Leaderboard

Popular Content

Showing content with the highest reputation on 12/07/20 in all areas

-

3 points

-

How much endplay there is at the pallet and escape wheel? Between DD and DU even a small change in the area the pallet stones present to the escape teeth can introduce variances.2 points

-

Balance tack #2. This one will have 2 tacks, one for pocket watches and the other for watches. IMG_0951.MOV1 point

-

Good oils but natural oils, which means shorter shelf life, shorter in-watch life, and lesser performance. So the current practice, whenever possible, is to use synthetic watch oils all around, including on vintage / antique movements, and that explains why they aren't a recommeded purchase. Would one use (if even available) the same oils made 60 years ago on a 60 years old car? I don't think so.1 point

-

Not all snap casebacks have notches, but that is more frequent with contemporary Swiss watches. Please post good pictures back front and side.1 point

-

Thank you all for the discussion, I will try ordering the VX42 as the price is ok for giving it a go. And yes the reason for this original question was the fact that the exact replacement is out of stock with not much visibility on the restock date. Thanks.1 point

-

Hello all! I am in the middle of a fun treasure hunt and I'm wondering if anyone here can help me out. I have a very old Landeron 11 (or 13) column wheel movement that is good but is missing the balance and balance cock. This is a 13 ligne movement. These movements are sooo hard to find parts for, does anyone have any clue if any of the other landeron movements have compatible balances? If I can get a balance wheel, balance cock, and hairspring I can replace the staff. Any help would be appreciated!! Thanks, Emily1 point

-

Hi. New to this modern world of community and not sure how it all works. I have been repairing clocks for over 25 years and it has been a rewarding experience from the people I have meet to the numerous types of clocks I have repaired.Like most it just happened.Got an old junker got it to run and the rest was history.Along my travels I was blessed to be able to work with a watchmaker who survived the Holocaust due to his watch making skills.We shared true bond till the day he passed at 93.Hope to learn more and maybe share some of my experience. Thank you Pinetreepete 12/6/20201 point

-

It’s all about tolerance (T.I.R.) and repeatability. You cannot make pivots which are .005” diameter when your machine run out is half that. Traditionally the parts were made by hand, with gravers. I wouldn’t attempt that personally, unless you just wanted to make the part, but not actually fit it to a watch. I have respect for those who can make these parts by hand repeatability (I guess reliability) when using a cross slide- if you dial in 0.001” on diameter, is that what you get? Sloppy ways on a lathe are double jeopardy- you can index (go in) more deeply than the hash marks indicate; and also the lathe can “pull” the tool into the work further than intended. The shape, sharpness, rake angle, feed (how much does the tip move down the length per revolution) etc. are all important to make accurate cuts and produce a reasonable surface finish. You don’t want to have to leave it .010” oversized so you can file, sand and polish as needed. I have a very reliable lathe at my disposal but I know better than to try this. But I probably could make it pretty decent and would still need a Jacot tool to size and burnish the pivots. No way I can get the surface speed to properly finish small pivots like that. If you study basic machining manuals (probably available at the library) you will learn about all this stuff- surface speed, infeed, tool prep based on material, post machine hardening (if needed) and so on. Heck, I don’t know how many times I went onto a machine after someone else and the cutting tip is not on center... Also how best to make a precise part- make all the features of the part without removing it from the chuck and then part it off when done. Knowing which cuts to start with, on a complex part, is a good skill too. Sometimes you have to make a nest or arbor to hold the part for second operations... Just owning the best piece of equipment for the job does not guarantee success. Unfortunately.1 point

-

Hi watch people I am a new member here,I am 67 so need to pick the members brains. I used to tinker with pocket watches for some years but stopped when my Wife passed away. Now I am getting back into it with the help of my Granddaughter and this internet thing, I have read through the 12 pages of lubrication with some interest, Moebius do seem to do a lot more oils than they did 10 to 15 years ago. The 2 Moebius oils that I have not seen mentioned is the Moebius 8000 & 8141 both a good oil, still available and quite cheap. I have 4 or 5 downloads of Moebius oil sheets recommending what oil to put where on a watch, the 8000 has now it seems been replaced with ,941, 9010, 9020 and the 8141 with D3 to D5. So instead of 2 bottles of oil we now have 5, That must have increased their profit margins by a few hundred %. I did have a few books on watch & clock repair and 2 of them date back to the turn of the last century, one old watchmaker used walnut oil to lube his clocks, by simply sticking the pivot into a walnut. Any way thats my first penny's worth. Thank you for your time.1 point

-

1 point

-

I am "hammering" one right now! Elgin pocket watch. Another tip: do notice roller's and hairspring stud's position in relation to balance wheel. Usually someone already made orientation marks to simplify life for you. Good people... kind, friendly ?1 point

-

I am glad it worked for you and I have no doubt that vx43 would work just fine in many case. I simply noticed two differences: 2.92mm Vs 2.62mm Height, and Sec .18 Vs Sec .20 hand dia. I will take a look at your Sept 9 post. Cheers!1 point

-

One tip for anyone new to riveting staffs is to choose a light weight hammer to help you make consistent, light blows. It’s quite easy to crack/hairline the rivet.1 point

-

this might be worth a look at https://mitka.co.uk/2019/11/22/service-bifora-115-skin-diver/ cheers1 point

-

1 point

-

1 point

-

1 point

-

Welcome! But, you will never stop collecting tools... they just get more obscure and more expensive.1 point

-

Hi, I would recommend watching this video. This is obviously way too much, but it explains well how to align the balance wheel, impulse jewel, etc.1 point

-

1 point

-

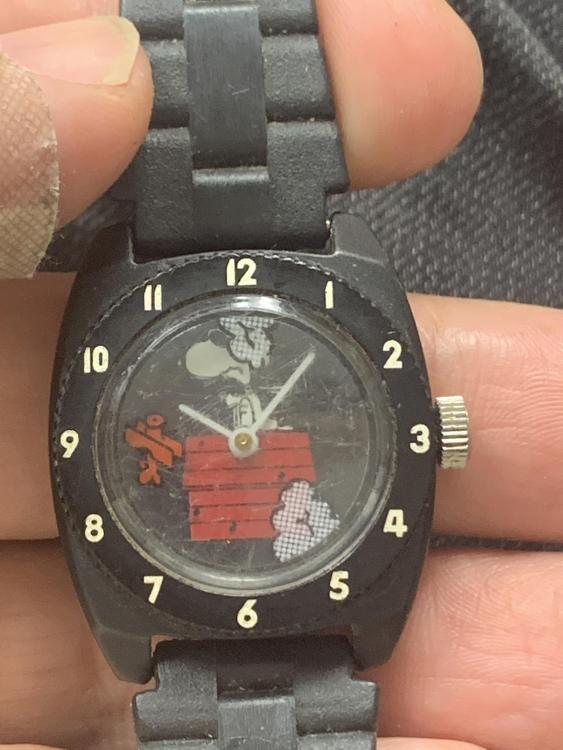

Yes I know its quartz. But the watch came minus stem and crown ,the seller made an offer I couldn't refuse. I just swapped in a vx43 movement and Installed a new crown.Easy as pie. It wears it's original knicks and dings ,and keeps time in typical Seiko fashion.its a 7n43 9181. S/N 812266 eighties vintage I reckon.1 point