Leaderboard

Popular Content

Showing content with the highest reputation on 03/19/22 in Posts

-

1 point

-

Looks very much like an ETA 2391. Compare fig 4 at http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2uswk&ETA_2391 Is yours an 11.5 ligne movement?1 point

-

1 point

-

1 point

-

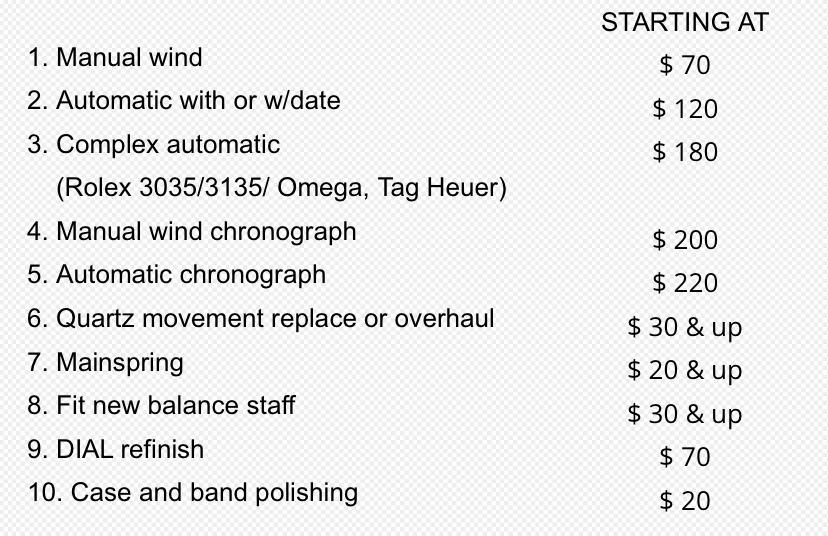

I'm shocked by these prices. I could completely strip down a manual wind and have it finished within 40 minutes. At these prices I could have been a millionaire. OK yes I know I switched to high grade clocks. Anyone got a price list for clocks or can you tell me what the charges are these days. I have a few that need repairing which I have been putting off for a few years and I need to know how much to charge my self. One is a French strike on a bell, French Timepiece and a Georgian bracket fusee chime on a peal of bells which I bought about 5 months ago.1 point

-

1 point

-

On these the carbide wheel can be reversed, one side has a radius, the other is square shouldered. They are handy for things like center wheels where the wheel might have 0.05mm clearance to the shoulder of the upper pivot- that's very tricky to handle freehand with a burnisher. The Pivofix is another animal, with significantly larger diameter wheels, is overall more rigid and precise, and can handle larger diameters with far greater ease (and just larger diameters- a typical Jacot with center wheel runner tops out around 1 or 1.2mm, the Pivofix will do up to 3mm). When you get to 1+mm diameters it can be tedious to retouch on a Jacot with handheld burnisher, but these also take a while as you can't really put that much pressure on the wheel without making one of the belts slip. In that regard the Pivofix wins. But a used Pivofix usually has a an asking price of 1500 to 2500 Euros. These, since you usually supply your own Jacot, can be cheaper (though they usually go for a fair bit, over 1000 in my experience). I have access to one of these in my workshop (shared space), the last time I wanted to use it it just didn't want to take off the material. It was a Zenith, nice hard center wheel lower pivot; I ended up using my industrial pivot burnishing machine. Basically a Pivofix on steroids built to run 16 hours/day for 20 years. Fiddly to set up for a given diameter, but super fast with perfect finish once set up, haha.1 point

-

As this is a Swiss movement it is measured in lignes (the Swiss made a lot of watches that emulated American stuff back early 20th century, using American city names and often with an image of a locomotive on the dial or case or both). "Size" as a designation for the movement size was used for American made movements. You need to figure out who made the movement; the mark on the mainplate to the right of the escape wheel is almost certainly the maker's mark. Once you figure out the maker, and know the size, you can start narrowing down possible suitable staffs. For any given size of movement, regardless of Swiss or American, there are dozens or hundreds of possible staffs. If you can get a clear closeup shot of that mark it will help identify it.1 point

-

Hello and welcome to the forum, attached a couple of documents for your interest. 1612608791_ToolsfortheHobbyist (2) (1).pdf TZIllustratedGlossary.pdf1 point

-

1 point

-

The biggest problem with removing rust is that because watch parts are quite small and often very thin, once the rust has been removed, either chemically or mechanically there is often very little of the original part left or what is left is so physically weakened that it soon fails in use. In the end it's probably "best practice" to replace all rusty parts. Easier said than done I know1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. In this field of Horology you never stop learning. I started my apprenticeship back in the early 70's and still today I still find and see movements that I have never seen before by members that upload photos.1 point

-

Welcome Miguel! If you need help fixing your father's watch, you are in the right place.1 point

-

1 point

-

Do you a wooden box or blocks to rest the movement when you put it down on the bench? I use these type of stands too. But they do get in the way at times and I have to move them out of the way to work sometimes. And they do leave slight marks on the brass plate. Sometimes I just rest the movement on an old Tupperware box.1 point

-

1 point

-

rodabod, I've read some pretty interesting methods and the Loctite seemed to be the most popular and widely acceptable between both watchmakers and tinkerers. Over on the NAWCC boards someone suggested to use a strand of hair between the shaft and ID of the roller table. While a novel concept, being a toolmaker by trade I know that putting an object in between two fit parts that is literally 1/3 the diameter of the shaft, will throw it out of balance when spun and if the roller table is as delicate as you suggest, I would bet that the roller table becomes distorted wedging that hair between the to parts. So not only is the roller table sitting off center of shaft because the hair interference, its also no longer the proper shape. Another option was to use shellac to fix the roller table in place. I see how that would work but with limited experience as a tinkerer, I would not want to risk knocking the roller jewel out of place while heating the shellac for the table. In the end I decided to go with using the removable type of Loctite I use for stem threads.1 point

-

Agree with klassiker, shouldn't touch the bakning pins, not yet anyway, you can easily create new problems .1 point

-

Oddly enough, I had the same with an ETA 28xx one time. I think it was a relatively high beat model. What came off the pallets and escape wheel was pitch black and I was inclined to believe it was actually worn steel from the escape wheel.1 point

-

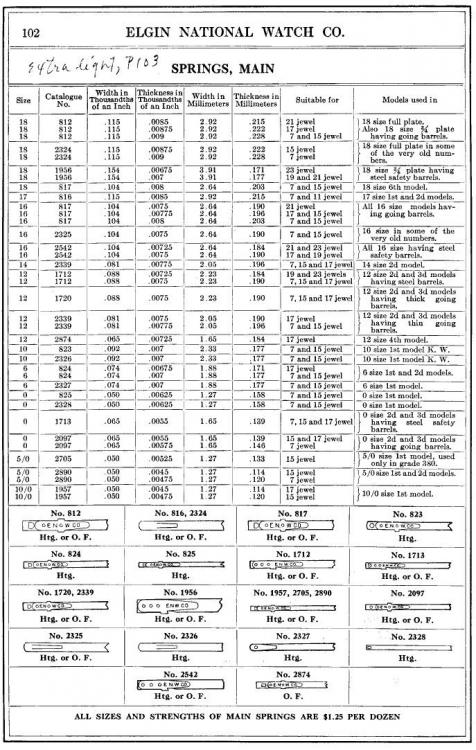

American pocket watch mainsprings can present an interesting challenge today. I have some images for you to show the problems. Catalog pages from the Elgin parts catalogs 1915 you can see there are four different strengths of your mainspring. The catalog conveniently gives you a clue of strengths versus number of jewels. They even have a lighter than normal spring because occasionally for some of the higher jewel count watches the Springs would be too strong. Then I have an image out of a list of modern mainsprings. This is where things get really interesting in that the modern white Springs typically for the same thickness can be stronger than the original Springs. The other bigger problem with modern mainsprings are the availability of them is limited. The one time the readily available but the Swiss don't like to make mainsprings for American pocket watches so the ability to get modern Springs is decreasing. Or for some watches they just consolidated all of various sizes into one spring. So the unfortunate reality can be can have a listing of a lot of different sizes which are lucky to get just one. If you look at the catalog page that I have it does list the mainsprings suggestions for the number of jewels in the watch. Usually it's not a problem of using a spring of a different thickness. Then it wrong the strength mainsprings and problems I found have been extremely limited. Occasionally a seven jewel watches unhappy with the week mainspring because basically it's worn-out. Or one occasion I had a Hamilton 21 jewel watch that had too much amplitude. This is where eBay is nice I found the weakest mainspring they made an original spring it solved my problem.1 point

-

Hi all! Persistence saved the day. So after thinking about the barrel and not finding any additional information on the internet I attempted to remove the barrel lid once again after soaking the assembly in Naptha and blowing out the excess with a bulb blower. I applied slight more downward pressure on the barrel assembly and Pop it opened! Elated I took some photos to give everyone a look inside this barrel. The stem protruding through the center has a small square nut holding it into the barrel itself, that was what I was seeing under the microscope. Hopefully this additional information and photos will help someone down the line. Thanks to all who replied. PS found out where the extra screw came from the winding counter weight was missing the center screw and the other two were loose. Problem solved!1 point

-

Here http://thewatchspotblog.com/?p=4176 it refers to the base calibre of the 560 RSS as a Bidlingmaier ebauche, with an added automatic winding mechanism. Not a company I've heard of.1 point