Leaderboard

Popular Content

Showing content with the highest reputation on 01/14/21 in Posts

-

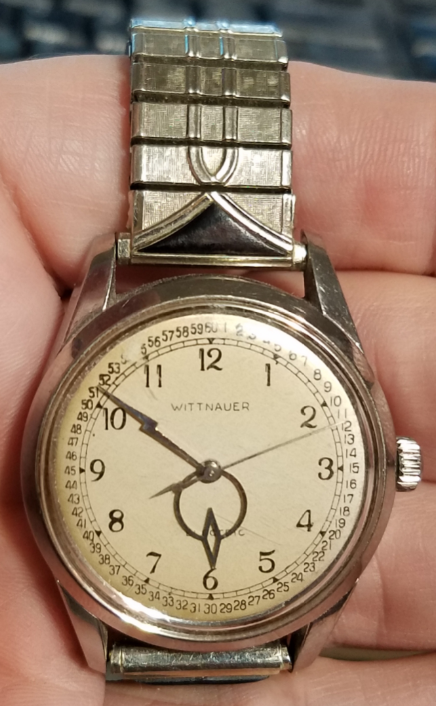

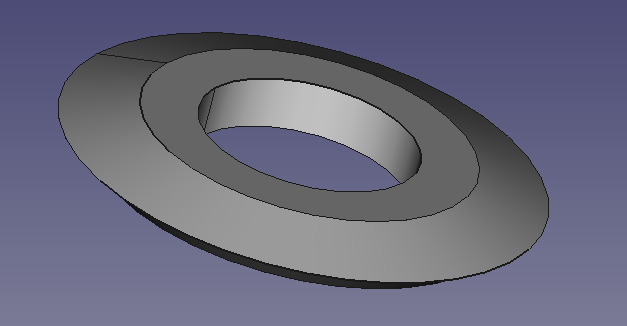

Several years ago, I dug this out of my dad's box-o-watches. Further research indicated it is somewhat rare. The battery that it used is no longer available--it is shaped like a flying saucer with lines to fit the case back. Needless to say, no modern battery would fit this profile. Fortunately, 1.5 volts is the battery voltage required and others had already discovered that a 389 was the correct thickness. Someone in the UK had produced some spacers that would fit in the case back and hold the 389. I tried to contact him...to no avail. Undaunted, I designed a spacer and printed it with my 3D printer. Voila! Works great. The pictures are of the watch and the spacer as illustrated in the 3D CAD tool.2 points

-

https://www.instagram.com/p/B-oAzLGFff3/?utm_source=ig_web_copy_link https://www.watchuseek.com/threads/simple-and-effective-homemade-microphone-stand-for-watch-timing-apps-timegrapher.5135031/2 points

-

Out of curiosity starting with your brand-new movement did you evaluate the movement before you disassembled it? In other words you wound it up you verified it ran 41 hours. You timed it in more than one position because one positioning timekeeping is not adequate for evaluation purposes? It's always good to know what your starting with versus discovering after you service that you have a problem.2 points

-

One other thing to check. It is possible to fit the plate that holds the oscillating weight two different ways. In other words, the plate is not symmetrical. If you screw it on in the wrong position, then the pawls will be in the wrong position and the weight will not work correctly. I have done this a couple of times, however in my case the weight wouldn't turn correctly either when the movement was cased. If the case has more space though, then it might be possible to case the movement and still have the plate on back to front. Also check that the spring for the pawls is correctly fitted and the pawls turn the winder when you engage them manually. If not, then you will need to swap parts from a donor. Also there is a manual available on line which explains how it all fits together much better than I have. I've attached it here in case you do not already have it. It also details where to oil. From memory, the pawls that drive the winding wheel should sit more like this picture. 109.pdf1 point

-

You may be surprised to know that one of your watches is featured in the collection of the V&A museum. Source:- http://collections.vam.ac.uk/item/O1160743/hopalong-cassidy-watch-timex That's some pretty creative cardboard engineering going on there. The one in the V&A pictures is described as being located in the collection of the V&A Museum of Childhood. https://www.vam.ac.uk/info/transforming-the-va-museum-of-childhood This is presumably not directly related to the Museum of Childhood in Edinburgh which I visited many times when I was young. https://www.edinburghmuseums.org.uk/venue/museum-childhood https://duckduckgo.com/?q=Collection++Museum+of+Childhood&t=newext&atb=v124-1&ia=web&iaxm=places If you want a trip down memory lane, or have some youngsters to amuse and you happen to be near Edinburgh, this too is well worth a visit.1 point

-

1 point

-

I have been unable to check the tubes on the clock I originally posted, because I gave the clock to my dad for his 75th birthday, so because of the covid situation I have not seen either it or my parents for a long time, but I would agree with the above post that the air in the tubes prevents the mercury moving in the end the warm water I used to warm the tubes made it more viscous and helped get it moving.1 point

-

1 point

-

Will do.i have had a quick look at the site and noticed a few queries along those lines so of the few different mvts i have i will find the most suitable for my dial then send them a request for their suggestions then go from there.thanks for your input. B1 point

-

Please be aware that your dial is 34mm in diameter. Most of the Vostok dials I have are about 29mm. Most of the Vostok housings I own do take (measured) around 31mm dial max. Therefor I'm not so sure that "Pick whatever you like" applies here. As usual, please check the info given first before you take any action ?1 point

-

1 point

-

Your watch has no pendant tube, so I don't see how it can be water resistant, unless you fit one. Beside that a pendant tube is needed to avoid the crown wobble and the stem bend easily. The tube is measured on the ouside diameter, to match the seal on the crown. Yes, so called waterproof, Swiss style. All assortments are very useful especially you intend to do a lot of resturations on watches that match the boxes you have. And having the right part ready to fit is a great achievement. Look the table which lists the sizes, see if there's what you need before buying. Otherwise Cousins has a good selection of individual crowns also.1 point

-

1 point

-

Pick whatever you like: https://meranom.com/en/amphibian-classic/cases/1 point

-

You wouldn't. It's about barrel sizes. The ETA set is sized (and I'm sure labeled) according to common ETA movements. Generic sets are sized by unit measurements (mm). If you do a lot of ETA stuff, it's probably nice to have, and you can always use the nearest size for whatever non-ETA movement. The generic set would be easier to use since the intervals will be more regular, and there's nothing special about ETA barrels that will keep them from working with the ETA movements in the same way there's nothing that would keep the ETA sized set from working with non-ETA movements. A word on the Chinese winders (possibly dated information), Mark did a video a while back where he did a pretty comprehensive analysis. It was a bit on the critical side, but the big takeaway for me was the shafts being brass. As a hobbyist, it could be a while before you eat through one, but it could also be a single simple mistake. The Chinese manufacturers seem to be pretty good about keeping up with things like that, but I don't know how much noise has been made or if it's been made in the right places to catch the right ears for anything to have changed.1 point

-

I've had this several times at work somebody asks me to time a Seiko. I asked if they wound it up they assured me they wound it up and it looks pathetic on the timing machine? so I ask how they wound it up or specifically how many times they turn the crown and that's the problem. I've snipped out something from the service manual. When winding with the crown a minimum of of 55 turns. Then winding the ratchet wheel screw eight turns. Then there's another problem with the barrel wall breaking grease. If somehow it is wrong for a variety of reasons when the spring slips it will slip too much.1 point

-

at this point iam leaving it as is, i feel like if i service. it it wont run as good1 point

-

Had somthing similar with a well known catalogue shop with a disc failure, replaced disk got backup disc it was faulty went back and checked the rest of the discs all useless so drove to Sunderland shop and borrowed their working back up and re build it from there different shop different stock and levels took a week to manually adjust every thing, after that they ran Verification on the backup. Lesson learned, Manager not a happy bunny.1 point

-

Most barrels have the cap at the bottom, facing the dial. In that case (with the exception of 8 day movements), the arbor will hook so that it winds anticlockwise. This means when you wind it into your winder, it is backwards so you want to wind clockwise. A big problem with vintage winders is often the arbors are very large in diameter compared to modern watches. Sometimes you can use a smaller arbor in a larger winder barrel and it works ok, sometimes it's just a big pain. Even if you have a vintage full set of Bergeons and a modern set, you still run into situations where it's all a big compromise. Also, often the hook on old winder arbors is waaay too long; this can kink the spring in addition to making it really hard to seat and unseat the hook in the hole. I always check the hook on unknown older winders and redress the hook as needed. With a perfect winder, for a non automatic watch, you have to be very careful when the spring is almost all the way in the winder. They want to slip in really fast those last few mm (it's like they know, like when you need a bathroom and you're finally near one) and you can snap the tongue off. It's a never ending strife, I watched a Finnish watchmaker lose about a year of his life from stress mucking around with a problem spring and he's an amazing watchmaker. In the end I wound it in by hand for him, mostly out of fear that he would start destroying the workshop (yes you can wind them in by hand without damage but it takes practice).1 point