Leaderboard

Popular Content

Showing content with the highest reputation on 01/03/22 in all areas

-

I use an old pocket watch mainplate with a handle bolted on. It has lots of holes to put the pallet pivot in, and is thick enough to heat slowly/maintain the heat. As mentioned above, go slowly, it only takes seconds (maybe 10-20) to melt the shellac.2 points

-

2 points

-

I like the guide rails for the honing guide. Well done! Here's mine: Slightly different approach. Sapele (body and lid), leather (gasket), hide glue, and garnet shellac, with flush inlaid DMT diamond stones, and a honing strop made of wenge (iirc), steel plate, hide glue, and leather. Lid on is the first pic, coming off is second, and in the third it's attached to the bottom using the same leather gasket that keeps it tight to the top. Guides and such live in the pocket. If I need to use a stone from the side, I can pull it out with the magnet (tool pocket, top left), and the pocket to the right keeps it in place while retaining access to the shoulder. Definite overkill for screwdrivers, but that's not what I made it for. I also do a lot of hand tool woodworking, and keeping blades scary-sharp is a necessity.2 points

-

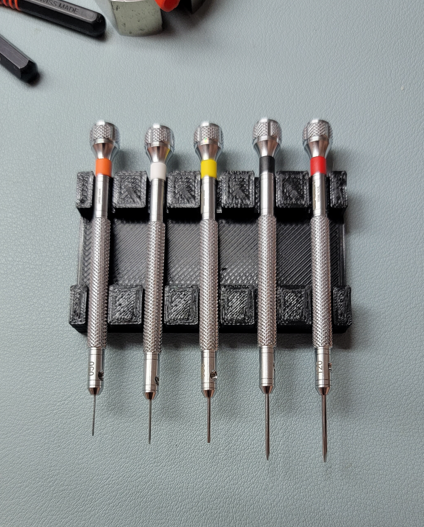

I bought some more Bergeon screwdrivers because Esslinger was having a special. Anyway, I hate those standing screwdriver holders...I have two. So I made this 3D printed stand/holder. I like my drivers to sit in order of size in a nice neat fashion. They get scrambled up during a service, by I always put them back neatly. Now I have this to assist.2 points

-

I use these in my toolboxes in the garage. They seem to work well for all the machinists tools. https://www.zerustproducts.com/products/electronics-tools-parts/plastabs/ Matt1 point

-

Apply a thin film of oil with a rug all over, place a silica-gel bag in the case, store in heated, low humidity environment.1 point

-

LOL..this is true even for amateur watchmakers like myself!! But, it is beyond watchmaking for me...I save every screw, bolt, nut, spring, funny-shaped piece of metal with hole on end and a tab on the other...1 point

-

OP said the hairspring has "broke away from the balance", so he should still have these parts. But yes, watchmakers including wannabes newer throw away anything. I didn't write that myself because I didn't wanted to be lecturing all the time.1 point

-

Back to ebay to see how much the roller table plus impluse jewel and stud was worth.1 point

-

For future reference watchmakers never throw anything away. It's why You have to very careful in buying stuff off of eBay material in particular if the packages been opened it's probably the old one. Although it's not just watchmakers that put the old thing back in the package for unsuspecting people to purchase I've seen that happen with machine tool components. Then in the case of your hairspring the other reason to not throw it away would've been if you can find somebody to vibrate a new one they would have needed the stud and the collet. Because unfortunately generic replacement studs don't fit Rolex watches. It's a misleading question has problems. For somebody who's learned how to vibrated hairsprings and knows how to work with hairsprings then it shouldn't be a problem but the picture is hard to see exactly where the problem is. But if you don't have hairspring experience and you not good the outcome probably won't be good either.1 point

-

1 point

-

Anyone want to post a link to the specific video? I don't have an actual internet connection up here, so pouring through that many videos is not a thing within the realm of feasibility.1 point

-

One may think of these prices as unreasonable but a Rolex 1210 watch sells starting at €2,000 all the way up to €6,000 and more, you can check chrono24.com. Parts or complete mov.ts are rare and precious, as mentioned work on these should be done only by qualified people, or at least by following the "best practices" I tried to outline before. Too bad no picture of the hairspring has been posted, despite people asking for these in order to help you better.1 point

-

Yes. Cousins will tell you that this is their post / carrier regulation, no lose Li-ion battery shipments, it's permitted only if contained in the device and up to a certain size. If the UK regulation makes exception for minuscole sizes, I don't know. However, recently they added the option to ship ground to Europe, which helps with these as well cleaning fluids. All that being said, fortunately there is abundance of other sellers for the same items which are happy to ship anywhere.1 point

-

Hi Ithink if you make a tool such as the one done by Mark and warm it over a gas light you should be ok, only problem with the oven is access when its warm enough the manouver the stones. As indicatd by Mark use indirect heat. and note what Vwatchie has said on the topic.1 point

-

1 point

-

No it is not, one needs to watch and control from very near the amount of heat In other words, the heat must be indirect and diffused by contact - from that the need to use a plate. In addition to the related discussion on this forum, watch our Host Mark Lovick making a pallets heather.1 point

-

Parts are oftentimes difficult to get by, and that goes both for DIY'ers and independent watchmakers (the industry generally don't want DIY:ers and independents). Anyway, there are several good parts suppliers, but it very much depends on in which part of the world you live. I live in one of the many EU vassal states (Sweden) so I do most of my shopping on CousinsUK.com. Anyway, start by taking a look at the "Resources" section here on WRT. https://www.watchfix.com/2019/11/08/watch-parts-tools-suppliers/1 point

-

This company specialises in Seiko on eBay. https://www.ebay.co.uk/usr/relojesvintage1 point

-

That is one of the predecessors of the 7S25B, that is the date-only version of the ubiquitous 7S26. An original part is not impossible to be found, but likely excessively expensive, You can probably find a direct replacement after-market dial in the large offering for "Seiko modders", as it's the same size and they love no day or no calendar dials.1 point

-

As noted in my previous reply--the balance was out of beat. Significant screwup on my part, but hey...I am still on this journey.1 point

-

1 point

-

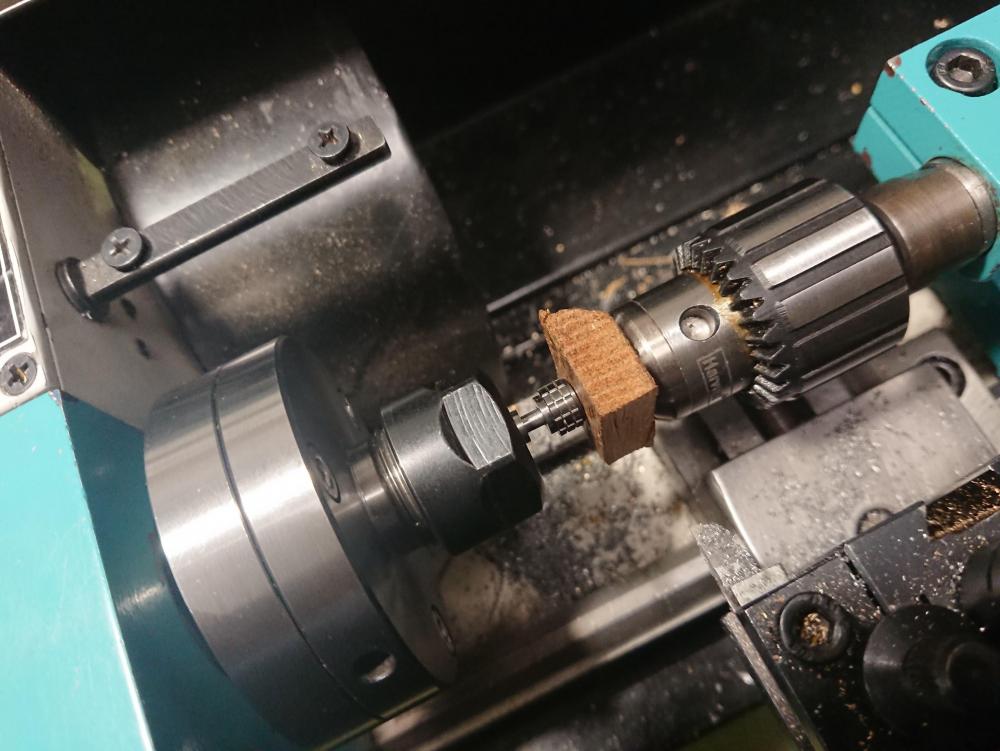

Someone had tried on a large Sector watch at the jeweler shop. Only later the owner found that the person managed (how?!?) to snap the stem in the little time he handled it, but didn't say anything. The crown is signed and of a peculiar look, of course Sector service center said that it's not available anymore. Then, somehow I botched on the correct way of removing a stem broken flush on the crown, that is to cut around the top of the female threaded section about 1mm to grab it. The sliding portion left for good and the fixed one was ruined. Time to think something different, all in all it took about two years until yesterday. All work was done an a non-watchmakers baby lathe with standard tools. An extremely useful one is the carburetor jets gauges below. These are now discontinued or sell for a stupid price but I had secured the pair from a German metrology seller. As the usual I apologize for the rough pictures. I started by drilling a blind hole in the original crown "core" to be the largest possible without touching the threads. Then cut off the button from a spare screwdown crown. That revealed the mistery of how the pipe, which holds the sliding portion and its spring, is attached to a screwdown crown. It's screwed in as well! But, once turned to press fit size into the hole of the original crown (3mm) there was not enough material to hold a firm friction fit. That I remedied turning and pressing in a brass sleeve. I left the contact surface a little rough to improve friction on the 0.05mm interference. I don't know why but most of my mechanical repairs involve sleeving and shimming. Then I turned a tube to push the above into the crown. It's sized so to be also used as a stump on the staking set. It went in without issue. Compressing air in there is not ideal, but once I realized it was too late to pull it out back and cut an escape groove. The finished item works fine on the case, all is left to do is to cut a new stem to size and return it to the happy jeweler.1 point

-

Yes, that's ethanol, and I find that it works far better than IPA. IPA will dissolve it though, after some time.1 point

-

How can you contact an hairspring producer. There are only like 2 or 3 in Switzerland and they don't correspond with repairers or individuals.1 point

-

Go to the British Horological Institute web site and download their accredited watch repairer’s pdf list. There are quite a few listed in London.1 point

.thumb.jpg.3cad98a9ff77201b699301ef3212357c.jpg)