Leaderboard

Popular Content

Showing content with the highest reputation on 11/11/21 in all areas

-

4 points

-

https://www.timewornwatches.co.uk/manufacturers/ebauche-movements/ The word ebauche means incomplete movement. In the past there were lots of manufacturers of watch movements , Finishers would buy these incomplete (ebauche) watches and finish them put them in their cases with their name on the dial. Therefor it was possible then and now to purchase two watches with different dial names (finishers) with the exact same movement with mods by the finisher. Now when trying to locate parts the vital information is the maker (stamp under balance wheel or on the top plate or the rotor in automatics) and the caliber number for example AS 1215 or ETA 251.262 as these numbers relate to the specific watch. Through the web site Dr Ranfft as mentioned by Joe you can find the base movement caliber and all the derivitives built from that base which can be several, thats why the caliber number is important. Have a look at the link posted for a little more detail. cheers3 points

-

The round part where the pivot hole is is 0.80, but also has part of that circle removed, so it would have to be something like 0.40 diameter jewel, with a 0.12 hole. The smallest jewels you encounter normally are 0.70 diameter, and occasionally a 0.60 crops up. Outside of that it's really custom stuff.2 points

-

1 point

-

Hi The unitas 6497 brings up the ETA6497 and as no tech seems to be available for the Unitas/UT and everything equates to the ETA movement . from the drawings (attached) there are three heights measured from top to bottom of, 2.65 3.00 3.15 so in answer to your question it would look like you measure the total height of the canon pinion Hope all this is some use to you cheers Unitas 6497-1, 6498-1 (1).pdf Unitas 6497-2, 6498-2 (2).pdf1 point

-

Nickel plate is tough, but not very thick (10-20 microns?). So you can only polish out very slight surface scratches. I use Dialux white on a dremel with a hard felt disk. As you say, if it's too bad you need to replate. I've been experimenting with nickel plating recently with some pretty good results. I do electrolytic stripping, which always results in a pitted surface. So there's work to get the case nice and polished. I tried making my own plating solutions, but the results were mixed. I finally bought some proper plating chemicals, and the results were very good - a really shiny even coating.1 point

-

Instead of paying your watchmaker $200, why not just buy a staking tool and a staff remover and attempt it? It's really not that bad a repair, especially if you're competent enough to change the balance anyway. Re. those two examples above, note that one is Breguet and the other is not. Hairsprings cannot be transferred so you need to buy the correct type. In any case he doesn't list the staff type so you would have to message him and see if he will check. I think 1365 is the more common of the two '83 staffs but you should still measure to be sure... Also it's not just the length that is important. The divisions (horizontal distances between components) have to be correct. For example here the distance from bottom pivot to roller seat differs by 0.03, not 0.01, which raises the risk the fork won't engage properly.1 point

-

1 point

-

For anyone curious about viscosities and properties of moebius Lubrication I'm attaching a PDF. MoebiusProductCatalogEN.pdf1 point

-

Normally that's the beginning of a good plan. Always measure the old then measure the replacement. Also verify that whatever you think you're ordering correspondence to whatever you think you've measured. But not for this staff apparently? Because any of the references I have appear to be almost exactly identical. Or basically I can't tell which staff except? To explain the problem I snipped out a variety of images including the answer to your question. One of the images shows the standard measurement locations of a balance staff if you're looking for staff. Then taxed out of another reference showing the measurements commenting that there is a difference in size but visually by the numbers they appear to be identical. Although you will note as is usual with American pocket watch staffs there are pivots size variations. Then the answer to the question. One of the books I have is a cross reference of staff sizes give you have a size you can find the staff. In the back of the book is reference material from various watch companies. Then in the very back somebody measured some of the balance staffs. On that image we find a measurement it's not standard and we also find the number 1.68 then the other one is 1.94. Or basically both staffs are identical and it really shouldn't matter which one you use. Then if you really pay attention to the drawing you'll see minor variations in size? From another discussion group in reference to this book it was suggested that the numbers are always accurate. But there's also the problem of the American watch companies changed or sometimes changed things. So basically the numbers are really really close. Which is why from time to time staffs may or may not exactly fit. Plus I suspect sometimes companies manufacturing replacement staffs may or may not of exactly follow the size scheme of the particular staff. I have a suspicion some staffs were deliberately made large so you can reduce them in size to fit. But that's just the speculation on my part.1 point

-

Think of the movements as automobiles. There can be several 'models' (Fiesta, Kuga, Focus etc) in many 'brands' (Ford, Volvo Seat etc) of which many are part of major groups (PSG, VW GM etc). It is likely some or many parts within a model will be compatible, less so across brands and very unlikely across groups. So a movement might be ETA2824 which means it is a model 2824 of the ETA brand, whilst ETA is part of the Swatch Group which includes Omega for example who have their own models. There may be some interchangeability between ETA models but unlikely between ETA brands and extremely unlikely between Swatch and other groups. ETA is only one example, the analogy would apply to other brands such as AS, FF etc. It should be noted that not all brands make their own movements or model/brand, but buy in from other model/brands. Much like engines being used in specialist cars etc, PSG and GM groups are typical. Also some model/brands do not make the full car (ie watch) but supply the main transmissions (watch movement), eg Sellita. Now your even more confused !!!!1 point

-

Attend the Bay problems with horological literature. It can span a considerable length of time with some aspects not changing at all over that time. It's why you can pick up a book on watch repair 400 years ago and a lot of it still relevant. Then procedural things unfortunately aren't always covered in normal technical documentation and a lot of times watchmakers don't even know this other stuff exists. Sometimes you had a clue because they would refer you to another document that you don't have conveniently. So things like lubrication surface treatment sometimes required which would change the choice of lubrication's and other procedural stuff may not actually be known did anybody unless there were lucky enough to find a technical documentation. Even though it's been covered somewhere else. The oldest I was looking at was a 1945 Army training manual.The improper still applies you're supposed to put the oil next to the pivots not on top of the play or on top of the pivots. Then things get interesting when you get to the proper quantity. The other documents or from Omega Rolex where the proper quantity of the past is now the minimalistic basically. The maximum from 45 is borderline still of being the maximum. It appears to be have to see the top of the pivots and you should fill up the entire oil sank that's too much. But what is now considered acceptable would've definitely be considered too much in the old days. Then there's a problem of lubrication choices in the factories no one ever explains why they change their mind on those. There may be a trend towards heavier lubricants but that's more of a guess on my part. Some of what you're seeing is the watch companies are discovering that the early recommendations a super minimalistic doesn't last in between servicing. Where before they would blame the watchmaker for just doing a poor job now that there's less watchmakers and they're servicing their watches their finding out that the lubrication didn't hold up over time is by guess.1 point

-

No. There were, and still there are, an huge variety of Swiss manufacturers, some sold much more than others and are more likely to be encountered in the low price segment. Only within the same family of mov.t. Theee are document that list common parts. Search here for the bestfit catalogue posted by Oldhippy that has a lot of this type of information.1 point

-

Actually Dr ranfft has packed more info for each caliber than meets the eyes at first. Julesborel.com is currently offline , I guess its being updated. It list parts to most calibers ever made also contains info on some interchangable parts. When in does get back online, you will find tons of information there.1 point

-

ETA was/is an expansionist company, they bought many of other brands, so in a way yes applies to your question, as they have used some of the design, parts, know- how all under one hood which made ETA a big brand, another big movement manufactirer is AS ( adolf Shields) some brands merged or formed groups, some movement are still in- house, but thats not going to help much with interchangabilities or identifification of a piece ..etc. Dr ranfft lists member of a family that make the entire generation of a caliber( go to Dr ranffts website ) and see a base caliber( commonly a manual wind) and its variants, including modification and new families. A new family usually beats faster, a new member usually got more jewels or have been otherwise modified. Most parts interchange between members of a family or even generations as listed by Dr ranfft. You can find more about groups of brands listed in Timezone forum. Regs1 point

-

Here's the problem with databases what makes you think they're right? Yes I went back to the website I looked at all of the variations of C11 and they're all 19,800. But what if we look somewhere else will that agree with us? The answer is it does not agree how weird. The reason why make the reference of how weird is that I know of other databases out there that are wrong in horology. That's not the knob he was talking about? Yes everyone should know that was the fuse. I snipped out your image and crossed out the fuse I believe he's talking about the other Knob like thing. But I've seen another variation of the printer where the knob is on the right-hand side.1 point

-

Gustav Becker, They are a quality clock I did one some years back with the disc pendulum, nice. look forward to the pics cheers1 point

-

1 point

-

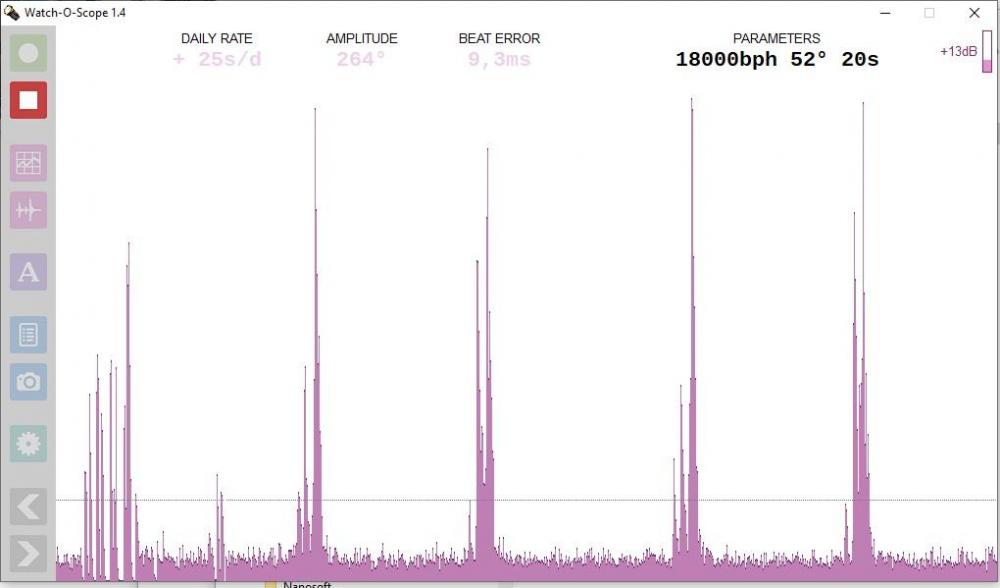

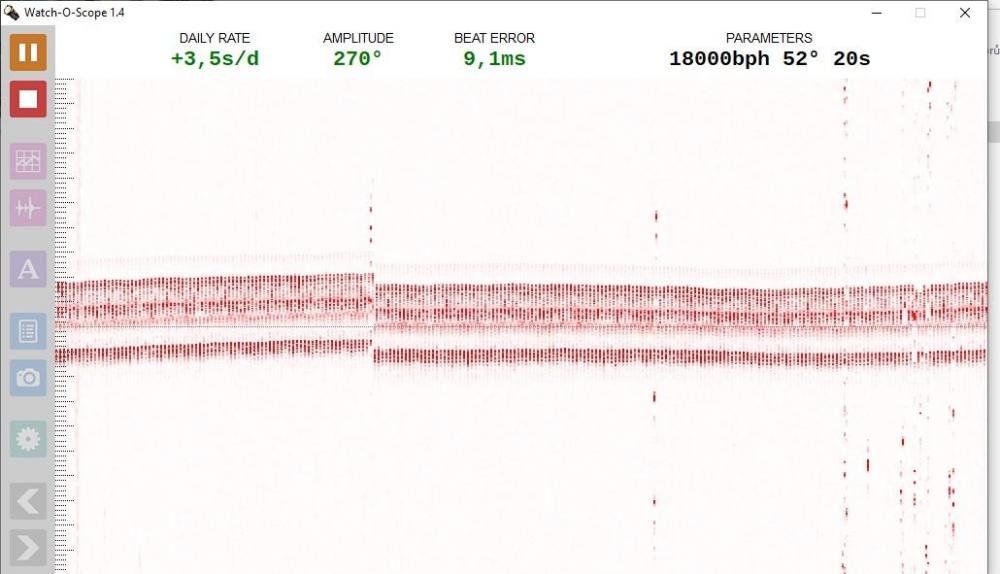

Hello to all, i am new here, let me introduce my version of the amplifier ( is the same scheme as Watch o Scope). I go the way all in one sollution, so the piezo is directly on the top of the amp therefore the cable is much shorter and is soldered directy to the amp without any connector, then i take out the potentiometer instead of the trimer inside the box, output 3,5mm jack is for connection to the computer (or headphones if you like to test it) i am curius how much sensiting the amp is.. i am able to hear if somebody is speaking in the room. if i need some aretation for the watch i use the hairrubber acros the screw of piezo, works great and its possible to test it in several position. Just like to thank you for sharing this, its really awesome idea and work perfectly see the result which i have. (watch is not in 100% condition - i am beginner ) Just one point which i have is the sensitivity of the amp if i touch whatever.. ( notebook also... ) maybe i will try to desolder the ground from the output jack (maybe is there some ground loop) this problem is great visible on the begining of the scope screen.1 point

-

1 point

-

If it's just on the rim, isn't connected by an oil trail to the cup, and really is microscopic, it's better to leave it. If you want to really get it off, fresh cut pegwood under microscope... but- Really you should reclean. I know it sounds extreme but that's the professional thing to do. Your watch? Do as you please. Customer? Do it right. I'm not saying there's no situation where the excess can be safely tidied up, but I wouldn't advocate it. 50 or more years ago when folks had their watch serviced once a year it was possible to get away with a lot that just doesn't fly anymore. I see watches all the time that have perhaps 10 years since the last service, where maybe one Incabloc still has sufficient oil still and the other is bone dry. How'd that happen? I would guess the dry one got a Rodico cleaning after overshooting on the oil or something similar. If someone is paying 2-600 bucks for professional work that's what they should get.1 point