Leaderboard

Popular Content

Showing content with the highest reputation on 03/12/21 in Posts

-

Very few movement plates are Lacquered just clean them and polish with French chalk and a soft brush, blowing out the pivot holes afterward to remove any excess. I have Lacquered large plates before on one Fusee clock you must block every pivot hole with peg wood before Lacquering, its such a phaff of a process that I would not bother Lacquering any movement plates again plus the next time it needs cleaning it all needs removing again. Plates that have been chalked should stay bright and shiny for quite a while.2 points

-

I forget just how I decided to start learning about watchmaking, but here I am. Other than my Garmin watch that I use to track my backpacking activities, I only own one "real" watch, a 1928 Bulova Surrey that I bought on Ebay 15 years ago. I think it was probably that watch that sparked an interest as it stopped running many years ago and has just sat in drawer ever since. I remember looking at ways to service it over the years and I think I just figured I'd try and see if I couldn't do it myself and here I am ? I've gone through the first two of Mark's courses and have been practicing on some scrap watches I got off of ebay. I'm a retired dentist and some of the hand/eye skills do seem to carry over but as I watch some of the videos I have filmed of myself as I've stripped and then rebuilt movements I do see that I'm a bit heavy handed. I need to add another fine motor gear or two into my repertoire ? It looks like there is a great community here and I'm looking forward to climbing that road to where I can at least service that beautiful Bulova in my drawer. OK, I'm off to post my first of what I'm sure will be one of many questions ?1 point

-

Yep, no bezel. And I would bet money it's a split stem. Even though it's a lever set case, I don't see a lever protruding from the movement, so I'm guessing you have a crown-set cased in a lever-set case. In which case (pardon the pun) you'll want to remember to pull out the crown to the set position before lifting out the movement. Pocket Watch Database will give you a picture and tell you more. Nice old Waltham you have!1 point

-

So how the stem is removed? Of course if the crystal is held by the bezel, or the mov.t can be removed, that is what needs to be done. Also I wanted to show another alternative to a claw type tool, which is made like a plier, Seiko S-14. Although designed to remove glass crystal from monocoque cases, it has worked perfectly good for me in a variety of cases.1 point

-

From my experience with Timex Dynabeats, the movement has to come out from the front. The caseback is epoxied in. The winding stem is not designed to be pulled out by force. With some stubborn crystals, I tighten the crystal lift as much as possible then wedge my thumb between a lug and one of the claws of the crystal lift then push the tool off. It usually comes off. Somehow after I got a decent crystal lift, I don't have a problem with stubborn crystals anymore.1 point

-

French chalking will give a lasting shine to any clock movement that has been polished. Yes you need to plug all the holes I used cocktail sticks. Some things do take a time to achieve but what is the rush. Just think how nice it will all look when you see the final results.1 point

-

There is a guy on YouTube “Richard Perrett” who repairs services high end watches and pocket watches. He has an excellent vid on restoring a fusse pocket watch his tip on how to release the power without breaking the chain is excellent. PS I have seen many job lots of fusse chains on eBay.1 point

-

The way of keeping brass as you say shiny is to use a clear lacquer and apply with a good fine artist brush. It drys very quick, just make sure it is absolutely clean and free from tiny hairs/dust particles. This is what I alway used. You need the brass clear. https://www.cousinsuk.com/product/lacquers-rapid-drying1 point

-

That is what I wanted to see. It is a fusse pocket watch which should have a chain,one end should be attached to the fusse which is the cone shape (red arrow) the other end attached to the barrel. It was an invention because it those days it wasn't possible to have the same strength in a mainspring from end to end, with a fusse it was possible to regulate the strength so the watch would keep better time. There are loads of these pocket watches about made by various makers, the famous makers the watches are very valuable. A well qualified watchmaker should undertake this type of repair if you decide to have it in good working condition.1 point

-

That is a genuine quartz module, made specifically for Timex, and it may be now discontinued. Power flows from the battery via pad contacts, that may be the issue.1 point

-

The part that is broken is very common. Just about any tri-fold snap clasp of the correct width, e.g. 16mm or 18mm, should fit. The hole on the end of the buckle, where the other end of the folding part should be attached, looks strange. I'm guessing this is the one the spring pin slides through? It looks like maybe this buckle has been repaired by putting in a rivet pin, which caused the circular worn area around the hole.1 point

-

1 point

-

1 point

-

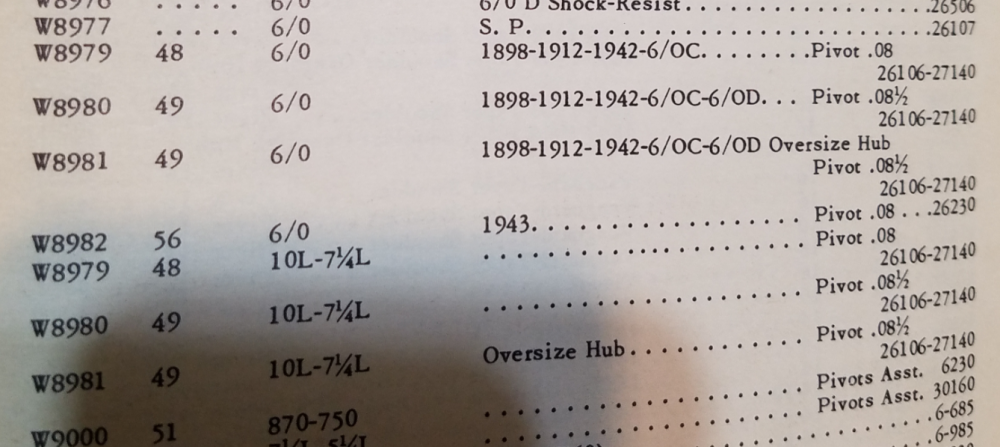

Usually for American pocket watches I looked up the serial number of pocket watch database. Then I get a model number so I can look up the parts for that model number if you're lucky on the pocket watch database site that list the parts saving you having to look in your books. Then several problems with just having a staff number. Typically with American pocket watches in most cases you also have to have a pivots size as you can have one staff number for several pivots. Or there's an Elgin that you can have a whole bunch of variations for one staff number beyond the pivots size for the same number. So once you get a staff number then I look on my staff listing which I've snipped out the section for you. You'll actually see the number that you have listed but? The other thing that's viable to do is to measure the staff that's currently in the watch. To verify that it's measurements agree with whatever you think you're going to purchase. Then before putting in the newly purchased staff you do have to verify that it's measurements agree with whatever you think the measurements are. Otherwise unpleasant surprises will happen later on and their lot easier to fix when the staff is not in the balance. If you look the list I have below you'll notice that there is a reference to a G.I. watch and the staff number is slightly different and some of the dimensions are slightly different. This is why you need to measure what you have to see how it compares to listing and pick one based on that and hope we'll be right.1 point

-

The list came from the link below. You'll notice if you look the link below it does point out that that the database is out of date and I'm guessing specifically that means the prices. It's why you have to take the numbers and then go to their home page and paste them in and see if they come up as in stock and what the current price is. Then as it's a US company it's probably an dollars at least that's what I always assumed it was. http://cgi.julesborel.com/1 point

-

19800 bph/18000 bph = 1.1 1.1 * 60 m/h = 66 6 minutes fast.1 point

-

The great Archie Perkins, in his restoration books and his staking set book, recommended using a domed staking set punch. You'd place the minute hand on the staking set plate and lightly tap the hole using a domed punch. The peening will slightly reduce the diameter of the hole by compressing the edge inward. To avoid tooling marks, you can place the hand on plastic and peen the underside of hole.1 point

-

It has been a bit of saga but worth it. Finally cut a screw for the 8 days French alarm clock. One of the four to fasten the pillars to the base, three were missing. I am almost sure that all its sizes are in French lignes (symbol: ‴), to begin with the pitch of 4 threads per ligne (0.564mm). The head is 2‴ x 1 exactly. The pitch is easy to get if your lathe has a bunch of gears. But the profile is another story, antique threads have rounded crests and valleys. I can only hypotize on how that could be reproduced in an home shop - not easily. Anyway, just like my Swiss-exiled counselor has confirmed, with a bit of care in tool grinding and cutting the result is working and acceptable. Original on the right.1 point

-

I figured I'd post the watch that started me on this journey. It really is quite gorgeous. I saved the photos from the original ebay listing. The listing said, "ART DECO 1930s BULOVA ENGRAVED CASE WATCH NEAR MINT" I've since learned that the watch is not from the 1930's but is a 1928 Surrey. Also, not mentioned in the listing is that it was recased in an Illinois Watch Co. case. I actually like this case much more than the original Surrey case so I can't really complain about that. The only real issue is that the movement just kind floats in the case since the movement isn't actually attached to the case in any way.1 point

-

Well here goes. At my work wrist watches are forbidden so I dug up a vintage no name pin pallet pocket watch out of my collection,so if I damage it all OK. I stripped the movement out of the case cleaned it in the ultrasonic wholus bolus. Put it back together. And experimented with oiling all pivots and pin pallet with only mobius 9415. D5 on the mainspring and 9415 on time setting mechanism. Well 3 years later it is still running perfect. Here is some photos. Tomorrow I will relume the hands with Superluminova. Mmmmmmm. I never set the time and have kept it wound seven days a week for 3 years as an experiment. Once I am home back on goes a wristwatch. Has anyone else done a lube experiment. I must admit this old German movement is like a tractor.1 point

-

1 point

-

Here's one for all the electro-mechancal clock fans, and fans of Russian horology everywhere. ... and if you enjoy that, you might like to take a look at his earlier series on the electronic version here. Actually most of CuriousMarc's videos are worth a look, so you might want to spend some time browsing through some of his other stuff. There are lots of bits computer history and electromechanical calculator stuff too.1 point

-

0 points