Leaderboard

Popular Content

Showing content with the highest reputation on 04/11/22 in Posts

-

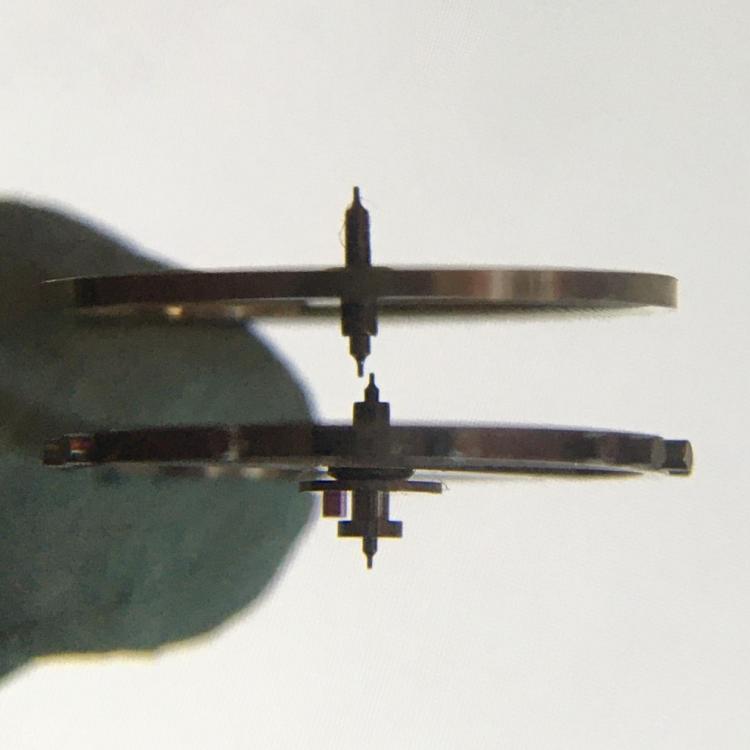

At least we had a decent enough picture to see the image so I snipped out the offending hairspring. One of the things you always want to do with all of your watches is to make sure they hairspring is centered and level. It's always quite amazing all the clever things in hairsprings can do to touch things that they're not supposed to.4 points

-

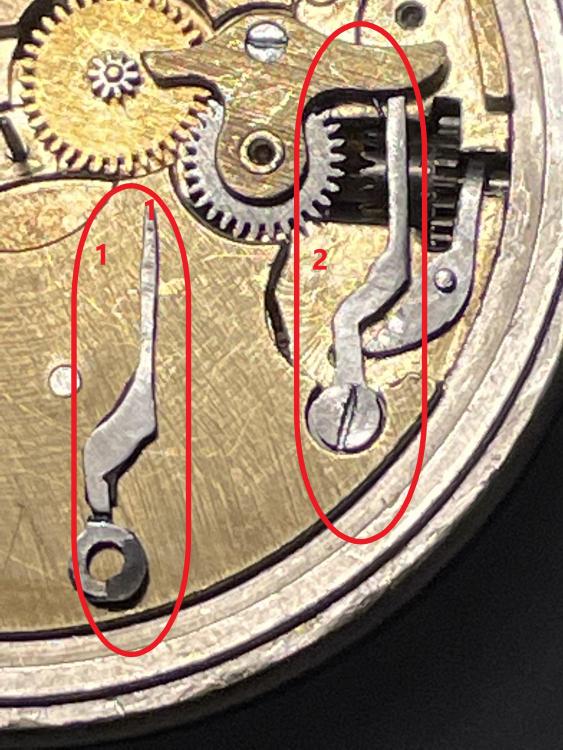

Ok...here we are. Thank you JDRichard for your advice on the feeler gauges. Also to everyone for your comments to this novice. I had a set of feeler gauges (I dont use anymore. After all who gaps sparkplugs these days ) and tired making it and it worked!!!!. See the picture (#1 is the broken piece, and # 2 is the piece I made fitted into the watch) of the broken clutch lever and the one I made installed. It was definitely quite a bit of work. But time wasn't the problem :-). I didn't have time to get the Tix so I tried a few things and really wanted to see what it takes to make such a small piece. First tried super glue and JD was right, it popped off pretty quickly. But I then roughened all the surfaces and did good alcohol cleaning, then epoxied the feeler gauge to a piece of 3/4" wood, then epoxied the broken piece to the feeler gauge. I then cut it with the rotary blade on the Dremel. I was very careful, slow and steady. The wood seemed to stabilize it. Then a lot of filing and emery paper. PS: I was surprised at how hard that feeler gauge steel is, it can really take a beating. Thanks again.4 points

-

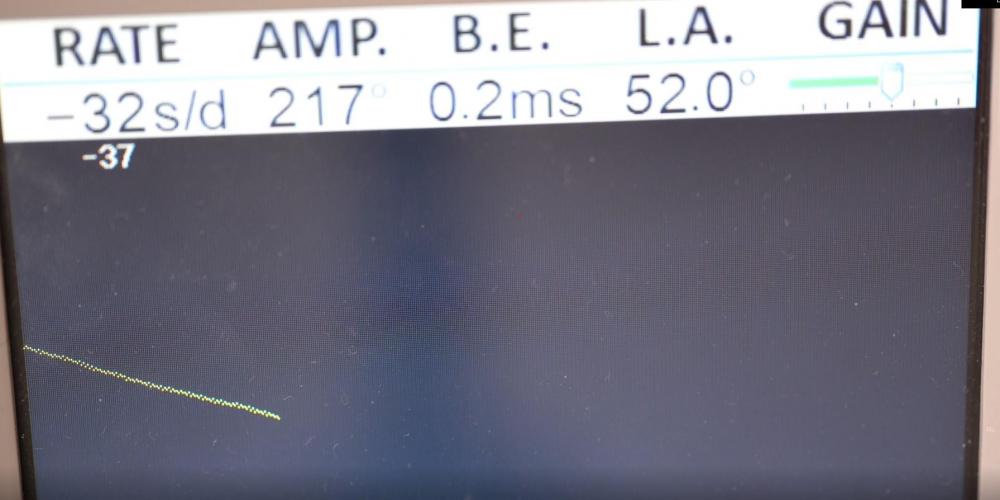

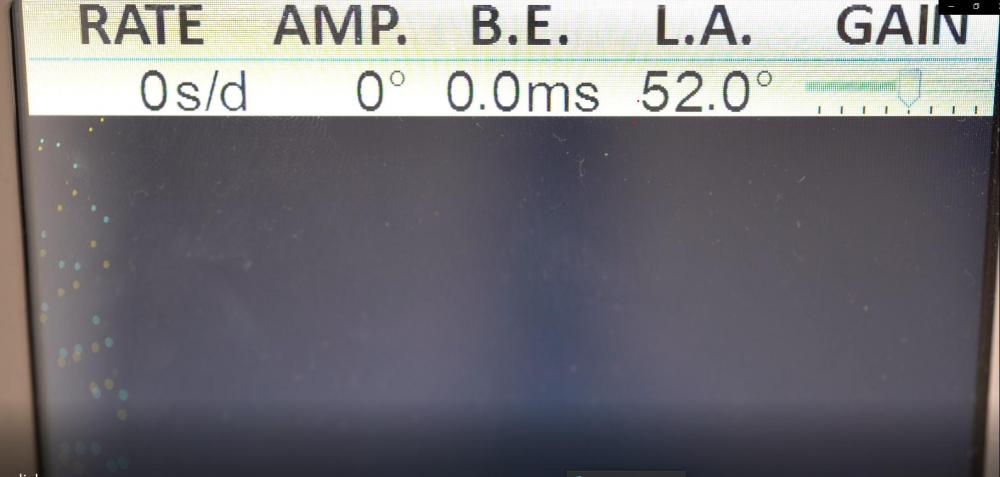

Check for train freedom with fork out Check the pallet fork snaps back and forth cleanly with balance out Check that balance oscillates freely with fork out Check that balance endshake is correct (as well as fork and other endshakes) Check that hairspring is level and centered If you do that last check you will see that your hairspring is sitting on top of the center wheel. Once you correct that, note that the lift angle for this piece is 42 degrees, not 52.3 points

-

I've always demagnetised running watches with no problems. Check that the hairspring hasn't popped out from between the regulator pins.3 points

-

What watch? Is it recently serviced? Is everything working correctly? The timing machine is (sometimes the first, just to get a look) usually the last thing you look at after servicing a watch. The cause of your issues is somewhere in a laundry list of possible causes. I love that watch repair has become a popular hobby but diagnosing and repairing watches is also a profession that takes years of school and years more to become proficient. If your watch was made 50 years ago and the service history is unknown it really needs a full service. If it's a year old, warranty work. 5 years old, probably a service. For anyone to give more than pure speculative responses we'll need to know the caliber, the amplitude (must know the lift angle to tell your machine), and a pic or two or three, of the balance and hairspring from top and as much as possible from the side to even guess. If your rate is changing so much with beat error correction you likely have a regulator setup where the beat arm also moves the regulator arm. And/or the hairspring is not true. Or- (the laundry list begins.. )3 points

-

Watches that implies more than one you're only supposed to put one on the timing machine at a time. Timing machines get hopelessly confused if they're trying to time more than one watch at a time. Also what gets hopelessly confused or people answering questions when you're trying to get diagnostics from a whole bunch of watches as each watch is unique. What I thought that's what a crystal ball is for I stare at my crystal ball and I make diagnostics on the discussion group? We can but you have to slow down I suggest following the helped it's been given above one watch at a time. Proper description a picture of the watch more pictures as requested above and a picture of the timing machine. You need to have a timing procedure also. A timing procedure would be to wind the watch up let it run about 15 minutes. Put it on the machine although it can be on the machine but don't look at it for about 15 minutes. Give us a picture of dial up, dial down and at least one crown/pendant position. If it's a pocket watch crown up if it's a wristwatch crown down. Make sure it runs for about 30 seconds in each position and allow us 30 seconds stabilization time between rotating the microphone. Oh and? I see it's already been posted up above but basically we need the history of recently acquired recently serviced its condition etc. Unfortunately a whole variety of things can cause a whole variety of problems and it's always helpful to know ahead of time what were dealing with. Even though the timing machine can look at a watch sealed in its case is not entirely helpful for diagnostic purposes if we don't know the condition. If you're actually seeing a sine wave effect on the graphical display it can be caused by magnetism or a bent pivot. I'm attaching a PDF that gives you a sampling of what you might see. As stated above understanding what you see in the timing machine takes a long time to learn & grasp. It's not a clear-cut exact science sometimes. It's more of a generalization of if it looks bad your watch is having a problem if it looks good your watch is probably okay. Then as I also commented timing and more than one position is also extremely important. It's amazing how many people only look at the watch in one position and then ponder why that watch doesn't keep time. Because after all it look perfect dial down on the timing machine it's only when they put it in a pendant/crown position do they realize it may be they have a problem or even just looking at the other side they might have a problem. Timing-Machine-Charts.PDF2 points

-

Hello, there is no "standard shockproof staff", but there are shockproof systems of different brands. If you look at balancestaff.com, they list 6 different staffs for L51! I doubt you can discern by image, but you can by measuring their sizes and compare with those listed. Frank2 points

-

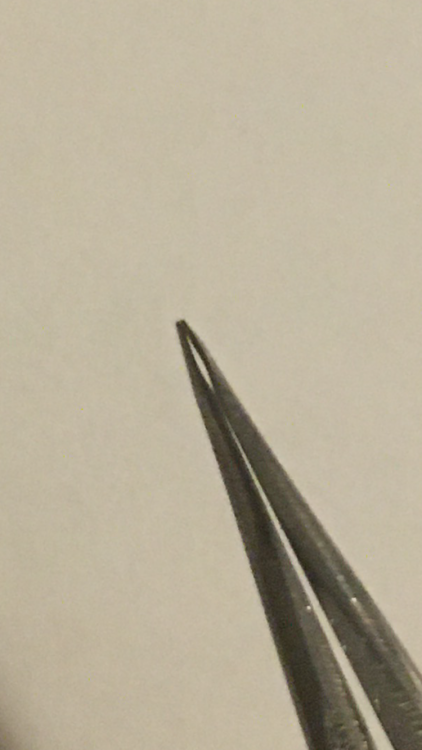

This is something that I’ve figured out that helps a lot when doing incabloc jewels. These are just regular number 3 stainless antimagnetic tweezers and What I use is a round dremel stone that’s used for sharpening a chainsaw. Don’t use it in a dremel for this! DO THIS BY HAND ONLY and go slowly. Take your time Then after I have the round shape in tweezer tip I take a piece of 1000 grit wet/dry sandpaper and cut a small piece about an inch wide and about an long and roll it up tightly into the round shape like the stone and smooth it out some. Then I do the same thing with 1500 grit wet/dry paper.Here’s some pictures. It works great for me and I hope it helps some of you.2 points

-

Hello all, I am Ron and I reside in central Florida. Thanks for the add, I have a meager yet eclectic watch collection and enjoy doing my own repairs. Look forward to learning and bettering my skills and maybe gaining some new friendships. Thanks again, Ron1 point

-

...and a watch in bad? shape. I was searching easy option to get old watch repaired, but got myself just watching repair-videos on youtube. -so I hardly can repair my find, but interesting stuff this is all the timepieces.1 point

-

Hi! I am Futuristdede from Berin and 33 years old. I am new here and also new in watches. someone gifted me a longiness watch which made me fall in love with mechanic watches. since then i have been doing my research and thinking about getting a new one (seiko srpe51k1) but also buying some old ones just to repair them. Since i am pretty new, i thought it would be wiser to be with the people who have experience in watch repairing. This is why i wanted to join this great club. Hereby, i am greeting everyone of you and wish you a great week!1 point

-

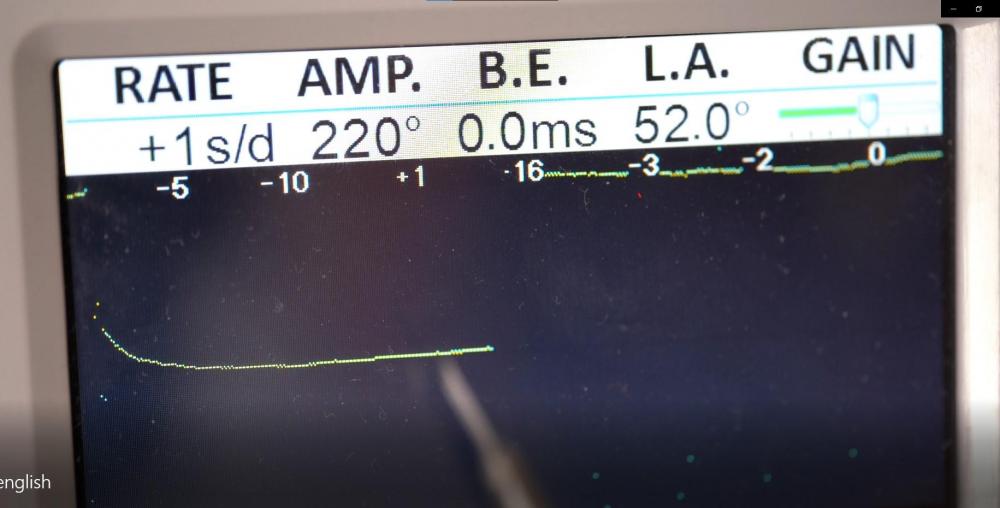

Hello fellow watch enthusiasts! After alot of logistical drama with DHL, I finally got a few parts and calibers which I ordered off of Ebay last year. Coincidentally, a friend of mine gifted me an old book about watchmaking for my birthday, so I thought what better way to show him my gratitute for his thoughtfull present, than to show him that cramming the books contents had payed off! This little documentation hopefully can help people work on their Luchs in the future! I did post a wlak through on a different forum and was informed that while the dial was original ( yay!) the hands, case and crown are from historically different models so this watch has had quite an interesting life! At least all parts are original luch components haha Here to the initial state of the Watch: - Missing crystal - Wear on case - Missing movement holder claps and screws - Winds but no ticking. Hands move erratically after the watch gets some kind of shock ( dropping it onto the table) - Loose Second hand: - Missing jewel on mainplate : Here is the complete disassembly: 1. Remove the bezel so that the watch movement can be taken out. In my case the dial was loose so that popped out aswell. 2. Remove stem by pressing down on the stem releasing button and isolate the watch movement. 3. Remove minute wheel and canon pinion. 4. Remove the setting system cover. 5. Remove the three translation (two small and one big one) wheels. 6. Remove the setting system compontent : The setting lever, the setting spring, the two clutches. The left over lever will be removed later on. 7. Flip the movement and remove the balance wheel and pallet fork + bridge. ( Love the older designs with the pertruding wheights on the oscilating wheel,so pretty!) 8. Remove mainbridge. 9. Remove visible gear train 10. Remove the secondary bridge and the two small gears which it holds and the hidden canon pinion. ( forgot to take a picture sorry!) 11. Remove winding system. Beware, there where small metal rings between the wheel and the metal pins! 12. Remove barrel bridge, mainspring barrel and unhook the lever in the front. That concludes the strip down! Mainspring service: Now the mainspring looked pretty decent and I didnt have one spare on hand really so I took it apart. Washed it in lighter fluid, alcohol and lubricated with Moebius 8200 before winding it in by hand, Since it is manual winding, there was a hook on the bridle which you could hook onto the floor and the lid of the barrel, interesting since ive only known manual watched which hook onto the side of the barrel! I winded it in the wrong direction and broke it haha I did end up finding a replacement though! Here are some steps of the way: Cleaning: Good old Soak in lighter fluid followed by a rinse in isopropanol alcohol. Of course the palletfork aswell as the removable jewels for the balance where not included here. The dial was treated to a good session of rodico aswell as some rough Q-tip rubbing with luke warm soap water. Lubrication: - Moebius 9010 for all jewels except for the pallet fork jewel bearing - Moebius 89415 for the pallet fork jewels tips - Hp 1300 for the gear teeth contacts - Molycote DX for Setting system and Winding friction points -Moebius 8200 for Mainspring ... And for a the reassembly just reverse the dissasembly and dont forget to oil and clean the balance jewels! Oh and intersting the acryl crystal, that was done by hand, not with a crystal lift. Finally I put it onto the timegrapher after demagnatizing : 1. As you can see, the result is horrible haha. But I did replace it with a different balance wheel from a donor. 2.Much better! 3. After regulation Final pictures with the strap, me and my friends bought, for my friends timepiece present: Over all a great and fun project I must say! Ive shipped the watch to him now so lets hope he will like it! I know that there are see through backs for the Luch 2209 however I have not gotten around to getting my hands on any of them. Would love to show off the pretty golden movement! Any questions, comments or improvements please feel free to write me! Oh and here is a full narrated video of the process: So long watch bangers!1 point

-

1 point

-

Yes getting decent watch photos can be problematic. Not necessarily expensive though 99% of all the photographs I've ever taken is with a Canon SD 1000 camera. This is a small ancient point-and-shoot camera. What makes it interesting is it has a digital macro mode hopefully the word macro is right? In other words you put in a digital mode and it will magnify and then you can take all kinds of nice photos of watch parts. Then of course edit the photos and make things even bigger to make your point of view. So in the absence of photos you become our eyes for diagnostic purposes. Microscopes are both good and bad. The bad aspect is looking at something now that's really the egg doesn't necessarily mean that it's going to be easier for you to grasp which are looking at. From the picture the problem appears to be related to the balance wheel. That would mean the balance pivots if one is missing or both are missing unlikely on a system like your watch though but they still could be missing. The balance jewels? I think I mentioned it to pages I'm probably going repeat myself or repeat what others said. I'd have to go back and look at the parts list I can't remember if the balance hole jewels are identical? Many times on watches the dial side will be smaller and thinner. On the other side to bigger so visually can see how impressive they look yes they really are there for the visual aspect and the functionality which is why that side of the watches usually nicer the dial side. Sometimes the settings with the jewel may be identical but the end stone on the movement side is thicker that's the make up for the thickness of the plate the regulation components etc. Then we also have the end stones have a curved in a flat surface the flat surface has to go down. Shouldn't happen on a wristwatch if somebody bent the bridge up that would cause too much and shake and you'd see something like this perhaps. If you're not seeing the problem take a break. If you have another watch to work on look at that look at how it works look at the pivots sometimes taking a break in looking at something else you might recognize something you're not seeing on this watch.1 point

-

Some do, some just take it for granted. Others are too lazy to use the search function and read what is already available. This from someone somewhere in the middle, able to offer advice, but still asking questions, so maybe in a good position to see both sides. Yes, sometimes there is a response on here which I consider a bit harsh when replying to a beginner, I've been guilty of it myself, but just remember, it might be the umpteenth time that particular god has addressed a similar question, with the same paucity of information to enable a diagnosis. The basic requirements have been spelled out many times. Those gods also post on here voluntarily, in their spare time, because they want to help. They are also free to leave this forum, if it stops being fun. Maybe a little more tolerance and reflection on both sides is the answer?1 point

-

I've told my wife that if she tells my 28 year old son that he's more than welcome to come live at home again if things don't go right AGAIN. I will cure her of her snoring in the middle of the night and I will make it look like an accident.1 point

-

In photos I've seen (I didn't draw it when I popped the lid) the spring coils clockwise from the arbor in the barrel. I purchased a RH handle and winder.1 point

-

Hiya Boyd, I also have experienced this mysical phenomenon on my timegrapher that can only be answered by true watchrepair gods during their break from being worshipped. But with my very limited knowledge i may have one maybe two ideas that probably won't be helpful at all. But I also find that initial sarcasm with a hint of patrony quite unhelpful as well.1 point

-

Hiya Lecorb. Sorry about that matey a very frustrating event I know only too well. What size room and work area are we talking about ? Is it not worth carefully clearing everything off your workbench. Emptying out any open containers and the like. Another really thorough look costs nothing and might be your only course of action if a replacement is not available. A click isn't really that small in comparison to its spring. Diashock springs on small movements are crazy small as are stud screws. Is the room carpeted? Is a big magnet available for use ? I use a whacking big one that is used for magnet fishing. There is nothing that I've lost that it hasn't retrieved. It's certainly worth a try. Good luck.1 point

-

That is a front loader case and your is the most frequently asked question by beginners, enter "front loader" with double quotes in the search box top right. In short, it is opened removing the bezel and lifting the dial while rotating the crown to free up the two piece stem. I recommend against owners trying that without proper tools to avoid damage.1 point

-

The tweezers in the hole is better replaced with a pointy piece of rodico because unlike tweezers that doesn't slip on the domed surfaces, and captures the spring. As mentioned various times in identical topics, the alternative is an hollowed piece of pegwood as I had shown below.1 point

-

Hi Had a look onthe bestfit book, yours converts to 13.2 lignes and is a simple lever and spring, no flat setting lever spring unfortunatly nothing showed up will have to see if anybody else has any ideas. cheers1 point

-

Hi One of our ontributers from Canada JD Richard is the man for lathes he has a collection of them sure to have a Wolf Jahn. what size is it 6.5mm or 8mm1 point

-

Hello crackpot, I like the idea of that. I made a simple shocksetting spring press out of a toothpick for clipping a diashock spring in place , it was giving me some grief. I lost the slippery little 3 pronged begger twice. The toothpick made sure he wasn't leaving home a third time. I won't be using any similar method on my adult children though that's for sure.1 point

-

Hello all! Newbie here! I've always been interested in watch repair but didn't think I could handle the small parts with my aging eyes. I've done a bunch of SMT electronics work this last year and it's gone great so hopefully the tiny parts in watches wont be an issue. Am starting off with a tool kit and class from TimeZone and if all goes well, will probably enroll in the nightly program at the Norwest School of Horology in the fall. Excited to dig into the forums!1 point

-

here is some topic on the wolf jahn https://r.search.yahoo.com/_ylt=AwrIQZFzClRi.WkAwhJ3Bwx.;_ylu=Y29sbwMEcG9zAzEEdnRpZAMEc2VjA3Ny/RV=2/RE=1649703668/RO=10/RU=http%3a%2f%2fwww.lathes.co.uk%2fwolf-jahn-watchmakers%2f/RK=2/RS=kLbFb4AE6odm5ss_0ZverNc5LMM- https://r.search.yahoo.com/_ylt=AwrIQZFzClRi.WkAxBJ3Bwx.;_ylu=Y29sbwMEcG9zAzIEdnRpZAMEc2VjA3Ny/RV=2/RE=1649703668/RO=10/RU=http%3a%2f%2fwww.lathes.co.uk%2fwolf-jahn-watchmaker-2%2f/RK=2/RS=61_bEHW5lDINAcjckR70BNc6CKM-1 point

-

We have all been there and spent time on our knees looking for parts so you are not alone. Can you get the movement size (Lignes) and I will look in the book and see what we get.1 point

-

Over the years I've had people tell me and I've seen it in print that it is very bad to Demagnetize A running watch yet I do it all the time with no problems except? The second part of the quota unfortunately applies make sure the hairspring is still between the regulator pins or make sure it's not caught on the regulator pins. Or the basics look at your hairspring does it look right?1 point

-

Six is a nice number to deal with unlike the link below which has nine different staffs. http://cgi.julesborel.com/cgi-bin/matcgi2?ref=LAN_51 The answer is yes. I'm attaching picture notice how the staff has square shoulders as opposed to normal rounded shoulders found on a conventional staff. I also have a link to a video and you'll notice the shoulders are there to keep the staff from going too far individual assembly. https://youtu.be/FakIAZxcDII1 point

-

1 point

-

Hi again Gary. A semi retired day off today for me, so I was just trawling through a few posts that are relative to issues I've experienced that might help me in the future. I love gathering tips and tricks. Spotted yours after having just posted a silly story relating to barrel and mainspring winder sizing, rather applicable to beginner enthusiasts like myself. I hope you don't mind me jumping in. I'm not sure if you would ask for a left or right handed winder to use for a particular orientation of the mainspring in the barrel if that is what you are asking. I do things a different way so I'm a bit green on ordering tools. Or if you are asking how you know which way the spring fits back into the barrel after it's been taken out. If its the later and I did this a few times and forget which way the spring fitted into barrel. I first started by doing a little drawing but that was sometimes a bit confusing, so then a picture before it's taken out really helps. If I don't have either of those to refer to then a loupe inspection of the inside of the barrel wall and the barrel arbor points me in the right direction. Depending on the mainspring tang end and there is a few, The vintage Swiss watches I restore I find are mostly ones that have the mainspring tang that engages with a ledge on the inside of the barrel wall but not always. That tapered ledge direction will give you an indication of which way the spring outer coil is going to start to curl, anti clock or clockwise. And the barrel arbor assuming it is the right way up, the hook on it also has a direction to it and if you can imagine once the hook is in the mainspring eye that will also indicate an anticlockwise or clockwise direction of the inner coil of the mainspring. The two indications of outer and inner coil direction should tally up. Hope this all makes sense. It may not even apply to the mainspring you are working on because of a different tang design, but the barrel hook description may well do. Unfortunately I haven't laid tweezers on any American watches as yet so the information about my experiences with Swiss brands may not be fully relevant to you. Apologies if you knew all of this, but someone hopefully will make use of this information. Rich1 point

-

Hi sorry to jump in on this. I do have a little mistake experience on this and I don't want to hear of any newbies make the same one because it can be costly in the sense of ruining a new expensive tool. Most of what I say is pretty obvious but often overlooked in a haste to get something done, never a good start in the world of watch repair to place time ahead of sensible thinking. Most of my tools are second hand ebay purchases, I can't justify paying a lot of money on expensive tools when I can get by with well chosen secondhand gear. Besides if the hobby interest fades for whatever reason I will have wasted a boat load of cash. So this post mostly relates to similar ilk as myself. Mistake coming up shortly. The mainspring winders I have are a generic set of 7 and 3, so 10 in total, so I thought this should cover most bases, I was wrong. They often don't fit and I frequently reinstall the mainspring by hand with a little gadget I devised, nothing clever because I'M not particularly, but it works ok. Now when i say my winders dont fit a barrel I mean it doesn't fit the barrel well, because its quite important that it does. Mistake coming up very soon. I was sizing up a winder to fit a barrel I was working on, only by eye i might add as I find skeg of E works for me on stuff like this. Mistake coming up now. "Not that one, not that one, ah that's not a bad fit a slight gap around the edge of the winder but it should work". Oopsey. A slight gap by eye is a big bloody gap under a microscope or 10 x loupe. So I'm winding the spring in, it felt a little tight towards the end but I got it in. I looked inside to check it was ok, "oh crap it looks a bit bloody snug in there". Would it pop into the barrel ? Would it f---. Mistake arrival. The winder hook was well and truly jammed in the mainspring eye with no room for any release to ease it back out. 15 minutes of tugging pulling and cursing, left me with a minature version of a slinky that looked like it had just finished coming down the people crowded steps of the Eiffiel Tower and a broken hook winder embedded workshop wall. So the moral of this lengthy detailed story ( apologies I'm very recently early semi retired and have far too much time on my hands ) is to make sure the winder you are going to use, fits the barrel in a positive undestructive, stress limiting and good resulting way. Thanks, I hope this helps at least one person that is in any kind of rush and thinks that they can get away with a - that pretty much fits attitude.1 point

-

1 point

-

If your smartphone has a slow motion video recording mode, film the balance for about 15 seconds and see if the coils are sticking to each other. If I remember correctly, the hairspring was sprayed with contact cleaner. Some contact cleaners contain silicone which can be really difficult to clean off. If you have an ultrasonic cleaner, try putting some benzine in a small jam jar and put the whole balance with the hairspring in it and ultrasound it for 10 minutes.1 point

-

Thanks for the introduction and welcome to WRT @ryanscott6 ! I'm also pretty new to all of this. At 68 and following a stroke that clobbered my left eye a year ago, I was also worried that my eyesight wouldn't be good enough. It seems that it's fine - as others here have pointed out, you're usually looking through a loupe one-eyed anyway. I'm stalled partially through my first watch movement restore due to waiting on oils and tools (all of which should be on their way). Let us know what your first project is and don't be a stranger1 point

-

Carbide gravers 2mm flat and 2mm round, +4mm flat and round. From a US company engravers.com I think1 point

-

I bought a couple of Bergeons recently. I have quite a number already but wanted to complete a set on two benches. Anyway, I noticed that they changed the design in a very good way. Now, there is a bevel at the driver end. Before it was just squared off.1 point

-

I should recheck the watch for magnetism with a compass, sounds like you have inadvertantly magnetised it and its affecting the balance spring coils, take the back off and have a look at the coils when working are they concentric and beating evenly and also flat.. Post pictures or a video of ithe movement.1 point

-

What have you checked? I know full plate watches are a pain, but it's still important to check train freedom with the fork out, endshakes, and on these old American watches the escapement in particular as they tend to get messed around with quite a lot. The bankings tend to get messed with first, but it's important to do a full escapement check: drop lock, run to banking, full lock, fork horn shake and guard pin shake. Also, these will almost always have a single roller, which is less secure than a double roller, and the guard pin needs to be adjusted correctly or it will jam against the roller. Perhaps your balance endshake is too much now with the shim (shimming a balance cock would get you in big trouble in a professional environment or school), maybe the guard pin isn't performing it's job- face up, with too much endshake on the balance, could very well get the roller table out of engagement with the pin. Did you check the pivots of the new staff with the balance jewels? They can be several sizes for the same caliber family on these, maybe the pivots are too small, thus not fitting the jewel holes, and thus the lack of endshake. If that's the case and the pivots are simply contacting the entry of the hole, you will have extremely bad performance in the verticals or it will stop completely. (Also- the jewels could have been changed at any time in the past, maybe only one, so important to check both with its pivot).1 point

-

Power discharge due to malfunction of the click or loose ratchet wheel screw. You will be removing the auto device anyway, so why not clean it and epilame treat the reversers if you have the grease.1 point

-

No this is not the same watch as the broken pointer. I am starting to think the same. Move on. But I do want to try to make the clutch lever. If that doesnt work out it will be time to move on with this watch. My other watch is the one with the broken pointer which now has a broken hairspring. Sighhhhh. I may be learning something here. If you're going to do old pocket watches, it may be favorable to focus on the popular names like Hamilton, Elgin, etc. where many basic info and parts are available. All especially when you just learning.1 point

-

1 point

-

From the side on view the balance does not look level.. Is the endshake of the balance ok? It should have no discernible movement but will allow a free balance to spin freely. I will go back to basics.. 1. Remove, clean, inspect and oil the balance holes and the pivots. The positional error is too great. A damaged or dirty jewel is my suspicion here. 2. Dismount the balance from the cock, remove hairsprng and install balance and balance cock. Check for free movement and levelness of the balance, not only as it spins but also relative to the main plate. 3. Reattach the hairspring + balance to the balance cock and install it back on to the naked mainplate. On most watches you should be able to see some limiting stops for the pallet fork (either banking pins or cast in the mainplate. The impulse jewel should be in tne centre when the balance is at rest. The beat error using this method will usually be less than 1 which is acceptable. If you cannot determine the exact centre then the impulse jewel should be on a line drawn from the balance pivot to the pallet-fork pivot (at least on this movement.. there are some others with offset levers). 4. Also check all wheel pivots and jewels.. A jewel with a chip in it will run but if it is in a position where the chip is bottom-most thenit will run badly. Good luck. Anilv Anilv1 point

-

Normally I'm not a big fan of looking at the balance wheel out of the watch because usually the problem with the balance wheel isn't when it's out of the watch it's when it's in the watch. But I snipped out there image and put a couple a little lines in a circle. If you notice the terminal curve how the spacing when it starts off from the stud the outer terminal curve spacing in relationship to the rest of the hairspring starts off relatively small and actually gets bigger which is not supposed to do. Then I circled your stud it may be misleading because the balance is out of the watch it really need to look at it back in the watch but it looks like because of the bend of the terminal curve that the outer coil of the hairspring is almost if not touching the stud itself. This could all be caused except terminal curve because the balances out in its leaning a little bit the terminal curve does look like it's not quite bench right this is where if you're going to fix it you ideally want to do it in the watch C can see what the heck you're doing because it might look really beautiful out of the watch and look like total crap in the watch and that's where it has to look right Then depth of field for close-up pictures is really really really hard to doSo we really can't see what we need to see with the balance wheel other than were all in agreement it doesn't look right? I initially thought the balance bridge look like it was up I think it's probably where it's supposed to be. Even when I magnified image it's hard to tell whether the balance wheel is exactly where it's supposed to be. ButWe don't have the proper depth of field which we need to see. So not sure if the balance wheel is not parallel to the plate but if you look at the hairspring it looks like it's angling downwards a little bit which of course is going to make the balance wheel look like maybe it's angling upwards a little bit? We also can't see the hairspring at the stud as to how close it is there. Then you want to be really careful when you're playing with your Omega hairspring because they're usually butter soft. There also usually really really expensive like all the components in the Omega watch. This is were ideally before playing with hairsprings inexpensive watches should have been practicing with cheaper hairsprings in disposable watches. Practicing looking at how the hairspring looks practice bending the hairspring the practice bending the hairspring back that sort of thing so that when you come time to do something like this you get a grasping of maybe what you're supposed to be doing as opposed to the easy route a buying a balance complete after all it's an Omega how expensive could that possibly be?1 point

-

1 point

-

Updating to THIRD Vulcain Cricket (Sensilarm) done except for the sweep second hand. To bring this one to life I had to: 1) new staff 2) turned a new pusher 3) replaced keyless works (clutch and winding pinion, crown gear, setting lever and setting lever screw) 4) sweep second pinion I am now in the hunt for a sweep second hand. I put a lot of money into this thing...I think...it has been going on for about nine months. Bought parts on ebay, NOS material houses, donor watch, and I made the pusher.1 point

-

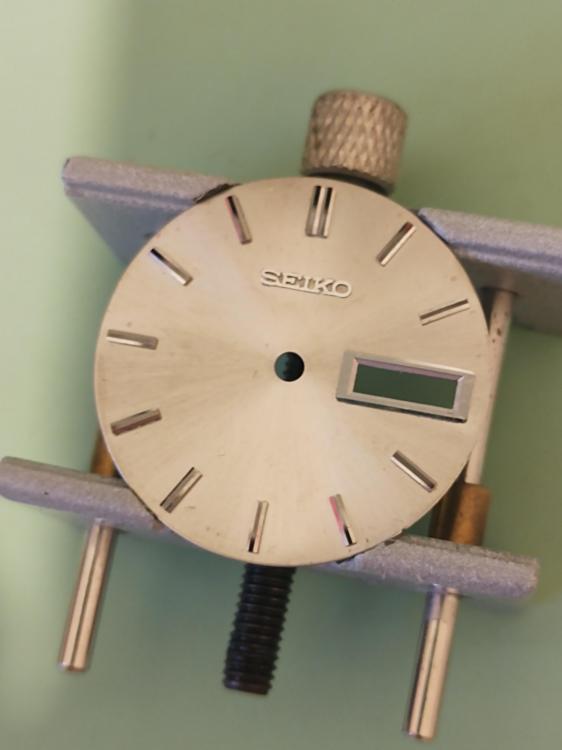

Its likley that the driving wheel point is worn and also the calendar/date ring both could contribute to the problem. Does the watch stop when its changing over or keep on working. parts sheet attached 488_Seiko 6619a.pdf1 point