ocean and to the peaks of the himalayas. And recruiting famous folk such as Ali to adorn their wrists with them all in order to promote their brand. A tactic employed by other brands, more famously Rolex who were masters of it. So yes in history a very good brand. Sad to say that all this information is more or less irrelevant to the Certina brand of today as the company was taken over by the swatch group in 1983 . As you can see by my disgruntled face that fact bothers me. Maybe it was out of necessitity for a failing company or maybe it was the family just wanted out and a large lump of cash in their pockets, i suppose who can blame them. Either way another quality brand plucked from history by swatch to add to their collection , note my annoyance once more. So probably still a good watch probaby still made in the same factories made by the same people but under swatches rule. Your watch is still swiss made so of resonable quality probably on a par with Tissot possibly a bit better as im no expert on Certina's quality of this period. All this besides it was your old man's watch, its a nice watch and you have good sentiment my friend and your children will cherish it. I have my grandfather's russian sekonda, its a battered piece of shite but its my favourite watch. X1 point

-

1 point

-

No, that is how the slipping should be, nice and gradual. Just wind the Citizens manually. 50 back-and-forths each on the crowns should be plenty. Then leave them to run down undisturbed. If you wear a Seiko for two or three days consecutively, that should be enough to fully wind it, unless your day-job is as a living statue or similar.1 point

-

Hi LWS Thats a nice old guy, there is always somthing that appeals about a clock. On holiday I found one that plays a musical box on the hour but had to back down I have a house full of clocks, so had to leave it shame.0 points