Leaderboard

Popular Content

Showing content with the highest reputation on 02/12/22 in all areas

-

I picked this up at a garage sale yesterday and tried to research it but found very little information. It's pretty rough missing the crown and stem and cracked bezel but for two bucks I thought it was worth it. The dial has buler 21 jewel 30 ATM beryllium balance, the case back has a cool design. I'm guessing you have to enter this watch through the front as it is a solid case. Anybody familiar with these ?2 points

-

So I believe the issue was that the screw going through the cover at the Maltese was just a hair too long and actually touching the mainspring. I had replaced the mainspring during service with the same dimensions (Dennison 3/ 1.20mm). It could be that screw wasn’t torqued that extra quarter turn before? anyway, three swipes of the bottom of that screw across a stone and problem gone…Interesting how many little things can turn out to be the issues we encounter. Thanks for everyone’s replies and help.1 point

-

1 point

-

Rate regulation. Most watch owners don't know the difference either. Also, it would help if in the future posts the OP title is about issue at hand. You can show us the boxes if you want. Just not the rest of the lab please, there is a limit to what an average hobbyist can take. Another item on my list. I like to make screws and related jokes.1 point

-

That is just right if you think about it, otherwise abuse and unfairness would be way too easy. Anyway immediate dismissal is possible in some cases, e.g. violence. https://www.gov.uk/dismissal/reasons-you-can-be-dismissed My post had nothing to do with labor regulations, unions or the like, but rather with honesty or lack of it, because I know for a fact that the shop "laboratory" is most likely an unregistered individual. The other nice episode was when mom was charged nice money to repair her old washing machine, she complained about it making a strange noise, the guy replaced a solenoid. Of course that didn't stopped the noise that was due to some lose drum spring or mounting. The old machine was eventually replaced, and I still have the perfectly working "broken" solenoid, in fact it seems to me it's a new part still boxed. I guess the moral of all this is, when someone close to you need some repair don't be lazy and try to fix it right away.1 point

-

1 point

-

It is somewhat counter intuitive but stem diameters and tap sizes don't work that way, it just happens that Tap 9 coincides with 0.9mm which makes it look like it does. Have a look here for a Tap size to diameter conversion chart.1 point

-

thank you JDM, I appreciate your knowledge and help, and I agree I think that would be well beyond my fledgling abilities! I have a movement on the way and hope to make a working (ish) watch out of the two.1 point

-

Whenever working on older watches changing parts introduces typically new problems. People helping you on this discussion probably didn't grasp that you change the barrel. I think the only mentioned changing the mainspring and failing to disclose this little discrepancy well wasn't helpful it's amazing what happens if things aren't exactly the size there supposed to be. I was once puzzled by an Illinois pocket watch I was servicing I like the pre-time on the timing machine but I couldn't get at the time so I just went ahead and cleaned. It still wouldn't time after cleaning? I only saw one thing that troubles me which was the mainspring barrel it just didn't look right but it was in the watch. Investigation revealed that somewhere in his life somebody changed the barrel and getting a proper barrel in solved all of my timing problems. If you didn't have a timing machine it's conceivable because I never put the hands on may be the thing did run don't know for the Time but it definitely look like crap the timing machine which is why they're very good diagnostic tools. The problem with the early production watches are they tend to be made in batches and you tend to have parts variations a lot of times parts are actually fit per each watch. Always best to stay with what you have unless there's some reason you absolutely have to change to something else. I'm going to attach an image the gear ratio will depend upon the particular watch there be some variation but it gives you a clue that the only thing revolving around For around your seven hours is the barrel.1 point

-

Ladies watches are no ideal collectible pieces and I doubt if you can find someone to wear one when fixed, so you shouldn't spend more money on these, I just enjoy practing on them. Regards1 point

-

1 point

-

Are you sure that it's a 2509.HA, I don't think that I've ever come across a 25mm russian movement (the first 2 digits usually denote the movement size), Sekonda's of a particular period used a lot of Raketa 2609.HA movements. Can you post a photograph of the movement?1 point

-

Welcome to WRT forum. How about ruining that Russian watch first. Ha ha lol1 point

-

Hi, Some answers; I sourced the replacement spring from Cousins, and I understand(hope) that it is the correct one; 2.10 x .18 x 440 x 14.5 I have been testing with the movement cased, initially it seemed to be running ok, so I just went ahead and cased it. There is no obvious damage/wear to the barrel, bridge or plate. One point I should probably have mentioned previously; I swapped out the barrel from a donor movement before the service as the original had a disfiguring stain - I assumed that as the movements were the same calibre that they would be automatically interchangeable, but I have just compared them again and see that there is a slight difference in the shape of the teeth, so I'll reassemble the movement with the original barrel and test again. Thanks again for the answers1 point

-

It is an absolutely needed tool when working on mechanical movements. Without it you won't know how well the movement.t is running. Exercised eyes and ears helped with that, but one can't expect a beginner to have that. Only the barrel could make a revolution in approximatively 7 hours. But it takes something very wrong to stop it when it still has the most torque. Before taking it apart you could check if it happens in different positions too.1 point

-

The idea was it would help the rate in the vertical positions, but as you note the increase in inertia did away with any benefit.1 point

-

1 point

-

I am gonna order an assortment of pallet stones and see where that goes. It is a cheap movement...I think I paid maybe $15 for it, but it is important for me to see this through!!! We shall see...1 point

-

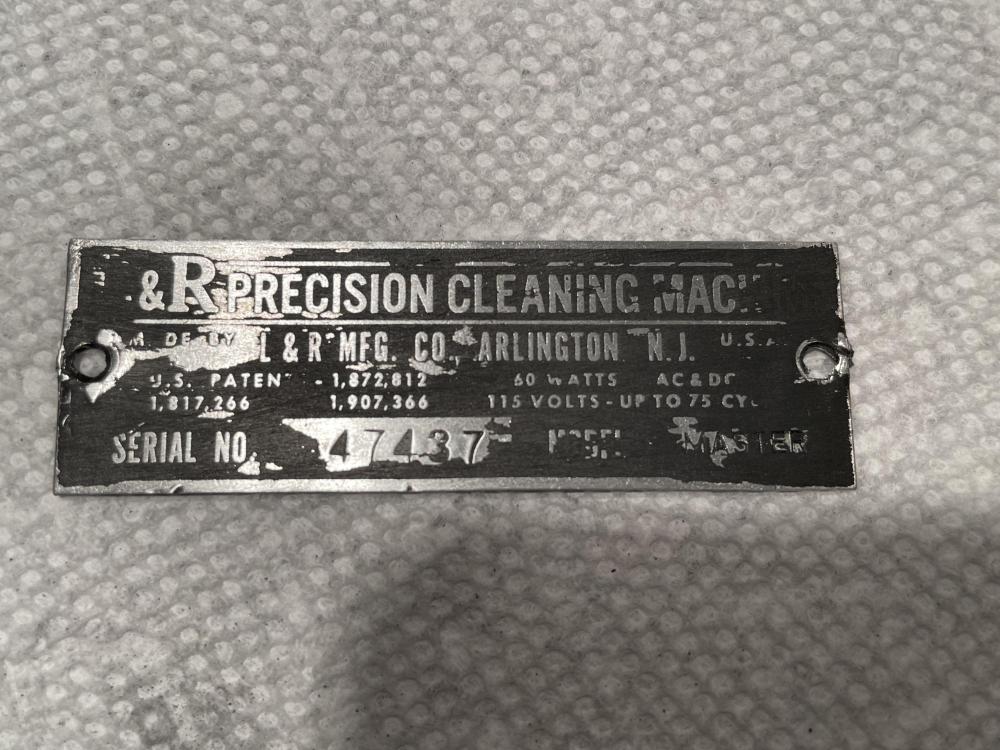

Update so far.... Primed, 3 coats of Hammered paint (actually 4 coats as the first coat was Gray Hammered and thought the gray had a darker tint but it didn’t so went with Hammered Black, 3 coats). Then I added 3 coats of lacquer and everything was looking good, no drips or runs. But then after an hour I noticed a ring around of a run and here I thought I was getting better, but after thinking about it more and also seeing inside where you put the jars, I think the lacquer did end up reacting and causing the run, so lesson learned. So I have two options regarding the paint, strip and do over or be glad it is better than it was before, see pics below. I am going with the 2nd option, not because I”m lazy but because I plan to use this as my goal is to just do preventative maintenance (update switches and wiring) as well as make the appearance better than it was when I got it and I feel, even with the runs, I did that. This lead me to the next step, the panel (where the switches and dial are) and the manufacturer’s tag (metal tab on motor top housing). At first I tried one of those oil paint pens and while I was able to scrape off the lettering, the rest looked terrible. So I went with a Semi-Gloss black, just 2 coats, and then had to find a way to expose the lettering. I really wanted to use sandpaper but the lettering is hardly raised at all and when I tried it with the oil paint, it didn’t work. I then tried a toothpick and just went around and scraped slowly and BINGO, it worked great. Does it look like factory, of course not, especially for the smaller lettering at the bottom as the lettering is so close, but it does look better than what it originally looked like, pics below. However the manufacturer’s tag has such small writing, the toothpick really didn’t work as well, so I tried sandpaper at first (2000 grit) and while it started to work, I guess due to the letters being so tiny and not raised much, it took some of the background off. I then took the route of using a Scotch Brite pad, and this worked A LOT better. I think I will redo the paint job on this and put a couple more coats and then do the Scotch Brite pad again. If anyone has any tips on how to make the main rod that holds the motor a little shinier or what to use to clean the spots off of it, looks like water spots, please let me know as I’ve tried steel wool as well as metal polish, but that didn’t work. I don’t have a buffing wheel, only a Dremel sized one, and thinking that is the really only way to shine it up. I mean it’s not bad from a distance. Well that’s the update so far, next goal for hopefully tomorrow is the wiring as I got my Rheostat and switched in today and didn’t need to replace the ceramic resistor nor the heating resistor. I’m going to let the unit dry for at least 48 hours (can says 24 for fully dry) due to paint and lacquer but just after 2 hours, it’s was dry to the touch. Hope everyone this helps someone in the future and hope everyone has a great night, stay safe.1 point

-

I'm pretty sure it's best not to just add more oil to a dirty movement as any debris will remain and further wear the pivots. Probably best not to use it daily until you're ready to service the watch properly.1 point

-

Just to add confusion, in Argentina naptha is spark engine fuel, in Italy indicates diesel engine or heating fuel. When mentioning benzine (spark engine fuel) many English speakers will assume that is benzene, and will warn you about, but these are not the same. We could use insted chemicals identifier numbers or names, but I don't think that would help much, we have 40 pages in this topic but most most discussion is always about two or three same matters.1 point

-

By my observation, virtually everything is known to cause cancer in California. CA has cornered the market on warning labels.1 point

-

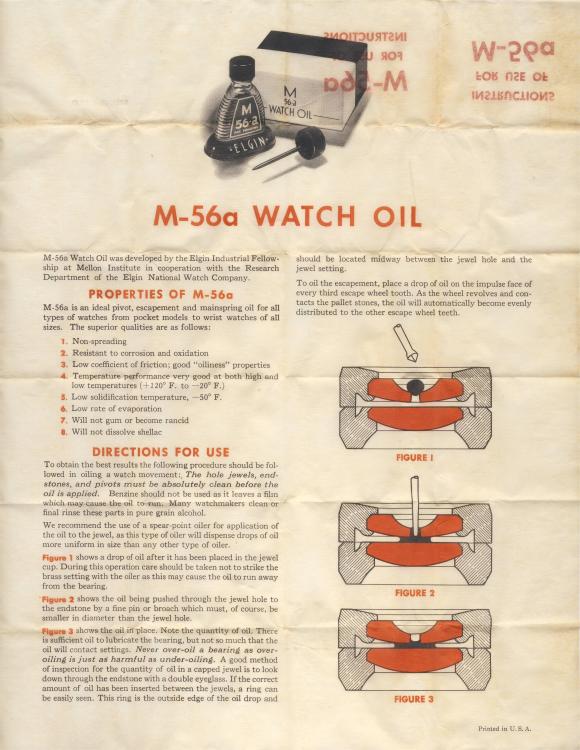

I would agree but looks like there's a little piece of paper in the back of the box? If you take it out unfolded place it on your flatbed scanner which I'm sure you have then we could all see what it says. Unfortunately I only have the A version of the oil. If you look at the chart that I posted up above you'll notice for viscosity is claimed to be light? My definition of that is it's almost like water I would never think of using it as a lubricants. The problem with superlight lubricants are and the chart shows that they really spread easily without surface treatments.1 point

-

Well I would definitely start with Moebius 9010 (for train wheels and balance endstones) and 9020 (for train wheels) if you are working on Pocket Watches. Moebius 9415 is a must for Pallet/Escape wheel teeth. A quality silicon grease. Moebius D5 is essential (barrel arbor, motion work). Molycote DX or Moebius 9501 grease for keyless work. Moebius 9501 or 9504 for high friction (e.g. Cannon pinion, Setting lever spring and anything at high friction). Moebius 8200 grease for mainspring. Moebius 8217 for barrel wall (automatic watches) It's a lot but at a minimum get 9010, 9415, D5 and 8200 I hope this helps. Recommended Lubricants for Getting Started.pdf Moebius_Oil_Chart.pdf1 point