Leaderboard

Popular Content

Showing content with the highest reputation on 12/04/21 in Posts

-

First the easy questions the questions? Can the balance spring be replaced no. Yes but it's not going to happen so the answer is no. Can you purchase another balance wheel and swap hairsprings definitely not they come together typically. We would have to identify the movement and see if anyone carries old stock parts unlikely for balance complete the third question is more interesting? We need better pictures and a better description? Common practice back then was that they hairspring will stick out beyond Where it is pinned. If the protruding part isn't touching anything it's probably just fine. Then as far as a terminal curve goes a lot of these watches never had A terminal curve. We really need better pictures but it looks like there's not even space for terminal curve. Basically it's really important to ascertain the situation understand exactly what you're looking at for this watch before attempting to fix things otherwise you going to have to fix whatever you thought you were fixing.2 points

-

Look on here and you can see what the movement is like. If you type in google Pulsyenic Master clock then click on images you will find loads of pictures of them and there movements. http://www.thetimeworkshop.uk/gents-pulsynetic-master-clock-for-sale/ I found Bonhams sold one for around £700 but It doesn't give a date of the auction.2 points

-

I realize I'm responding to a comment that is a few months old but some things make me twitch. Isopropanol aka isopropyl alcohol aka 2-propanol has a toxicity in humans only marginally worse than ethanol. Still don't drink it - isopropanol intoxication can hit hard enough to stop your heart. It's why moonshiners sometimes adulterated their products with it - packs a punch in a hurry. But casual exposure is no big deal. Methanol is far more toxic in humans. Don't use regularly without good ventilation and good gloves toxic. And over time it can be sensitizing, which is to say that if you are exposed to it frequently there is a risk that you could have increasingly severe reactions to it. I use hardware store "solvent alcohol" which is up to 50% methanol and the rest ethanol in alcohol burners because it burns clean and isopropyl does not. fwiw, people refer to methanol as "wood alcohol" but in actuality it can be obtained through the fermentation of any sugars with an odd number of carbons, iirc. Have to ask my retired chemistry professor friend again. And at any rate both isopropyl and methyl largely come from oil refineries these days. In some regions you can get "alcohol fuel" that is straight ethanol + a bitterant that makes it undrinkable, and that would be the safest alcohol to use as a cleaning product, but you should always check the safety sheet (formerly called an MSDS in north america, now called an SDS globally). And you might want to wear gloves anyway, because bitrex is the bitterest substance on earth, and it's not a pleasant bitterness. For the rest of it, my chemist friend and i went over a lot of safety sheets for watch cleaning products years ago. L&R 111 is 60-65% naphtha, 15-20% mineral spirit, 5-10% oleic acid, 1-5% Isopropanolamine, 1-5% 2-Propoxyethanol, 1-5% Ammonium Hydroxide. My chemist friend proposed that, aside from some of it forming a soap with some of the ammonia, the oleic acid may leave a single-molecule-thick film on parts that may help protect them from corrosion. For what it's worth he seems to be of the opinion that ammonia is a bit harsh for cleaning brass since the ammonia is literally removing the oxidized copper and zinc from the surface, which is why the resulting surface is so bright. Thiourea is gonna be more gentle but, uh, carcinogenic, and stinky in a different and somewhat more noxious way. So how much does it matter to you if your brass is shiny? Maybe use the ammoniated products sparingly when you need to brighten things up. We postulated maybe going with 3:1 naphtha and mineral spirit with a drop of olive oil. I do note that L&R's rinse products don't contain the oleic acid. Or the ammonia. A whole lot of Zenith's wash and rinse products appear to be straight naphtha. Zenith Hi-Solv is Crest Hi-Solv - a product marketed as a final paint prep solvent for automotive work - in a different can. Auto paint guys are extremely serious about clean surfaces and there's nothing in it that would dissolve shellac. I'm considering seeing if i can get it from a paint store locally. Crest sells it online for $22/qt + $13 ship and $35 seems a bit much for a quart when i can get a gallon for $55 (plus ship) from esslinger. Zenith Hi-Tech is an isoparaffin concoction and i would not be surprised if it turned out to be very similar to one of the "naphtha substitute" products sold in CARB-restricted regions of the USA. If it works, great. Chemist said, isoparaffin solvents work great except when they don't, and a "substitute" for naphtha won't perform like naphtha in all cases. I am pretty sure that the admonition not to use any volatile solvents in ultrasonic baths is related to the whole idea of just filling the tank with solvent. Not just the heat, but the rapid vaporization that would happen. And some people do it anyway and don't die. But solvent in a sealed jar set in water in the ultrasonic is going to be pretty safe, and that's what i have done in the past and expect to do in the future. Final advice from the chemist was that a lot of hardware store solvents and fuels may contain waxes and other heavier oils and greases that may not be in the commercial watch and clock cleaners. In particular, mineral spirit often has some waxes in solution. To get rid of those, put the solvent in your freezer for a few hours. The heavy stuff will plate out and most of it will stick to the walls of the container. What doesn't, you can take care of by running the solvent through a paper coffee filter while still freezing cold. You could theoretically use this method to recycle spent non-ammoniated wash solution into, well, I guess you probably still wouldn't want to use it to wash parts, and you could use it as bbq lighter fluid without purifying it. You could use it to clean tools? *shrug*2 points

-

In my opinion that hairspring has been distorted by someone poking with the watch, which is (and was) actually very common. The reason of the watch not running could have been something else, and from that the supplementary damage by a total incompetent trying to "repair" it You can take it apart and check if, for example, if the mainspring or a balance pivot is broken.1 point

-

Hi Ross yes its doable but as Joe said there is a lot to think about even before attempting such a job, first you need to learn about balance/hairsprings and their formation the types of metals used as some are brittle (usually old blue springs) and the newer ones berillium are a bit better. you will also need to know the techniques involved with straightening springs such as yours, and a great deal of practice. watch Marks videos on the subject and read the books on the subject and be prepared to learn a lot, Keep the watch in its box untill you feel confident then go for it. You have now got a target to aim for. all the best and good luck.1 point

-

Hi the (pin) you bumped is the regulator Lengthening the terminal coil makes the watch slow down shortening it makes the watch go faster, but what you also may have done inadvertently is to move the pinning point of the hairspring knocking it off beat. This can lead to the watch stopping prematurely, If you have access to a timegrapher or other test software ie watch o scope, Tg. or the like check the watch for amplitude and beat error, beat error of 0,02 or close should be ok. I am not too happy with the shape of the hairspring coils they look a little compressed at the side of the index.1 point

-

I've typed up a half dozen responses to this since it was first posted, and I'm going to commit this time! This is not a criticism in any way of the method/tool there. Just genuine discourse, engineer to engineer. Please consider it in the spirit it is intended. I place cap jewels flat down on a piece of watch paper (so far so good), then fold a corner over, and just rub it around with my finger tip wearing the requisite finger cot. Not sure where I picked this up, but it's such a simple solution to a task that can go so horribly wrong that I'm sure I got it from somewhere else. Mark or some other youtube person, most likely given the fundamental nature of it. What is wrong with that approach? The only thing I can think of based on the above discussion is that it might go flying if I were to crinkle the paper or something. I've had that happen to where the jewel jumps, but never very far. I know better than to discount my own clumsiness and relative naiveté though... What about that is this addressing, and what other issues might be being introduced? The paper being taped down solves the fly away crinkle problem, but the stick seems like an abstraction from the manual manipulation that could (and in the not discounting clumsiness paradigm, will) result in equally annoying unplanned flight. Additionally, the tendency to apply additional force through the tool without its own escape prevention feature seems to magnify this, compared to the finger method having all that squishy finger enshrouding the jewel on all sides, prohibiting any possibility of escape during manipulation. A simpler solution, if we allow/agree/accept/whatever that the paper being taped down is a mandatory practice to avoid Alcatraz-esque exploits in escapery, would be to replicate the cotted finger and a second sheet of watch paper over a second, taped piece of watch paper. You have the required manual control over pressure and position, the escape prevention of the finger flab, and backup escape prevention in the form of the captive second sheet of paper, combined with the sproing mitigation of the taped piece of paper. Again, consider this in the spirit it's written AND consider the source. I'm not quite two year into learning this stuff, and that's on a as-can-find-time basis with work and a baby/toddler in a pandemic.1 point

-

I think you'll find that a lot of the screw type you have to push a little bit. It depends on the parts on the other side but it's not just unscrew pull the stem out a lot of times you have to hold the screw down. You should build the use your hand press or staking said or basically anything that puts an even downward pressure. As to how much force is required that is the interesting question? Did you try flipping the wheel over and seeing if it goes on better the other direction. Usually they always seem to be facing one direction. Conveniently the instructions don't tell you which side goes down. Then yes there is a possibility that you may have to open up the whole a little bit. But I would be extremely careful with doing that as it's easy to go too far.1 point

-

Hi Gina As said by watchmaker dial dots can be used if the feet are wrong, be careful if the movement has day/date complications it can be problematic achieving the clearance required. you can also purchase dial feet which glue on to re position the dial,available from most good material houses and ebay, so plenty of options1 point

-

Hi @gina If this is just for a fun project then also consider dial feet dots. Whilst for purity and ultimate security then dial feet (posts) are favoured, the adhesive dots can provide a possible solution. This means you can remove original dial feet and thus fit a dial to a movement of your choice with dots instead. For the amateur this avoids needing to invest in a dial feet soldering machine or otherwise learn the fine art of feet positioning which is a precision art in itself.1 point

-

I think you are right to narrow it down to the final assembly. Matching up "foreign" movements, cases, dials and hands is tricky, because the clearances are so small. You need to carry on with your process of elimination, removing one possible area of collision at a time (hands to crystal / hands to hands / hands to dial / hour wheel to dial) until the problem disappears. Beautiful-looking watches by the way.1 point

-

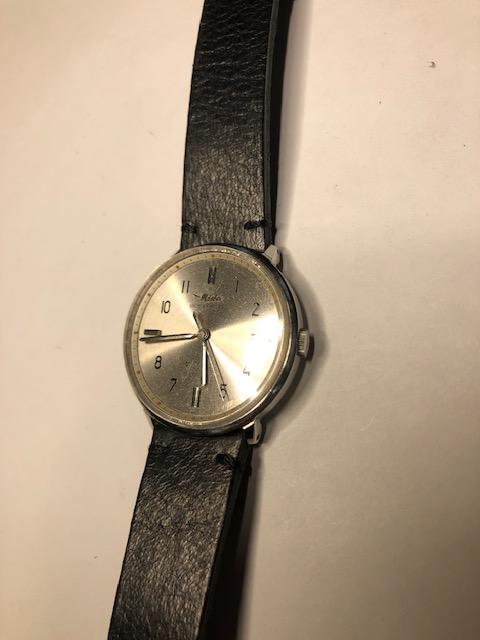

Hello Watch repair posters. I'll add this post as a follow up. I'm new to this hobby and having quite a bit of fun and gaining some skill while encountering plenty of challenges. So I've completed my work on this Mido pictured in my earlier post. I purchased it with a few issues. No crown, a broken off pendant tube. cracked crystal, oxidized face and bent second hands. I have managed to attach a similar 'Mido' crown. I have completely disassembled this auto winder, cleaned reassembled and lubricated to the best of my know how. With a new strap, it's my new daily wear. Keeps great time. This is my fifth watch project. I'm currently working on three different ladies automating watches. Wow are these movements tiny. My problem now must be a common one. Too many watches to fix. I better quit ebay !1 point

-

Hello L. I am not sure if use of staking set is a sure approach, have just heard about better success rate by its . Pull streight up with presto tool is about the only advice you can expect here, yet facts are removal/repalcement of min wheel is risky. I think your right bout the logics of even pressure distribution. Regs Joe1 point

-

1 point

-

The vast majority of staking tools use 4.7mm punches, and 4mm (bottom side) stumps. I don't know where this norm developed, but 3/16" is within a few hundredths of a mm of 4.7, and my guess is the Yanks originated it. I use K&D stakes in my Star tool, no problem. I've seen Boley staking tools that had 5mm stumps (centering diameter)but not all, and Horia used to make staking tools with 5mm punches, which makes sense- but they don't make them anymore. I keep 4.7mm steel on hand for making custom punches.1 point

-

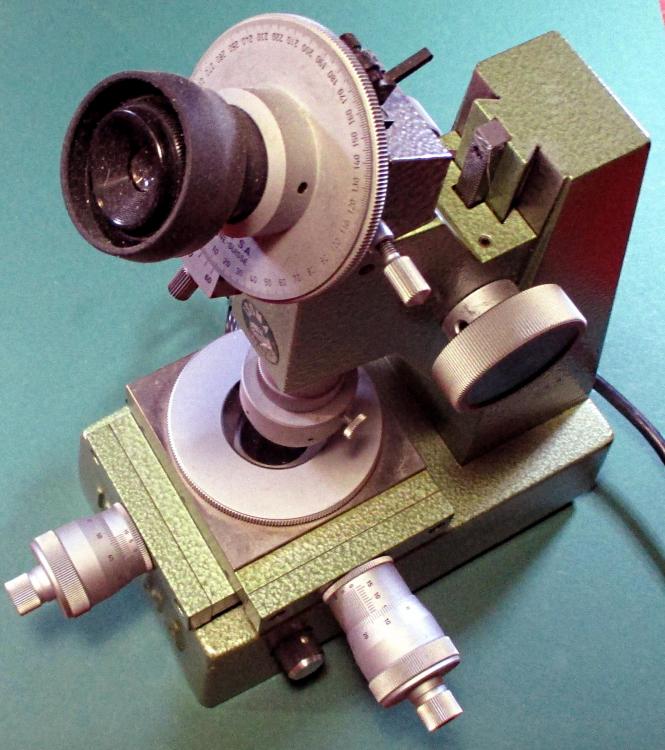

As I mention in the video, I tried with regular printing paper, but on closer inspection (40X using my stereo microscope) I noticed printing paper acts a bit like sandpaper creating tiny scratches on the jewel. So tiny that I'm not sure it would impede staff pivot performance. Using watchmaker's tissue paper from Cousins I couldn't detect any negative impact on the jewel so I'll be sticking to that.1 point

-

Any extra cash made can be invested in new tools or watches which is a bonus for us all.1 point

-

This arrived today. Bright spot in my life...been buried in my work (unrelated to watches). This is another Vulcain Cricket. Looks like I don't need to fix it. Beautiful!! Another ebay purchase. Now I have three working Crickets...two of which I fixed. I have another that needs a few things but I am working on it!!1 point

-

1 point

-

Hi Gents of Leicester, manufacturers of the Pulsyenic Master clock widly used in factories during the 50s onwards. My brother worked for Seimens and repaired/maintained some up into the 90s. the factories had a master clock and several slaves which got their pulses from the master and one was used as the clocking in clock for the time cards for the workers. Values vary according to condition and originality as some were modified for domestic use. They were noisey in operation with a noticable clunk when pulsed. The one shown looks in good condition and therefore will pull a fir price.1 point

-

Hi Hector thats one hell of a transformation. When it started out it was a basket case a lovley job well done.1 point

-

The hairspring was probably a replacement and was never shaped and trimmed. By trial and error, I was able to get the correct length for the spring and trimmed off half an inch of it. And with another half an inch through the hairspring stud, I managed the get enough space to form the endcurve. The spring moves up and down between the regulator and the 2nd coil of the spring doesn't hit the regulator when it breathes. I cleaned up the case and sprayed silver paint on the sides, top and bottom panels. I also reprinted a new dial on cardboard. Looks good for the moment but I would really like to get the case chrome plated.1 point

-

Don't sell it...wear it!! What would you do with the money anyhow?? That is a beauty!!1 point

-

1 point

-

Your comment got me thinking and I passed. I'm really glad I did because a NOS C&E Marshall came up, totally unused and 100% complete. Including newspaper packing from Wednesday May 4th 1949 The packing paper was from THE LIFE newspaper Chicago Ill. (Same as the company) Here is an interesting thought. I bought in on May 7th 2021 and it arrived yesterday.1 point