Leaderboard

Popular Content

Showing content with the highest reputation on 03/20/20 in Posts

-

4 points

-

Don't count on that. However if you want to stay with current ETA mov't Cousins (for now) has all 2824 parts but some grade or maker specific ones.2 points

-

Just ETA parts? Actually that policy is pretty much uniform for all Swiss watch makers. And the "independent" mov't makers of which there is really just 2 or 3, do not exactly stretch to make their parts available. Sure you see the periodic postings from desperate owners or beginners, "where can I find parts ?" When approaching to this hobby that is something one has to consider and accept, together will the other difficulties of course.2 points

-

Hi there , an ETA 959.001 is a 9 ligne , expensive movement .ETA 210.001 is also 9 ligne you can get these new but are around 160-200 USD .Only other suggestion would be go the 8 3/4 ligne and go with a spacer . There is a good book called Quartz watch retrofitting by wesley r. door .This book has loads of information and good to have in situations like yours ,there are many measurements to determine such as thickness for the fitting into the case,dial feet position , hands .But there is most of the time a work around for theses problems .Hope this helps2 points

-

... also on its way is a Citizen, with a crazed look on its face. That one cost a whopping 0.99p plus postage. The listing states.... "CITIZEN 21J 4-020511K 63-4093 Hand Winding Gents Watch. Condition is Used. Working perfect keeping great time crystal has ware scuff Mark's. " The serial number and movement dates it to January of 1974, so I'll no doubt have to judge if it is indeed still "keeping great time", and it will almost certainly need a service.2 points

-

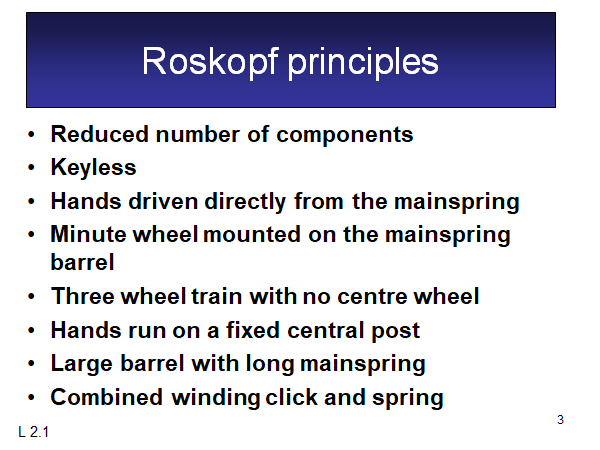

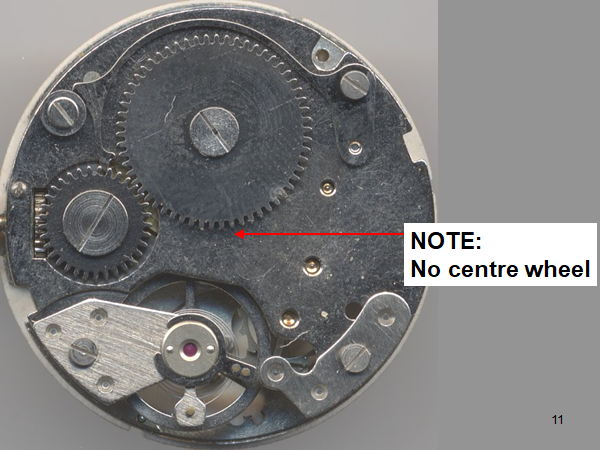

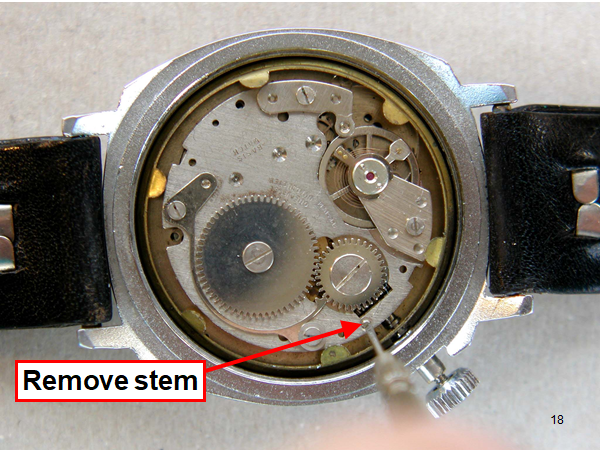

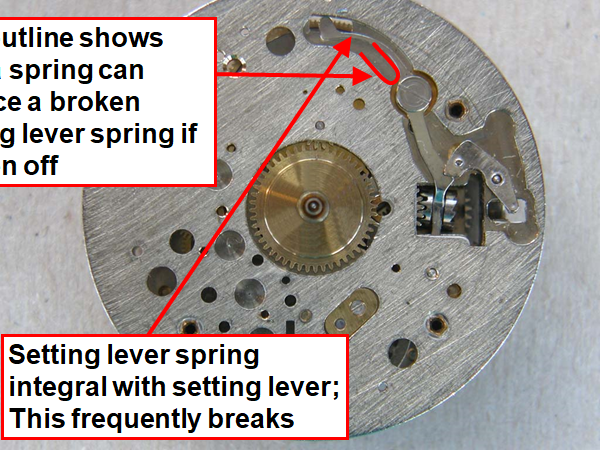

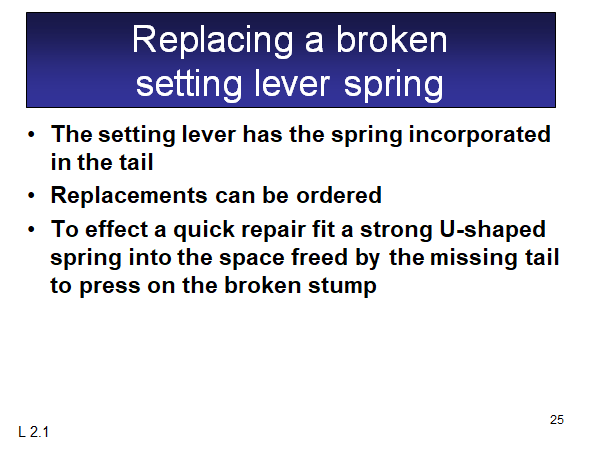

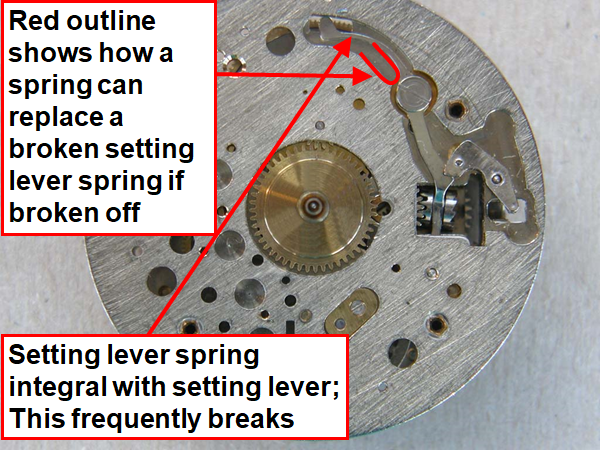

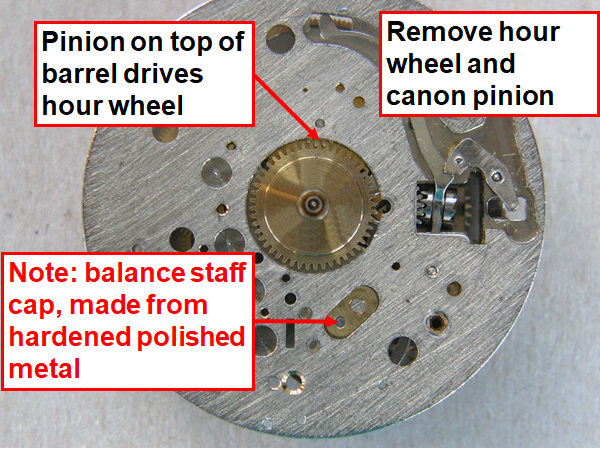

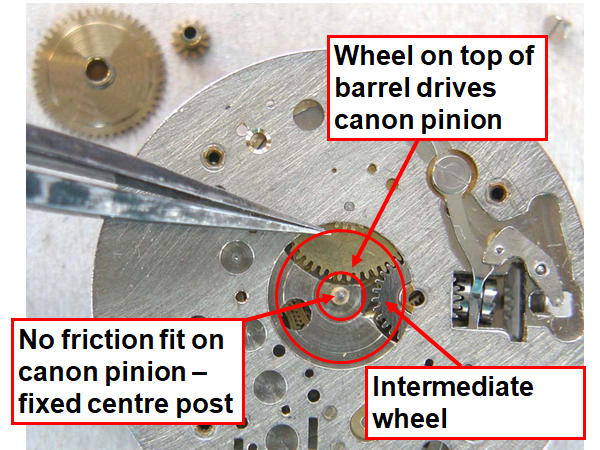

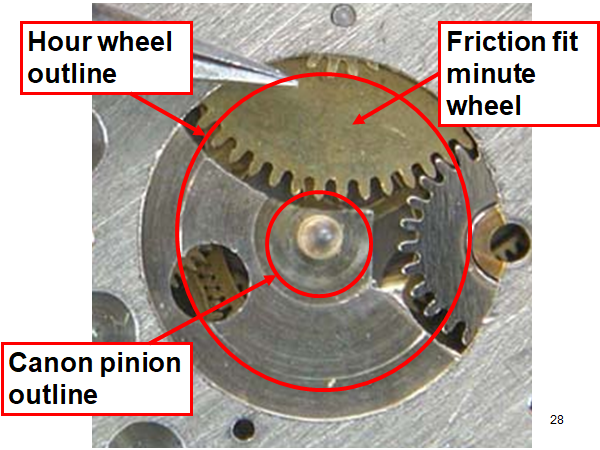

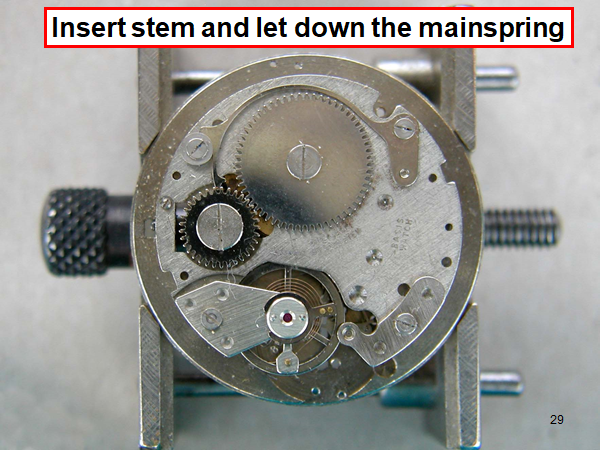

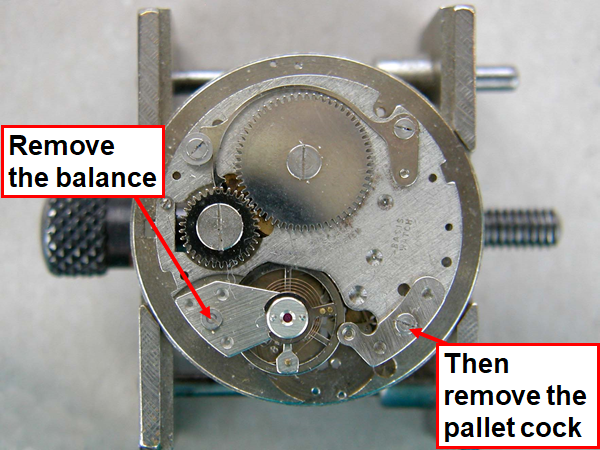

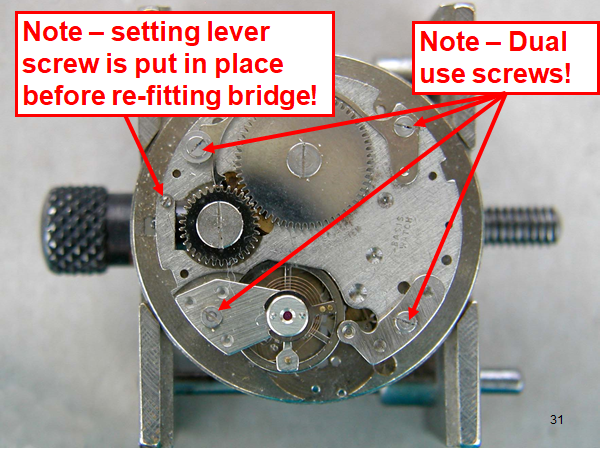

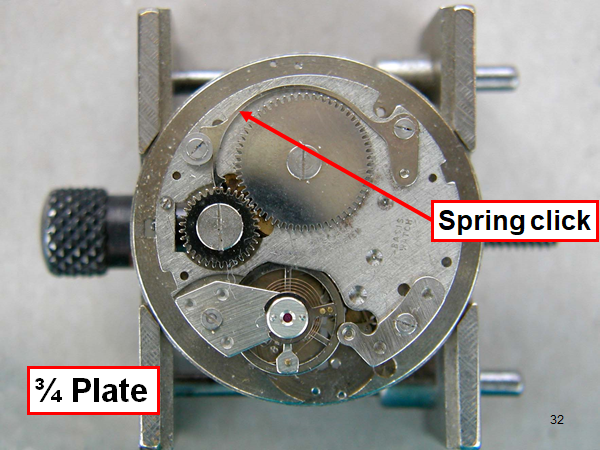

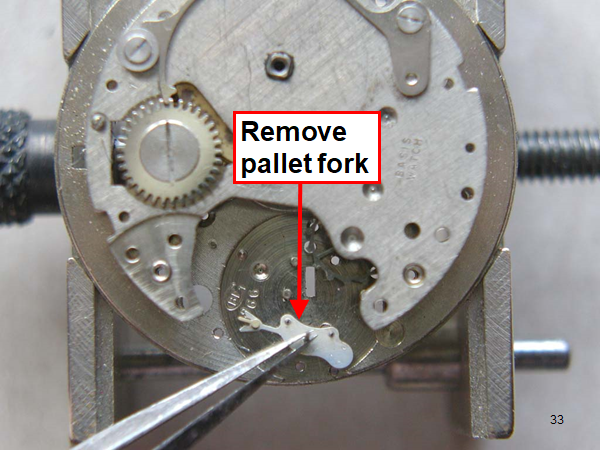

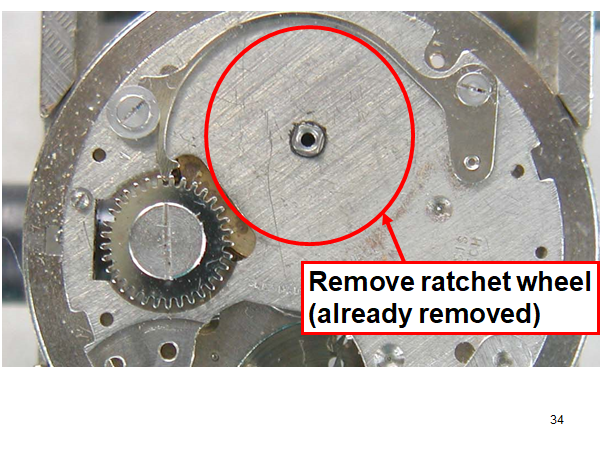

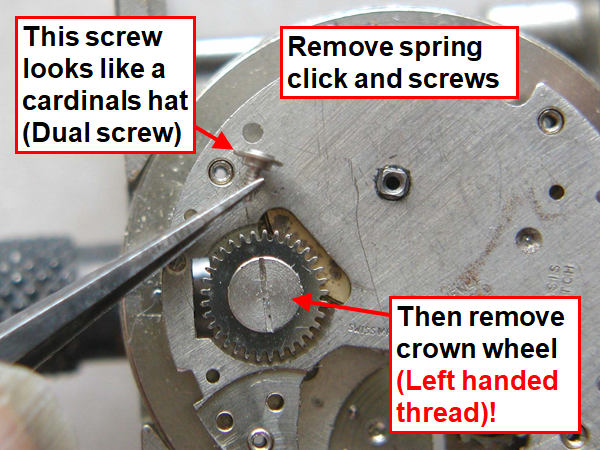

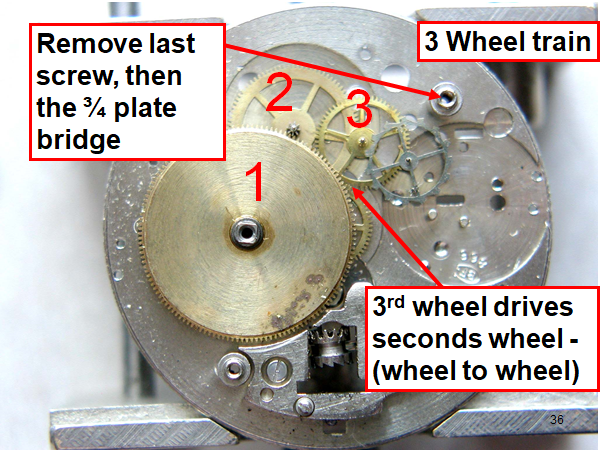

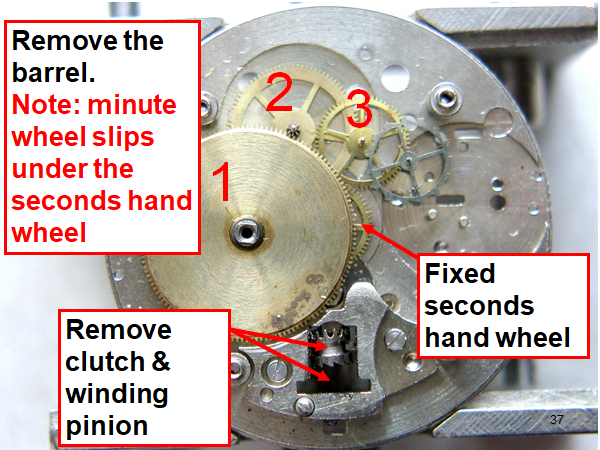

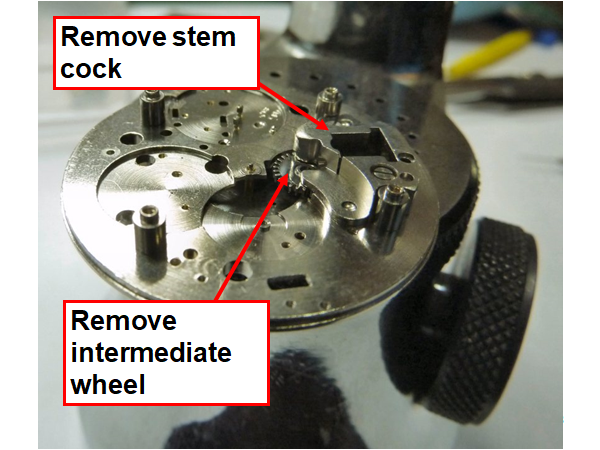

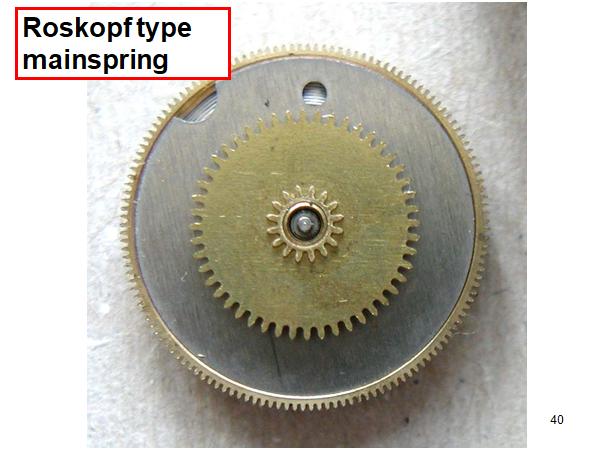

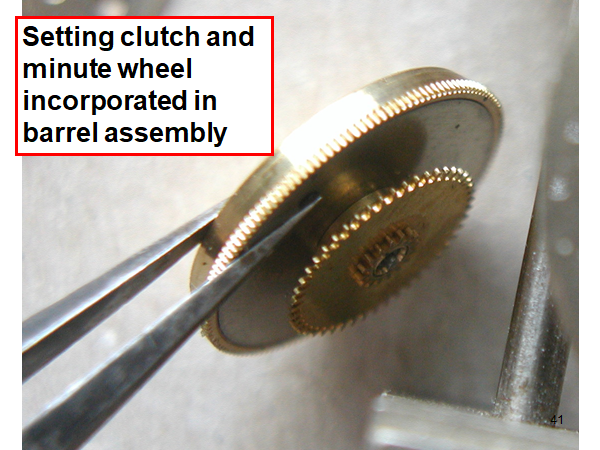

Hi, I teach watchmaking to complete beginners at Epping Forest Horology Centre, close to Epping and this is one of the lessons on the BFG 866. I wanted to show my class a classic pin pallet (Roskopf) movement and how to service it, as many watchmakers won't touch these watches as they hold no monetary value. Turn the setting lever screw 1 to 1 and a half turns to release the winding stem A piece of watch paper or small plastic jiffy bag to protect the dial, whilst removing the hands The driving pinion is part of the friction fitted minute wheel on top of the barrel. This work in a similar way to a friction fitted canon pinion to set the watch hands Remove the keyless work: setting lever, held in place by the setting lever screw, screwed from the other side of the mainplate, then the yoke, which sits on top of the clutch (castle) and also the winding pinion. I have three other lessons on this movement that cover bringing the watch 'into beat' as well as taking apart the friction fitted minute wheel from the barrel, lubricating and staking back on to achieve the correct friction setting and finally how to remove the centre seconds wheel safely and refit using a staking set. Many people leave the friction fitted minute wheel on top of the barrel, not realising the amount of old grease that can't be cleaned out from it, as well as not removing the wheel of the centre seconds arbor and again not cleaning out the pipe which has old grease inside. Hope you enjoyed the tutorial? More to come....1 point

-

Hi MrRoundel , if you choose to go down the road of a smaller movement and have trouble finding a spacer there is a product called speedy-fit case filler which is available from cas-ker http://snotboards.com/speedifit.pdf this pdf shows you how to go about it .1 point

-

1 point

-

A new, or used but efficient bearing is needed. It will not. The more oil, the less efficient it becomes. I can search (again) an old topic here and link here. More likely than not there is no oil at all. But even if it there is one can clean it with simple soaking in the usual liquids.1 point

-

I just acquired this Antique H Samuel, English Lever pocket watch. My goal in getting this watch was to educated myself on the unique mechanism inside and to help a fellow WRT member with his dilemma (Discussed here). Plus I am attracted to odd, quirky and unique watches, and this one fits the bill. On the surface it seems like any Antique English lever of the time, but the "Climax Trip Action" feature has me intrigued.1 point

-

1 point

-

1 point

-

Another elegant quartz number for 0.99p (plus P+P and a battery). This one even has an, as new, soft calf skin leather strap, which got an antiseptic bath and a splash of leather restorer. It now feels kid glove soft, and smells of fresh leather with a faint whiff of vanilla. Other than that tiny scratch on the crystal, the thing looks like new.1 point

-

... and from Cousins' site.. So you *may* be able to use *some* Sellita parts, but you would be dong so at your own risk. Not because of quality issues, since Sellita is a quality manufacturer, but simply because of differences in geometry and materials. Not all parts will be cross compatible. This kind of nonsense has gone on for years, and it almost invariably ends the same way. Someone, usually in the far east, clones the parts, and flogs them as if they are genuine. The manufacturer's reputation takes a hit as their quality is poor. The manufacturer(s) react by making things difficult for their customers, and... the manufacturer's reputation takes an even bigger hit. One example springs to mind -> https://en.wikipedia.org/wiki/FTDI My advice, for what little it is worth, is for ETA to make the parts generally available, make certification of watch repairers extremely affordable, but insist on high skill level for successful certification. Then kill the competition by using fear uncertainty and doubt about non certified repairers and parts. You need to keep *both* the customers and the repairers on side, otherwise you will shoot yourself in the foot.1 point

-

I have also seen sticky hairsprings deceive my timegrapher. Shorter swings can be interpreted as a higher rate in auto detect.1 point

-

From what I understand there is no getting round this other than becoming an authorised ETA repairer, which obviously isn't a viable option. This is why a number of independent shops are moving away from selling ETA branded watches as they cant service them. Its is also what caused Selita to start making their own movements based on older ETA calibres and why a lot of independent watch companies now use Selita movements instead of ETA movements.1 point

-

I would hazard a guess though that which ever technique is adopted, after 10 minutes of running it would be impossible to determine whether an escapement was lubricated dynamically or statically. As ever, when it comes to lubrication it's impossible to get any two watchmaking practitioners to agree and it comes down to personal preference. As long as which ever technique is carried out correctly, both will achieve the same end result, and preference is largely determined by which technique a given watchmaker finds easiest or most convenient.1 point

-

The idea then is for the whole dial to glow. And for the hands and the dial not too? Do you intend to use non luminous hands? I think that usual luminous dive watch hands could be a problem to see.1 point

-

1 point

-

I think in this case a small flat punch is all that is needed to flatten the rolled portion and restore the crimp. Don’t over think this it is just a very simple basic repair. Make sure your anvil supports the lower flange .1 point

-

I have gotten alot of Seiko parts from Otto Frei. They are very helpful and good about calling back. Call them and make sure you have the caliber number.1 point

-

Brand new in box, never worn, and with original guarantee and user manual, all for the heady sum of 0.99p plus postage, no other bidders. Admittedly it had been sitting around so long, unworn and unloved that the battery was flat, but never the less, I think this one more than qualifies for the 404 club.1 point

-

I've always wanted a jump hour, and now one is on its way to me. I've seen these Heritage ones before. They're the same exact configuration as a dozen other brands except the dial is unique. There is an ubiquitous EB8800 beating on the inside, hopefully the blurred balance means its actually ticking as I know these wear out without proper attention. On the outside it's clean as hell, the inside however, looks like ass! That will be the first task when it arrives! The second task will be to fit a black band, it seems more appropriate for the black printing on the dial and overall silver tone of the case.1 point

-

It would be interesting to see how fine the powder is, I bought some crap of eBay and was too grainy to use for hands1 point

-

Just curious, have you ever produced a dial before? How are you going to paint it, airbrush or perhaps traditional brush with a artist touch? What about the indexes, will you detach and then reapply these small fiddly thingies? Not to mention, having some sort of logo is often desirable, how do you plan to do that? No matter how you will solve these small issues or the choice of the paint with the greatest albedo, I look forward to to see the results of you work, good luck!1 point

-

I have been busy with this bench lamp, I think I spent at least about 30 hours with it and even if it is not perfect I am pleased with the end result. Would I do it again? My immediate answer would sound like: Not a chance! Second thought: Maybe I would be happy to set up the tools and processes for a kind of a mass production. It was worth it economically as I have not spent much money on it, and it was worth it because I enjoyed bulding it and learnt? some new skills like knurling. Question mark is there because I am not sure if I learnt it, the result is again acceptable, but I dont really know how should the end result for knurling look like, when it is kind of perfect. I made, as always many mistakes during the process, blood was also shed when I tried to use my hand as a machine vice, and that spring barell tried to slice me up when I failed to hold it, instead it only could get some of my skins of one finger. Luckily my company sends me to regular first aid trainings so I could quickly apply an oily rug lying in the dust around my bench to the wound and carry on with the drilling. It also gave me the opportunity to suck some blood when I was hungry/thirsty. They say money is time so if you dont want to spend about 30 hours with sawing/planing/drilling/polishing/gluing/sanding/swearing and soldering you just could go to cousins and buy that led lamp which is a lightweight bench lamp with dimmer and you can even position it better over your work piece compared it to mine. I think this lamp will be a usefull addition to my bench from now on anyway. I used pallet and crate wood and you can see nail holes here and there and i left them there on purpose. I am going to add a switch to the base and I am in the process to decide how to lead that cable in a nice looking way still to be able to move the upper arm in and out if needed with the cable in place. Skills what were used: - some woodworking - some soldering - skip diving - time finding Tools what were used: - different kind of woodworking tools (planer and thicknesser/ chisels / sanding paper/ router / table saw / mitre saw) - angle grinder - pillar drill (used it for drilling and polishing) - laser printer - unimat 3 - cordless drill - and other tools like screwdivers / pencil / ruler / caliper / etc.. Materials what were used: - threaded stainless steel rods from the skip - copper bolts and nuts and washers from the skip - 2 core speaker cable (i had from previous project) - spring barells (i had a box of them / bought them from eBay earlier without knowing what to do with them) - a BT hub from the skip for the 12V power supply and the connector - I bought 5 led strips ($10.78) but only used 3 of them as the power supply was rated to 1.5A and one strip is using about 400 mAmps. - used pallet (collected earlier for other projects and firewood) - used building materials crate (collected earlier for other projects and firewood) - wood glue (had it, its like bread and butter you need it every day ;-) - gel medium for the photo transfer (had it from earlier project) - polishing material (had it) - some wood screws (had them) - bought a switch for £3.64 If you ever thought about what skip diving is, I can teach that to you, but be prepared that you have to give up some of your dignity. I am a professional skip diver and I can stay there longer than 10 minutes! Years of practice!1 point

-

Hi *, Inspired by Andy I decided to record the things I do with clocks and watches here, for the unforeseen future it will mean that I am going to describe the mistakes i make and complain a lot, and cry, and cry a like a baby a little bit more. Mark put a Valjoux (ETA) 7750 movement together using spare parts from the scrap heap, now i am planning to do something similar, if I can spend enough time with watches I am going to try to put a movement together using parts coming from my carpet only. Tonight there is no mistake or complaints i made a few wrist watch display holders still made out of my neighbor cut-down tree. I am planning to make another set where the middle section will be wider. lui1 point

.thumb.jpg.2df924dddf6ceacb595c3f8ebacab5bb.jpg)

.thumb.jpg.363d251b375b0e25ef913be7848f9c7b.jpg)