Leaderboard

Popular Content

Showing content with the highest reputation on 12/07/21 in Posts

-

Measure the slots and reference from the attached table. I believe that either alkaline 1.5V or silver oxide 1.55 V will not make a difference. To see if it works fit any battery you may have which makes contact. 1_Battery Cross Reference Guide.pdf3 points

-

Hello there, I'd like to gauge interest for a project idea of mine. I'm a web developer by trade and for the moment I'm stuck at home with the good ol' rona, so it got me thinking. What I'd like to do is fairly simple. Just a new online database for watch calibers. I know how hard it can be to find information on new and old watch movements. And the existing resources albeit great are also showing their age. So here is what I propose: I would build an open source web app based on Ruby on Rails and SQL (mariaDB, MySQL, PostgreSQL). Each caliber would have its own page with the following information: brand, model, pictures, year of production, width, height, mainspring reference, lift angle, hand sizes, dial feet position... Since all the data will be relational, you could browse by brand or by size or width or whatever. Obviously I cannot gather all this data by myself, I have a bit of experience, but I am an amateur watchmaker at best. I would therefore create formular pages where everyone will be able to upload his/her own caliber information via his/her personal account. Of course, I would add a basic search engine support. Currently the online resources I know of: Ranfft Watchguy.co.uk: lift angles and mainsprings https://17jewels.info https://calibercorner.com/ To bootstrap the database, I would ask those respective website if I'm allowed to scrap their data and of course reference them. The project would be developed in an open source fashion and published on Github What do y'all think, would there a need for such or am I just wasting my time. Is there some things I'm overlooking, functionalities you'd like to have? Thank you2 points

-

The end flat of the screw should hold what ever it is touching tight, is what I meant to have said.2 points

-

You will need diamond abrasives to work sapphire. You don't want to use it on a jacot tool as it wears the beds.2 points

-

Been restoring another cricket and discovered that the pusher stem seems to be damaged, so I decided to turn a new one. Notice that I made the each end a little longer than the reference piece. I can shave it down if necessary. I made the narrow end on the right a little bit larger in diameter than the sample because I noticed that the pusher button was not seating well (still loose).1 point

-

This guy is one of worlds best watch makers. Only the very wealthy can purchase one of his watches for sure https://www.youtube.com/watch?v=9v5jwctHtf41 point

-

After assembling few watches from readily available parts of AliExpress it was very natural to want something more of a custom thing. This is a result of my first attempts in making a custom dial and casing and all techniques involved. Original dial stripped down to bare brass, soldered movement posts to match new movement, primed and painted silver then inkjet waterslide decal and finally glossy coating. Movement holder is 3d printed. Seiko VH31 quartz movement pretending to be mechanical ticking at 4Hz. 34mm case used is from and old and broken beyond repair soviet Poljot which itself is a homage to Omega Geneve. And I twisted it further to be a homage of Explorer :)1 point

-

Typically for LED watches the batteries will be large as they consume a lot of power. The picture in the link above looks like a 386. At the link below it looks like a 357 which are both identical in diameter but very only in height. http://www.crazywatches.pl/novus-led-19751 point

-

Always important to have a picture because they're literally hundreds of thousands of movements out there and without a picture we don't know which one you have. Even Waltham made a lot of watches so I can't really assume which one you have without a picture. The easiest way when working on the watch is not the put the cannon pinion on and the watch will run just fine out of the case. Then is a lot of variables here in some cases you would have to put the watch back in the case. There is there is a variety of mechanisms to put the watch in too winding mode out of the case. Hamilton for instance sometimes had a blue colored screw that just needed be rotated a little bit. Most of the other watch companies had a lever to pull out somewhere near where the stem goes in. When the watch was disassembled you should and noticed a part that seem to have had no function. Typically the part is pressed into the main plate and stays there until needed where it's just pulled out a little bit. Occasionally like I've seen with Illinois it will fall out. So you have to remember to put it back in. for instance depending upon which Waltham you have you should have something like the picture below. You can see the part labeled D just has to pulled out a little bit. Then the watch will be in winding mode out of the case it will run just fine.1 point

-

1 point

-

1 point

-

1 point

-

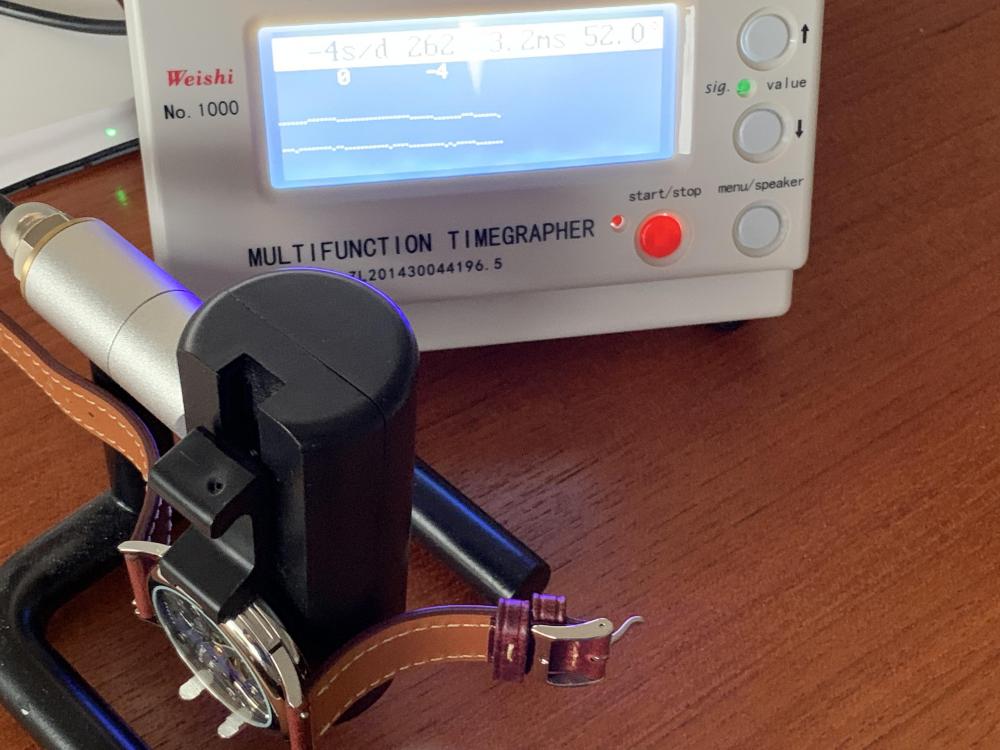

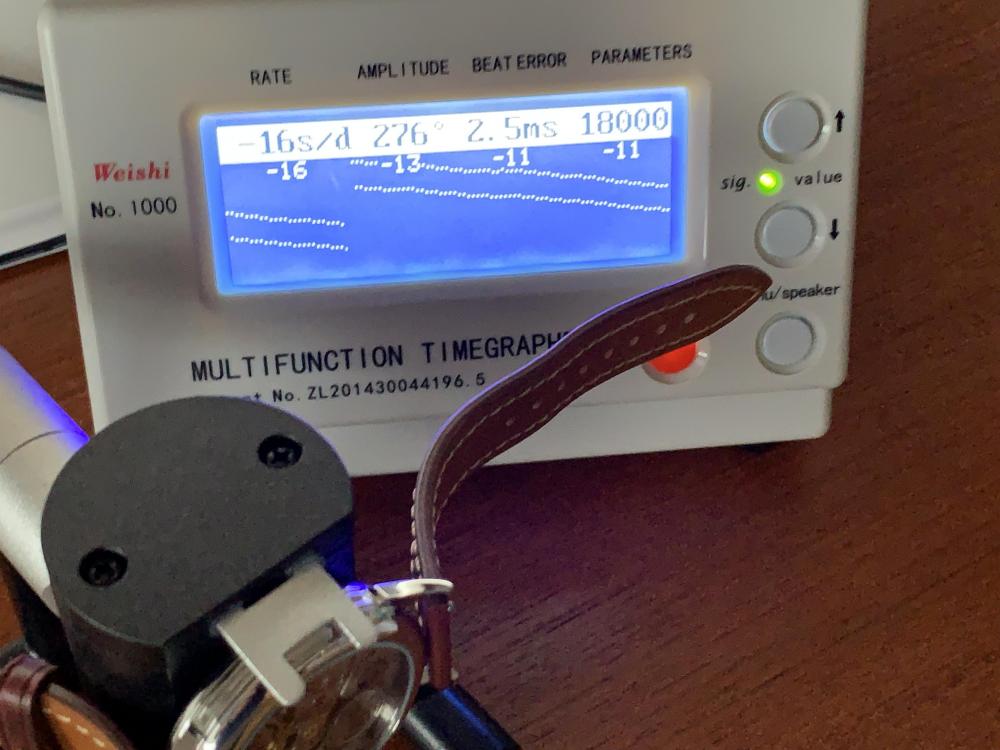

To go back to my original post - I had done maybe a handful of Molnijas by that time. I was systematically going through the calibres since we couldn't do much else during covid where I live in Australia (for a long time we had night curfew and couldn’t travel more than a few miles from home in the daytime). So I had time to get an understanding of their “interesting lives” as you put it. Most were actually fine from the get-go and came up well – and as you say, those that weren’t rescued were probably always doomed (although I had a couple of successes). If they worked at the end, I'd usually on-sell them at a loss - it's a hobby and I can afford to spend on a hobby at my age. The watch in question in the original post was a relatively rare transition model (Krystal) between the early 15 jewel ChK-6 Molnija calibre and the later 18 jewel 3602. I was frustrated because I thought I had the knack of it and the watch worked well for some time after service. I didn't photograph the timegrapher reading, but I recall it being little different from what I’ll show below even when it was starting to play up. What I’ve found with most of these old watches is high beat error. So when the suggestion came in that it was the problem, I decided to give it a crack – but I cracked it instead. After the Molnijas I transitioned to small American Hamiltons, which was always my goal. They also have had interesting lives, although not as hard as the Russians. It’s one of these that has the issue with the tight tolerance between the cannon pinion and hour wheel – I think the latter got crimped at some point in its interesting life. Yes, I understand about starting on cheap new (Chinese) movements – and I did (an ST36). It was useful, but the Mollies were going to give me the experience for what I wanted to do, so I quickly moved on. Below is the timegrapher of a serviced Molnija that’s been working for months – part-wound, dial up/down & crown up/down. Most have looked like this. I understand the beat error to be high (like the Krystal) and the amplitude OK given it’s an old watch. It runs fine in different positions except slow face down – but it keeps good time on wrist, so I’ve left it as is. But again, it's a learning experience for me - so if I'm missing something - then kindly let me know. Thanks.1 point

-

Check out the 4th photo in this listing. I think you will get all the info you might need from this.. https://www.ebay.com/itm/124972474298?hash=item1d18f09fba:g:4OgAAOSw~eNhdveu1 point

-

At the end of the day, I repaired the hands, put it on the wall and tested and tweaked the timing. No cleaning. Returned it to the owner yesterday. No charge (I dont charge anyone for my work), but she gave me a cherry pie! I explained the situation with the glued-in bellows. If it does start losing time, I can repair it but will have to do significant surgery and spend the money for new bellows. She understood.1 point

-

As advised by jdm measure diameter and depth and refer to the cart for sizes. They are likley two 1.5v cells be aware that fitting the cells incorrectly ie wrong polarity can damage the module. The battery guide attached gives you the cell dimensions. Battery Guide 2018.pdf1 point

-

Out of curiosity, is it normal to refer to something like this as tit in the US and UK? The online dictionaries give different meanings.1 point

-

These stud screws are usually similar. I'd measure the thread width and find any spare from a scrap watch.1 point

-

What WW says. Very handy, especially on smaller screws where there is little to aid guiding the screw into alignment.1 point

-

Hi quite often see them on the balance cock and pallet cock, I assume the tit is to guide the screw into the starting point of the thread keeping the screw upright making it easier to start. .1 point

-

Welcome to the forum John. Watch your footing. It is one of the deepest rabbit holes out there.1 point

-

Thanks, anilv. On reflection – I reckon it was the mainspring not releasing for some reason. I dismantled the barrel assembly, cleaned everything and put the spring back by hand. I’ve done a few now and they can vary – probably the most variable part of these watches. I can’t remember the state of this one, but I wouldn’t be surprised if it wasn’t perfect (I’ve yet to find one that is) or if the mainspring was on its last legs. Unfortunately, I took the advice about fixing the beat error and did that first – but with a non-adjustable stud carrier it was beyond me, so I slipped and wrecked the hairspring. A pity. But it’s all part of the learning experience.1 point

-

OK thanks everyone for all the feedback. Am going to clear the decks before starting this and wait for a quiet time.....watch this space! Have a good Christmas, Cheers Simon1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

1 point

-

1 point

-

I've typed up a half dozen responses to this since it was first posted, and I'm going to commit this time! This is not a criticism in any way of the method/tool there. Just genuine discourse, engineer to engineer. Please consider it in the spirit it is intended. I place cap jewels flat down on a piece of watch paper (so far so good), then fold a corner over, and just rub it around with my finger tip wearing the requisite finger cot. Not sure where I picked this up, but it's such a simple solution to a task that can go so horribly wrong that I'm sure I got it from somewhere else. Mark or some other youtube person, most likely given the fundamental nature of it. What is wrong with that approach? The only thing I can think of based on the above discussion is that it might go flying if I were to crinkle the paper or something. I've had that happen to where the jewel jumps, but never very far. I know better than to discount my own clumsiness and relative naiveté though... What about that is this addressing, and what other issues might be being introduced? The paper being taped down solves the fly away crinkle problem, but the stick seems like an abstraction from the manual manipulation that could (and in the not discounting clumsiness paradigm, will) result in equally annoying unplanned flight. Additionally, the tendency to apply additional force through the tool without its own escape prevention feature seems to magnify this, compared to the finger method having all that squishy finger enshrouding the jewel on all sides, prohibiting any possibility of escape during manipulation. A simpler solution, if we allow/agree/accept/whatever that the paper being taped down is a mandatory practice to avoid Alcatraz-esque exploits in escapery, would be to replicate the cotted finger and a second sheet of watch paper over a second, taped piece of watch paper. You have the required manual control over pressure and position, the escape prevention of the finger flab, and backup escape prevention in the form of the captive second sheet of paper, combined with the sproing mitigation of the taped piece of paper. Again, consider this in the spirit it's written AND consider the source. I'm not quite two year into learning this stuff, and that's on a as-can-find-time basis with work and a baby/toddler in a pandemic.1 point

-

As I mention in the video, I tried with regular printing paper, but on closer inspection (40X using my stereo microscope) I noticed printing paper acts a bit like sandpaper creating tiny scratches on the jewel. So tiny that I'm not sure it would impede staff pivot performance. Using watchmaker's tissue paper from Cousins I couldn't detect any negative impact on the jewel so I'll be sticking to that.1 point

-

1 point

-

1 point