Leaderboard

Popular Content

Showing content with the highest reputation on 12/12/21 in Posts

-

Well, I discovered the problem and I am sorry to say that it was caused by my lack of skill. Given the information received from everyone, the problem seemed to point to the pallets, or a single pallet. I knew they were not cracked but I removed the fork and took a closer look and saw that there was some oil on the top surface of the exit jewel, which made me think that I may have put too much oil on the jewel as well as a poor job of oil placement. I cleaned the fork once again and placed it back without re-lubricating and got a nice clean trace!! After cleaning the whole movement and parts once again, I carefully oiled the exit jewel and still have a nice clean trace on the TG. Success. The moral of this story: Get better at oiling pallets! Thanks for all the help and suggestions.2 points

-

You will need a watchmaker to repair these not a watch repairer. I don't know where you live. Here in the UK you can go to the B H I site put in where you live and what you need to be repaired or made and it will advise you where to take them. It is no good thinking you will just find spare parts on the net because it won't happen, suppliers don't stock such parts for Benson P/W or the other.2 points

-

Which way is off? If it's dial down, it could be that the roller plate comes too close the horns, so check again end play. Our it could be that the escape pivot supporting the bad position is not perfectly straight. Also worth to give all the involved jewels a good look under the microscope. In the end one could be trying another escape wheel.2 points

-

Hey all, I inherited this 1959 deep sea alarm. I’m very excited about having it restored. Ideally I would love to find someone in Florida who would allow me to be apart of the process as this is something I’m not ready to tackle. I told my mom I’m getting into watches and asked her to keep an eye out as she thrifts and yardsales. She said I have a couple of cheap ones of your grandfather’s. I was shocked when I looked up LeCoultre. It’s in rough shape and I want to get her ticking correctly again. I know it needs a full service and am not sure if the alarm works but the watch runs a bit. I have purchased a k815 caliber of eBay as a donor in the event I need parts. I am waiting on some jlc crowns and nos stems(found the service bulletin for the k815 on here.) I’m looking for guidance on finding the right watch maker to do it. I have emailed with Zaf of classic watches.com but mailing this thing scares the hell out me.1 point

-

Well, I am pretty sure that I can safely say that I have this. These screwdrivers, those screwdrivers. Should I buy a big set or individuals. Make my own base or buy screwdrivers that come with a base? Tweezers! Don't even start. Hand lifters? What size do I want? Movement holders? Spring winders? Clocks or watches. This cleaning fluid, that cleaning fluid. Do I buy an ultrasonic? Is it really necessary yet? Which oil? Which grease? Which polishing wheels do I get? Which timegrapher? Which desk light? Should I buy a microscope yet? Do I want a lathe? Do I need a lather yet? Do I want a mill? Do I need a mill yet? Do I get a lathe/mill combination? Would the Chinese machines be good enough to do precision work? Where in the hell am I even going to set things up as my house is already full of other stuff? Do I do Marks course? Do I do the BHI course? Will the watch companies succeed in their bid to basically shutdown access to parts? What would that mean to me, well any of us, that are looking to have a crack at all of this? Will I find people that have older clocks that need work or do people just not have that interest anymore? My head just doesn't stop. I hate it when it does this......... I know the answer is to just do something, but then I worry about what the other half will say. "You've got all these things that you want to do, now you want to add clocks and maybe watches? No-one is interested in them! Everyone has a smartwatch or a mobile phone." As I said, my head just doesn't stop.1 point

-

1 point

-

Greetings everyone! I just joined. I got interested in watch repair when I found myself in possession of a small ladies pocket watch that a client gave me, and no way to figure out the manufacturer or value. I went down the Youtube rabbit hole and became obsessed with watching people repair and restore watches. Like, hours of watching this stuff. I now have invested in a set of tools, bought my first non working watch, have disassembled it and discovered some hidden rust and corrosion...so I bought a donor movement and am pretty deep into this hobby already and loving the quiet time it gives me sitting at my desk and focusing on small parts and gizmos. Still can't figure out how to open that first case to see the movement, but that will come with time I suppose. Anyways, hello!1 point

-

The challenge was that after replacing a jewel in setting on a pocket watch, there was too much end shake and the pivots were falling out of the jewel hole in certain positions. So I created a technique for removing material from the outer ring of the setting, making it thinner and thereby seating it deeper within the plate and resolving the end shake issue. Here is the video, enjoy.1 point

-

What is your definition of really fast? The reason I'm asking is the watch only has a limited regulation range of 28 seconds a day. If it's running faster than that it's classically a phasing issue. If you looked at the link I gave you for phasing with a silver cell then explain you have to do that because the modern batteries have a slightly higher voltage. The watch was designed for Mercury battery of 1.34 V and the silver cell is 1.55 V. You really have to do fall a different procedure to prevent running superfast caused by phasing issue. Which is why we need a definition of how fast is fast.1 point

-

I picked a box of watches...maybe 30 total (have not counted) at a resale shop for $20. So that is less than a buck a piece. The majority are quartz and some interesting ones at that. The ones I tested so far are working. But the big find was the fake Rolex. I opened it up and it has an ETA 2834 movement and it is running!! Also picked a Caravelle with a Bulova 11DP movement. There was a 14k rose gold plate bulova lady's watch lurking at the bottom of the box. There was this funky mirror-faced LED watch. LOL The 2834 (-x) seems to be a popular movement so I may be able to get another dial and case for it. Researching.1 point

-

Hi As JohnR725 said pictures are always useful, you never know some one might just have an old watch and be able to help.1 point

-

I think Which magazine highlighted that 92% of items on sale during Black Friday were available cheaper during other times of the year. Maybe not all at once though? I'm still a sucker for special offers - I recently bought my 4th Dremel just because it was cheap, it's still in its box but I just couldn't miss out on a 'great deal'! Aaaarghh.1 point

-

Update Really enjoying the new hobby. I've been able to give life to 7 of my wife's old watches. Only opening, fitting new batteries. Low end for members, but for a novice it's one heck of a feeling of achievement. I have two mechanical pocket watches of Russian origin. One is missing many parts, so a practice for disassembly looms. the other is all there, but the balance spring is bent and deformed. Job for when I have more experience. Two mechanical watches. Ladies Sekonda. No Crown. Gents Sekonda. Hands need realigning. No second hand. The gents Sekonda and pocket watches are from my father-in-law. Due the missing parts in his watches I would hate to have used his repairer/s. Glad I never met them. I have a basic set of tools from ebay. Magnifying glasses (2) One is 3.5 flip down, the other is a 10/15/25 zoom. Both with LED. Small Yogurt pots hold my tools. In the New Year I need to (want to) purchase better set of tweezers, better screwdrivers and a mini vice set. Can do for all under £15 on ebay. Practicing an hour a day after my home bike work out. No not Peleton. Just a bike with the facility to put a tablet on the handlebars to cycle round sites in the world. My wife talks to the people she passes? Regards to all. And a special thank to the members of the forum. So friendly, not condescending, but very knowledgeable. Ross1 point

-

If I can guess here that the wires on the top are colored correctly, then we have the neutral connected to the hot and the hot connected to the 3rd terminal. But the 3rd terminal also has the case earth ground for some part of the case. And the earth ground from the cord is connected to the case too. Since the heater or motor don't actually care which is hot and which is neutral, we do have a circuit here. Hot/brown to blue to the motor/heater to brown to earth ground wire to the case to the earth conductor in the cord. Of course using the earth line as the neutral return isn't allowed. And will trip a RCD or GFCI. But the electrons don't care and will follow this path.1 point

-

Sorry, before I misunderstood what this part is for. I still think that the thin section is not 0,01mm but some amount more than that. But what's important is not measuring precisely, but making it. The original may not have been just cut off or machined, it may have been pressed between dies in the thin section. And almost certainly it is not made of the same material the OP has at hand, and is heath treated. Reproducing all that in the right sequence at home could be difficult, so perhaps one should think out of the box. When something can't be made as one piece, it could be made in more. For example one could try glueing a strip of 0.04 feeler gauge to the two "bigger" sections.1 point

-

I think there is something wrong with this connection. The blue wire of the incoming AC doesn't seem to be connected to anything. And on the other side, the blue wire is connected to the live wire. There is a green/white wire, which should be ground, that is connected to the last terminal. Check that out carefully.1 point

-

Just want various views of the rheostat. Possibly moot I'd the axle is broken from the rheostat frame. If you have an ohm meter, measure the resistance through the outside terminals. You will need that info to get a replacement.1 point

-

Fortunately this is straightforward too. I believe the movement in these lady Sekondas is a Chaika 1601A : https://17jewels.info/movements/c/chaika/chaika-1601a/ As such this should have a 0.90mm diameter stem size (also referred to as Tap 9). On the assumption you're fine to have a replacement crown that looks similar then just search for a term like 0.90 crown on ebay and take your pick (or look on Cousins etc.). Be aware of other dimensions like height and width too. Circa 5mm diameter is typical for a small watch like this. [But ask the owner ... if they found the original crown a bit small and have a preferred crown size then no reason you can't match that]. With the stem pushed in just mark with a felt tip the protrusion from the case. Take the back of the watch off and remove the stem. This looks fine and intact from your pics. You'll do this by pulling the stem out to the time change position. Now, whilst applying light pulling pressure on the stem, loosen the stem release screw. This is the very small screw on the left in the movement picture from the URL above. It's usually a 'turn and a bit' before the stem is released but I'm giving you the apply light pressure tip as you don't want to unscrew more than necessary and too far as that's then a dial off situation to reseat the screw! Now screw the crown on the stem. Ideally you want a drop of Loctite on the end (but superglue will do) so the crown isn't lost again. Don't screw beyond your felt tip mark though (assuming your replacement crown might not be identical to the original). Now put the stem with crown back in position and tighten back up the stem release screw. That's it! Happy days!1 point

-

A nice little French timepiece. Should give you hours of fun repairing it.1 point

-

Some off-topic postings have been split here. In addition, since these had images of dead game, these have been hidden for now. If possible, text content without the images will be restored. In all cases, when quoting a post with long text and images, please don't include these.1 point

-

Please do not post photos of dead animals as this can be up setting to members including me. This is a forum for horology not hunting.1 point

-

My partner showed an interest in my watches for the first time recently. She really liked the military inspired one, and requested one for Christmas. So I made here a more feminine version of the dial (is that sexist? If it is and offends anyone please let me know and I’ll retract it!). Not sure she likes mother of Pearl, but that’s what she is getting!1 point

-

All watches I own over 40mm are currently gathering dust. I have some lovely Panerais and a Planet ocean XL that I really need to get rid of. I can’t see myself ever wearing them again. I only tend to wear my homemade watches these days. I’m quite a big chap, but my favourite is 35mm. Everyone laughs at it, but I love it.1 point

-

Just like the service method, Timex parts do not fit into the standards of other makers. Your best source is to buy a mixed lot of "spares or repairs". the good news is that Timex used many of the same hands across many models so they are very interchangeable but not always. Also not that the Timex seconds had does not have a tube to fit to the pinon.1 point

-

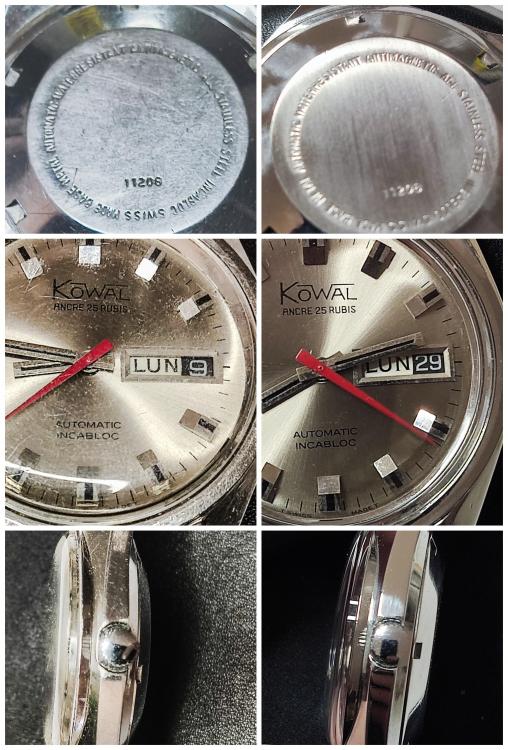

Hey friends. I'm posting this not really to show case, but to say thank you to everyone of you who gave me tips and help to finally achieve this. As I mentioned in my very first post, introducing myself, this summer I purchased 3 of watches in a jumble sale. This is one of those 3 watches, fully serviced and restored with the skills I learnt from Mark's courses and this forum. It is named Kowal Ancre, I think it was a Spanish company that bought the name from a old Swiss company, it mounts an As2066 movement. Noting more to add but some pictures. Again, thanks a lot. @Mark @jdm @Plato @Marc @HectorLooi1 point

-

Thought I'd share another triumph, for me anyway. I'm still new to this game and don't have a dedicated work space and only functional tools. Picked up this 1970's "30" jewelled automatic wonder just before Christmas. It wasn't without issues. In it's past someone had poured a load of oil into it (smelt a bit on opening) and it took a while to clean it all by hand, soaking this and pegging that. I was lucky enough to find parts which proved invaluable and educational. I even plucked up courage and practised removal and lubricating shock jewels which was a first for me, still have a healthy respect of them though Replaced the double toothed hour wheel, missing three teeth. Date wheel, ruined by the old oil. Rotor as the brass bushing was too worn, and it sounded like a bag of spanners, now it's gloriously silent. It then turned into a labour of love as I even had a go at the hands. After much deliberation I applied lume by way of my own improvement, they were originally painted white but the oil had affected these to the point the paint had dissolved. It's now my favourite watch, it's been running really well for over a month now and keeping great time, so I must have done something right. Anyway I thought I'd share it, as perhaps what can be achieved at the dining table with determination.1 point