Leaderboard

Popular Content

Showing content with the highest reputation on 10/29/20 in all areas

-

Its got quite a bit of verdigris and muck around the ring you could try putting some penetrating release spray on a cotton bud and rubbing around the ring to see if it free's it up.2 points

-

He has removed it. These are his replies to me Question Why have you described this clock as a very rare clock saying it is buy HUGUENIN A PARIS. When it is a Chinese fake. Answer HI IT HAS IT ON IT THANKS Question So you believe everything that has writing on it to be true. How bloody naive you are. So you don’t mind ripping people off. Answer HOW DO YOU NOW IT IS FAKE I HAVE A VERY GOOD RATING THANKS Question Simple. There has only ever been one made by Huguenin. Compare the genuine to the rubbish you are fobbing off. Look here. http://www.my-time-machines.net/Huguenin.htm Answer Ok mate I have taken it of1 point

-

Hi The loose ring with the slots in unscrews and the flat back cover is removed. check that its not a left hand thread.1 point

-

Hello again. Just to let you guys know that as a collector of Helvetia watches I reached out to bjd1020 with an offer to buy this watch for restoration. I received it a couple of months ago and have been slowly getting it back to it's original condition. I received the crown I needed today and here is the result: And with it's 13 away serial number brother I found while looking for parts for this one. Thanks. Carl.1 point

-

Here are two pdf files for you with the names of the watch parts. 1033305402_TZIllustratedGlossary(1).pdf 704789946_TZIllustratedGlossary(2).pdf1 point

-

1 point

-

1 point

-

Tip: don't loose parts. Good practiced technique helps but it's a known hazard. Arrange your workspace so that springs and screws that do go missing are easy to locate. Put a back face on your desk, and ridges on the other edges. Keep your floor space clean and uncluttered. You can use magnet to comb the floor (some people make magnet brooms for this) and you should be able to find your parts. Trust that they are there, it just takes patience. I work over a carpet (! ?) and with my magnet-on-a-stick I still manage to find 95% of missing parts. There's tricks to springs and screws: using pegwood to de-tension or hold the spring; using rodico to hold parts as you remove them; holding a thin clear plastic bag over the movement while you remove the part to catch it if it does try to leave. There's lots of parts that are hard or impossible to replace. Fortunately, those "shepards hook" springs are not particularly special, you can buy them in bulk for a few dollars from your parts supplier and use the one in the pack that fits best.1 point

-

I’ve done enough of my own stupid stuff. I doubt this guy’s going to show me anything.1 point

-

You're not rebanking, but that is a lot of amplitude. What is the amplitude when you let the spring down about 1/2 turn? As for the rate, that is not that bad for such a movment. If you close the regulator pins a bit it should bring the vertical rates up some.1 point

-

That doesn’t look like re-banking to me. How is the timing in pendant down and pendant left orientations?1 point

-

Well Bradders, Just you get on with whatever you want to do the waches are yours to do what ever. The main thing is to learn and enjoy the Horological experieance1 point

-

Welcome! That won’t get you banned here. ( just don’t let it happen again!) kidding of course. Seikos are fun to modify for sure.1 point

-

1 point

-

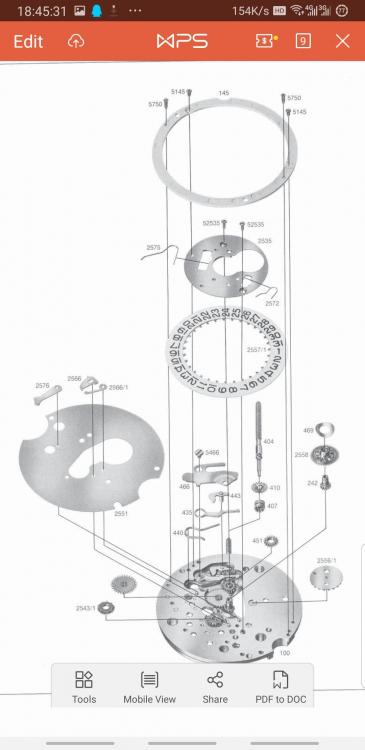

It is pretty hard to set the time. It must be something wrong with the module. And I noticed that teeth of the date ring is almost missing! And the date corrector and yoke...... I browsed the intercharge list on JulesBorel. These also can be found from BFG 582. But both are rare calibers in Chinese market...... I am searching Internet...... A day-date BFG 628! From the technical document on Cousins, parts I need (2566, 2566/1, 2557/1) look like the same. So I bought this immediately and I am waiting for 4 days delivery...... Continued1 point

-

It's hard for me to say, as I don't know the condition of the watch, mainspring, pivots, holes, etc. There's a lot of variables, I suggest looking at how the pallet pins lock with the escape wheel teeth. How did you grease this? On the pins or on the escape wheel 'root' of the tooth? Is it locking evenly on both pins and deep enough, as the 'draw' is vitally important on these and they 'lock' much deeper. Check your hairspring is dead flat to the balance and it isn't magnetised and how does the hairspring 'breathe' between the curb pin and boot on the underside of the balance cock? Did you clean and re-grease the mainspring and arbor and peg out all the holes and clean all the pivots and pinions. Did you lubricate the top cap jewel and bottom polished metal cap? Did you completely take the top jewel out of the setting and clean to a mirror finish before replacing, screwing into place and oiling through the oil sink and push the oil through with an adapted oiler that has been honed down. You can see why many don't like working on these, as they are easily worn to the point of being thrown away, because if the low quality of parts on a cheap 'pillar' construction watch0 points